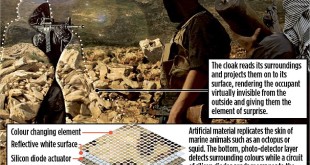

Advanced sensors and actuators, together with exponential improvements in computer technology, are causing a surge of interest in the development of “intelligent” structures and equipment. A smart structure consists of four key elements: actuators, sensors, control strategies, and power conditioning electronics. Numerous applications include automotive springs, smart skins on aircraft, smart bridges, improved biomedical devices, and advanced military systems. The shorter-range interests address incorporation of sensors into systems that monitor structural performance throughout the life cycle. The long-range goal is the deployment of active systems that are able to autonomously adapt in response to a change in the environment. These technologies offer the potential of substantive advancements for better, more reliable structures.

For developing smart structures, Many types of actuators and sensors such as piezoelectric materials, shape memory alloys (SMA) (alloys that can remember their original shapes), electrostrictive and magnetostrictive materials, and fiber optics are being considered for various applications. Scientists and engineers are investigating materials systems that are capable of monitoring condition, changing shape, controlling vibrations, accommodating changes in the environment. Smart materials or Active materials or Functional materials are designed materials that have diverse, dynamic features that enable them to adapt to the environment. They have one or more properties that can be significantly changed in a controlled fashion by external stimuli, the stimulus and response may be mechanical, electrical, magnetic, optical, thermal, or chemical.

One of the class of smart material is Piezoelectric materials. In a piezoelectric material, the application of a force or stress results in the development of a charge in the material. Conversely, the application of a charge to the same material will result in a change in mechanical dimensions or strain.These are materials that produce a voltage when stress is applied. Since this effect also applies in the reverse manner, a voltage across the sample will produce stress within the sample. Suitably designed structures made from these materials can therefore be made that bend, expand or contract when a voltage is applied.

Piezoelectric crystals, like quartz have been long used in devices like watches and medical instruments. These materials provide the ability convert electrical energy into mechanical energy in the form of tiny deformations in the material. The piezoelectric effect, have been extensively utilized to demonstrate various devices, such as transducers, sensors, actuators, surface acoustic wave (SAW) devices, frequency control, etc. Piezoelectric materials are being used for contact sensors for alarm systems and in microphones and headphones. Piezoelectric materials are widely used in sensors and help in measuring fluid density, the force of impact, and fluid composition.

The demand of Piezoelectric Devices is being driven by factors such as arrival of smartphone, internet boom and IoT. They are also enabling technologies that help in generating energy using different sources. The technologies that can convert body movement into electric energy that can charge mobile phone, power streetlights, etc. are expected make considerable headways in the future.

Piezoelectric Applications

They have been also found useful in empowering robots and skins with high resolution, high sensitivity, and rapid response sensing capabilities is significant to a broad range of applications including wearable healthcare devices, human–machine interacting robots such as service robots for the elderly and electronic skin (e‐skin) applied on or in the body that provide an unprecedented level of diagnostic and monitoring capabilities. Flexible multifunctional sensors are essential components of e‐skin to allow biomedical prostheses and robots to naturally interact with humans and the environment. They can also be used in future mobile health monitoring and remote diagnostics in cardiovascular medicine.

Conventional rotary fans struggle in the environments which piezos excel in because of their inherent robustness. These namely include dusty, corrosive or extreme temperature environments. Piezos also offer a thinner form factor and lower audible noise characteristics. Piezos also don’t have any electromagnetic interference concerns.

Piezos do not require any power to be continuously monitoring and sensing an environment. Therefore they are especially useful as triggers to “wake up” an electronic circuit when given a mechanical impulse. This is useful in shock and vibration testing applications (you don’t want or need the sensors to be on if the system is static, only once it’s started moving) and anti-tamper applications for military or industrial systems.

There are an unlimited number of other uses for piezos. They can be used to generate high frequency waves for ultrasonic technology and they can generate audible signals for alarms. Let us know your idea on how piezo motor might help you solve your engineering challenge with its low power, thin form factor, and precise control!

Flexible electronic skins based on piezoelectric nanogenerators and piezotronics

Skin, the largest organ in the human body, is sensitive to external stimuli. Particularly, there are seven types of receptors in the skin for sensation, including pain receptors, two types of temperature receptors, and four types of mechanical receptors.1 External stimuli are converted into electrical signals (action potentials) by the receptors, then the signals are transmitted to the brain through the nerves.

In recent years, an increasing number of skin‐inspired electronics, including wearable electronics, implantable electronics, and electronic skin, have been developed because of their broad applications in healthcare and robotics. Electronic skins have received substantial attention in recent years and found great potential in prosthetics, robots, wearable devices, medical equipment, and many other areas. Development of various flexible physical sensors, including mechanical sensors, temperature sensors, humidity sensors, electrophysiological sensors, with high sensitivity, fast response, and high‐resolution is the prerequisite for realizing the desired skin‐mimic sensing functions.

Physical sensors are one of the key building blocks of skin‐inspired electronics. Typical physical sensors include mechanical sensors, temperature sensors, humidity sensors, electrophysiological sensors, and so on. The development of the emerging field of nanogenerators and piezotronics unveiled new types of flexible electronic skins. These devices demonstrated high sensitivity, rapid response, and self-power capability.

An international research team has developed “electronic skin” sensors capable of mimicking the dynamic process of human motion. This work could help severely injured people, such as soldiers, regain the ability to control their movements, as well as contribute to the development of smart robotics, according to Huanyu “Larry” Cheng, Dorothy Quiggle Early Career Professor in the Penn State Department of Engineering Science and Mechanics. Cheng and collaborating researchers based in China published their work in a issue of Nano Energy.

“Here, we report a novel biomimetic flexible dual-mode pressure sensor that is based on the interlocked piezoelectric and piezoresistive films with pyramid microstructures. The sensitivity of the sensor is significantly enhanced because of the induced larger stain variation along the thickness direction of the former piezoelectric film and increased contact area in the latter piezoresistive film. The synergistic effect of the piezoelectric and piezoresistive responses to stimuli also allows the dual-mode sensor to detect over broad pressure and frequency ranges,” write the authors.

The piezoelectric effect can take an electric signal to drive or deform a piezo to provide haptic (communication using the sense of touch) feedback. Using piezos for haptic communication is especially useful in applications where low-power, thin & light form factor, and/or non-magnetic capabilities are important.

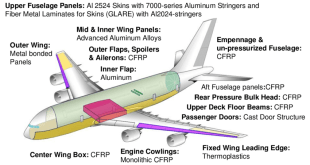

Piezoelectric in Aerospace

These materials help in controlling the airflow across the wings of an aircraft and maintaining it during take-off and landing. Furthermore, these materials are also used to solve common problems with the aircraft, such as engine vibration, high cabin noise levels, ice formation on wings, flow separation due to turbulence, and control surfaces in cold climatic conditions. Also, piezoelectric materials find extensive applications in military and defense sector like smart sensors, smart nanorobotics, smart combat suits, and smart skins.

Structural health Monitoring

Piezos are used in structural health monitoring (SHM), where the integrity of mechanical structures is checked while in use. This is highly relevant where safety is an important issue e.g. transport structures, infrastructure and building structures. The continuous monitoring also holds an obvious financial advantage to traditional inspection of e.g. an airplane that requires a planned interruption of service and even a dismantling of selected parts.

The sensors used in SHM are fixed to or integrated in the structures, which they monitor continuously. SHM systems can either be “active” or “passive”. A “passive” system only “listens” to eventual noise originating from crack propagation (particularly in the case of composite structures) or to changes in the frequency response of the structure.

The “active” systems generate a sound wave in the material. When the high frequency pulses of sound radiating from the transducer hit a material with a different acoustic impedance (density and acoustic velocity), they can be partly absorbed or reflected. There are different methods for “active” SHM, the most common ones being to analyse the transmission between two transducers (“pitch-catch”) or to listen to the reflected sound (“pitch-echo”). Is there is a flaw in the structure, the reflected signal will increase; the transmitted signal will decrease. The detection, localization, characterization and assessment of flaws requires complex signal processing and analysis.

SHM applications are typically constructed with monolayer piezo transducers providing low power, high sensitivity and wide frequency range.

Active Vibration Damping

Piezos offer unique benefits for vibration damping applications. Piezoelectric actuators are used for active vibration damping in mechanical structures where vibrations are undesirable. Vibration damping can be designed to reduce noise, fuel consumption and energy waste. The reduction of sound levels in helicopter structures has drawn a lot of interest recently, however the technology can be applied to other areas such as planes, wind turbines, motors, machine tools, laboratory tables (especially optical), etc.

There are two methods of damping undesired vibrations in mechanical structures using piezo components: active and passive vibration damping. Passive vibration damping is a method, where the vibration is converted into electrical energy through the piezo effect and then stored or dissipated into heat, by means of resistors or inductors. They can be used passively to convert mechanical energy into electrical energy that is then dissipated over an inductor to convert that energy into a harmless magnetic field. Due to the conservation of energy, this energy conversion will have reduced the levels of vibration (the harvested mechanical energy) in the system.

Piezos can actively fight vibration by vibrating at the same frequency as the structure to which it’s mounted but in the opposite direction. In the active method, the piezo actuators generate counter movements in the control loop, which effectively damps the vibration. This is the preferred method as it is most effective, however it requires power and a complex controller.

Active vibration damping in the aerospace sector usually focuses on high amplitude, low frequency vibrations, which require powerful, large stroke actuators. Stacked multilayer piezoelectric actuators are preferred for their high strain and are often integrated in amplifying structures.

Micro Thrusters for Satellites

Piezos are used in micro-thrusters for satellites, where the micro-thrusters are used to position and stabilize the satellite. Naturally, there is a very strong focus on reliability and functionality of products used in space.

Micro-thrusters can use different technologies, but the technology of interest here is the so-called “cold gas micro-thruster”. In this approach, the thrusters generate a very small and controlled force (<500µN) by expelling a jet of gas, typically Nitrogen, stored in a high-pressure tank. This requires both an accurate control of the pressure of the propellant in the circuit and a fast and precise “dispensing”. Piezo actuators integrated into valves can ensure both functions. For redundancy, the micro-thrusters are fitted with several piezo actuators. The movement of the piezo actuators ensures a fast and precise control of the flow during operation.

On the low-pressure side, the piezo elements integrated in micro-thrusters are selected for their low power requirements, reduced size and mass, high stroke, low force. For this application, a multilayer bending actuator is preferred, providing fast and precise motion in a small package.

Piezoelectric Energy Harvesting Technologies

The conversion of dynamic mechanical energy into electrical energy using piezoelectric materials is typically called piezoelectric energy harvesting. Generally, vibratory energy can be converted to usable power using piezoelectric, electrostatic, electromagnetic, magnestrictive, and triboelectric convertors. The piezoelectric effect converts kinetic energy in the form of vibrations or shocks into electrical energy. So in effect, the piezo is harvesting vibration energy in the environment which can then be used to power an electronics assembly. This is especially useful in applications where the labor cost of replacing batteries on a fixed schedule is too burdensome.

The advantages of piezoelectric generators over the other methods include their inherent transduction capacity, the preservation of efficiency as scale is reduced, higher power density, and capacity to function in high frequency applications .

Given the fact that most piezoelectric harvesting systems operate at the microwatt to milliwatt scale, the most common application of piezoelectric energy harvesting is to provide energy for low-power electronics including embedded electronics, implantable biomedical devices, wireless sensor nodes, portable electronics, and the military and vehicle industry.

As future sensor systems come to be designed smaller and smaller it would be convenient if the power source could also be scaled down. Piezoelectric energy harvesting provides this possibility with the most miniaturized size in the regime of microelectromechanical systems (MEMS). Another advantage is the long life span as the piezoelectric ceramics can be manufactured to operate over wide temperature ranges and designed to endure demanding dynamic conditions for several years.

Piezoelectric harvesting systems can provide a permanent, autonomous power source that does not need replacement or maintenance. Compared to traditional energy sources, like batteries, autonomous operation can reduce costs associated with battery replacement. Furthermore, autonomous power supplies allow electronic devices to be embedded into structures or placed in remote locations.

In order to capture vibration energy from a structure, a piezoelectric harvester must be attached to the host structure so that the vibratory energy is effectively transferred from the host to the harvester. At the same time the mechanical design has to protect the piezoelectric material from intense forces that might cause cracks, while still transmitting the kinetic energy efficiently. These requirements usually mean a specific energy harvest design for each ambient energy source at hand.

Recently, the piezoelectric energy harvesters with unique structures and fabrication methods have been significantly developed, which can be classified with bulk type, microelectromechanical systems (MEMS), and flexible energy harvesters.

MEMS Piezo Pressure Sensor for Military Applications

PZT is a smart material that can be used as a multifuction integrated film for both sensors and actuators. It is widely used in memory cells of logic circuits. In missile applications that require the use of a guidance and control systems, it can act as a backup inertial measurement unit (IMU). PZT is also gaining attention in the field of power MEMS for applications in energy storage and power reclamation.

ARL has developed smart material piezoelectric PZT (Lead Zirconate Titanate) pressure sensors for extremely harsh environments encountered in projectile launched munitions. The ARL in-house stateof-the-art MEMS fabrication facility and advanced technology enable miniaturized, low cost sensors that are rugged enough to withstand pressures of 100,000psi, and an axial acceleration of 75,000g.

The insertion of a PZT pressure sensor into the tracer well system of direct fire tank ammunition enables routine in-bore pressure measurements without major projectile modifications. It also enables the development of smart munitions concepts where launch disturbances can be computed through knowledge of the in-bore excursion.Insertion of smart material MEMS sensors into projectiles can lead to development more precise and lethal projectiles for future combat systems.

Navy scientists develop state-of-the-art sensor for detecting blast-injured brains

A group of U.S. Navy scientists have created a new and improved way to detect traumatic brain injuries. The cutting-edge technology, a very small but highly sensitive blast sensor, can operate at extremely high frequencies, allowing it to measure rapid changes in force and therefore predict and analyze traumatic forces more accurately than current tools.

The Navy built prototype sensors, illustrated here, using PMN-PT Piezoelectric Single Crystals purchased from CTG Advanced Materials. The primary component of the pressure sensor is an aluminum cylinder with two windows allowing for positioning of the crystal and to allow for wiring. The center of the cylinder has been bored out to hold the active piezoelectric crystal and other components. The crystal (103) is positioned between two ceramic cylinders that have a layer of tape on the side in contact for the crystal for additional compliance and electrical insulation. A strain transfer rod (105) is directly connected to a diaphragm (106) to convert a pressure wave (e.g., a blast wave) into a force on the piezo crystal.

Piezoelectric transducers for Sonars and Underwater communications

When the transducer is used to generate sound, it is called a projector, transmitter, or source. When it is used to detect sound, it is called a receiver. Furthermore, when the receiver is employed underwater, it is referred to as a hydrophone. Sonar systems use sound propagation to navigate, communicate with or detect objects on or under the surface of the water, such as fish or other vessels. An underwater sonar system consists of projectors, hydrophones, and associated electronics such as amplifiers and data acquisition systems.

Underwater communication benefits from the acoustic waves radiating from the sonar. Acoustic waves are the best solution for underwater communication as a mean to send and receive data underwater. Piezos are used in sonars for underwater communication, where you benefit from the acoustic waves radiating from the sonar.

Applications for underwater communication are normally fitted with piezo components, which can be all shapes and sizes depending on the application. If the application is low-power, you would use a soft doped piezoceramic material. However, for high power applications the electrically hard materials should also be considered. Sizes depend on the application. The multilayer piezoelectric element used as a transmitter could significantly reduce the level of driving voltage.

Piezo-ceramic transmitters with varying geometries that cover a frequency range of 5 kHz to 10 MHz are used in the different systems. Some systems use the same piezo-ceramic transducers for transmitting and receiving. Others use different ceramic transducers for transmitting and receiving, such as in towed array sonar systems which can work over long distances. Large ships use transducer arrays, which consist of a high number of individual piezo-ceramic elements. These elements can be controlled separately and electronically delayed. This makes it possible to use electronic beam deflection.

An echosounder, is one of the simplest forms of underwater sonar. It operates by using a piezoelectric transducer to send an ultrasonic acoustic pulse into the water and then listens back for echoes to return. With that information it’s able to determine the distance to the strongest echo, which is usually the ocean floor or a large object. It can also provide the full echo response (echo strength versus time) which can be plotted like the display of a fishfinder sonar.

The Ping uses a 115 kHz transducer frequency, away from those used on most boat echosounders to avoid interference. It has a measurement range of 30 meters (100 feet) and a measurement beam width of 30 degrees, perfect for applications on a rocking boat or for obstacle avoidance. An advanced bottom-tracking algorithm runs on the device to determine the distance to the seafloor, even in complicated situations with multiple echoes.

Underwater imaging uses sonars directed towards the bottom and other imaging principles. Underwater imaging is the most complex type of sonar, where the returning echoes of the sound waves are displayed in detailed 2D or 3D mapping. For smart sonars working with high resolution, respectively with aperture synthesis, you would normally use soft piezoelectric materials, which provide higher resolution. The varieties of piezoelectric transducers go from simple single transducer up to sophisticated multielement phased arrays of transducers.

Market Growth

The piezoelectric device market is projected to grow from USD 23.5 billion in 2016 to USD 31.3 billion by 2022; it is expected to grow at a CAGR of 4.9% from 2019 to 2022,according to a report available from markets and markets. Key factors fueling the growth of this market include the increasing market for piezoelectric materials, emerging applications of piezoelectric devices, increase in R&D investments, and increasing demand for low-power portable energy sources and energy harvesting devices.

In 2016, the piezoelectric actuators segment captured the largest share of the piezoelectric device market. The growth of this market is propelled by the growing demand for high-accuracy systems. Piezoelectric actuators offer a considerably higher level of precision required in positioning systems, thereby making them highly suitable for use in such devices. These actuators are also being used in semiconductor manufacturing, optics and photonics, industrial automation, and medical engineering.

Another growth factor is the rising demand for energy-harvesting techniques using non-conventional energy sources. However, legal restrictions with regard to the use of lead, the high cost of materials, and burgeoning research and development costs are the some of the major factors expected to limit the adoption of piezoelectric devices over the forecast period.

Among materials, the piezoceramics accounted for the largest share of the piezoelectric devices market in 2016. The growth of this segment of the market can be attributed to the increased demand for piezoceramics because of its high piezoelectric sensitivity and ability to acquire desired shapes and sizes. Currently, the most widely used piezoelectric ceramic material is lead zirconate titanate (PZT). It is used in a variety of applications such as medical, industrial, and automotive.

Exelis Inc. (U.S.), Morgan Advanced Materials (U.K.), APC International, Ltd. (U.S.), piezosystem jena GmbH (Germany), and Physik Instrumente (PI) GmbH & Co. KG. (Germany) are a few major companies operating in the piezoelectric devices market.

References and Resources also include:

http://www.noliac.com/applications/item/show/underwater-imaging/

https://www.sciencedaily.com/releases/2018/09/180906100453.htm

https://www.marketsandmarkets.com/Market-Reports/piezoelectric-devices-market-256019882.html

http://www.noliac.com/news/item/show/piezo-products-in-underwater-applications/

http://www.noliac.com/applications/item/show/micro-thrusters-for-satellites/

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis