Propulsion systems can be classified based on their dependence on the onboard power: electric and non-electric systems. Electric propulsion systems are mainly classified into resistojet, electrospray, ion, Hall and pulsed plasma systems, and they actively require on-board power for their operation, while the non-electric propulsion systems can be classified into cold gas, liquid and solid rocket systems, and they require on-board power only to regulate (initiate and terminate) the propulsion process.

Among a multitude of currently pursued propulsion technologies, electric propulsion systems emerged as one of the most promising technologies, with Hall-type and gridded ion thrusters being the most well-known of these systems.

Hall Effect Thruster (HET) technology has matured to an operational level, but has not yet become a mainstream propulsion solution for manufacturers or deep space researchers. Current electric satellite thrusters employ xenon propellant stored in high pressure tanks limiting the amount of total impulse available to the satellite.

Electric propulsion (EP) systems have the appealing factor of providing exceptional propellant efficiency compared with traditional chemical propulsion, however, HET devices do not provide superior system-level performance when compared to existing propulsion systems, but using iodine as a propellant eliminates this shortfall.

Currently, xenon gas is the propellant of choice in electric thrusters. Xenon offers many advantages: high atomic mass, low ionization energy, no toxicity, long term (albeit high pressure) storage, material compatibility.

However, Xenon is a very expensive substance, though, and is not mined in high quantity. Xenon is rare, making up less than 1 part per 10 million in Earth’s atmosphere. It is also expensive, at about $3,000 per 2.2 pounds (1 kilogram). Moreover, the gas requires bulky pressurized tanks, as well as complex networks of pipes, valves and pumps to shuttle it around a propulsion system.

Iodine is cheaper and more abundant than xenon and can be stored unpressurized as a solid that changes directly into a gas when heated, potentially enabling significant miniaturization and simplification. Previous research has shown electric thrusters using iodine can prove more efficient than ones employing xenon in ground-based tests.

Iodine is stored as a solid (no high-pressure vessels), at density three times those of xenon (impulse density two to three times). The increase in total impulse for a small satellite will enable the satellite to reach the Moon and other near-Earth objects. A quick comparison of required spacecraft volume for propellant tanks shows how iodine is advantageous for missions requiring extensive maneuvering. Lower ionization potential demands less energy on the spacecraft. This means for a given power setting, more iodine will be ionized (increased current) and available to propel the vehicle. Increasing current flow directly increases thrust.

ThrustMe claims the use of iodine as a propellant is a breakthrough for the satellite industry. It allows propulsion systems to be delivered completely prefilled to customers, and for the satellite integration process to be significantly simplified and streamlined. Conversely, most conventional electric propulsion systems use rare, expensive xenon or krypton which also require storage under high pressure. When heated the solid iodine turns to gas without progressing through a liquid phase. French startup ThrustMe has performed the first on-orbit tests of an innovative iodine-fueled electric propulsion system, proving its ability to change a CubeSat’s orbit.

Notably, the system could have an impact on space sustainability efforts. It allows a small satellite to lower its altitude, reducing its time in orbit, seeing the satellite burn up on re-entry into Earth’s atmosphere, and helping reduce space debris in lower Earth orbit. The development comes as national space agencies and private companies plan launches of so-called mega-constellations, each consisting of hundreds or thousands of satellites.

As well as speeding up deorbiting, the low-mass system also provides small satellites with propulsive capabilities for maintaining orbits and collision avoidance. Explosions caused by remaining fuel and batteries for satellites and rockets and collisions between spacecraft are major contributors to the growing space debris problem. The European Space Agency estimates that there are 34,000 debris objects greater than 10 centimeters in size and 900,000 pieces from between 1 to 10 centimeters in orbit as of January 2021. Traveling at several kilometers per second, even the smallest fragments can threaten spacecraft, including the International Space Station.

Cost, performance, and efficiency are the primary focus factors in the field of space propulsion. Increased performance and efficiency for spacecraft propulsion systems is best referred to as mass efficiency. The less propellant mass needed to maintain or change orbits in space, the more payload mass is able to be on orbit. In addition to reduced mass, higher electrical efficiency specific to in-space propulsion reduces the demands of the power subsystem, which also decreases the mass and cost of a satellite. Iodine has the potential to provide a significantly more efficient propulsion solution. Iodine’s low vapor pressure permits low-pressure storage and minimizes potential adverse spacecraft-thruster interactions. The iodine will not condense inside the thruster at ordinary operating temperatures and pressures

Performance of spacecraft propulsion systems has to include total system impact, not just propulsion device performance. Storing propellants at cryogenic temperatures, for example, places significant demands on the satellite designer resulting in spacecraft power demands, monitoring of the propellant, and propellant conditioning. For a notional long-term mission requiring large quantities of propellant, the volume of the iodine tanks will be 1/3 the volume of the comparable xenon tanks (higher xenon density is possible than just 1.6 kg/l but then cryogenic storage is necessary). Additionally, the iodine has the advantage of being stored at moderate temperatures and pressures, reducing the demand for high-pressure tanks and plumbing. Iodine enables the potential for ‘fitting’ the tanks to the volume available in a spacecraft using additive manufacturing as well (no domes or composites are needed).

Initial mission profile studies have shown iodine will enable micro-satellites to reach the Moon and other Near Earth Objects (NEOs). The use of iodine enables spacecraft to be capable of surveying asteroids for mineral mining at a fraction of the cost of today’s interplanetary missions. By imparting volume-constrained spacecraft with up to three times the delta-V, several Air Force missions become possible using much smaller, cheaper satellites; orbit raising, deorbiting, rendezvous, maintenance mission, orbital debris removal, retrieval of errant spacecraft.

Challenges

However, iodine presents challenges of its own when it comes to propulsion. For example, iodine is highly corrosive, posing a potential danger to electronics and other systems onboard spacecraft. In addition, vibrations during launch and spacecraft motion once in orbit can make solid iodine break into pieces, which may damage the propulsion system, among other problems.

Iodine presents unique challenges, though. Accumulation of iodine film on spacecraft surfaces could present several unique issues such from un-ionized neutral iodine. Of particular concern would be shorting dielectric surfaces, changing radiator emissivities, and damaging optical coatings. Specifically, rates of material sputtering, exhaust flux levels and material deposition will erode antennas, instruments and solar arrays, deteriorating their performances. Of particular concern would be shorting dielectric surfaces, changing radiator emissivities, and damaging optical coatings.

Initiatives

NASA continues its investment in iodine based Hall Effect Thruster (HET) systems to capture two distinct mission niches; very-low power small satellites and high-power exploration class electric propulsion.

Phase Four’s propellant-agnostic propulsion is poised to dramatically reduce costs of large satellite constellations, extend orbit ROI, and de-risk space debris encounters

Phase Four, the creator of the radio-frequency thruster for satellite propulsion, announced in April 2021 that it has secured a contract with the U.S. Air Force for the company’s propellant-agnostic Maxwell thruster. Under the contract, Maxwell will utilize iodine, a new alternative fuel, to replace the costly, legacy electric propulsion propellants in high-performance commercial and defense applications.

The hallmark of Phase Four’s versatile RF Thruster technology is its flexible architecture, which can utilize traditional noble gases and new alternative sources ranging from iodine to water to air. Together with the Air Force, Phase Four will demonstrate major new advantages that the Maxwell iodine-fueled engine can provide to large satellite constellations, including:

- Vastly lower propellant costs

- Increased satellite range and lifetime on orbit, due to the ability to store more fuel on board, as iodine is 4x denser than traditional xenon propellants

- Lower risk of debris incidents, due to the elimination of high-pressure storage

- Increased sustainability, due to the ability to decommission and responsibly dispose of satellites at their end of life

“Iodine is a promising propellant, due to its densely storable nature, lack of high-pressure components, and performance potential, compared to traditional noble gas propellants like xenon,” said Phase Four CTO, Umair Siddiqui. “More efficient smallsat propulsion systems, such as an iodine RF thruster, will enable new missions in remote sensing, space surveillance, communications and other areas.”

Phase Four’s RF thruster is simpler, smaller, lighter and less expensive than legacy electric propulsion systems, due to technical innovations and the use of low-cost RF electronics developed by the smartphone and wireless charging industries. These improvements will enable government and commercial space operators to deploy critical mission capabilities in space at a lower cost and faster cadence than currently possible.

Promising new electric iodine thruster passes key test in orbit, reported in Nov 2021, potential boost for space debris mitigation efforts

Now scientists have for the first time launched an iodine-based electric thruster into space and showed that it can help propel a spacecraft in orbit.

“We show that iodine can be safely used in space, bringing an option for propulsion systems onboard even the smallest spacecraft,” said study lead author Dmytro Rafalskyi, chief technical officer and co-founder of space propulsion company ThrustMe, which is headquartered near Paris.

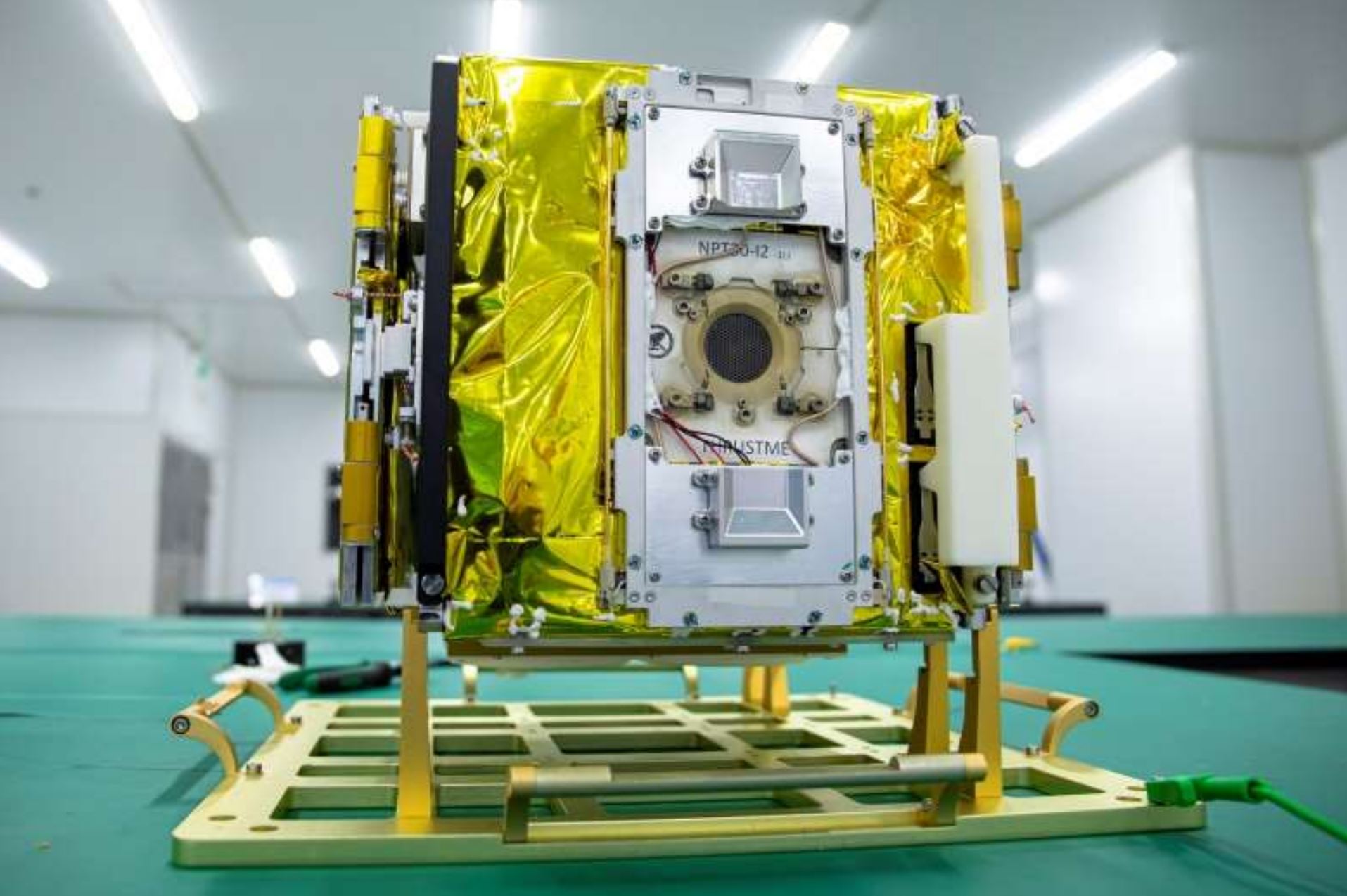

The new electric thruster, the NPT30-I2 from ThrustMe, fits within a single package about 4 inches by 4 inches by 4 inches (10 centimeters by 10 centimeters by 10 centimeters) in size and about 2.6 pounds (1.2 kg) in mass. It served as the propulsion system for a 44-pound (20 kg) cubesat, the Beihangkongshi-1 satellite operated by Chinese satellite company Spacety, which launched into space on a Long March 6 rocket on Nov.

6, 2020.

Ground radar stations confirmed that the NPT30-I2 helped the miniature satellite maneuver in orbit. All in all, the new thruster let out puffs of iodine that cumulatively boosted the cubesat’s altitude by more than 1.8 miles (3 kilometers).

After weeks of commissioning the propulsion system was tested during two 90-minute burns in late December and early January. In 2019, ThrustMe tested a cold gas thruster based on the iodine propellant storage subsystem of its electric thruster on Spacety satellite.

The burns resulted in a total altitude change of 700 meters according to a ThrustMe press release. The firms says the results prove iodine to be a viable propellant for electric propulsion systems and mark a step towards commercialization of the system. Notably the system could have an impact on space sustainability efforts. It allows a small satellite to lower its altitude, reducing its time in orbit, seeing the satellite burn up on reentry into Earth’s atmosphere and helping reduce space debris in lower Earth orbit.

To deal with the problem of corrosion, the scientists developed ceramics and polymers to protect metal components within the satellite. To keep the iodine from shattering, they strengthened it by embedding the iodine crystals in a porous ceramic block.

A further demonstration will be aboard the GOMspace GOMx-5 mission planned for Q2 2022. NPT30-I2-1U is also being prepared for the Geostationary (GEO) satellite market. ThrustMe is a spin-off from École Polytechnique and the French National Centre for Scientific Research (CNRS). The firm has also gained support from ESA through its Advanced Research in Telecommunications Systems (ARTES) programme . ThrustMe and Spacety, a Chinese private firm established in 2016, collaborated for the first time in 2019, with the I2T5 non-pressurized, cold gas thruster aboard the Xiaoxiang-1 (08) CubeSat. That tested critical technologies for iodine storage, delivery, and sublimation.

The new findings show that iodine is not only a viable propellant, but can also achieve nearly 50% more efficient propulsion than xenon, because of factors such as how iodine is easier to electrify than xenon. The company has opened a production line for these new thrusters and has already delivered more than 10 of them to satellite manufacturers worldwide, Rafalskyi said.

In addition to ThrustMe’s propulsion, Spacety’s first 12U cubesat houses a laser communications module and autonomous airplane tracking technology, James Zheng, Spacety Luxembourg CEO, told SpaceNews by email. Spacety created a new bus for the Beihangkongshi-1 cubesat with batteries, a thermal radiator and a solar panel “to support payloads with high power consumption and duty cycle,” Zheng said. Beihangkongshi-1 is designed to demonstrate key technologies for multi-beam and multi-channel Automatic Dependent Surveillance-Broadcast to provide continuous global aircraft tracking, communication and intervention for future air traffic control systems, Zheng said.

In upcoming tests, ThrustMe plans to demonstrate a far more complex propulsion system that pairs the iodine propellant storage with a gridded ion thruster. The goal, Aanesland said, is to demonstrate “electric propulsion with high delta-v operations,” meaning the thruster will produce a significant change in the satellite’s velocity. The European Space Agency provided ThrustMe with funding for the upcoming in-flight demonstration. It was ThrustMe’s first ESA contract. ESA supported development of ThrustMe’s engineering and qualification models as well as flight hardware through its Advanced Research in Telecommunications Systems Competitiveness & Growth program.

European FACT (iodine Fed Advanced Cusp field Thruster) project

FACT (iodine Fed Advanced Cusp field Thruster) project was successfully launched in Friedrichshafen, Germany in January 2020. Funded by the European Commission as part of its Horizon 2020 Programme, the 2M euro project will run for 24 months. iFACT aims to further develop iodine as alternative propellant for electric propulsion by creating a European ground test infrastructure, further development of the Advanced Cusp Field Thruster (ACFT) principle, and generating a detailed iodine – material compatibility library.

The unique thruster principle paired with the use of iodine as propellant and a tailored feeding architecture has the potential to significantly change the space sector. The iFACT subsystem enables a serious reduction of subsystem mass, in particular the dry mass required for the propellant feeding along with the cost and volume savings of the propellant itself.

The program will foster the use of iodine for in space propulsion by tackling main questions, marks such as iodine corrosion impacts to the satellite platform through extensive material testing; it further aims to develop an iodine compatible cathode/neutralizer including a dedicated investigation towards calcium aluminate as potential low work function emitter candidate.

Due to the creation of an independent European iodine compatible test infrastructure especially tailored for long firing tests, the development of iodine based propulsion systems will be enhanced even for parties that are not participating in the iFACT program directly. iFACT intends to examine developing variations of EP subsystems besides the main 300 W version. In this content, a 10 W subsystem will be experimentally validated enabling the fast and cost-efficient demonstration of key technologies. Furthermore, a 1000 W iFACT upscaled laboratory model will be tested in addition to the other development lines.

With iFACT, Europe can become the leader with respect to iodine as xenon successor as well as a provider of efficient, but very low-cost electric propulsion subsystems. With this in mind iFACT has the ambition to enable future European small satellite constellations. The project is coordinated by Airbus Germany and involves 7 partners with different areas of expertise from several European States. The iFACT partners are Airbus France, EASN-TIS (Belgium), University of Southampton (UK), Fraunhofer IKTS (Germany), Aerospazio Technologie (Italy), University of Giessen (Germany) and EnduroSat (Bulgaria).

References and Resources also include:

https://spacenews.com/thrustme-2020-demonstration/

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis