Integrated circuits and power devices utilized by the semiconductor industry for the production of advanced computers, consumer electronics, communication networks, and industrial and military systems have been almost exclusively based on silicon technology. The requirements of future electronics place a great emphasis on achieving new devices with greater power density and energy efficiency, especially in the power electronics arena. This emphasis poses an increasing challenge to come up with new design protocols, innovative packaging, and even new semiconductor materials, as it is widely believed that silicon technology has finally reached its fundamental physical limits. In addition to the devices’ electrical requirements such as voltage and power ratings, the operational environments of power systems might encompass challenging conditions that include radiation, extreme temperature exposure, and wide-range thermal cycling, where conventional silicon-based systems are incapable of survival or efficient operation.

Power semiconductor devices are critical to the development of lightweight, highly efficient electronic systems needed for a wide variety of applications such as planetary exploration, deep space missions, terrestrial power grids, industrial machinery, and geothermal energy extraction. The next generation of power electronics necessitates different types of semiconductor materials as today’s dominant power semiconductor device material, silicon, is limited in terms of performance and efficiency at higher power levels and higher temperatures. WBG semiconductor devices, such as those based on GaN or silicon carbide (SiC), have emerged in the commercial market and have shown great potential to replace traditional silicon parts gradually in the high power arena.

Silicon carbide, also known as carborundum, is a unique compound of carbon and silicon and is one of the hardest available materials. Characteristics such as relatively low thermal expansion, high force-to-weight radius, high thermal conductivity, hardness, resistance to abrasion and corrosion, and most importantly, the maintenance of elastic resistance at temperatures up to 1650 ° C, have led to a wide range of uses.

SiC can be doped with nitrogen or phosphorus to form an n-type semiconductor and doping it with beryllium, boron, aluminum, or gallium to form a p-type semiconductor. SiC is Wide-bandgap power semiconductor which withstands high voltages, works even at high temperatures, is chemically robust and is able to work at high switching frequencies, which enables even better energy efficiency.

Just as Silicon (Si) became the semiconductor standard 30 years ago SiC is now revolutionizing the electric power industry. SiC has one-tenth the switching losses of silicon, 10 times the blocking voltage, four times the thermal conductivity, and 10 times the switching speeds. SiC technology also provides a junction temperature threshold in excess of 600 °C. All of these physical advantages that SiC has over current silicon technology will greatly enable increased power density, which is the chief limiting factor of today’s power electronic systems.

https://www.youtube.com/watch?v=R6DuWziKLzw

The development of new semiconductor devices capable of tolerating high voltages and currents using materials such as SiC and gallium nitride (GaN) has provided a decisive and positive change for power electronics. SiC will significantly enhance energy efficiency, and shrink the size of power electronics systems by an order of magnitude. All of these factors will also result in cost savings. Whereas the IC drove the computer revolution that shrank mainframes to the size of wall cabinets to fit on a desktop, so too will SiC technology be the prime mover behind shrinking wall-sized power electronics systems to the size of a suitcase.

While more expensive than silicon MOSFETs, which are typically limited to breakdown voltages at 900V, SiC allows for voltage thresholds at nearly 10kV. SiC also has very low switching losses and can support high operating frequencies, which allows it to achieve currently unbeatable efficiencies, especially in applications that operate at over 600 volts.

Innovations in Semiconductor Technology: From Wide Bandgap to Ultrawide Bandgap Materials

Goldman Sachs even predicts that utilizing silicon carbide in electric vehicles can reduce EV manufacturing cost and cost of ownership by nearly $2,000 per vehicle. SiC also optimizes EV fast-charging processes, which typically operate in the kV range, where it can reduce overall system loss by almost 30%, increase power density by 30%, and reduce the component count by 30%. This efficiency will allow fast charging stations to be smaller, faster, and more cost effective.

High-temperature operability reduces the complexity of cooling systems and therefore, the overall architecture of the power supply system.

The ability of silicon carbide to operate at high-temperature, high-power, and high-radiation conditions will improve the performance of a wide variety of systems and applications, including aircraft, vehicles, communications equipment, and spacecraft.

A particular area of application is electric vehicles, in addition to the aerospace sector, wherein the demand for greater compactness, high power density, and high-temperature operation are of critical importance.

Aerospace Applications

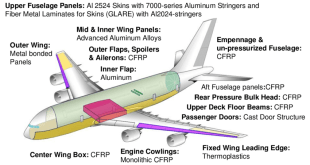

The aviation industry has recognized the potential benefits of SiC with an evident impact on all areas of the power supply system. In an aircraft, we can identify various electronic systems that use power components. The AC/DC and DC/DC power converters are used for various solutions both for high voltage and low voltage (28 V). Furthermore, SiC MOSFET technology promises to significantly reduce the size and weight of avionic power switches, with significant reductions in fuel consumption and emissions, by reducing an aircraft’s weight by 1,000 lbs.

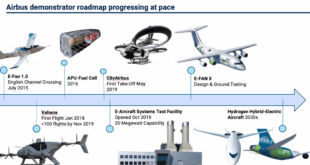

Silicon Carbide will also be enabler of More Electric Aircraft (MEA) and All Electric aircraft, increasing more electric vehicle ranges by 10%. The result has led to the expansion of new power solutions from a predominantly auxiliary support network toward a significantly higher energy requirement to power not only flight entertainment systems (rear flat screens) but also environmental control devices, electric motors, and a myriad of safety systems and sensors throughout the aircraft.

Aviation business is currently developing a SiC-based, lightweight inverter for MW-class power conversion working to NASA-set goals for power density and efficiency under two programs. This novel inverter will advance the state-of-the-art by leveraging GE’s ultra-high efficiency and high voltage SiC power devices to achieve an industry best power conversion peak efficiency (goal of 99%) and power density (goal of 19kW/kg for the active components). This SiC-based MW inverter will be ground-tested and represents the first step towards a lightweight flight-worthy inverter to enable hybrid-electric aircraft applications. This technology could revolutionize how we travel in the future.

The next-generation of SiC-based power systems for Military Applications

The ability to greatly increase the power density of current power systems makes the technology attractive for every branch of the military. A powerful argument for using SiC power electronics is the size and weight reductions that can be achieved with high-temperature operation. For example, a silicon-based power module with a 3 kg heat sink can achieve a maximum power of 5 kW assuming a junction temperature of 150 °C; while a SiC-based power module with a 0.3 kg heat sink can achieve a maximum power of 7.5 kW assuming a junction temperature of 600 °C. This implies that the use of SiC technology allows for a 50% increase in power and a 90% reduction in weight and volume.

The Army’s Future Combat Systems (FCS) program will require lighter, more compact power supplies to easily deploy the new communications and computers systems, networked logistics systems, and intelligence, reconnaissance and surveillance systems. Moreover, FCS will require a range of high-efficiency power supplies for the infantry and new ground vehicles, such as the armed robotic vehicle (ARV), small unmanned ground vehicle (SUGV), multifunctional utility/ logistics and equipment (MULE) and the infantry carrier vehicle (ICV).

The Air Force, through its More Electric Aircraft (MEA) program, aims to minimize and replace hydraulic control systems with light, low-maintenance electric actuators and motor drives. Last, the Navy’s next-generation destroyer DD(X) will require high voltage and high-power density systems to implement the envisioned compartmentalized power distribution architecture.

To take full advantage of the high-power density capabilities offered by SiC electronics, the development of high-temperature electronics as well as high temperature packaging technologies and design methodologies are required. In particular, the integration of high-temperature power devices and high-temperature control electronics into a single module greatly minimizes parasitics, allowing for very high frequencies of operation.

U.S. Air Force researchers announced a project to stand-up a manufacturer of affordable high quality silicon carbide films for RF and power switching semiconductor wafers for radar, electronic warfare (EW), and military communication.

Officials of the Air Force Research Laboratory at Wright-Patterson Air Force Base, Ohio, issued a presolicitation for the Development of Large-Diameter Silicon Carbide Substrates and Homoepitaxial Processes project. Such technology is expected to be crucial to Air Force sensor superiority for radar, EW, and communications in the DC to microwave and submillimeter-wave spectrum from 300 MHz to 300 GHz, researchers say.

Using homo/hetero-epitaxial devices fabricated on silicon carbide holds promise for revolutionary improvements in the cost, size, weight, and performance of a broad range of military RF, power-management, and power-distribution components, experts say.

SiC is an emerging power semiconductor material that has electrical, thermal, and mechanical properties that allow it to surpass the performance of conventional silicon (Si) power technology, Army researchers say. The Army is considering high-voltage switches for applications that require switches to operate in a totem-pole configuration at plus 15,000 volts and minus 10,000 volts at a peak of 30 amps and a frequency of 35 kHz. Another application under consideration requires power switches and diodes to control the discharge of 20-kilovolt storage capacitors in a Marx-type power supply with 10-amp average current and 100-amp short-circuit currents. Traditional power packaging approaches today are the limiting factor in realizing the performance benefits of SiC power device technology, Army researchers say.

U.S. Army researchers is interested to push the state of the art in silicon carbide (SiC) semiconductor power electronics technology for next-generation high-voltage switching devices for military and commercial applications. The Army released a solicitation for the Silicon Carbide High-Voltage Power Technology (SiC HVPT) program, which focuses on SiC semiconductor switch design, epitaxial material growth, semiconductor device fabrication, and multi-die packaging for high-voltage application.

SiC power products

Silicon based insulated gate bipolar transistor (IGBT) technology has enabled the design of innovative power converters that achieved higher efficiency at lower costs.However, as the switching frequency increases, switching losses mount. That, in turn, generates more heat that needs to be correctly dissipated, raising costs and reducing system efficiency. Silicon carbide (SiC) technology drastically reduces switching losses, maintaining the same voltage-blocking capability but with unprecedented efficiency, better thermal management, and smaller size.

In the past few years, multiple suppliers have released 1,200-V SiC MOSFETs that offer high channel mobility, long oxide lifetime, and high threshold voltage stability. Solid State Devices, Inc. (SSDI) in La Mirada, Calif., is introducing the SFC35N120 1200-volt silicon carbide (SiC) power metal oxide silicon field-effect transistors (MOSFETs) for high-reliability aerospace and defense power electronics applications like high voltage DC-DC converters and PFC boost converters.

Using lifetime-accelerated techniques such as time-dependent dielectric breakdown (TDDB), researchers at the National Institute of Standards and Technology (NIST) in the United States have predicted the oxide lifetime of a primary manufacturer’s SiC MOS technology to exceed 100 years, even at junction temperatures higher than 200°C.

The next hot SiC topic is likely to be the so-called multi-chip power or hybrid module, integrating a conventional silicon transistor and a silicon carbide diode on the same physical device. These modules can operate at higher temperatures by providing a high breakdown voltage. They promise high-efficiency operation and further downsizing of equipment.

References and Resources also include:

https://www.eetimes.com/sic-devices-boost-power-system-efficiency-in-aircraft/#

https://www.militaryaerospace.com/articles/2013/01/Army-SiC-power.html

https://www.eetimes.eu/sic-mosfets-bring-disruptive-breakthroughs-to-power-systems/

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis