LCOS microdisplay technology

There are two broad categories of LCoS displays: three-panel and single-panel. In three-panel designs, there is one display chip per color, and the images are combined optically. In single-panel designs, one display chip shows the red, green, and blue components in succession with the observer’s eyes relied upon to combine the color stream.

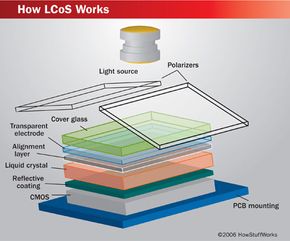

LCOS microdisplay is constructed with a liquid crystal layer sandwiched between a thin-film transistor (TFT) and a silicon semiconductor with a reflective coating, hence the name. Like in DLP technology, light passing through a polarizing layer is reflected, but in the case of LCOS, it uses a reflective semiconductor instead of mirrors, while the liquid crystals act as gates that control the amount of light that passes and reaches the reflective surface, modulating the light and creating the image. As with LCD technology, LCOS modulates light in the RGB channel, so there are still three separate subpixels of red, green and blue.

A liquid crystal is a substance that is in mesomorphic state — it’s not exactly a liquid or a solid. Its molecules usually hold their shape, like a solid, but they can also move around, like a liquid. Nematic liquid crystals, for example, arrange themselves in loose parallel lines. Most LCDs use twisted nematic (TN) crystals — with the application of an electrical charge, the twisted crystals straighten out.

In an LCoS display, a CMOS chip controls the voltage on square reflective aluminium electrodes buried just below the chip surface, each controlling one pixel. For example, a chip with XGA resolution will have 1024×768 plates, each with an independently addressable voltage. Typical cells are about 1–3 centimeters square and about 2 mm thick, with pixel pitch as small as 2.79 μm. A common voltage for all the pixels is supplied by a transparent conductive layer made of indium tin oxide on the cover glass.

Parts of an LCOS microdisplay starting from the top:

- Glass cover — Seals and protects the system.

- Transparent electrode — Completes the circuit with the liquid crystal and the silicon.

- Alignment layer — Aligns the liquid crystal in order for them to accurately direct light.

- Liquid crystal — Controls the amount of light that reaches and leaves the reflective layer.

- Reflective coating/layer — Reflects light that creates the picture.

- Silicon or chip — Controls the liquid crystal in a one-to-one ratio between pixel and transistor using data from the display driver.

- Printed circuit board — Carries instructions from the television or computer into the devices.

LCOS offers the following advantages:

- High brightness while maintaining a contrast ratio of 2,000:1

- High light efficiency as 70-80% of light is reflected

- High-quality image as there is no “screen door” between pixels

- High heat efficiency

Military Applications

Engineers at Barco-Xenia (formerly Barco Electronic Image Systems) in Xenia, Ohio, say liquid crystal on silicon or LCoS—a commercial projection technology—will provide the next generation of military simulation displays with real-world resolution.

LCoS “has the capacity to match image generator output, giving aircrews incredibly realistic visual images, whether that is terrain, sky images, or ground and airborne targets,” says Jay Luis, director of marketing communications for Barco. “In general, LCoS projection technology is a good bet to have a huge impact in the simulation industry.”

It gives defense simulation customers more accurate flight training, Luis continues. “They are looking for visual systems that provide greater detail for target imagery—both air and ground,” he explains. “Increased image fidelity yields enhanced aircrew visual acuity. Now the challenge becomes how to capitalize on that capability—how to keep up with the multimillion pixel output of today’s image generators and to project images that look just as real as possible… with minimal latency or artifacts.”

Not so long ago CRT projectors were the state of the art in display systems, but they were surpassed by rear-projection projectors such as LCoS solutions nearly a decade past, says Paul Lyon, international product manager for display systems at Barco.

There are two types of rear-projection technology—Digital Light Processing (DLP) and LCoS, Lyon says. “DLP uses millions of little mirrors” that form a pixel in the image. It was developed by Texas Instruments, Lyon adds. Their maximum number of pixels is about 2 million. They are typically used in cinema or home theater applications through rear-projection TVs, Lyon says.

LCoS projectors do it a little differently, Lyon says. They use liquid crystals instead of the mirrors. “The concept has been around since 1980s early ’90s,” he adds. The crystals are applied to the chip’s surface and coated with layers that are very reflective, Lyon explains.

In F-16 jet fighter simulations pilots need a more realistic point of view, Lyon says. The F-16 display is a wrap-around that shows the real world through each of the cockpit windows, therefore the greater the resolution, the better the pilot will be able to train, he says.

Barco’s new SIM 7 projection system’s LCoS technology provides 3 million pixels, one million more than best DLP device, Lyon says. Barco also has solutions where 9 projectors are used, providing about 27 million pixels, he adds. “It’s perfect for fast jet applications” with its smear reduction capability that enables the SIM-7 to maintain the sharpness of fast-moving images, Luis notes.

One of those is optical and electronic edge blending, which eliminates the overlap zones, which occur in images when projections converge, Lyon says. The blending helps create a seamless image. Barco also has something called “linked constant light output,” which guarantees a constant level of brightness for the whole image, he continues. Barco’s warping technique provides a projection that not distorted, eliminates frame delay and pixel loss on a spherical or curved screen. Lyon notes that with LCoS technology the pixel lines are not easy to see, but if you stand close to a DLP image “you can see the actual pixel lines.”

Barco also has a system—the LX-5 which offers a 10-million pixel resolution, Lyon says. However, it is targeted more at the automotive and oil and gas industry. LCoS is such a “big advantage in terms of cost per pixel,” Lyon says. It is “trending downward in price more than any other display technology,” he continues.

To obtain that type of resolution, the simulations projectors will need millions and millions of more pixels—something that technology such as DLP cannot provide, Lyon explains. Barco’s new SIM 7 projection system’s LCoS technology provides 3 million pixels, one million more than best DLP device, Lyon says. Barco also has solutions where 9 projectors are used, providing about 27 million pixels, he adds. “It’s perfect for fast jet applications” with its smear reduction capability that enables the SIM-7 to maintain the sharpness of fast-moving images, Luis notes.

“Today’s visual display systems used for military simulation and training are more compact, produce higher quality images, are easier to operate and maintain, are easily scaled, and are more cost-effective than the technologies of only a few years ago,” Luis says. The challenge now lies in how to optimize systems that will utilize 100 million pixels or more, Lyon says. For example, he says, a solution that uses 20 of Barco’s LX-5 ten million-pixel projector, would have 200 million pixels to deal with, he notes.

Liquid Crystal on Silicon Technology (LCOS) Market

At 5.8% CAGR, The “Liquid Crystal on Silicon (LCoS) Market”Size is expected to grow from 1224.1 million USD In 2020, to reach 1824.3 Million USD by 2026. There has been an increase in the adoption of Liquid Crystal on Silicon (LCoS) in various industries such as Consumer Electronics, Automotive, Aviation and Military.

LCoS-based products, which offer higher quality and more precise results than competing microdisplay technologies, such as liquid crystal display (LCD) and digital light processing (DLP), are being preferred by component manufacturers. Therefore, increasing demand for high-resolution display is supporting the growth of the liquid crystal on silicon (LCoS) display market.

However, the cost of technology, when compared to competitive technologies, like LCD and LED, are hindering the market. In addition, LCoS microdevices are difficult to manufacture, because of which several companies, including Intel, have abandoned their efforts after consistently low yields in manufacturing.

Liquid Crystal on Silicon (LCoS) Market 2021 is segmented as per type of product and application.

Liquid Crystal on Silicon (LCoS) market based on types include Projector, Head-mounted Display (HMD), Head-up Display (HUD) and geography.

Head-mounted Displays to Witness Huge Demand for LCoS Systems

- Head-mounted displays used for augmented and virtual reality have unique characteristics that handheld displays and spatial displays do not offer.

- Training of all types is the most important potential use of AR/VR. Navy researchers are integrating AR technology into head mounted displays (HMD) to effectively provide ground deployed troops with the technology utilized by pilots.

- In June 2018, Spex, a division of Toronto-based wearable medical device developer eSight, released a new hardware and software platform intended to combine the best current augmented reality (AR) and virtual reality (VR) features in a head-mounted device that can be worn all day.

- HMDs are not only used in virtual reality gaming, but also been used in military, medical and engineering contexts. In March 2019, Valve launched a teaser site featuring a brand-new virtual reality headset, called the Valve Index. It has inside-out tracking to allow players to move around a room without worrying about placing base stations or external tracking cameras.

Leading Key Players In the global Liquid Crystal on Silicon (LCoS) market are Sony, JVC Kenwood, Canon, AAXA Technologies, LG, Silicon Micro Display, Google, Microsoft, Magic Leap, and Guangzhou Weijie Technology

Commercial implementations of LCoS technology include Sony’s Silicon X-tal Reflective Display (SXRD) and JVC’s Digital Direct Drive Image Light Amplifier (D-ILA/). Every company which produces and markets LCoS rear-projection televisions uses three-panel LCoS technology,[citation needed]. Sony and JVC both produce and market front-projection displays that use three LCoS panels, as well as Canon, with XEED and REALiS projectors.

- February 2019 – Fourth Dimension Display, a subsidiary of Kopin Corporation, launched a 2K x 2K high-performance reflective LCOS device at Photonics West 2019.

- January 2019 – Syndiant Inc. introduced a portfolio of 1080p and 4K UHD LCOS microdisplays and optical engine platforms at the 2019 Consumer Electronics Show in Las Vegas, Nevada.

- October 2018 – OmniVision Technologies Inc. announced the OP02220, the industry’s first 1080p liquid crystal on silicon (LCOS) microdisplay, with integrated driver functions and memory. This compact, low-power, and cost-effective microdisplay is especially valuable for augmented reality (AR) applications, such as glasses and head-mounted displays.

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis