Metamaterials are artificially structured materials designed to control and manipulate physical phenomena such as light and other electromagnetic waves, sound waves and seismic waves in unconventional ways, resulting in exotic behavior that’s not found in nature. This class of micro- and nano-structured artificial media are predicted to be able to protect the building from earthquakes by bending seismic waves around it. Similarly, tsunami waves could be bent around towns, and sound waves could be bent around a room to make it soundproof.

Metasurfaces are the two-dimensional version of metamaterials: extremely thin surfaces made up of numerous subwavelength optical nanoantennas, each designed to serve a specific function upon the interaction with light. The metasurface elements act as subwavelength phase or amplitude modulators, which can be static or dynamic. Arrays of these elements act in transmission or reflection to encode arbitrary optical functionality such as focusing, steering, and other kinds of wavefront manipulation.

The metasurfaces contain regularly spaced nanoparticles that can modulate electromagnetic waves over sub-micrometer wavelength scales. They allow or inhibit the propagation of electromagnetic waves in desired directions, can concentrate the waves and guide or can control the scattering of light with exceptionally high precision. These devices enable efficient beam steering, local control of optical polarization, and enhancement of emission and detection of light.

The main advantages of metasurfaces with respect to the existing conventional technology include their low cost, low level of absorption in comparison with bulky metamaterials, and easy integration due to their thin profile. Part of the promise of these devices lies in their ability to perform these complex optical functions using metasurfaces that are manufactured using standard lithographic techniques common in the semiconductor industry.

Engineering the morphology and/or dielectric environment of these resonators allows controlling the phase, amplitude and polarization of light along the surface and yields properties that are not found in nature such as negative refraction. The possibility to generate arbitrary wavefronts has enabled a large number of exciting applications such as beam deflection, vortex beam, hologram generation and frequency conversion. Metasurfaces are an attractive alternative to conventional bulk optical components which offer the possibility to integrate complex optical functions in lightweight and cheap miniaturized components. They hold great promise for applications such as portable or wearable devices, automotive, aeronautical and space applications and augmented/virtual reality.

Typically, the functionality of an optical metasurface is “hard‐coded” in its fabricated design. However, it is highly desirable to dynamically tune or even freely program the metasurface functionality also after fabrication.

Metasurface beam steering enables solid-state, high-performance lidar

Lidar is considered the primary sensor for self-driving cars, acting as the ideal complement to cameras and radar. Beam steering is often the defining component of a lidar system, determining performance, size, and reliability. First-generation lidar systems use rotating assemblies of lasers, optics, and detectors, while second-generation lidar systems are beginning to use MEMS-based mirrors—each approach has substantial limitations. Automotive lidar presents a unique challenge because these large-etendue systems require a large product of aperture size and field of view. In mechanical-scanning systems, the aperture size and field of view are often coupled: as aperture size increases, the field of view decreases in resonant scanning systems such as MEMS mirrors and galvanic mirrors.

Most work on metasurfaces thus far has focused on static devices where the optical functionality is determined during fabrication. Dynamic metasurfaces that perform high-speed, large-field-of-view beam steering, for example, have been widely sought, but present several challenges. To obtain a large steering field of view and prevent diffraction-grating lobes, the metasurface elements must be less than half the operating wavelength in pitch. At the same time, each metasurface element must approach a 2π phase shift to enable large phase gradients, as needed in beam steering. Even with unity refractive-index contrast, the requirements of large phase shift and subwavelength elements are contradictory. The solution as commonly implemented in metasurfaces is to use resonant elements, where light makes multiple passes through each element, accumulating phase shift proportional to the quality factor of the resonator.

The challenge is thus to create a manufacturable, electrically addressable resonator design with adequate quality factor, coupled with a material capable of large and fast refractive index modulation.

Novel display technologies aim to provide the user an ever-increasing immersive experience. In this regard, displaying true 3D images that can be seamlessly integrated with the real world is a long-sought dream that hold potential to revolutionize the way we receive and interact with information. In order to generate truly 3D images, i.e. holograms, one needs a device that allows to control one of the fundamental properties of light, namely, its phase. While such devices exist (they are the so-called Spatial Light Modulators), current liquid-crystal based technology has a very strong limitation. Specifically, the 3D images that can be generated with them can only be seen from a very narrow range of viewing angles, which strongly hinders the experience. Importantly, this limitation, which stems from the large pixel size of these devices, is not one of engineering nature but rather a physical limitation imposed by the principle used to manipulate the light. Therefore, to overcome it, a radically different idea is needed.

In this work, the team of researchers from IMRE’s Advanced Optical Technologies department (Shi-Qiang Li, Xuewu Xu, Rasna Maruthiyodan Veetil, Vytautas Valuckas, Ramón Paniagua-Domínguez and Arseniy Kuznetsov) has put forward a new approach to dynamically manipulate the phase of light with ultra-small pixel sizes. Instead of using the modulation of phase acquired by light when travelling through a medium, as is the case in liquid-crystal-based devices, they used a set of tiny nanostructures (smaller than the wavelength of light), so-called nanoantennas, that resonate when illuminated by light.

In a similar way that TV or cell phone antennas do with other electromagnetic waves, these nanostructures can efficiently collect and re-emit visible light. In this process, however, they can alter the phase of the re-emitted light, opening the possibility to control its wavefront and ultimately, to generate holographic images with unparalleled viewing angle and unprecedented resolution. By surrounding these nanoantennas by a thin liquid crystal, this can be done dynamically, opening the door to realize full-depth, true 3D holographic displays that do not require any goggles or special equipment to be viewed. Besides its application in displays, the concept developed in this work can be applied in 3D mapping and ranging, telecommunications or bioimaging, etc.

Liquid-crystal metasurfaces

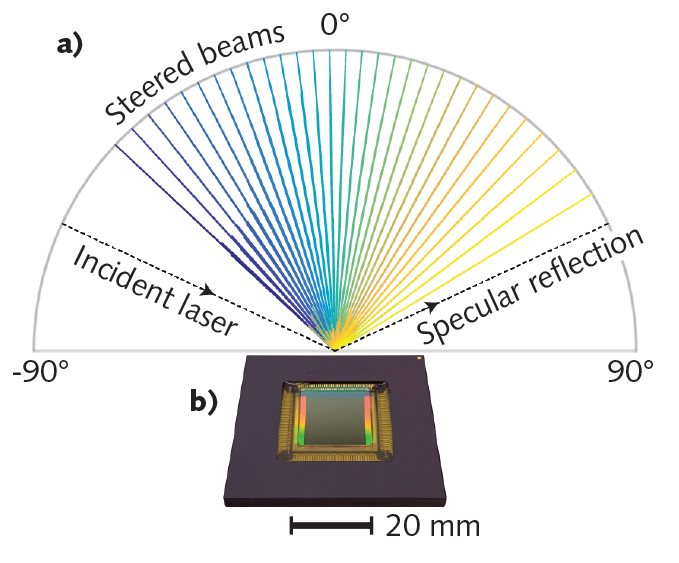

Lumotive has recently developed a reflective 1D dynamic metasurface based on liquid-crystal tuning of resonant subwavelength elements. The liquid crystal metasurfaces (LCMs) are fabricated in a CMOS foundry using conventional materials and patterning processes. The elements are resonant, enabling large local phase tuning using liquid crystals while being deeply subwavelength, thereby delivering uniform steering efficiency across a large 120° field of view with uniform efficiency across the field of view. Figure 1 depicts a conceptual illustration of the beam steering operation. Much like in a phased array, the spatial period of the phase gradient across the chip determines the steering angle, which can be derived from the first-order diffraction equation. The phase delay at each resonator is proportional to the voltage applied to that resonator, which locally rotates the liquid crystals, shifting the resonant wavelength. The LCM actively steers in one axis, while acting as a mirror in the perpendicular axis.

Measured radiation patterns from an LCM chip show beam steering over a wide field of view, where the radial plot has a linear scale and the radiation patterns are normalized (a); a photograph of LCM chip in a ceramic chip carrier is also shown (b).

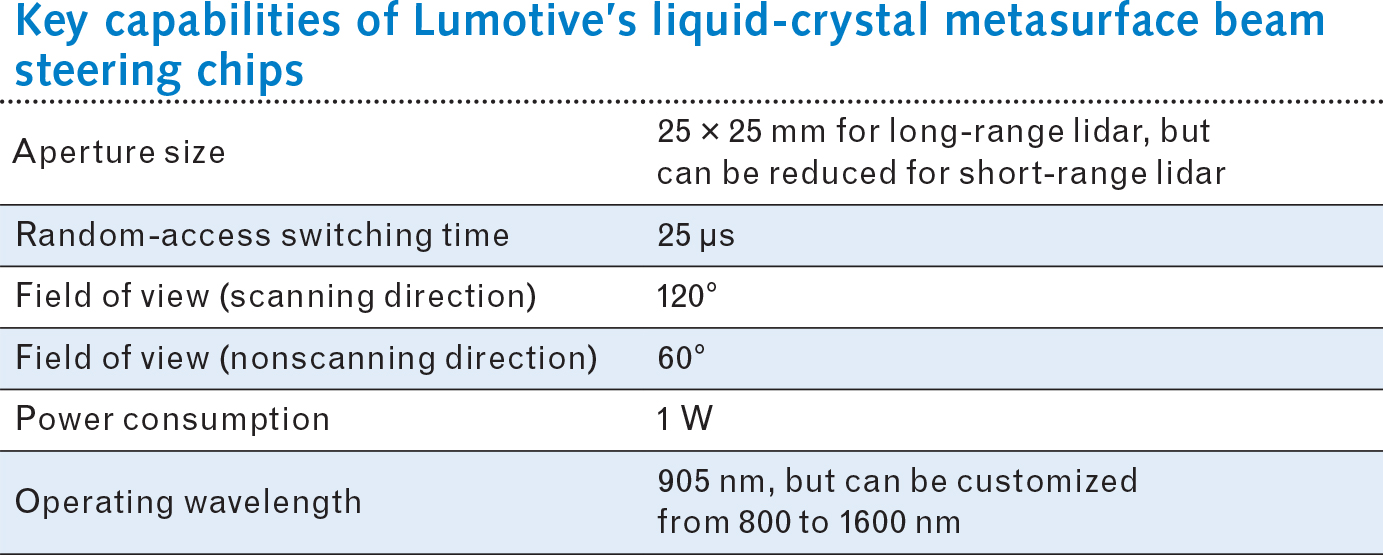

Figure 2 demonstrates beam steering over a wide field of view using an LCM, while the table summarizes the key features. The aperture of a single LCM is up to 25 × 25 mm with nearly 100% fill factor, limited only by the lithography reticle size. This large aperture is possible because all elements are illuminated by the incident laser wavefront from free space, in contrast to optical phased arrays, which require a lossy waveguide distribution network.

Using conventional liquid crystals, the switching speed of the LCM is about 25 μs when using conventional liquid crystals, which is dramatically faster than the millisecond-timescale switching speed typical of LCOS and liquid-crystal displays (LCDs). This switching speed is possible because of the nanoscale resonator dimensions, in contrast with the typical LCD electrode spacing of approximately 3 μm. The switching time is independent of the angles that are being steered between, which allows a lidar system using an LCM to perform arbitrary, random-access beam steering. This capability enables the lidar to zoom in and focus on objects of interest in a software-defined manner, which is not possible with mechanically scanned systems.

Furthermore, while the birefringence of liquid crystals decreases slightly with temperature, the LCM steering angles are independent of temperature. The pointing angles are determined only by the spatial period of the voltage pattern, which is in turn based on the fabricated resonator pitch and does not change with temperature.

The LCM wafers are fabricated in a conventional 0.13 μm CMOS semiconductor foundry with few process modifications. The liquid crystals are applied to the surface of the chips and sealed with a cover glass during packaging in the same manner as in LCOS display assembly. Standard LCD drivers are then attached to the LCM chips, which provide the voltages to drive the resonators. From wafer fabrication to assembly, mature commercial technologies are used, speeding up time to market for the LCM technology.

Lidar based on LCMs

The Lumotive lidar system employs two LCMs, one each for transmit and one for receive. The large aperture on transmit allows more optical power to be transmitted at the eye-safe power density, which has been a limitation of systems operating at 905 nm. Meanwhile, the large receive aperture collects more return signal compared to small-aperture mechanical and solid-state systems. By scanning on both transmit and receive, a large fraction of solar radiation can be rejected, improving system range, which is in contrast to systems that scan only on transmit and use wide field of view receivers.

References and Resources also include:

https://www.photonics.com/Articles/Metasurface_for_Nonlinear_Manipulation_Could/p4/a64253