Microfluidic systems are any device that processes minuscule amounts of liquids. Microfluidics is the general term for the manipulation of nanoliter volumes of fluids through micro-channels. It deals with the behavior, precise control, and manipulation of fluids that are geometrically constrained to a small, typically sub-millimeter, scale.

The fluids travel through channels thinner than hair, and tiny valves can turn the flow on and off. These channels are made of materials such as glass, polymers, paper, or gels. One way to move fluids is with a mechanical pump; another way is to use the surface charges of certain materials; and yet another is to use the so-called capillary action – more commonly known as wicking. Wicking is the process by which the energy stored within the liquid propels the liquid through narrow spaces.

At small scales (channel size of around 100 nanometers to 500 micrometers) some interesting and sometimes unintuitive properties appear. In particular, the Reynolds number (which compares the effect of the momentum of a fluid to the effect of viscosity) can become very low. A key consequence is co-flowing fluids do not necessarily mix in the traditional sense, as flow becomes laminar rather than turbulent; molecular transport between them must often be through diffusion. Fluids move down the channel in organized parallel streams – called laminar flow. The fluids and particles in laminar flow follow paths that are mathematically predictable – a necessity for precision engineering and medical device design.

Microfluidics exists in Nature in many forms: such as capillarity through which Plants transport nutrients from their roots up to the highest branches and intricate blood capillaries that bring food, oxygen, and signaling molecules to every cell.

Microfluidics is a multidisciplinary field and potential applications of this new field range from chemical lasers, to implantable drug delivery systems, to detection of biological or chemical hazards, to DNA analysis. Developments in the field of microfluidics have triggered technological revolutions in many disciplines, including chemical synthesis, electronics, diagnostics, single-cell analysis, micro-and nanofabrication, and pharmaceutics.

Advantages

Microfluidics attractive for a number of reasons:

Size — When you’re working with microfluidics, you don’t need big samples. This means microfluidics requires fewer samples to work with to make the same discoveries. Scientists can do experiments on a small scale and not waste samples.

Time — Because you’re working with small samples, reactions happen more quickly. As a result, microfluidics shortens the time of experiments, and you can see results more quickly.

Cost — Microfluidics cost less because scientists use fewer samples and take less time to complete experiments.

Precision — Scientists improve the precision of experiments because they’re already working with such precise measurements. If they can make things happen at this level, then they’ll have precise results and also know how to make the same experiment happen accurately on a larger scale.

Limits — Microfluidic experiments lead to a lower limit of detection. Scientists can detect changes at a much lower limit than when working in a larger setting.

Multiple Analyses — With microfluidics, you’re using less space and material, and as a result, you can conduct several analyses at the same time. In medicine, microfluidics’ analyses of fluids regularly reduce hospital visits and overall healthcare costs.

Applications

NASA has been considering microfluidic analyzers for its Mars rovers for a long time. The analysis of precious fluids – such as human blood – also benefits from the ability to use small samples. For example, glucose meters are microfluidic instruments that require only a drop of blood to measure a diabetic’s blood sugar, inkjet printheads that shoot tiny ink droplets, and 3D printers squeeze out molten polymer through a microfluidic nozzle. It is used in the development of DNA chips, lab-on-a-chip technology, micro-propulsion, and micro-thermal technologies.

The field has led to the development of microfluidic devices or chips which are commonly used for high-throughput screening in biosciences. The basic idea behind microfluidics is to implement operations that used to require an entire lab in a single micro-sized device.

Lab on a Chip

A lab-on-a-chip is a device that integrates one or several laboratory functions on a tiny single chip to achieve automation and high-throughput screening. The emergence of the lab-on-a-chip field mainly relies on two core technologies: microfluidics and molecular biology. The basis of the lab-on-a-chip dream is to integrate onto a single chip thousands of biochemical operations that could be done by splitting a single drop of blood collected from the patient in order to get a precise diagnosis of potential diseases. Lab-on-a-chips deal with the handling of extremely small fluid volumes down to less than pico-liters.

Lab-on-chips is an integrated miniaturized device used in laboratory operations on a single micro-process chip in a small scale. The system integrates onto a single chip one or several analyses, which are usually done in a laboratory; analyses such as DNA sequencing or biochemical detection. Lab-on-chip is also called a micro-total analytical system (µTAS) as it allows researchers to perform all the operations from sample collection to final analysis onto the same chip. Lab-on-a-chip devices are a subset of Micro-electro-mechanical systems (MEMS) devices and often indicated by “Micro Total Analysis Systems” (µTAS) as well.

Microfluidics will be critical for ushering medicine into a new, fast-paced, affordable era. Wearable devices that measure substances in sweat for exercise monitoring and implantable devices that locally deliver cancer drugs to a patient’s tumor are some of the next frontiers of biomedical microfluidics.

Organ-on-a-Chip

With organ-on-a-chip, three-dimensional cell culture is developed on a microdevice, which attempts to reproduce a living organ’s major functions, only on a computer chip. A scientist can research human physiology for a specific organ while testing advancements for diseases on that model. Examples include heart on a chip, liver on a chip, tumor on a chip, and even multiple organs on one chip.

For example, tumor-on-a-chip platforms are being developed to test cancer drugs more efficiently. By virtue of their small size, microfluidics can trap the tiny tumor pieces in multiple wells, one well per drug. These samples retain the appropriate cellular environment of the tumor which will allow researchers to more accurately predict how a drug will work for a specific person

Microfluidics in COVID-19

The COVID-19 pandemic created an urgent need to track how and where the virus spread. COVID-19 experts have long asserted that effective testing and tracing protocols are essential for keeping the virus at bay. Thanks to advancements in microfluidics, it’s not always necessary to have advanced equipment to get test results efficiently.

A microfluidic device designed at Rice University gives the outcome in less than an hour and plugs into standard smartphones. It contains programmed magnetic microbeads that detect the concentration of SARS-CoV-2 nucleocapsid in blood from a quick finger-prick procedure.

Alongside vaccination and social distancing, rapid testing for SARS-CoV-2 – the virus that causes COVID-19 – is a critical element of global efforts to bring an end to the pandemic. Currently, the most widely applied testing techniques use chemical reactions to amplify certain biomarkers associated with the virus, such as the RNA molecules that carry its genetic information. However, these processes are time-consuming, which has resulted in slow testing turnaround times.

A rapid and low-cost test for the virus that causes COVID-19 has been developed by researchers in the US and Taiwan, reported in June 2021. Featuring a disposable testing cartridge and a reusable circuit board, the team’s portable system can detect the presence of the virus in fluid samples within just 1 s. By adjusting its design, the system could be adapted to test for other diseases.

Now Minghan Xian and colleagues at the University of Florida and National Yang Ming Chiao Tung University have developed an alternative approach, which instead measures distortions in electrical signals associated with the presence of the virus particles in a circuit. Their design is based around a circuit board containing a metal-oxide-semiconductor field-effect transistor (MOSFET), which is a common electronic device that amplifies electrical signals.

Their system also includes a disposable testing strip that plugs into the MOSFET circuit. The tip of the strip has a microfluidic channel that contains clusters of gold-plated electrodes coated with SARS-CoV-2 antibodies as well as bare carbon auxiliary electrodes. When fluid samples are introduced to the channel, short electrical test signals can pass between the electrodes, amplified by the MOSFET and then sent to the circuit board for analysis.

If SARS-CoV-2 is present in a sample, spike proteins on the virus particles will bind to the antibodies on the gold electrode surface, which alters the nature of the amplified test signal waveforms. By converting these distortions into digital readouts, the system can determine the concentration of spike proteins; and subsequently, the concentration of virus particles present in the sample – within just 1 s. Their technique remains reliable over a broad range of concentrations: from just 100 virus particles per millilitre, to up to 2500.

Furthermore, the detection process is not limited to COVID-19. By attaching other types of antibodies to the testing strip’s gold electrodes, the system could be repurposed for other diseases.

Military Applications

The growing threat of bioterrorism attacks, combined with repeated outbreaks of emerging infectious diseases, underlines the importance of infrastructure improvement for the detection and diagnosis of biowarfare agents and emerging pathogens. There is an increasing need for compact biodefense devices that work autonomously and consume minimal reagents. These requirements can be well met by microfluidic technologies.

The destructive potential of genetically engineered bioagents is huge. Toxic genes can be hidden in innocuous organisms and expressed at high levels. Expression timing and genotypic specificity could be controlled to maximize impact and potentially limit spread to a defined racial pool. The detection of bioengineered organisms presents even greater challenges than detecting conventional pathogens, and may require multi-tiered screening, including high-resolution detection of target genes and DNA sequencing.

Moreover, as with many other scientific fields, research for military purposes stimulated a lot of effort on the development of microfluidics technology as a tool of defense against potential bacteriological threats. In particular, government institutions, such as the DARPA (Defense Advanced Research Projects Agency), commissioned microfluidics systems for fast and in-situ detections. Military agencies such as the DARPA and the DGA have also invested a lot of money in advancing research on lab-on-a-chip technologies since such advancements would allow them to detect biological threats towards troops and civilians as soon as possible.

Sandia develops new detectors for chemical, biological threats

Sandia National Laboratories scientists have invented microfluidics-based tiny detectors that can sniff out everything from explosives and biotoxins to smuggled humans. Their potential seems unlimited. The military needs to find low concentrations of chemicals, such as those used in roadside bombs or chemical warfare agents, before they hurt anyone, said researcher Ron Manginell. Soldiers often use detectors in less-than-ideal situations, looking for dangerous substances from among a rich miasma of diesel fumes, smoke and dust. They carry detectors into the field, where instruments must be portable, rugged, reliable and easy to use. In addition, inspectors at checkpoints and border crossings that see large numbers of containers lack automated ways to find trafficked people or contraband.

Sandia has developed many microfluidics- and microelectromechanical (MEMS) systems-based instruments that identify chemicals based on gas chromatography, or GC, and resonator-style instruments such as surface acoustic wave (SAW) detectors. Manginell said SAW-based instruments will continue to be extremely important. But the world of detection also needs new instruments that can find compounds such as carbon dioxide, chemical signals unique to humans or the volatile signatures of pathogens and diseases in livestock and humans.

Sandia National Laboratories researcher Ron Manginell displays new miniature pulsed-discharge ionization detectors, or mini-PDIDs, he is developing along with Sandia colleagues. The tiny detectors have broadened the scope of chemical targets for Sandia’s microanalytical detection technology to toxic industrial chemicals, biological volatiles, greenhouse gases and more.

Manginell led a project to develop such a detector and couple it with GC. Together, they identify vapors by “sniffing” volatile organic compounds (VOCs). The prototype of the new detector, a miniature pulsed-discharge ionization detector, or mini-PDID, is about 1 inch by 1 inch by 2 inches, can be coupled with commercially produced micro-GCs and can run for nine hours on a charge of helium.

Experiments have shown the mini-PDID can detect explosives-related compounds, pesticides and toxic industrial compounds. “These are nasty things,” Manginell said. The detector also homes in on signatures of human odors and bacteria, light gases such as carbon monoxide and carbon dioxide and a broad range of organic compounds.

“We now have new detectors, like the PDID, with higher sensitivity and broader applicability that would integrate well with the SAW and micro-GCs to provide both sensitivity, the ability to detect a few molecules of a given compound, and selectivity, the ability to distinguish compounds from one another,” Manginell said. A miniaturized vapor detection unit and subsidiary electronics could fit in a format no larger than a cell phone, he said.

The mini-PDID’s universal detection abilities are allowing researchers to look at vapor detection of bacteria, an approach aimed at bringing biological and chemical detection into a small, common platform, Manginell said. He highlighted the work, funded by Sandia’s Laboratory Directed Research and Development program, in a presentation at last fall’s International Breath Analysis meeting in Sonoma, Calif. The Journal of Breath Research published a paper by the team in July. The team demonstrated the possibility of a VOC-based detector for humans as part of the project.

“People are brought across the border for many reasons, sometimes for a better life, sometimes for malevolent reasons” such as drug, weapons or explosives smuggling, Manginell said. Current commercial detectors to find human cargo are about the size of a large shoebox, minus the electronics that operate them. Thus, Manginell’s team saw promise for a miniature vapor-based detector for what he calls “indications of human presence.” In other words, sweat. No other animal has one component of human sweat called hexenoic acid. The action of bacteria on sweat excreted by human glands results in that distinct eau de locker room smell — what’s really a byproduct of bacterial metabolism, or a bacterial VOC.

The project proved the miniature detector could find hexenoic acid at the parts-per-billion level. Sandia researchers wondered whether the technique could detect other bacteria, and tested it on the VOC signatures of Microbacteria bovis and Microbacteria tuberculosis. M.bovis causes TB in livestock and can cause TB in humans; M.tuberculosis causes human TB. The bacteria produce four unusual compounds not made by other bacteria that infect humans, and Manginell said the GC-PDID approach can detect those markers at concentrations comparable to or better than current techniques.

Further development sought

The proof of concept works for biological detection, and Sandia is seeking funds to develop software and mathematics for pattern recognition for specific targets, Manginell said. It will be several years before the technology could be ripe for tech transfer.

Manginell said the technology also needs engineering innovations, such as a tiny low-volume, high-flow-rate valve that can operate under high pressure. In addition, researchers are looking for funds to further develop the mini-PDID and make it even smaller. Manginell wants to reduce the housing to the size of a AAA battery, and ultimately to MEMS size — typically devices measuring between 20 micrometers to a millimeter. For comparison, a human hair averages 70 microns in diameter.

In general, Sandia’s chemical detection instruments work by collecting and concentrating a sample of air, separating the chemicals using a GC and finding the targeted ones through selective detection. Manginell likens the GC to a racetrack for chemicals. Compounds in a mixture all enter the race at the same time, but various compounds get to the finish line at different times, based on how they interact with the GC. The passage of time also helps indicate what a compound is since compounds separate at different rates, he said.

The micro-GC system can filter out common interfering agents such as water in the form of humidity, and detected compounds at sub-parts per billion concentrations in 6 seconds to 2 minutes in lab and field tests, Manginell said.

Sandia’s micro-GC system approach is more compact and faster than commercial GC units and can be operated by non-experts, he said. It eliminates the need for a mass spectrometer, which detects chemicals by measuring the relative concentrations of atoms and molecules. Eliminating a mass spectrometer removes the need for vacuum pumps, which are too big and costly for broad field use.

Profusa wins $7.5m DARPA Grant for Implantable Biosensors

In 2016, DARPA and the U.S. Army Research Office (ARO) awarded Profusa a $7.5 million dollar grant to develop the company’s implantable biosensors for the simultaneous, continuous monitoring of multiple body sensors. Over the past few years, Profusa has focused research and product development on providing real-time monitoring of a combat soldier’s health status to improve mission efficiency and overall performance.

While fitness trackers and other wearables provide insights into our heart rate, respiration and other physical measures, they don’t provide information on the most important aspect of our health: our body’s chemistry,” explained Natalie Wisniewski, Ph.D. “Based on our ongoing studies, tissue-integrated sensor technology has the potential to enable wearables to live up to the promise of personalized medicine, revolutionizing the management of health in wellness and disease.” Dr. Wisniewski, who leads the team of biosensor developers, is the chief technology officer and co-founder of Profusa Inc., a San Francisco Bay Area-based life science company.

Conventional sensors, such as those found in continuous glucose monitors, have a sensing electrode wire that penetrates the skin to measure a target chemical in the fluid that surrounds cells. But because the body “sees” the electrode as foreign material, it needs to be removed and replaced within several days at a different location to avoid the effects of inflammation and scar tissue that eventually prevents the electrode from functioning accurately.

The team at Profusa is developing a family of tiny biosensors composed of a tissue-like hydrogel, similar to a soft contact lens, that are painlessly placed under the skin with a single injection. Each sensor is a flexible fiber, between 2 and 5 mm long, composed of “smart hydrogel,” and are designed to be integrated into the body’s tissue to overcome the foreign body response for more than 1 year, the company said. Rather than being isolated from the body, the biosensors work fully integrated within the body’s tissue — without any metal device or electronics, thereby overcoming the body’s attempts to reject it. To date, the injected biosensors have functioned for as long as four years.

Smaller than a grain of rice, each biosensor is a flexible fiber about 5 mm long and half a millimeter wide, comprised of a porous scaffold that induces capillary and cellular ingrowth from surrounding tissue. The hydrogel is linked to light-emitting fluorescent molecules that continuously signal in proportion to the concentration of a body chemical, such as oxygen, glucose, or other biomolecule of interest.

Adhered to the skin’s surface or held by hand, a separate optical reader is used to read the fluorescent signal from the embedded biosensor. The reader sends excitation signals through the skin to the biosensor, which then emits fluorescent light in response to the biomolecule present. The data is relayed to a smart phone for an encrypted personal record and historical tracking. Data can be shared securely via digital networks with healthcare providers.

In 2016, Profusa said, “The new sensors will be designed for the simultaneous, continuous monitoring of multiple body chemistries, the company said, with their initial use slated to provide real-time monitoring of combat soldier’s health status. “Profusa’s vision is to replace a point-in-time chemistry panel that measures multiple biomarkers, such as oxygen, glucose, lactate, urea, and ions with a biosensor that provides a continuous stream of wireless data. We are gratified to be awarded this grant to accelerate the development of our novel tissue-integrating sensors for application to soldier health and peak performance,” CEO Ben Hwang said in prepared remarks.”

“Long-lasting, implantable biosensors that provide continuous measurement of multiple body chemistries will enable monitoring of a soldier’s metabolic and dehydration status, ion panels, blood gases, and other key physiological biomarkers. Our ongoing program with Darpa builds on Profusa’s tissue-integrating sensor that overcomes the foreign body response and serves as a technology platform for the detection of multiple analytes,” CTO Natalie Wisniewski said in a prepared statement.

Microfluidic Cooling

The challenge in scaling chips and increasing clock rates is mainly due to limitations in removing excess heat. In order to overcome the stubborn heat removal problem, air and liquid based cooling with fans and metallic plates is used. However, these methods have low heat-removal efficiency and undesired thermal resistance.

To solve these problems, microfluidic cooling approaches are emerging, which exploit microchannels positioned on wafer surfaces. Microfluidics are promising for addressing hot spots in mobile devices, not only for high-performance computing applications. They can cool hot spots directly, and are useful for thinned die and 3D stacks.

DARPA’s Intrachip/Interchip Enhanced Cooling (ICECool)

The increased density of components in today’s electronics has pushed heat generation and power dissipation to unprecedented levels. Current thermal management solutions, usually involving remote cooling, where heat must be conducted away from components before rejection to the air, are unable to limit the temperature rise of today’s complex electronic components without adding considerable weight and volume to electronic systems. The result is complex military systems that continue to grow in size and weight due to the inefficiencies of existing thermal management hardware.

DARPA’s Intrachip/Interchip Enhanced Cooling (ICECool) program seeks to overcome the limitations of remote cooling. ICECool will explore ‘embedded’ thermal management by bringing microfluidic cooling inside the substrate, chip or package and by including thermal management in the earliest stages of electronics design. Success with ICEcool may help close the gap between chip-level heat generation density and system-level heat removal density in high-performance electronic systems, such as computers, RF electronics and solid-state lasers.

Microelectronics experts at IBM Corp. are taking the next step in a U.S. military research program to design convective or evaporative microfluidic cooling directly into microchip designs and packaging. For the latest contract, IBM electronics thermal management experts will build on completed research in military electronics to help designers make substantial reductions in size, weight, and power consumption (SWaP) of computer chips, while retaining or advancing chip performance.

The BAE Systems Electronic Systems segment in Merrimack, N.H., and the Boeing Co. Defense, Space & Security segment in El Segundo, Calif., also are involved in the DARPA ICECool program. BAE Systems and Boeing are working on the ICECool Applications program to find new approaches to electronics thermal-management in military embedded systems and RF MMICs.

IBM will continue searching for ways to shrink chip-cooling technologies such that they can build cooling into the chip itself. The goal is to close the gap between chip and chip-cooling technologies for military electronics like computers, RF transceivers, and solid-state lasers.

Cooling High-Powered Systems From Within

Qorvo and Lockheed Martin are working to apply its thermal management techniques with Qorvo’s gallium nitride (GaN) on silicon carbide (SiC) QGaN15. This technology has the exciting potential to cool systems that need it the most — from sophisticated military equipment such as radars and electronic warfare to high-performance computers and servers.

This approach can also be extended to existing or future die technology such as gallium arsenide (GaAs) and GaN on diamond. Roger Hall, general manager of Qorvo’s Infrastructure and Defense Products said, “Qorvo has been working with DARPA since 2013 on breakthroughs involving GaN on diamond. Now we’re thrilled to be working on a new microfluidic cooling approach for GaN and other microelectronics.”

Significant Increase in RF Output Power

Qorvo and Lockheed Martin demonstrated an impressive, six-times increase in RF output power with its new chip-level heat removal, versus conventional cooling techniques. Hall said, “Fast and cost-effective cooling for high-powered microchips has far-reaching applications for the hundreds of chips inside everyday devices. By increasing the thermal conductivity and reducing device temperature, we are paving the way for new generations of GaN devices that may be much smaller than today’s products.”

Qorvo and the ICECool team is developing a transmit antenna prototype and increasing the technology readiness level of this new cooling technique, so the electronics we all rely on perform effectively and efficiently. Other applications of microfluidics include the implementation of fluidic valves and channels with liquid metals, thus enabling reconfigurable radio-frequency antennas

Tunable Liquid Metal Antennas

Researchers have held tremendous interest in liquid metal electronics for many years, but a significant and unfortunate drawback slowing the advance of such devices is that they tend to require external pumps that can’t be easily integrated into electronic systems. Team of North Carolina State University (NCSU) researchers have created a reconfigurable liquid metal antenna controlled by voltage only by using electrochemical reactions to shorten and elongate a filament of liquid metal and change the antenna’s operating frequency. Applying a small positive voltage causes the metal to flow into a capillary, while applying a small negative voltage makes the metal withdraw from the capillary.

The shape and length of the conducting paths that form an antenna determine its critical properties such as operating frequency and radiation pattern. “Using a liquid metal—such as eutectic gallium and indium—that can change its shape allows us to modify antenna properties more dramatically than is possible with a fixed conductor,” explained Jacob Adams, coauthor and an assistant professor in the Department of Electrical and Computer Engineering at NCSU.

The positive voltage “electrochemically deposits an oxide on the surface of the metal that lowers the surface tension, while a negative potential removes the oxide to increase the surface tension,” Adams said. These differences in surface tension dictate which direction the metal will flow.

This advance makes it possible to “remove or regenerate enough of the ‘oxide skin’ with an applied voltage to make the liquid metal flow into or out of the capillary. We call this ‘electrochemically controlled capillarity,’ which is much like an electrochemical pump for the liquid metal,” Adams noted.

“Mobile device sizes are continuing to shrink and the burgeoning Internet of Things will likely create an enormous demand for small wireless systems,” Adams said. “And as the number of services that a device must be capable of supporting grows, so too will the number of frequency bands over which the antenna and RF front-end must operate. Liquid metal systems “yield a larger range of tuning than conventional reconfigurable antennas, and the same approach can be applied to other components such as tunable filters,” Adams said.

In the long term, Adams and colleagues hope to gain greater control of the shape of the liquid metal — not only in one-dimensional capillaries but perhaps even two-dimensional surfaces to obtain nearly any desired antenna shape. “This would enable enormous flexibility in the electromagnetic properties of the antenna and allow a single adaptive antenna to perform many functions,” he added.

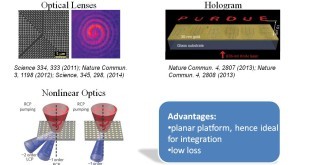

Other applications

A related microfluidic fabrication technology that has been developed at Lincoln Laboratory is low-voltage electrowetting. In this process, a thin dielectric layer is applied to the walls of microfluidic channels, and the application of suitable voltages enables the switching and propagation of two-component fluids (such as oil drops in water) in complex paths.

Electrically controlled microfluidic circuits can be designed and implemented, including pumps, valves, mixing elements, and filters. Besides biomedical applications, the Chemical, Microsystem, and Nanoscale Technologies Group is pursuing applications of low-voltage electrowetting in microoptics and microhydraulics. In microoptics, the group has demonstrated the fabrication and functionality of switchable liquid lens arrays, with dimensions of individual lenses down to 50 µm and even less, capable of changing focus over a wide range as the applied voltage changes the shape of the oil-water interface.

A related application envisions electrowetting-based optical beam steering, where the variable-focus liquid microlenses are replaced with variable-angle liquid microprisms. The group’s initial studies into microhydraulics applications have recently shown efficient fluid displacement through arrays of microchannels in a conductive matrix, leading to the development of pistons and actuators.

References and Resources also include:

https://theconversation.com/microfluidics-the-tiny-beautiful-tech-hidden-all-around-you-160436

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis