The complexity of current 4G/5G phones comes from the need to cover multiple bands. Modern modems like the ones used in mobile phones are compatible with multiple transmission bands, including 3G, 4G LTE, Wi-Fi, and Bluetooth. The radio frequency front-end (RFFE) section of cellphone includes components like antennas, LNAs, filters, and switches. The usual arrangement is to divide the RFFE into sections for low bands (698-960 MHz), mid-band (1710-2200 MHz), and high-band (2400-3800 MHz). 5G would add another section. Filters are components required for dividing the frequency band. Filter main role is to selectively transmit and receive desired signals and greatly attenuating the other frequency components, reduce the interference of the signal.

To avoid cross talk and optimize the quality and throughput of each band, a dedicated analog filter is used for each of the bands. Good filters like surface acoustic wave (SAW) or bulk acoustic wave (BAW) types are essential to minimize cross talk and intermodulation distortion. In addition to the 2/3 / 4G signal Send and receive filtering, but also need to Wi-Fi, Bluetooth, GPS signal filtering, so a phone about 30 or so for different bands of the filter. Unlike general filter components which are based on electromagnetic (EM) signals, the Surface-acoustic-wave (SAW) and bulk-acoustic-wave (BAW) resonators, filters, oscillators, and delay lines are based on Acoustic waves. Since Acoustic waves have much shorter-wavelength it’s possible to create extremely small resonators, filters, oscillators, and delay lines for SAW structures that process higher-frequency electromagnetic (EM) signals.

The advantage of acoustic wave filters over electromagnetic filters is generally recognized as their small size resulting from the approximately five orders of magnitude reduction in the acoustic wave velocity. Bulk acoustic wave resonators have such unique advantages since they are at least an order of magnitude smaller than dielectric resonators or lumped elements, and possess much lower insertion loss than Surface Acoustic Wave devices. When compared to Surface Acoustic Wave devices, BAW resonators exhibit a lower frequency drift with temperature, a better power handling, and their technology can be made compatible with standard IC technology, hence moving a step closer to the one-chip radio concept.

Bulk Acoustic Wave (BAW) piezoelectric resonator is a device that has the potential for meeting the needs of modern wireless communication equipments. RF systems between 1 and 10 GHz can be targeted with such devices, which provide a high Qfactor. Qfactor offered by BAW is greater than that for on-chip LC tanks. In addition to the high QFactor BAW resonators also provide low volume, low cost, and a reasonable coupling coefficient. These properties are all essential when portability is required, since they contribute to a reduced power consumption and a greater compactness.

RF filters will be disruptor in the military RF and microwave industries. “The number of mobile devices is growing. As it does, frequency and bandwidth will continue to be limited. This significantly impacts everything from commercial applications like smartphones, Wi-Fi, and base stations to defense technologies like radar and [communications] systems. The industry will have to rely on RF filters such as BAW [bulk acoustic wave] and SAW [surface acoustic wave] to solve this issue, which will ultimately improve user experience and connectivity, says Roger Hall, General Manager”, says Defense & Aerospace for Qorvo

SAW and BAW components

SAW and BAW components rely on piezoelectric materials to transfer or store acoustic energy. Storing acoustic-wave energy within the piezoelectric material has its advantages. At their higher frequencies, BAW resonators are capable of achieving high quality factors (Qs) that translate into highly selective filters. For bandpass filters, for example, low passband insertion loss is possible with very sharp filter skirts. This enables high rejection of signals closely located to a desired passband, as has become the case for many of the wireless communications standards.

Both SAW and BAW components employ interdigital transducers (IDTs) to convert electrical energy to mechanical acoustic waves and then back to electrical energy, enabling signal processing in the acoustic realm. Components based on these technologies have found their ways into many applications, from automotive navigation systems and smartphones to military radar systems.

A BAW filter has interdigital transducers (IDTs) to convert electrical energy to mechanical acoustic waves that travel through the surface of the piezoelectric material and are stored in it. But the acoustic waves propagate vertically as shown in figure below.

In a SAW component, acoustic waves travel across the surface of an elastic, piezoelectric material, with wave amplitude that typically decays exponentially with depth into the substrate material. In contrast, the acoustic waves in a BAW component travel through and are stored in the piezoelectric material.

These small structural features, however, ultimately limit the high-end frequency for which a SAW filter or resonator can be practically manufactured. Power-handling capabilities also become limited due to the high current densities in small structures. As a simple “difference between” for SAW and BAW components, BAW devices can handle higher frequencies and higher power levels than SAW components, although SAW components tend to be less costly.

Surface acoustic wave (SAW) filters are primarily used for 2G and frequencies below, while bulk acoustic wave (BAW) filters are used for 3G and above. SAW components such as filters can be manufactured to about 2.0 or 2.5 GHz before the dimensions of the SAW transducers become unmanageably small. BAW components, on the other hand, are sometimes known as “high-frequency SAWs” and can be used to 2.7 GHz and beyond for filtering, delay lines, and other functions. For some applications, such as Long Term Evolution (LTE) wireless systems, SAW and BAW filters both play roles; in this case, at the lower- and higher-frequency bands, respectively.

Since SAW filters are known to drift in frequency more with temperature than BAW filters, some designers opt for BAW filters in circuits or systems that must be used over wide operating-temperature ranges. In recent years, though, a number of SAW manufacturers have developed either temperature-compensated or more temperature-insensitive SAW filters that provide stable frequency operation even over wide operating-temperature ranges.

One BAW filter type is called a film bulk acoustic resonator (FBAR). These filters are made from piezoelectric material sandwiched together to create a network of resonating structures that resonate in the frequency range of 100 MHz to 10 GHz. FBARs are highly complex devices and are challenging to design since there are physical parameters (i.e. geometry and materials) as well as electrical properties to consider.

Piezo is Primary Material

To form a SAW or BAW filter or resonator, different types of metal films are deposited on the top and bottom of the piezoelectric materials. These metals include aluminum (Al) and tungsten (W), for lower and higher power levels, respectively. In such acoustic components, the resonant frequency is inverse proportional to film thickness, with both the metal and dielectric layers helping to determine the resonant frequency. Removing some of the top layer metal thickness, for example, can increase the resonant frequency.

SAW and BAW components rely on piezoelectric materials to transfer or store acoustic energy, and the choice of material can have a great impact on filter or resonator performance. In either type of component, the piezoelectric material layer is usually produced with top and bottom metal layers and mounted to a substrate material for stability. Piezoelectric materials for SAW components must exhibit optimum mechanical and electrical properties. One piezoelectric material that has gained widespread acceptance for its manufacturability and performance levels is aluminum nitride (AlN).

Piezoelectric material can also support different bandwidths for SAW filters, depending on the type. Basic quartz materials have been found to be adequate for low-bandwidth filters, while lithium tantalite has served well for medium-bandwidth varieties. Lithium niobate is typically employed for SAW filters with wide bandwidths. As with most high-frequency components, however, these materials yield other tradeoffs in exchange for such performance characteristics. In particular, lithium niobate is known for high temperature dependency and higher loss than some of the other piezoelectric materials.

Storing acoustic-wave energy within the piezoelectric material has its advantages. At their higher frequencies, BAW resonators are capable of achieving high quality factors (Qs) that translate into highly selective filters. For bandpass filters, for example, low passband insertion loss is possible with very sharp filter skirts. This enables high rejection of signals closely located to a desired passband, as has become the case for many of the wireless communications standards. BAW filters tend to be better suited for higher-power-level signals than SAW filters with their fine circuit features that can suffer the performance-degrading effects of electromigration at higher power levels.

As delay lines, both technologies are effective within their frequency ranges, with SAW delay lines somewhat smaller in size and less expensive than BAW delay lines. SAW delay lines operate at lower frequencies than BAW delay lines, and are somewhat limited in terms of the amount of delay time that they can introduce to a circuit or system compared to their BAW counterparts

Development of FBARs for 5G

SAW filters have been used in mobile phones for 20 years, but it was not until 2001 that BAW and FBAR filters were introduced into the market. While more complex and more expensive to fabricate, these filters are ideal for applications that require higher performance than SAWs. An FBAR filter generates a bulk wave inside a piezoelectric thin film that is sandwiched between two electrodes. A high-frequency signal is applied to the electrodes and an acoustic wave resonates in the structure at a designed frequency determined primarily by the shape and thickness of the piezoelectric thin film.

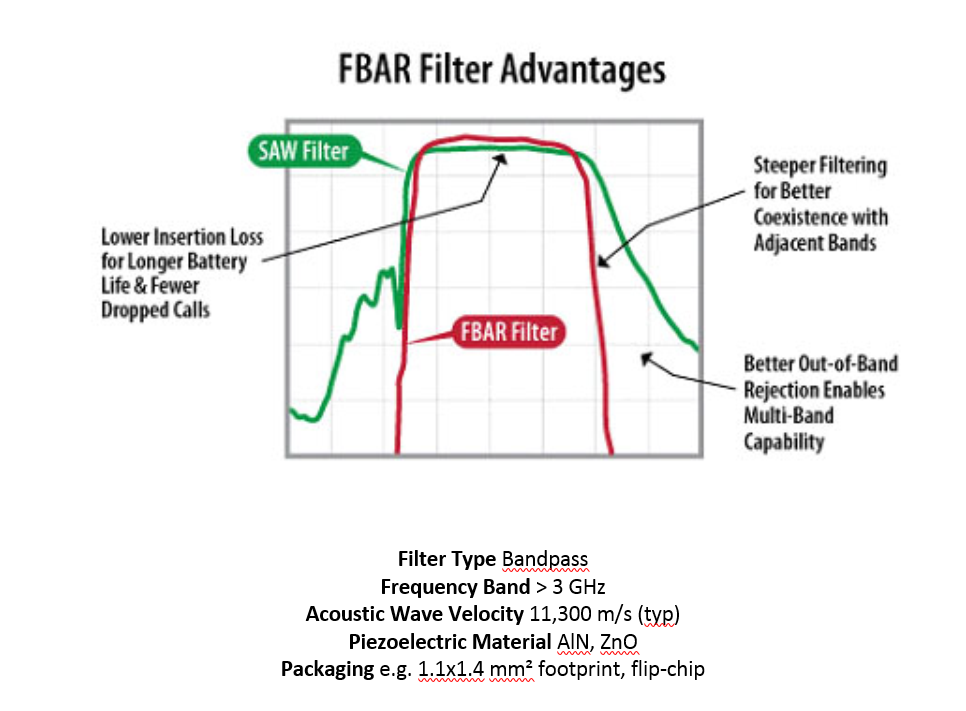

FBAR filters are a type of bulk acoustic wave (BAW) filter with superior performance and steeper rejection curves compared to surface acoustic wave (SAW) filters. FBARs feature lower insertion loss (0.3 dB to 0.5 dB), which equates to significantly lower current consumption and, as a result, extended battery usage for handheld electronic devices. FBARs use piezoelectric thin films with thicknesses from micrometers to tenths of micrometers and resonant frequencies between 100 MHz and 10 GHz. Two common piezoelectric materials used for the thin film are aluminum nitride (AlN) and zinc oxide (ZiO), with reports of PZT being tested as well. The structure of the FBAR is made by forming cavities in the silicon substrate, which can be effectively performed using deep reactive ion etching (DRIE) or by using sacrificial layers. It is in these cavities where the acoustic waves resonate when the FBAR filter is in use. While FBARs can process higher frequencies than SAWs and are more resilient to static electricity, controlling the thickness of the deposited piezoelectric layers during fabrication is very challenging.

TI Claims Breakthrough BAW Technology

Texas Instruments unveiled in Feb 2019 what the company describes as “breakthrough” bulk acoustic wave (BAW) resonator technology. With microresonator technology, TI no longer needs to use external quartz crystal. Instead, it can integrate high-precision and ultra-low-jitter clocks directly into packages that contain other circuits, according to the company. This has enabled TI to roll out for the embedded market the industry’s first crystal-less, wireless MCU, SimpleLink CC2652RB, with the clock included in the same silicon.

In parallel, by applying the same BAW technology to network infrastructure, TI is launching a network synchronizer called LMK05318, enabling 400-Gbps link performance even under high system-level disturbances. Ray Upton, TI’s vice president of Connected Microcontrollers, explained that the new technology is critical to “moving around massive amounts of data in a stable manner,” thus improving high-performance communication. The technology also achieves high precision and robust communication among IoT devices that can be developed now in a less bulky form, said Kim Wong, TI’s vice president of High Speed Data & Clocks.

Put simply, advancements in BAW technology lend wired and wireless networks “increased performance, simpler design, lower cost, and smaller size,” Wong explained. Philip Solis, research director for Connectivity and Smartphone Semiconductors at IDC, told EE Times that the new BAW resonator technology “is important because TI is integrating it into its silicon products, reducing design time, solution size, and component costs.” In addition, said Solis, “using a BAW resonator is much more accurate than using a quartz crystal.” A quartz crystal needs additional components to extend its accuracy as — over time — its properties change, beyond the temperature variations that can be controlled, he added.

As he explained, “If it were merely a different way of doing timing, it would be more accurate and reduce the need for other external components, but the BAW resonator is produced in silicon as part of various TI products.” Today, timing normally requires quartz crystals. “Everyone uses quartz crystals for the clock,” said Solis. In that context, BAW resonator technology gives TI a huge advantage by eliminating the need for external components mounted on the PCB, he noted.

Asked why nobody in the industry has built something like the BAW resonator, Upton said, “This is extremely difficult to develop.” TI had dabbled with it for several years while working on MEMS. But it was not easy to convert electrical energy to mechanical acoustics while keeping signals stable and robust within a clean clock.

Key features

TI’s SimpleLink multi-standard CC2652RB is a wireless MCU with a BAW resonator in a quad flat no-lead (QFN) package. It claims a reduced overall footprint, absent an external high-speed 48-MHz crystal.

This also offers a simplified design, said TI. The CC2652RB is the lowest-power multi-standard device supporting Zigbee, Thread, Bluetooth Low Energy, and proprietary 2.4-GHz connectivity on a single chip. Enabling more design options and flexibility in a wider range of applications and environments, the CC2652RB works in the full −40°C to 85°C temperature range, unlike many crystal-based solutions.

TI’s other splash, an ultra-low-jitter single-channel LMK05318 network synchronizer clock, provides higher network performance. Featuring a BAW resonator, TI’s single-channel network synchronizer clock for 400-Gbps links helps systems transmit more data faster while also providing a higher margin for system jitter budgets than competing devices, TI explained.

With ultra-low jitter and the industry’s best hitless switching performance, the LMK05318 delivers the lowest bit errors for 56-Gbps and emerging 112-Gbps pulse-amplitude modulation-4 links — enabling better network performance.

Tradeoffs?

Asked if there is any tradeoff by integrating a BAW resonator in the wireless MCU package, Wong noted a potential power delta at about 2% — “a couple of hundred microamps.” He called it “a reasonable tradeoff, [considering] its benefits outweigh [it].”

Akoustis Awarded New DARPA Contract to Advance XBAW Technology

Akoustis Technologies, Inc. (NASDAQ: AKTS) (“Akoustis” or the “Company”), an integrated device manufacturer (IDM) of patented bulk acoustic wave (BAW) high-band RF filters for mobile and other wireless applications, announced today that it has been awarded a new, multi-year direct-to-phase 2 (DP2) contract from DARPA to further develop Akoustis’ technology through the development of a Piezo MEMS process design kit (PDK) for the Company’s proprietary and patented XBAW™ process.

The DP2 program of the Small Business Innovation Research (SBIR) contract will be dedicated to developing a general purpose PDK that will enable BAW and other similar MEMS structures to be designed and fabricated using the Company’s state-of-the-art XBAW™ process. The proposed Piezo MEMS PDK will encompass all aspects of the Company’s process technology ranging from material properties, process rules for stack dimensions, process control monitoring, design rule checking, and example device models.

Upon successful completion of the DP2 program, DARPA may choose an option to fund a phase 3 program. This option supports multiple customer engagements leveraging the new PDK to create devices and circuits, including RF filters, using the Company’s XBAW™ process.

Jeff Shealy, Founder and CEO of Akoustis, stated, “We are honored to receive this contract award from DARPA to further develop the XBAW™ platform and expand the reach of our technology to facilitate new customers.” Mr. Shealy continued, “This will greatly expand the opportunities for XBAW™ moving forward as other designers will be able to develop new products utilizing novel piezoelectric materials and substrates outside of our current targets, which could lead to new opportunities in adjacent fast growing markets.”

Akoustis’ high frequency, high performance XBAW™ process and filters are experiencing growing interest as the Company has entered production in multiple markets in calendar 2020, including 5G network infrastructure, high-band WiFi and phased-array radar applications.

Akoustis has added 15 filters to its product catalog including a 5.6 GHz WiFi filter, a 5.2 GHz WiFi filter, a 5.5 GHz WiFi-6E filter, a 6.5 GHz WiFi 6E filter, three small cell 5G network infrastructure filters including two Band n77 filters and one Band n79 filter, a 3.8 GHz filter and five S-Band filters for defense phased-array radar applications, a 3.6 GHz filter for the CBRS 5G infrastructure market and a C-Band filter for the unmanned aircraft systems (UAS) market. The Company is also developing several new filters for the sub-7 GHz bands targeting 5G mobile device, network infrastructure, WiFi CPE and defense markets.

Market growth

Technology giant QUALCOMM predicts that the filter market will grow from $ 5 billion in 2015 to $ 13 billion in 2020. Increasing usage of tablets and smartphones are one of the key reasons behind the growing demand for bulk- acoustic-wave filters market globally. Rapid usage of smartphones and tablets and other smart electronic devices in economies such the U.S., Japan, China, South Korea, Brazil and India are expected to witness positive growth over the forecast period from 2016 to 2024

According to report Acoustic Wave Sensor (SAW and BAW) Market : Analysis, Opportunities and Forecast to 2025, the global acoustic wave sensors market is expected to grow at a considerable rate due to its competitive edge over other technologies. The wide array of applications for both surface acoustic wave sensors and bulk acoustic wave sensors include delay lines, transformers, oscillators, and filters. Both SAW and BAW applications in delay lines together provide additional advantages in terms of the signal wave technologies, such as in target generation in electronic warfare and in television and video communication sets.

The market is driven by factors such as the growing automotive industry. In addition to this, low manufacturing cost is expected to act as driver for the global acoustic wave sensor market. The growing NANO technology applications and wireless connectivity advancements in information technology and telecom sectors is serving as an opportunity, fuelling the growth of the global acoustic wave sensor market. On the other hand, due to their replaceable nature, the growth of the global acoustic wave sensors market is restricted.

Avago Technologies (The U.S.), Qorvo (The U.S.), TDK (Tokyo, Japan), Skywork Solutions (The U.S.), Akoustis Technologies (The U.S.) among others are some of the major players operating in the Bulk-Acoustic-Wave (BAW) filters market.

References and Resources also include:

https://spectrum.ieee.org/telecom/wireless/design-and-optimization-of-fbar-filters-to-enable-5g

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis