The illumination source employs different technologies, ranging from lamps to semiconductor light emitting diodes (LEDs) or lasers. The lamp, while straight-forward, is broad-band, bulky, and generally inefficient.

The main wavelengths of interest for illumination are around 808nm, 976m, 1064nm, and 1550nm. The 808nm region offers the best responsivity for a CCD camera and is compatible with Gen-III night vision goggles. As a result, it is one of the most popular wavelengths for illumination. However it has two main drawbacks: it is not considered eyesafe (depending on the power level) and the human eye is generally able to detect it (as a red glow), making it unsuitable for covert applications.

The 976nm region offers a good responsivity with a Silicon detector and can also be used with an InGaAs-based camera, albeit with a lower responsivity. While still not considered eye-safe, it cannot be detected by the human eye and is therefore suitable for covert applications. The 1064nm region offers a much better responsivity with an InGaAs-based camera, is considered a covert wavelength, and offers some improvement regarding eye-safety.

Finally, the 1550nm region offers eye-safety and the best responsivity when used with an InGaAs-based camera. However, semiconductor lasers at 1550nm are generally much less efficient than their shorter wavelength counterparts.

The semiconductor LED represents an improvement over the lamp in terms of cost, efficiency, and spectral width. In addition, LEDs can be manufactured at different wavelengths of interest for illumination. However, LED-based illumination systems still suffer from the high-divergence of the LED.

Semiconductor lasers are very efficient, narrow-band, low-divergence, and low-cost light sources, resulting in potentially very compact and efficient light engines for illumination purposes.

Vertical-cavity surface-emitting laser (VCSEL)

A vertical-cavity surface-emitting laser (VCSEL) is a semiconductor-based laser diode that emits a highly efficient optical beam vertically from its top surface (semiconductor wafer surface ) or surface-emitting. VCSELs differ from other common semiconductor optical sources such as Light Emitting Diodes (LED) that emit light from all directions. They also differ from Edge Emitting Lasers (EEL) where the laser light propagates among the direction of the wafer surface and is usually emitted at a cleaved edge (edge-emitting) .

There are numerous advantages of the vertical design. VCSELs provide coherent light with high power density, direct emission and simple packaging. VCSELs’ simple beam structure considerably decreases the cost and complexity of the coupling/beam-shaping optics and optimizes the efficiency.

Compared to light emitting diodes, VCSELs offer similar manufacturing costs, greatly increased power conversion efficiency, much narrower spectrum, and much narrower beam divergence. Compared to edge-emitting lasers, VCSELs offer lower manufacturing costs (both at the chip and packaging levels), comparable power conversion efficiency, narrower spectrum, improved reliability, high-temperature operation, and circular, symmetric low-diverging beam.

Because VCSELs emit light perpendicular to the surface of the laser, tens of thousands of VCSELs can be processed on a single wafer. In addition, VCSELs can be implemented in a two-dimensional array, enabling a single die to comprise hundreds of individual light sources to increase maximum output power and long-term reliability. This array can be customized to scale power output to optimally match application requirements using only a single optical driver and drive current.

Compared to an EEL, the VCSEL structure is easier to assemble than edge emitters. VCSELs can also be tested at various stages of the manufacturing process while in wafer form, resulting in a more controlled and predictable yield with lower fabrication costs compared to other laser technologies.

Vertical-cavity surface-emitting lasers (VCSELs) are an attractive candidate for IR illumination applications as they offer advantageous properties such as efficiency, intrinsically low diverging circular beam, low-cost manufacturing, narrow emission spectrum, and high reliability. VCSELs can also operate at high temperatures, thereby meeting the harsh environmental requirements of many illuminators.

VCEL applications

VCSELS can be utilized in numerous different ways, with some of the most common applications being in the fields of high-speed communications and precision sensing.

VCSELs have found a place in: 3D sensing, Automated driving and manufacturing, Lidar, Optical mice, Smartphones, Biomedical and gas sensing, High-speed data communication, Laser printers, and Computing. This versatility is driving exponential growth in the VCSEL market, which is estimated to nearly triple in size by 2025, from revenues of $1.1 billion in 2020 to $2.9 billion (a CAGR of 23.7% over the time period)5 and to be over $5 billion by 2027.

VCSELs are becoming the dominant light source technology for data communication and sensing and can replace LEDs or edge-emitting laser diodes because they are simple, have a narrow spectrum, and are stable with respect to temperature.

VCSEL 3D Sensing Applications

VCSEL-based sensing has become commonplace for driver monitoring and occupant monitoring systems (DMS and OMS), eye tracking and iris detection, gesture and facial recognition, lidar and autonomous vehicle sensing and multi-modal sensing for motion and gesture control. Laser-based measurements have become the method of choice, combining high accuracy with a compact form factor for navigation, augmented reality and/or virtual reality (AR/VR), or identification applications.

Smartphones, laptops, drones, robots, and cars require integrated illumination sources such as lasers to map the 3D space around them from proximity sensing in phones and observation of humans and objects in a few meters distance, up to light detection and ranging (lidar) systems in autonomous cars resolving small obstacles more than a hundred meters ahead.

Their utilization for time-of-flight (ToF) measurement is one reason VCSELs have become the technology of choice for 3D sensing. ToF emits a beam of NIR light, measuring the time gap between when the signal is emitted from a source (like VCSEL or LED) to when the signal returns after being reflected off an object. This depth measurement permits the 3D measurement of objects like an obstruction in the road (for automotive lidar), or a human face (for facial recognition applications).

So-called direct time-of-flight systems use short laser pulses and sensitive detectors such as single-photon avalanche diodes (SPADs) to determine the traveling time directly. Indirect time-of-flight systems measure the phase shift between the emitted and the received pulse train and are available on camera chips, allowing approximately QVGA lateral resolution.

Light detection and ranging systems, better known as LIDAR, are powered by laser based distance measurements of surrounding objects. As a key piece of the Advanced Driver Assistance Systems (ADAS), these systems visualize ever-changing environments to provide data for semi-autonomous and fully-autonomous vehicles and robots. VCSELs are a key component of high-resolution, solid-state LIDAR, which are typically higher-resolution, smaller in size and lower in power, bit much shorter range, than more conventional scanning LIDAR systems.

VCSELs provide the advantages of long operating distances, fast scanning, high efficiency and excellent resistance to ambient-light interference in ToF applications. In 3D depth detection modules, VCSELs enable wavelength, size, brightness and beam-angle selection to suit the application

The competition with photons emitted continuously by the sun or artificial light sources is the major limitation of the time-of-flight technique in practice. Spectral filters in front of the sensor and centered around the laser wavelength can suppress this background-the narrower the bandwidth, the narrower the laser spectrum can be made.

By passing an infrared light source through an optical element to spread the light either into a structured pattern or a sheet of light, systems are able to capture depth information across an entire room by measuring the light reflected off of objects. This enables, for example, consumers to control games or their entire entertainment center with gestures without the need for a physical remote or even getting up. Gesture recognition can also enhance touchscreen capabilities in cars by allowing users to make gestures a foot or more away from the dashboard without having to touch or block the screen. In future mobile devices, 3D sensing will augment camera capabilities to enable object recognition, depth data, greater precision, and object placement.

In data communication, large data rates combined with excellent energy efficiency and temperature stability have been achieved based on advanced device design and modulation formats.

Military Applications

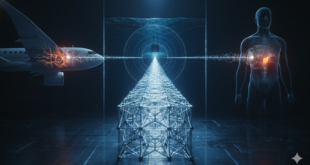

In infrared illumination, an infrared light source is used to illuminate a scene (generally under low-visibility conditions) while a charge-coupled device (CCD) or InGaAs-based camera (depending on the wavelength) is used to capture the resulting image.

Infrared illumination is used in the commercial and defense markets for surveillance and security, for high-speed imaging, and for military covert operations. For surveillance applications, infrared illumination can be used to monitor highly sensitive areas such as rail-road tracks or oil pipelines.

For military applications, invisible infrared illumination can be used to covertly reveal enemy presence and locations under night-time conditions. Infrared illumination coupled with a gated detection system can be used to image events masked by explosions, dust clouds, or other adverse conditions. Finally, infrared illumination can be used as an efficient means for 3D imaging and 3D location mapping and sensing.

VCSEL technology

A Vertical-External-Cavity Surface-Emitting Laser (VECSEL) is a small semiconductor laser, where the laser light propagates perpendicular to the semiconductor wafer surface (surface-emitting). This is in contrast to conventional edge-emitting semiconductor lasers where the laser light propagates among the direction of the wafer surface and is usually emitted at a cleaved edge (edge-emitting).

Another major difference to edge-emitters is the relatively short interaction length of the laser beam with the optical active material (often several QWs) of only a few 10 nm, compared to several 100 µm up to 1 mm or longer. The optical gain is therefore only in the region of a few percent and it is essential to minimize the losses in the cavity by using Bragg mirrors with a high reflectivity.

Unlike a VCSEL, in which two high-reflective DBRs are incorporated into the semiconductor structure to form the optical cavity, in a VECSEL one of these mirror is placed outside semiconductor structure and forms an external cavity. As mentioned above, the optically pumped gain region is typically very thin compared to the lateral dimensions of the beam. VECSELs are therefore also often referred to as Semiconductor Disk Lasers (SDLs) in analogy to the thin disk lasers.

VECSELs are optically pumped with conventional laser diodes. This arrangement allows a larger area of the device to be pumped and therefore more power can be extracted – as much as 30W. The external cavity also allows intracavity techniques such as frequency doubling, single frequency operation and femtosecond pulse modelocking.

VSCELs from 810 nm – 940 nm are typically utilized for 3D sensing applications. Yet, to the human eye these NIR wavelengths are invisible, with the potential to cause damage over time from exposure. So, to ensure the laser’s emissions are within the intended performance parameters, special care is needed.

Parameters of the laser light emission have to be precisely matching the requirements manifested by the particular laser application. Each laser platform differs in terms of flexibility and capability of tailoring the light emission parameters in accordance to the application requirements.

For illumination, power levels of interest range from a few hundred milli-Watts to several hundreds of Watts. The low-power range (<1W) is generally used for imaging and short-range security surveillance (<200m). The mediumpower range (1~100W) is used mainly for long-range illumination (>200m). The high-power range (~100W to kWlevel) is used for very long-range illumination as well as some military covert operations, and illumination through obstacles (dust-clouds, explosions).

Semiconductor vertical-cavity surface-emitting lasers (VCSELs) can be used as very high-power laser sources by fabricating large two-dimensional (2D) planar arrays of low-power, high-efficiency single emitters. Power levels can range from a few Watts to several hundred Watts, while keeping the power conversion efficiency (PCE) at high levels (typically >40%). These high-power, high-efficiency VCSEL sources preserve many of the advantages present in a single VCSEL device, such as low-cost manufacturing, high reliability, and operation at high temperatures. Finally, VCSEL-based illuminators offer very good, speckle-free image quality.

VCSEL Arrays

Individual VCSELs are limited in size (10 μm emitting diameter) and output power (10 mW), but scalable into densely packed arrays with tens to thousands of VCSELs on a single chip, enabling high-power devices. The emission pattern is circular, with about 20° full width at the 1/e2 points and with all VCSELs in an array superimposing in the far field.

In addition, such high-power VCSEL arrays emit in a spectrally narrow beam (full-width at half maximum typically <2nm) and in an intrinsically circular, narrow divergence uniform beam (numerical aperture typically between 0.15 and 0.20) without the need for optics. As such, VCSEL arrays offer much potential as a light source for illumination and related applications. Optical elements can easily be stacked on top of the VCSEL chip to collimate or to shape the emission pattern.

Time-of-flight measurements require short pulses of 1 to 10 ns or pulse trains with modulation up to and above 100 MHz. VCSEL arrays are well suited for fast switching—with demonstrated rise and fall times <1 ns, even at array areas on the order of a square millimeter and currents of many amps. While the VCSEL array itself allows pulses <0.1 ns, electrical connections to the driver and impedance in general are the limiting factors for pulse length.

Because of their many technological advantages, VCSEL arrays are very well suited for time-of-flight distance-measurement applications, giving high peak power in short pulses and a narrow optical spectrum, writes Holger Moench manager of technology and strategy at Philips Photonics, Aachen, Germany. Future VCSEL developments will expand these advantages even further:

- Arrays can be arranged into multiple segments by straightforward mask layout—this feature will be a necessity for next-generation 3D sensing systems;

- VCSELs allow for wafer-level integration of optical elements that will drastically reduce assembly efforts; and

- With the use of an extended cavity, the brightness of a VCSEL array can be increased by more than a factor of a thousand, enabling scanning lidar in automotive applications.

Device Structure and Fabrication

Depending on the power level required, arrays range from ~1mm x 1mm to ~6mm x 6mm in size and contain from a few hundred to a few 10,000’s of elements connected in parallel. The VCSEL-based illuminators contain single or multiple arrays, depending on the power level required and the application.

A VCSEL is produced in a single epitaxy process, providing on a substrate a first distributed Bragg reflector (DBR) mirror, a multiple-quantum-well (MQW) structure with current confinement, and a second DBR mirror. Both mirrors conduct the current from metal contacts deposited on the surface of the structure towards the active region. Millions of VCSELs can be produced on one gallium arsenide wafer and are all completely tested before separating them into single chips.

VCSEL-array chips can either be assembled directly into the sensing system or provided in a separate package for a surface-mount device (SMD) configuration.

For high-power VCSEL 808nm and 976nm arrays packaged on diamond submounts have demonstrated power levels exceeding 200W. For low-power illumination applications, and where cost is a concern, Watt-level VCSEL array modules can be packaged on BeO instead of diamond. While BeO’s thermal conductivity is much less than that of diamond (~200W/m-K vs. ~1,500W/m-K), its cost is also significantly less

One of military applications is a 976nm kW-class illuminator. This illuminator uses nine highpower VCSEL arrays emitting more than 120W CW each and requires water-cooling. This type of illuminator is used in military application for detection through adverse conditions such as explosions or dust clouds.

Unlike most types of illuminators where the far field radiation is used for illumination, this type of illuminator overlaps magnified images of the sources at a certain distance away (several tens of meters) so that a specific area (1~2 meters in diameter) is illuminated with maximum intensity. Nine large lenses in front of each array can be individually adjusted along different directions so as to adjust the magnified images of each array. The VCSEL arrays used have a very large number of elements (10,000’s), so that the projected images, when overlapped, create a very uniform, “top-hat” intensity distribution with no pixelation effect.

Forcing an array of VCSELs to merge into a single laser , reported in Nov 2021

Coherently combining an array of vertical cavity surface-emitting lasers (VCSELs) into a single laser could lead to very compact high-power, high-brightness laser sources, opening up new applications.

Researchers from Technion-Israel Institute of Technology (Haifa, Israel), in conjunction with teams from Julius-Maximilians-Universität Würzburg in Germany and the Cluster of Excellence, ct.qmat–Complexity and Topology in Quantum Matter (a joint research collaboration between Julius-Maximilians-Universität Würzburg and Technische Universität Dresden, also in Germany), employed a geometrical arrangement of VCSELs on a chip that forces the flow in a specific path, known as a photonic topological insulator platform. Described by researchers, “topological insulators are revolutionary quantum materials that insulate on the inside but conduct electricity on their surface without loss.”

To date, scientists’ efforts to enhance the power emitted by VCSELs by combining numerous units and forcing them to act as a single coherent laser have been generally unsuccessful.

Here, the researchers forced topological insulator lasers, which are “arrays of semiconductor lasers that exploit fundamental features of topology to make all emitters act as a single coherent laser,” to lock within a planar chip. This prompted light from each tiny laser to coherently synch with its neighbor, resulting in emitted light that is coherent across the surface of that chip, and emitted perpendicular to the chip (see figure). According to the researchers, their “experiments exemplify the power of topological transport of light. The light spends most of its time oscillating vertically, but the small in-plane coupling is sufficient to force the array of individual emitters to act as a single laser.”

The topological principle of this [combined] laser can generally work for all wavelengths and thus a range of materials,” says Sebastian Klembt, project leader and a professor at the University of Würzburg, where he is working on light-matter interaction and topological photonics within the ct.qmat Cluster of Excellence.

Previously, a group at Technion-Israel was able to exhibit the first photonic topological insulator—light traveled around the edges of a 2D array of waveguides and were not affected by defects or disorder. The same group also was able to use the properties of photonic topological insulators to force a number of microring lasers to lock together and act as a single laser. However, the researchers note, the “system still had a major bottleneck: the light was circulating in the photonic chip confined to the same plane used for extracting the light out.” The team’s new developments avoid this.

“Back in 2015, when we started to work on topological insulator lasers, nobody believed it was possible because the topological concepts known at that time were limited to systems that do not, in fact cannot, have gain,” says Mordechai Segev, a professor who led that work at Technion. “But all lasers require gain. So topological insulator lasers stood against everything known at that time. We were searching for something that was considered impossible. And now we have made a significant step toward real technology that has many applications.” Most notably, those applications include medical devices and communications systems.

Lasers targeting new wavelength ranges for nuclear medicine and quantum technology applications

In this doctoral thesis, Kostiantyn Nechay aimed on development of optically-pumped vertical-external-cavity surface-emitting lasers (OP-VECSELs), or semiconductor disk lasers, one of the most flexible laser platform, targeting nuclear medicine and quantum technology applications.

OP-VECSELs constitute a very flexible laser platform, delivering high-power and high-brightness emission at a vast wavelength range. This laser combines advantages of solid-state lasers with the emission wavelength versatility typical for semiconductor lasers. Thus, by engineering the semiconductor part, which plays a role of light-emitting section, it is possible to obtain emission at different wavelengths (or colors), with easily tailorable parameters thanks to external resonator. However, due to specific laser architecture, this laser is a subject for certain limitations, which arise from the impossibility to manufacture certain semiconductor compounds. Therefore, emissions at certain wavelength are more challenging to achieve with VECSELs.

“The goal of this work was to demonstrate VECSELs with emission at the specific wavelength range, namely 700-800 nm, where development of VECSELs were not extensively addressed. On the other hand, potential applications for such high-brightness lasers in nuclear medicine (i.e. radioisotope separation), quantum technology or spectroscopy, would point to a large audience interested in the results,” says Nechay.

The research on the topic has followed two alternative directions: first is to develop VECSELs employing AlGaAs quantum wells, which would provide direct-emission at 750 nm (deep red color), second is to develop VECSELs with fundamental emission at 1.5 µm and then achieve efficient frequency doubling to 750 nm.

VECSELs have benefited the quantum technology field, where they have been successfully employed in ion cooling and ion trapping in order to create qubits, the building blocks of quantum computers. Moreover, VECSELs at this wavelength range are being proposed for application in nuclear medicine with an aim on radioisotope separation. The newly invented technique of medical radioisotope separation, with efficiency surpassing previous methods by a factor of 1000, is promised to revolutionize medical isotope manufacturing. Medical radioisotopes are one of the most expensive and rarest commodities on Earth, which are routinely used in tens of millions cancer treatments per year. The new method of separation relies on lasers with tunable, high-power, narrow-linewidth emission at the specific wavelengths, the requirements that can be easily delivered by VECSELs.

References and Resources also include:

https://ams.com/documents/20143/214981/7952-15.pdf/fe3f2d83-35f3-e307-563d-938d6a8ed802

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis