Available and affordable energy has so far led to spectacular industrialization and development, but with growth accelerating in developing countries, demands on non-renewable energy sources are reaching their limits. Moreover, the recent confirmation that global warming is due to the increase of greenhouse gases in the atmosphere, together with the uneven global distribution of energy sources, urgently requires drastic changes in the way we generate and supply energy.

To deal with these rapid changes we need to simultaneously develop innovative strategies to regulate the price of carbon emissions, reduce the costs of generating energy from renewable sources, and develop greener, cheaper and scalable technologies for energy production and storage.

The sustainable growth of renewable energies depend on the availability of key materials, for example Lithium is the key limiting resource for most batteries – while rare earth metals, in particular “lanthanides” such as neodymium, are required for the magnets in wind turbine generators. Copper is the conductor of choice for wind power, being used in the generator windings, power cables, transformers and inverters.

US Department of Defense pursues a three-pronged strategy to secure supplies of rare earth elements, which consists of diversification of supply, pursuit of substitutes, and a focus on reclamation of waste as part of a larger U.S. Government recycling effort

The investigations for the use of more efficient materials could represent a transformation for the electric sector, which would be reflected in proposals that accelerate a technological deployment aimed at taking advantage of the energy coming from nature

Critical Energy materials

Task forces working for the European Commission have identified such raw materials as “critical”, meaning that they are of high economic importance to the EU while entailing high supply risks(EU COM,2014).

A recent study has analysed risks to European renewable industries from the Chinese supply of critical raw materials. The offshore wind sector was found to be the most vulnerable of the renewable industries to supply risks. EU and industry strategies should be able to deal with these supply risks in the short term, but there are potential long-term risks to solar and wind sectors.

By 2030 the EU aims to generate 27% of its energy from renewable sources. However, the renewable-energy sector in Europe is heavily reliant on China for the supply of raw materials critical for the development of technology such as solar cells and wind turbines.

In recent years, the Chinese government has moved towards greater state control of critical raw materials. The researchers say this is partly due to the environmental and health problems associated with extracting these materials, but also to ensure a domestic supply for its own, growing renewable-energy industries.

China is also concerned by the low prices they receive for these materials and has a desire to improve the competitiveness of its own renewable sectors. Consequent policies, such as the introduction of export licenses in 2015, are likely to increase the costs of raw materials for EU companies.

This study examined the supply of five critical raw materials: tellurium, gallium and indium (used in making solar cells), neodymium and dysprosium (used in manufacturing offshore wind turbines), all identified as at high risk for future supply due to supply being concentrated in only a few countries as well as likely increases in demand from renewable sectors.

The EU depends least on the Chinese supply of tellurium — 20% of which is sourced from China — followed by indium (58%), gallium (69%), neodymium (90%) and dysprosium (99%). Solar companies, therefore, have lower potential supply risks, as there are alternative supply sources of tellurium, indium and gallium (tellurium from Japan, Belgium and Sweden; small quantities of indium from Belgium, Germany, Italy, the Netherlands and the UK; while gallium production facilities are currently being built in France) and prices for these materials are currently low. In contrast, the European wind-energy sector is dependent on the continued supply of neodymium and dysprosium — 90% and 99% imported from China respectively.

In the long term, the most effective strategies to deal with uncertain supply from China are to look for alternative supply chains and to reduce the need for critical materials in renewable technologies. The EU is promoting research (e.g. Replacement and Original Magnet Engineering Options (ROMEO), Suprapower project, INNWIND.EU and EcoSwing) to develop renewable-energy technologies that do not depend on critical raw materials.

Recycling, in the long term, may also be a potential way to reduce mineral shortages. Recycling is currently more promising for indium and gallium than for tellurium and is currently not feasible for neodymium and dysprosium. Further R&D in recycling and alternative technologies to reduce dependence on these materials should, therefore, be a continued priority.

The development of alternative technologies less reliant on these raw materials, and methods to recycle these materials is, therefore, a priority.

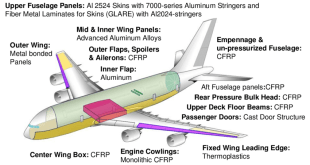

Carbon fiber resins

Traditionally, wind propellers are made of fiberglass; however, specialists are also developing ways to bring carbon fiber compounds to these designs.

Composite carbon fiber resins are more expensive than their glass fiber equivalents, but they are also lighter and stiffer, allowing the creation of longer propellers. “The longer the blade, the more wind it captures,” explained Shridhar Nath, leader in Compound Technology at GE Global Research.

Ceramic matrix composites can withstand temperatures up to 1315 ° C and are used in jet engines and gas turbines. For its part, the polymer compounds are made of glass fiber or carbon and are used in the manufacture of wind turbines. Both are lightweight and durable, therefore, they are ideal for making giant rotor blades. Likewise, they do not rust, nor wear out like metals, so they can withstand harsh environments for longer.

Circuit Breaker Maintenance

Lithium hydroxide Lithium ion batteries are used in smart phones, tools and electric vehicles ranging from transportation to heavy duty mining equipment. It could be said that they are the main batteries in the market, but they can still be improved. An example of this is the announcement made by the Avalon Advanced Materials, in June 2017, about the refinement of high purity lithium hydroxide.

According to this Canadian company, purity is essential to create better lithium batteries. “Maximizing the density of energy means being able to store the largest amount of it in a small space, so the battery can easily fit into different devices or vehicles and recharge quickly. As lithium hydroxide becomes purer, the companies will develop more durable cells, “said the manager.

Solar cells of perovskite

It is not so famous, but the perovskite has put a lot of heads in the scientific community during the last five years. In the Sargent Group, an institute affiliated with the University of Toronto, researchers have created a component of solar energy collection derived from this material capable of achieving up to 20 percent efficiency.

Although they do not reach the levels of silicon-based solar cells currently on the market (with 25 percent efficiency), those made with perovskite ore could become the leading technology in the near future.

” Perovskites are easier to work with because they self-assemble at room temperature, compared to the high temperature and pressure required for conventional semiconductors,” said Dr. Alex Ip, director of Research and Partnerships at Sargent Group.

Arguably, they are almost perfectly built for the processing of solar energy, added the manager, because its performance is so high that much of the research focuses on how to ensure that they are stable and how they can tune in the absorption of energy that is intended.

Nanostructured catalysts

Also at the Sargent Group, researchers are experimenting with nanostructured catalysts to convert carbon dioxide into other molecules, such as ethanol and ethylene, which have promising applications in energy storage at home.

This could be the answer to the challenge of intermittency in renewable sources. “The need is to find certain ways to store the energy to use it when required. Once you have the energy in chemical form, it does not discharge, but it is ready to become, “said Dr. Alex Ip.

For example, a house with its own sunroof could store surplus energy (such as ethanol) and save it for times when there is not much sun, such as the winter season. “The CO 2 used in this process would come directly from the air, which is why a lot of research is being done because the demand for these materials can be very high,” he added.

Meanwhile, it is clear that the pressure for manufacturers to meet market expectations is increasing and researchers will continue to examine the advanced materials that are necessary to achieve a greener future.

Petrolithium – Tech Breakthrough Could Transform Lithium Production

MGX Minerals Inc. (MGXMF) in their upcoming “petrolithium” pilot project, are going to prove the economic viability of processing lithium production from petroleum brine water. In order to reach NI 43-101 compliance for this resource, MGX is expected to prove that lithium production is commercially viable, and overall possible.

Currently, the world’s lithium supplies come from one of two production methods: solar evaporation, and hard rock mining. Both have their pros and cons, including a large difference in production time, cost, and availability.

Both the conventional method of solar evaporation, and MGX’s proprietary process involve separating lithium from a salt brine. However, the conventional method requires 18-months to produce the lithium, and utilizes a massive surface footprint to do so. The “petrolithium” concept, requires very little surface footprint, and is expected to produce lithium within hours instead of many months.

The process involves two stages, with the first being the removal of particulates and other dissolved materials, including emulsified oil, colloids and heavy metals, which otherwise may interfere with the mineral extraction phase. This first step is essential in providing the lithium production phase with a clean and consistent flow of lithium-bearing brine and other minerals for extraction. It’s in this step that the expertise of PurLucid’s technology is essential. The second phase is the one that everyone has their eyes on. This is where the separation out of the lithium and other valuable minerals takes place.

References and Resources also include:

http://systemprotection.in/innovative-materials-renewable-energy/

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis