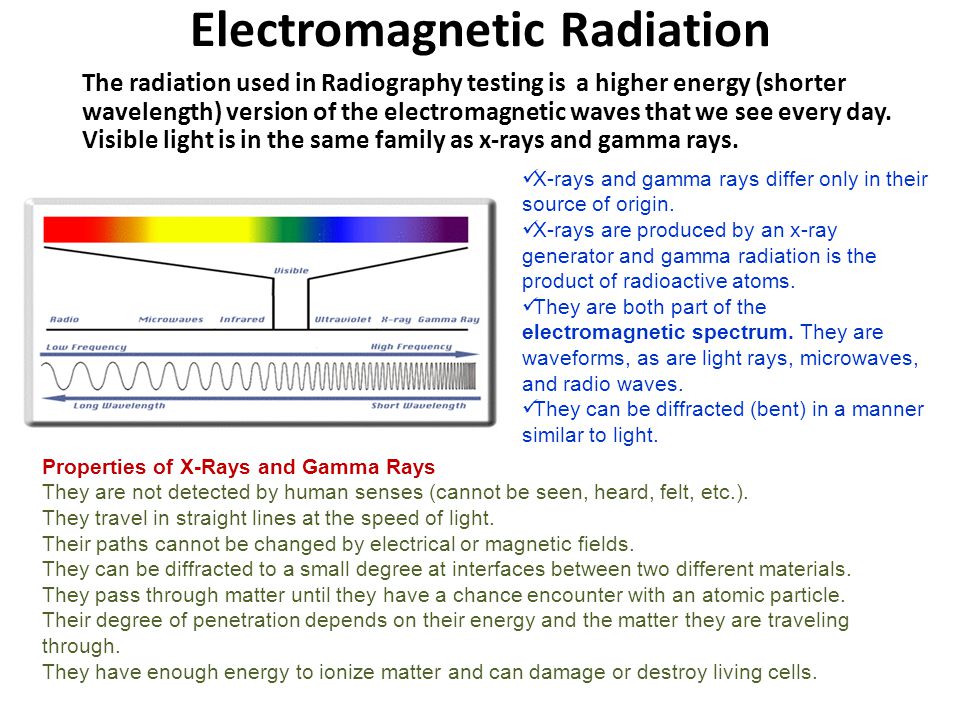

Gamma rays are ionizing electromagnetic radiation, obtained by the decay of an atomic nucleus. Gamma rays are given off by stars, and by some radioactive substances. Gamma-rays travel to us across vast distances of the universe, only to be absorbed by the Earth’s atmosphere. Different wavelengths of light penetrate the Earth’s atmosphere to different depths. Gamma-rays extremely high frequency waves have the smallest wavelengths and the most energy of any other wave in the electromagnetic spectrum. These waves are generated by radioactive atoms and in nuclear explosions. They pass through most materials, and are quite difficult to stop – you need lead or concrete in order to block them out. Gamma rays are more penetrating, in matter, and can damage living cells to a great extent.

Unlike optical light and X-rays, gamma rays cannot be captured and reflected in mirrors. The high-energy photons would pass right through such a device. Gamma-ray telescopes use a process called Compton scattering, where a gamma-ray strikes an electron and loses energy, similar to a cue ball striking an eight ball. Gamma rays are produced in the disintegration of radioactive atomic nuclei and in the decay of certain subatomic particles. When an unstable atomic nucleus decays into a more stable nucleus (see radioactivity), the “daughter” nucleus is sometimes produced in an excited state.

Gamma rays are used in medicine (radiotherapy), industry (sterilization and disinfection) and the nuclear industry. Because Gamma rays can kill living cells, they are used to kill cancer cells without having to resort to difficult surgery. This is called “Radiotherapy”, and works because healthy cells can repair themselves fairly well when damaged by gamma rays – but cancer cells can’t. Getting the dose right is very important! Shielding against gamma rays is essential because they can cause diseases to skin or blood, eye disorders and cancers.

X-rays and gamma rays have a wide range of applications including scanning suspicious maritime shipping containers for illicit materials, industrial inspection of materials and processes, and medical diagnostic and therapeutic procedures. Non-destructive testing (NDT) is a way to detect and evaluate flaws in materials. The simplest and most accurate way of testing materials and components is often to test them to destruction. Destructive testing is used in aerospace to determine the physical properties of materials, components and assemblies. It can reveal useful information about characteristics of materials including ductility, tensile strength and fracture toughness. However, destructive testing is not always possible or desirable when testing parts and materials destined for, or already in use on, aircraft mainly because of their high value.

Nondestructive testing (NDT) is a wide group of analysis techniques used in science and technology industry to evaluate the properties of a material, component or system without causing damage. The terms nondestructive examination (NDE), nondestructive inspection (NDI), and nondestructive evaluation (NDE) are also commonly used to describe this technology. Because NDT does not permanently alter the article being inspected, it is a highly valuable technique that can save both money and time in product evaluation, troubleshooting, and research.

There is wide variety of nondestructive techniques or methods. These methods can be performed on metals, plastics, ceramics, composites, cermets, and coatings in order to identify cracks, internal voids, surface cavities, delamination, incomplete defective welds and any type of flaw which would lead to premature failure. Gamma ray inspection utilizes electromagnetic radiation from high-energy gamma rays to penetrate material and manufactured components that are too dense for x-rays. This testing technique is often used to test welds on pipelines and pressurized pipes.

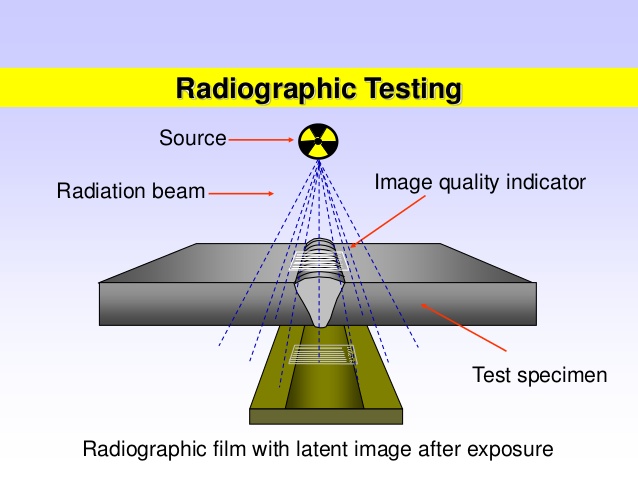

Radiographic Testing (RT or X-ray or Gamma ray) is a non-destructive testing (NDT) method that examines the volume of a specimen. Radiography (X-ray) uses X-rays and gamma-rays to produce a radiograph of a specimen, showing any changes in thickness, defects (internal and external), and assembly details to ensure optimum quality in your operation. Radiography- Radiography technique has a benefit or advantages over some of the other NDT methods in that the radiography provides a permanent reference for the internal soundness of the object that is radiographed. The x-ray emitted from a source has an ability to penetrate metals as a function of the accelerating voltage in the x-ray emitting tube. If any defect or irregularities such as void present in the object are radiographed, more x-rays will pass in that area and the film under the part in turn will have more exposure or spot light than in the non-void areas .

Conventional Radiography Testing (RT) uses gamma rays or X-rays to detect damage, corrosion, wall thickness, and welding imperfections on field and piping welds, investment casting, and pressure vessels.

Current technologies, however, are not ideal. X-rays produce a continuum of energies that limit their inspection and diagnostic performance, and gamma rays can only be produced at specific energies unique to a given radioactive isotope. The Defense Advanced Research Projects Agency plans to develop a tunable gamma ray technology to accommodate industrial, medical and national security usage. The agency intends to integrate tunable, high-intensity and narrow-bandwidth sources of gamma ray energy through a portable form factor device to help detect specific elements as part of the Gamma Ray Inspection Technology program, DARPA said in 2019.

DARPA Unveils Gamma Ray Inspection Tech Project

DARPA noted that the proposed system will stimulate the nucleus of an atom to cause a nuclear resonance fluorescence, an effect that will create a unique identifier to each isotope in the periodic table. “With GRIT, you could probe and detect specific isotopes of interest by fine-tuning the photon energy to minimize background noise and take advantage of the nuclear resonance fluorescence phenomenon,” said Mark Wrobel, a program manager at DARPA’s defense sciences office.

The Gamma Ray Inspection Technology (GRIT) program seeks transformational approaches to achieving high-intensity, tunable, and narrow-bandwidth gamma ray production, but in a compact form factor suitable for transporting the source to where the capability is needed. Such sources have the potential to help discover smuggled nuclear materials in cargo, provide new non-destructive inspection techniques at various scales, and enable new medical diagnostics and therapies.

“What we’re trying to do in GRIT is transform the use of x-rays and gamma rays,” said Mark Wrobel, program manager in DARPA’s Defense Sciences Office. “Current sources of gamma rays, like Cobalt-60 or Cesium-137, are not very flexible. They require special licenses to possess and only emit gamma rays at very specific energies. What we desire is a source of very high-energy photons that we can tune to match the application we need. This ranges from more effective detection of illicit cargo, to a more informative medical x-ray.”

GRIT aims to provide a source of tunable, pure x-rays and gamma rays from tens of keV (kilo-electron volts) up through over ten MeV (mega-electron volts). Currently, tunable and narrow bandwidth gamma ray sources only exist at highly specialized user facilities best suited for basic research and are not able to support broad practical applications. Shrinking these photon sources to a transportable system is a major goal and challenge of the GRIT program.

GRIT technology could make possible a range of new inspection and diagnostic protocols. In medical and industrial radiography, for example, GRIT could enable revealing specific elemental and material content, such as calcium in bones or specific metals in cargo. A typical x-ray only shows differences in density in the object being inspected – whether a piece of luggage at an airport, or an individual at a doctor’s office. If successful, a GRIT x-ray source could be tuned to detect and quantify the concentration of specific elements of interest, such as the amount of calcium in a given bone x-ray, enabling radiologists to actually see bone composition.

Tuning energy between 10s of keV to over 100 hundred keV would allow detection of specific elements that might be of interest in characterizing novel materials and processes at micron scales. These techniques would be relevant to defense applications including non-destruction inspection of novel additively manufactured materials and alloys for their elemental composition.

At energy levels in the MeV range, gamma ray photons have high enough energy to actually interact with the nuclei of atoms. Whereas x-rays work by interacting with the shells of atoms, GRIT would be able to stimulate the nucleus of an atom to bring about an effect called nuclear resonance fluorescence, a sort of “fingerprint” that is unique to each isotope of every element in the periodic table.

“With GRIT, you could probe and detect specific isotopes of interest by fine-tuning the photon energy to minimize background noise and take advantage of the nuclear resonance fluorescence phenomenon,” Wrobel said. “Those isotopes could be found in rare-earth elements of interest or special nuclear materials. To be able to definitively say, ‘Yes, there’s highly enriched uranium in this object’ and be able to characterize how much is present would be a significant leap forward over our current capabilities.” DARPA is seeking expertise in a range of technologies on the GRIT program including advanced accelerator technology, high-energy laser systems, novel control systems, and new x-ray and gamma ray detector technology.

DARPA Selects Teams for Work on Tunable Gamma Ray Inspection Technology

Two California companies were selected for DARPA’s Gamma Ray Inspection Technology (GRIT) program and have begun work to develop a transportable, tunable source of gamma rays for a host of national security, industrial, and medical applications. Lumitron Technologies and RadiaBeam Technologies started work on the GRIT program in April 2020 and are exploring novel approaches to achieve high-intensity, tunable, and narrowbandwidth sources of gamma ray radiation in a compact, transportable form factor.

GRIT aims to provide a source of tunable, pure x-rays and gamma rays from tens of keV (kilo-electron volts) up through three MeV (mega-electron volts). Currently, tunable and narrow bandwidth gamma ray sources only exist at highly specialized user facilities best suited for basic research and are not able to support broad practical applications. Shrinking these photon sources to a transportable system is the major goal and challenge of the GRIT program.

“If we can develop a transportable system that could be moved to the point of need on a flatbed semi-trailer or rail car, for example, it could transform nondestructive inspection in many areas of interest, such as radiography of critical-use, high-value aircraft or machine parts, or inspection of cargo for contraband,” said Mark Wrobel, program manager for GRIT in DARPA’s Defense Sciences Office. “A transportable, tunable gamma ray source could also be useful in mining to identify rare-earth elements in ores or for advanced medical diagnostics to provide more detailed information than is possible with existing Xray technology.” Phase 1 is 24 months. Depending on whether the performers meet threshold metrics at the end of Phase 1, DARPA will decide if the program progresses to Phase 2.

References and Resources also include:

https://www.darpa.mil/news-events/2019-06-14

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis