Agile Engineering: Accelerating Aerospace Innovation for the Future

Agile Engineering is transforming aerospace by enabling rapid prototyping, real-time testing, and faster time-to-market in space and aviation technology.

The aerospace industry, long defined by its meticulous adherence to rigid timelines and waterfall methodologies, is undergoing a seismic shift. As demand for faster innovation, cost efficiency, and adaptability surges, Agile Engineering is emerging as the cornerstone of modern aerospace design and production. This transformative approach—borrowed from software development but reimagined for complex hardware systems—is enabling companies to slash development cycles, mitigate risks, and respond dynamically to evolving technologies and market demands.

1. Why Aerospace Needs Agile Engineering

The Limitations of Traditional Methods

For decades, aerospace projects followed linear “design-build-test” workflows, with phases often spanning years. While this approach ensured precision, it struggled to accommodate rapid technological advancements such as artificial intelligence and additive manufacturing. It was also ill-suited to adapt to shifting sustainability mandates, including the push for hydrogen propulsion and carbon-neutral materials. Moreover, unpredictable supply chain disruptions, like those witnessed during the pandemic era, further exposed the inflexibility of traditional methods. A 2022 McKinsey study revealed that 70% of aerospace programs overran budgets under traditional models, while 45% missed deadlines due to late-stage design changes.

Agile to the Rescue

Agile engineering has expanded its influence beyond software development and is increasingly being adopted across all engineering disciplines, including aerospace and defense. Traditional product development methods often focus on sequential processes, but agile emphasizes iterative design and constant feedback, which is proving effective in the complex, high-stakes environment of aerospace and defense. By embracing agile, organizations can foster cross-disciplinary collaboration, combining software, electrical, and mechanical teams into integrated engineering groups. This allows for better coordination and faster problem-solving, especially in systems where different subsystems interact with each other.

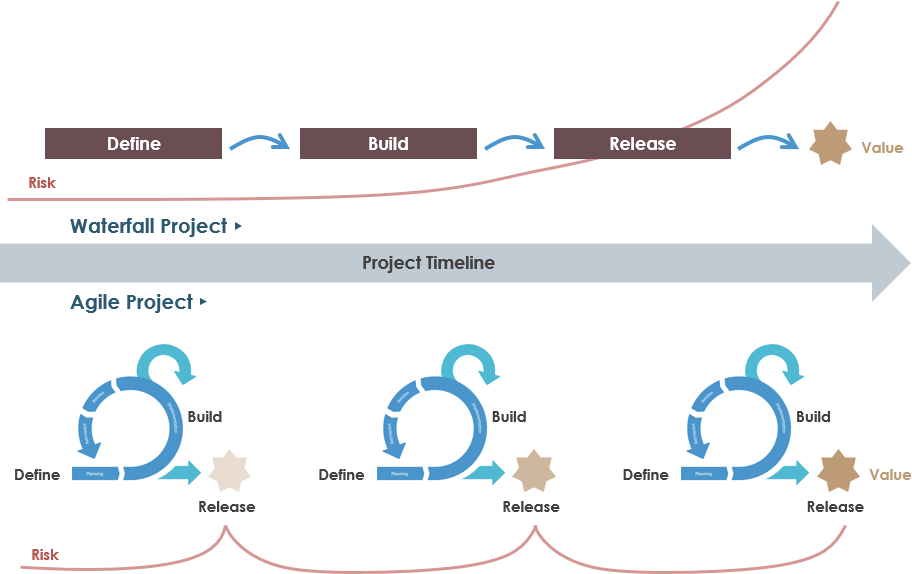

Transitioning to an agile approach allows for a more flexible and responsive development process. Agile engineering breaks down the project into smaller iterations or sprints, each resulting in a potentially shippable product increment. This method fosters continuous collaboration between cross-functional teams and stakeholders, ensuring that the system evolves in alignment with user needs and market demands. Testing is integrated early and frequently, providing real-time feedback that helps identify issues promptly. This allows for quicker adjustments to be made, reducing the risk of costly errors and minimizing delays in meeting project milestones.

Agile’s iterative nature contrasts sharply with the Waterfall methodology’s rigid structure, particularly when it comes to product testing. In a typical waterfall approach, testing occurs only at the end of the development cycle, often leading to delays if problems are found late in the process. However, with agile, testing is part of every sprint, and by the time the final product is completed, significant portions of the system are already tested and operational. This early validation helps to ensure that the product is built to meet user expectations and reduces the likelihood of costly redesigns in later stages.

Moreover, the transition to agile not only accelerates product development but also delivers economic advantages. Although initial costs may be higher due to the need for more frequent iterations and closer collaboration, the long-term savings are significant. Agile projects tend to be more adaptive to change, providing better alignment with evolving market conditions and customer feedback. By allowing teams to fail quickly and learn from prototypes, agile fosters a culture of continuous improvement, leading to more innovative solutions and higher-quality products. Ultimately, this approach enhances the ability to meet user needs effectively and efficiently, offering a competitive edge in aerospace systems design.

Agile in Aerospace Hardware

2. Core Principles of Agile Engineering in Aerospace

Iterative Design Cycles

Instead of freezing designs early in the process, Agile teams rapidly build functional prototypes. Boeing’s T-7A Red Hawk, for example, was developed in just 36 months—compared to the typical 5–8 years—thanks to digital twin-enabled iterations. Similarly, Rocket Lab’s Electron Rocket employs sprint-based workflows to test engine components in parallel, significantly accelerating the pace of upgrades.

Cross-Functional “Swarms”

Agile dismantles the traditional silos between engineers, manufacturers, and clients. NASA’s Artemis Program exemplifies this model, using integrated teams to concurrently design the Orion spacecraft’s hardware and software, which helps resolve conflicts and inefficiencies in real time.

Modular Architectures

Agile Engineering also prioritizes modular systems that allow for incremental upgrades. The F-35’s TR-3 update, for instance, uses open-system avionics, making it possible to integrate new AI-driven capabilities without necessitating a complete jet redesign.

3. Agile in Action: Transforming Aerospace Workflows

Rapid Prototyping & Additive Manufacturing

With the advent of 3D printing, same-day prototype iterations have become a reality. GE Aviation, for example, reduced the part count of its LEAP fuel nozzle from 20 to just one using additive manufacturing, slashing production time by 75%. Similarly, Relativity Space 3D-prints entire rockets within days, enabling rapid design iterations based on real-world test data.

Digital Twins & AI-Driven Simulation

Digital replicas of aircraft or engines allow aerospace firms to conduct extensive virtual testing. Rolls-Royce’s UltraFan engine, for instance, can simulate over 100,000 operational scenarios digitally, vastly reducing the need for expensive and time-consuming physical trials. Airbus’s Wing of Tomorrow project similarly uses AI to predict aerodynamic performance, cutting down on wind tunnel testing by 40%.

Supply Chain Agility

Agile methodologies also foster resilient supplier networks. Lockheed Martin, for instance, shares real-time production data with over 1,500 suppliers via cloud platforms, reducing part delays by 25%. Meanwhile, Joby Aviation collaborates with Toyota to repurpose automotive robotics for use in eVTOL (electric Vertical Takeoff and Landing) manufacturing.

4. Overcoming Aerospace-Specific Challenges

Regulatory Compliance

To align Agile practices with rigorous certification requirements, companies have adopted continuous documentation methods. For instance, the FAA’s SAFRA Framework allows for modular certification of hybrid-electric aircraft systems, facilitating faster compliance. Spirit AeroSystems, meanwhile, uses blockchain technology to track certification data across Agile sprints, ensuring traceability and transparency.

Cultural Shift

Transitioning to Agile demands a fundamental cultural shift within organizations. Leadership buy-in is crucial; Lockheed’s “Skunk Works” division has mandated Agile practices for all classified projects. Upskilling is equally important, as Boeing’s “Digital Hangar” initiative demonstrates by training engineers in AI tools and DevOps practices to stay ahead in an Agile world.

Hybrid Approaches

5. Case Studies: Agile Pioneers

Agile methodologies have proven successful in various aerospace projects, enabling faster, more efficient development processes. One notable example is the Johns Hopkins CubeSat Case, where Agile Systems Engineering concepts were applied in the Multi-Mission Bus Demonstrator (MMBD) project. This initiative involved designing and developing two small satellites at The Johns Hopkins University Applied Physics Lab. By adopting Agile principles, the project was able to iterate quickly, refining the design and addressing challenges in a responsive and flexible manner. This approach enabled the team to meet complex requirements within a constrained timeline, ultimately contributing to the success of the project.

One notable example of successful agile implementation in aerospace is the Munich Orbital Verification Experiment II (MOVE-II) project at the Technical University of Munich. The project applied agile software development to create the onboard computer software for a student satellite in just a few months. The process involved breaking down the satellite’s software into subsystems (e.g., thermal, communications, and power systems), with each component being developed iteratively. This approach enabled clear definition of interfaces between subsystems and allowed independent development of software components, which were then integrated into the satellite. By the end of the project, a minimum viable product (MVP) had been established, which could be tested and refined over time, allowing for continuous improvement and flexibility in responding to issues.

Companies like Airbus and Boom Supersonic have demonstrated that by adopting Agile methods, development timelines can be reduced by 30–50%, proving the viability of Agile even for billion-dollar projects.

Planet Labs

SpaceX’s Starship

By testing prototypes explosively and iterating quickly, SpaceX managed to achieve orbital flight for the Starship within just four years—a timeline unheard of under traditional aerospace development methods.

Beta Technologies’ Alia eVTOL

Beta Technologies showcased the flexibility of Agile by pivoting from a cargo model to a passenger-focused model within only six months, relying heavily on customer feedback gathered during FAA trials.

Northrop Grumman’s B-21 Raider

Agile teams at Northrop Grumman worked to integrate stealth coatings and propulsion systems in parallel rather than sequentially, keeping the B-21 Raider sixth-generation bomber on schedule and within budget.

6. The Future of Agile Aerospace

AI-Powered Iterations

Generative AI tools like Dassault’s CATIA GPT will soon automate design optimizations, enabling engineers to predict and balance trade-offs related to weight, stress, and cost in real time.

Hybrid Agile-Waterfall Models

Future aerospace programs such as the Next-Gen Air Dominance (NGAD) fighter initiative are expected to combine Agile methods for subsystem development with traditional waterfall approaches for full-platform integration, creating a best-of-both-worlds model.

Workforce Revolution

According to a 2023 Deloitte report, 60% of aerospace engineers will need Agile and DevOps skills by 2030, underscoring the urgent need for workforce transformation to support Agile initiatives.

Conclusion: Agile or Obsolete

The aerospace industry’s future belongs to those who embrace Agile Engineering. Organizations adopting Agile workflows are already achieving 50% faster time-to-market, 20–30% cost savings, and unmatched adaptability in the face of disruption. As sustainability pressures mount and global competition intensifies, Agile isn’t just an option—it’s the key to survival and dominance in 21st-century aerospace

References and Resources also include:

https://agileforhardware.org/wp-content/uploads/2018/07/An-Intro-to-MAHD-Ebook-Final-7_25_18.pdf

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis