Nanomaterials (NMs) have gained prominence in technological advancements due to their tunable physical, chemical and biological properties with enhanced performance over their bulk counterparts. NMs are categorized depending on their size, composition, shape, and origin. Newly discovered materials such as fullerene, carbon nanotubes (CNTs), graphene, transition metal dichalcogenides, hexagonal boron nitride (h-BN), and boron nitride nanotubes (BNNTs) have provided great opportunities for scientific and technical improvements in various application industries in the past several decades.

Among these materials, one-dimensional (1D) BNNTs and two-dimensional (2D) h-BN are highly promising nanomaterials that have attracted the worldwide attention of many researchers and companies in various fields owing to their excellent physical and chemical properties and lightweight.

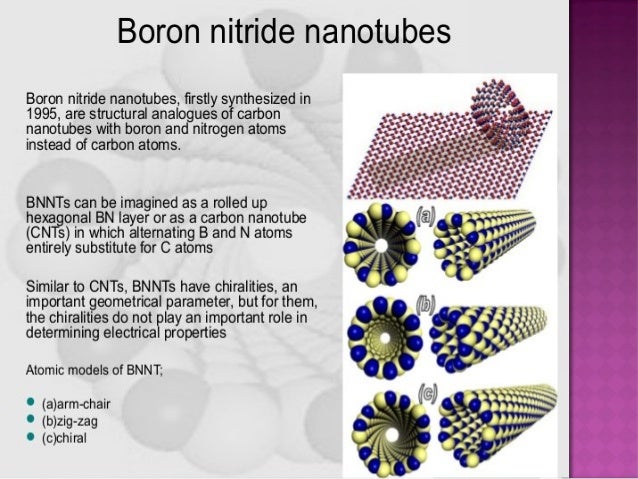

Boron nitride nanotubes (BNNTs) are a polymorph of boron nitride and considered the strongest light-weight nanomaterial. Structurally they are similar to carbon nanotubes, which are cylinders with sub-micrometer diameters and micrometer lengths. Boron nitride nanotubes are structurally similar to CNTs. They are both shaped like hollow tubes or cylinders and have nanometer dimensions and are microns in length. They are both high aspect ratio nanomaterials. CNTs only have Carbon atoms, whereas in boron nitride nanotubes the carbon atoms are alternately substituted by nitrogen and boron atoms.

However, the properties of BN nanotubes are very different: whereas carbon nanotubes can be metallic or semiconducting depending on the rolling direction and radius, a BN nanotube is an electrical insulator with a bandgap of ~5.5 eV, basically independent of tube chirality and morphology. In addition, a layered BN structure is much more thermally and chemically stable than a graphitic carbon structure. BNNTs have unique physical and chemical properties, when compared to Carbon Nanotubes (CNTs) providing a very wide range of commercial and scientific applications.

Boron nitride nanotubes (BNNTs) have higher thermal stability than carbon nanotubes (CNTs). They also possess higher electrical insulation and polarizability; wider band gap; higher transparency; and higher neutron absorption cross-section than carbon nanotubes. They can be made into transparent materials or dyed different colours. With carbon nanotubes, you’re stuck with basic black.

.jpg)

Boron nitride nanotubes are used in various applications such as thermal management packages, polymer composite reinforcements, neutron shielding nanomaterials, and piezo actuators.

Boron nitride nanotubes have a few key advantages over carbon nanotubes (CNT). Boron nitride nanotubes are electrical insulators as well as excellent thermal conductors. CNT’s are electrical conductors, so they cannot be used in places where you need electrical shielding. This means boron nitride nanotubes can be used to cool electronics without causing electrical problems.

One way to shrink field-effect transistors, the kind found in most electronic devices, is to build the gates that surround thinner nanowires. These nanowires are protected within nanotubes. Engineers at Purdue University performed the work in collaboration with Michigan Technological University, Washington University in St. Louis, and the University of Texas at Dallas. They found that transistors made with this material could carry significantly more electrical current, making them more efficient. The researchers built a transistor with a tellurium nanowire encapsulated in a boron nitride nanotube, provided by physics professor Yoke Khin Yap’s lab at the Michigan Technological University. A high-quality boron nitride nanotube effectively insulates tellurium, making it possible to build a transistor. In 2018, the same research team at Purdue discovered tellurene, a two-dimensional material derived from tellurium.

Although BNNTs and CNTs share similar tensile strength properties of circa 100 times stronger than steel and 50 times stronger than industrial-grade carbon fibre, BNNTs can withstand high temperatures of up to 900 °C. as opposed to CNTs which remain stable up to temperatures of 400 °C. This allows them to be added into materials such as metals and ceramics that need higher temperatures to be processed.

Unlike CNTs, boron nitride nanotubes can also effectively absorb neutron radiation and they may well help in NASA’s quest to go to Mars by 2030 for their Space Radiation Shielding qualities. Like BN fibers, boron nitride nanotubes show promise for aerospace applications where integration of boron and in particular the light isotope of boron (10B) into structural materials improves both their strength and their radiation-shielding properties; the improvement is due to strong neutron absorption by 10B. Such 10BN materials are of particular theoretical value as composite structural materials in future manned interplanetary spacecraft, where absorption-shielding from cosmic ray spallation neutrons is expected to be a particular asset in light construction materials.

BNNTS are packed with physicochemical features including high hydrophobicity and considerable hydrogen storage capacity and they are being investigated for possible medical and biomedical applications, including gene delivery, drug delivery, neutron capture therapy, and more generally as biomaterials. BNNTs are also superior to CNTs in they way they bond to polymers giving rise to many new applications and composite materials.

Toxicological investigations on BNNTs conducted in the 2010s seem to show that the enhanced chemical inertia of BN nanotubes favors biocompatibility. As a result, their use in the biomedical field was suggested both as nanocarriers and as nanotransducers. BN nanotubes have also shown potential in certain cancer treatments

Electrical and field emission properties of BN nanotubes can be tuned by doping with gold atoms via sputtering of gold on the nanotubes. Doping rare-earth atoms of europium turns a BN nanotube into a phosphor material emitting visible light under electron excitation. Quantum dots formed from 3 nm gold particles spaced across the nanotubes exhibit the properties of field-effect transistors at room temperature.

High stiffness and excellent chemical stability makes BNNTs ideal material for reinforcement in polymers, ceramics and metals. For instance, buckypaper-based BNNT/epoxy composites and polyurethane-modified buckypaper composites have been successfully developed. These composite materials exhibit Young’s moduli over twice the value for neat epoxy and 20 times the value for unimpregnated buckypaper. BNNTs are also one of the most promising classes of material for reinforcing aluminum-based structures.

The low reactivity of BNNTs facilitates the integration of this material into an aluminum matrix where CNTs fail due to the reaction between the carbon and the aluminum which forms the undesired Al4C3 phase at the interface. BNNTs also exhibit much higher oxidation temperature (~950 °C) than the melting point of aluminum (660 °C), which enables the homogenous dispersion of BNNTs directly into the aluminum melt.

Since BNNTs retain their mechanical properties at high temperatures while having a very low density, the development of new temperature-resistant lightweight MMC is achievable. BNNTs also exhibit good thermal conductivity. This renders them useful for applications in nanoelectronics where heat dissipation is critical. This also makes BNNTs multifunctional as it not only improves the stiffness of composites but also yields high thermal conductivity along with high transparency. The combination of high stiffness and high transparency is already exploited in the development of BNNT-reinforced glass composites. Other intrinsic properties of BNNTs such as good radiation shielding ability, high electrical resistance and excellent piezoelectric properties are likely to promote interest for integrating them in new applications.

Research interest in boron nitride nanotubes (BNNTs) has increased after the recent success of large-scale BNNT syntheses using high-temperature-pressure laser ablation or high-temperature plasma methods. Nonetheless, there are limits to the application and commercialization of these materials because of the difficulties associated with their fine structural control.

Nuclear research center agrees to develop new technologies based on boron nitride nanotube

South Korea’s state nuclear research center teamed up with a private company to develop new technologies based on boron nitride nanotube, a new nano-material that can be used for space and nuclear technologies due to its excellent mechanical, thermal, and neutron-absorbing abilities. The Korea Atomic Energy Research Institute (KAERI) said that it has signed a memorandum of understanding with Naieel Technology on the development of application technologies based on next-generation nanomaterials. Naieel was established by KAERI researchers for the commercialization of BNNT and its applications to areas such as IT, space, nuclear, bio-medical and energy.

The two organizations agreed to work together for the development of new technologies by combining next-generation nanomaterials and nuclear power technologies, the institute said in a statement. “Through this cooperation, we will make efforts to expand a new material business by incorporating boron nitride nanotube into the radiation field,” KAERI President Park Won-seok was quoted as saying. Through technical cooperation, they would try to create a new market in nuclear power and radiation fields by developing source technologies and products based on BNNT. “Boron nitride nanotube is a new core nano-material that will change the paradigm of future industries, and we will grow into a global leader in related fields through cooperation with the Korea Atomic Energy Research Institute,” said Naieel CEO Kim Jae-woo.

Canada Eyes Lighter, Stronger Armor

Canadian defense scientists are aiming to create armor that is 25 percent lighter than existing materials while offering the same or more protection. The Canadian program will use boron nitride nanotubes or BNNTs, which are 100 times stronger than steel and have 17 times the strength of Kevlar. While boron nitride nanotubes have been seen as a new potential material for armor, what makes the Canadian effort different is that the scientists have put in place the largest production capacity in the world for BNNTs. That creates the first possibility of producing the advanced material on a large scale.

While boron nitride nanotubes have been seen as a new potential material for armor, what makes the Canadian effort different is that the scientists have put in place the largest production capacity in the world for BNNTs. That creates the first possibility of producing the advanced material on a large scale. “It shows a lot of promise and [it’s] the one we’re focusing on the most right now,” said Guy Vezina, director general, science and technology – Army for Defence Research and Development Canada (DRDC).

BNNTs are an advanced material similar in structure to carbon nanotubes. Both types of miniature materials are developed in a laboratory and are known for their strength and fire retardant properties. But BNNTs have an advantage in that they can survive temperatures to around 800 degrees Celsius, about twice as high as carbon nanotubes. BNNTs are more chemically stable, and they are also transparent. In 2009, US researchers were able to create the first practical macroscopic yarn from BNNTs.

BNNano

We are an advanced manufacturing company that produces the patent-pending NanoBarb™, a unique and enhanced boron nitride nanotube. When NanoBarbs are added to materials, it improves natural properties, changing them into extraordinary materials. We are focused on materials such as aluminum, polyester, and copper, and are seeking to transform, revitalize, and revolutionize industrial commodities, said Steve Wilcenski CEO and Co-Founder BNNano

In January 2017, we opened our manufacturing facility in Burlington, NC. We have been manufacturing Boron Nitride NanoBarbs™ and developing products that incorporate Boron Nitride NanoBarbs™ ever since. BNNano is currently the only company globally with a commercially viable manufacturing process for boron nitride nanotubes.

Boron nitride nanotubes are electrically insulating and have a very high thermal conductivity – an extremely rare combination. They have oxidation resistance and are thermally stable >850 ◦C. They are of high strength and very elastic and flexible. BNNano is helping to establish and develop new commercial applications.

We are working with customers on a wide range of applications. Some customers are developing next-generation thermal management solutions to address the challenges of high-density and high-power electronics. For example, textile customers require stronger, tougher, and more fire-resistant polyester, while additive manufacturers are developing new materials for 3D printing applications.

We are supporting hypersonics, enhanced aluminum alloys, water purification, and many more. We have also shipped materials to all branches of the US military, NASA, and government labs worldwide. We are excited about our growing list of customers and their progress in completing new applications’ development and qualifications.

When we took on the challenge to manufacture boron nitride nanotubes, we wanted to make a material that satisfied business requirements – to be low cost and high quality. We did not try to make a “perfect” material, we made an engineering material.

What we have with the NanoBarbTM is a boron nitride nanotube with nanocrystals of boron nitride on the outside, and it really does look like rock candy. This surface morphology of NanoBarbsTM provides a much better ‘connection’ to the material. We wanted to solve or at least address the common problems seen in other nanomaterials such as carbon nanotubes, focusing on making an engineering material. We looked for existing materials that make things stronger and immediately thought of rebar, which is used to make more robust concrete structures. Nanotubes have a relatively smooth surface, so we wanted to make the outside surface less smooth.

We have been using additives to make things better and stronger for centuries. Think of the bricks used to build the pyramids. They added straw to the clay as a high aspect ratio additive to make the clay stronger. BNNano is doing essentially the same thing. When boron nitride nanotubes are added to polymers and composites, it augments what makes that material special. If an application requires a polymer for strength, when enhanced with NanoBarbs, it makes it stronger, and exponentially so. This allows you to use less material and retain the same capability.

Our material can do the same thing with aluminum. Think of what you could do for the military if you could reduce the amount of structural aluminum needed in land, air, or sea vehicles. What could you do if you used aluminum as ballistic protection in place of steel? What could you do if you could make polyester more like Kevlar? You would be on your way to making everything lighter, stronger, and faster.

We think they are critical. Almost all industries’ shared goal is to make things lighter, stronger, and faster, from microelectronics to automotive, space, and aerospace. As we push for new technologies such as hypersonic travel, advanced biomedical applications, and greener energy creation, we need new materials. Boron Nitride NanoBarbs™ can help advancements in all of those places.

We are focusing on developing our NanoBarb™ aluminum and copper but our technology is applicable to transforming a number of industries. Mobile electronics, defense, and aerospace are primary industries where our material is applicable and can revolutionize. Our NanoBarbs™ can be used to improve thermal management of mobile electronic components, as well as make military equipment lighter, more corrosive resistant, and more blast-resistant. It is also used in particular aircraft parts to help make them hypersonic.

NanoBarbs™ are also applicable to the water filtration and fireproofing industries. We also believe that NanoBarbs™ may be a key enabler in several industries such as next-generation rechargeable batteries and other industries. We are not just focused on high-value applications. With our low costs, we are beginning to work in markets and applications that have traditionally been excluded from nanomaterials due to price issues.

Our goal is to continue to improve the quality and reduce the cost of our materials. As we continue to lower costs, we can introduce our material into more industries and applications. These new applications drive demand and the need to expand and grow. We are planning a major production expansion in 2021.

Boron Nitride Nanotubes (BNNT) Market

Rise in Demand for Advanced Aerospace Materials to Drive Global Boron Nitride Nanotubes Market. Growth in the global aerospace industry is boosting the demand for boron nitride nanotubes. Rise in demand for low carbon emitting and lightweight advanced aerospace materials is driving the demand for boron nitride nanotubes. Abundance of boron minerals is also propelling the production of boron nitride nanotubes.

Leading manufacturers are focusing on the development of customized technological solutions based on industrial requirements

High manufacturing cost of boron nitride nanotubes is estimated to hamper the global market. Implementation of stringent government regulations and volatility in prices of raw materials are likely to hamper the global boron nitride nanotubes market in the near future.

Based on purity, the global boron nitride nanotubes market can be segmented into 70%-90% purity, 90%-98% purity, 98% purity, and others

The 90%-98% purity segment is anticipated to hold major share of the market during the forecast period. The segment is anticipated to expand at a rapid pace in the near future, due to the rise in consumption of boron nitride nanotubes in various end-use industries.

Based on application, the global boron nitride nanotubes market can be segmented into advanced aerospace materials, synthetic and biomedical, piezoelectric materials, and others The advanced aerospace materials segment accounted for significant share of the global boron nitride nanotubes market in 2019. This trend is anticipated to continue throughout the forecast period. Boron nitride nanotubes are widely used in the production of polymer composite reinforcements that are used in aircraft.

Based on end-use, the global boron nitride nanotubes market can be divided into electrical & electronics, aerospace & defense, medical, and others The aerospace & defense segment constituted prominent share of the global boron nitride nanotubes market in 2019. The electrical & electronics segment is anticipated to offer lucrative opportunities in the global boron nitride nanotubes market during the forecast period.

In terms of region, the global boron nitride nanotubes market can be segregated into North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. North America held major share of the global boron nitride nanotubes in 2019. The U.S. accounted for significant share of the boron nitride nanotubes market in North America in 2019. The boron nitride nanotubes market in Asia Pacific is estimated to expand at a faster pace than other regions during the forecast period. The market in countries such as China, India, and Indonesia is projected to expand at a high rate during the forecast period. Germany is anticipated to constitute large share of the boron nitride nanotubes market in Europe during the forecast period.

The global boron nitride nanotubes market is fragmented, with the presence of several regional as well as global manufacturers. Prominent players operating in the market are investing in mergers, acquisitions, expansions, and new product launches in order to maintain their leading position. Key players operating in the global boron nitride nanotubes market are: Tekna, BNNT, LLC., Nano Green Technologies LLP

Nan Integris.

References and Resouces also include:

https://www.azonano.com/article.aspx?ArticleID=5600

https://en.wikipedia.org/wiki/Boron_nitride_nanotube

https://www.transparencymarketresearch.com/boron-nitride-nanotubes-market.html

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis