Introduction

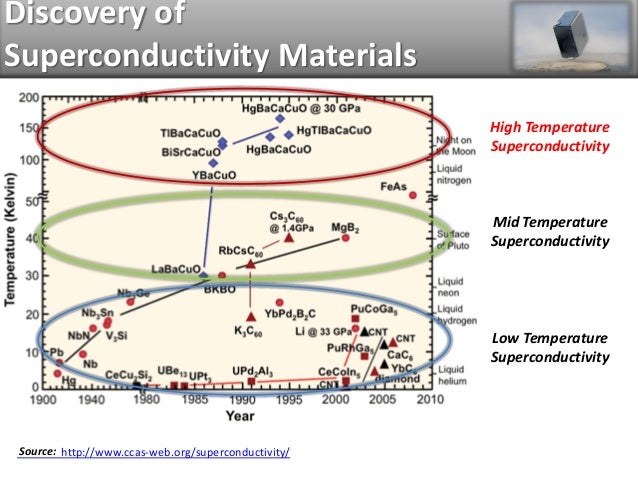

In 1911, a Dutch scientist stumbled upon a phenomenon that would change the course of science and technology forever. Superconductors, a class of materials capable of conducting electricity with zero resistance, were initially discovered to thrive only at temperatures near absolute zero. These early superconductors, known as Low-Temperature Superconductors (LTS), were limited in their practical applications due to the extreme cooling requirements.

Fast forward to the late 1980s, and the world of superconductivity experienced a monumental shift with the discovery of high-temperature superconductors (HTS). This newfound class of materials could exhibit superconductivity at significantly higher temperatures, opening up a world of possibilities for energy-efficient technologies and innovations. In this article, we will delve into the materials and technologies driving high-temperature superconductors, pushing the boundaries of what is possible in the realm of superconductivity.

The Quest for High-Temperature Superconductors

Conventional superconductors typically require temperatures close to absolute zero (-273.15°C or -459.67°F) to exhibit their remarkable properties. This limitation hindered their widespread use in practical applications. The discovery of high-temperature superconductors in the late 1980s, which can operate at significantly higher temperatures, marked a turning point in the field.

High-temperature superconductors can function at temperatures above the boiling point of liquid nitrogen (-196°C or -320.8°F), making them more accessible for practical applications. This breakthrough ignited a flurry of research into these materials, as scientists sought to understand the underlying mechanisms and potential applications.

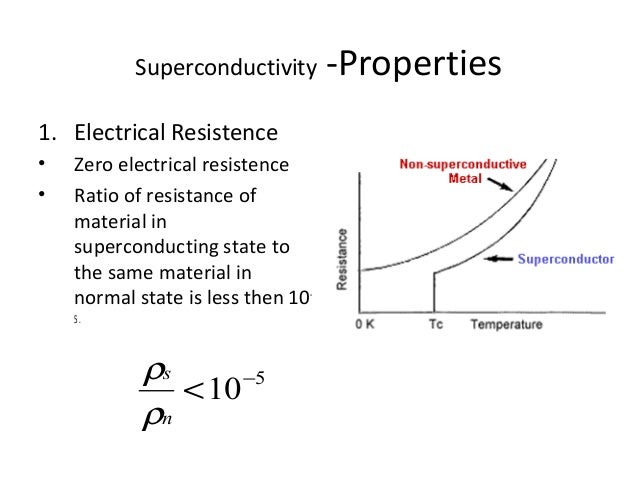

These materials called Superconductors have unique properties including, Zero resistance to direct current; Extremely high current carrying density; Extremely low resistance at high frequencies; Extremely low signal dispersion; High sensitivity to magnetic field; Exclusion of externally applied magnetic field; Rapid single flux quantum transfer; and Close to speed of light signal transmission.

The Mechanism Behind HTS

Understanding the mechanism behind high-temperature superconductivity remains a challenging task. While conventional superconductivity can be explained by the Bardeen-Cooper-Schrieffer (BCS) theory, high-temperature superconductors don’t fit neatly into this framework. Instead, scientists believe that the pairing mechanism in HTS involves complex interactions between electrons, known as “strongly correlated” electrons.

The exact nature of these interactions is still a subject of active research, and unlocking the secrets of high-temperature superconductivity could lead to even more groundbreaking discoveries in the future.

For in depth understanding on HTS superconductors technology and applications please visit: Superconductivity 2.0: Advances in HTS Materials and Technologies

Applications of HTS

Superconductivity endows materials with two remarkable properties: zero electrical resistance and the expulsion of any external magnetic field, a phenomenon known as the Meissner effect. This unique behavior allows for intriguing possibilities, including levitation, which could revolutionize transportation with the advent of frictionless, high-speed maglev trains.

The potential applications of high-temperature superconductors are vast and exciting. Here are some areas where HTS is making a significant impact:

- Energy Transmission: HTS can be used to develop highly efficient power transmission lines with minimal energy loss. This could revolutionize the way electricity is delivered over long distances.

- Magnetic Levitation (Maglev) Trains: Superconducting materials enable the development of high-speed trains that levitate above tracks, eliminating friction and enabling faster energy-efficient transportation. Maglev trains that use HTS materials for levitation and propulsion could travel at incredible speeds with minimal energy consumption.

- Medical Imaging: Superconducting magnets are crucial for high-resolution medical imaging techniques like MRI, making diagnoses more accurate and comfortable for patients. High-temperature superconducting magnets are already being used in advanced medical imaging techniques like magnetic resonance imaging (MRI), offering higher resolution and shorter scan times.

- Energy Storage: Superconducting energy storage systems have the potential to store large amounts of energy with minimal losses, improving the efficiency and reliability of electrical grids.

- Particle Accelerators: HTS materials are used in the construction of powerful particle accelerators for research in particle physics and materials science.

- Efficient Power Grids: Superconducting power lines have the potential to transmit electricity with virtually no loss, which could save up to 200 million megawatt hours (MWh) of energy annually, reducing costs and environmental impact.

- Faster Electronics: Superconducting materials can be used to create faster and more efficient digital logic and memory devices, powering the next generation of electronics.

- Fusion Energy: Superconductors play a vital role in the construction of tokamak machines, which harness the power of nuclear fusion for a clean and virtually limitless energy source.

Materials Driving HTS

High-temperature superconductors come in various forms, but one of the most famous classes of HTS materials is the cuprate superconductors. These materials are primarily composed of copper oxides and exhibit superconductivity at relatively high temperatures when doped with specific elements.

One notable cuprate superconductor is Yttrium Barium Copper Oxide (YBCO). YBCO was the first high-temperature superconductor discovered and can achieve superconducting states at temperatures around -181°C (-294°F). The high transition temperature of YBCO sparked significant interest and research in the field.

Another class of high-temperature superconductors includes iron-based superconductors (FeSC). These materials are based on iron and are more recently discovered compared to cuprates. They have the advantage of being more abundant and easier to synthesize, which could make them a more practical choice for certain applications.

In the world of high-temperature superconductors, there have been significant breakthroughs and advancements:

- Cuprate Superconductors: Materials like Yttrium Barium Copper Oxide (YBCO) were among the first high-temperature superconductors discovered. YBCO can achieve superconducting states at temperatures around -181°C (-294°F).

- Iron-Based Superconductors (FeSC): Iron-based superconductors are more recent additions to the high-temperature superconductivity family. These materials are more abundant and easier to synthesize, making them attractive for various applications.

- Record-Breaking Temperatures: Scientists have been working on pushing the boundaries of HTS by discovering materials that can function at higher temperatures. Some compounds have shown promise at -95°F, which is higher than any natural temperature on Earth.

- Room-Temperature Superconductors: The holy grail of superconductivity is the development of room-temperature superconductors, which would eliminate the need for costly cryogenic cooling. Some recent experiments have hinted at the possibility of achieving superconductivity at higher temperatures, potentially revolutionizing the field.

Promising Materials

In the quest for room-temperature superconductors, researchers are exploring various materials and approaches:

- Hydrogen-Rich Compounds: Hydrogen-rich compounds, such as hydrogen, magnesium, and lithium mixtures, have shown potential for superconductivity at extremely high pressures, up to 2.5 million times Earth’s atmospheric pressure.

- Carbonaceous Sulfur Hydrides: Scientists have explored materials like carbonaceous sulfur hydrides, which exhibit superconductivity at temperatures as high as 58°F when subjected to high pressure.

- Graphene Twisted at Precise Angles: Researchers have found that by twisting two layers of graphene at specific angles, they can induce superconductivity, opening up possibilities for practical applications.

- REBCO Tapes: Rare Earth Barium Copper Oxide (REBCO) tapes have shown promise due to their high current-carrying capacity, making them ideal for building more powerful and compact superconducting magnets.

The discoveries and evolution of high-temperature superconductors (HTS) have seen significant developments over the years:

- Discovery of MgB2 (Magnesium Diboride): In 2001, scientists discovered that MgB2 is a high-temperature superconductor, falling between low-temperature and high-temperature superconductors. It operates partly through the formation of Cooper pairs and exhibits outstanding conductivity when cold, making it suitable for potential applications in long-distance power transmission.

- BSCCO (Bismuth Strontium Calcium Copper Oxide): Following the discovery of MgB2, researchers explored copper oxide compounds like BSCCO as potential high-temperature superconductors. Different forms of BSCCO, such as Bi-2223 and Bi-2212, were developed and applied in various technologies, including transmission cables, transformers, motors, generators, and magnets.

- ReBCO (Rare Earth Barium Copper Oxide) and YBCO (Yttrium Barium Copper Oxide): ReBCO and YBCO are other high-temperature superconductors with transition temperatures around -181 degrees Celsius. These materials have been used in the development of high-field magnets and other applications like power transmission cables, motors, generators, and microwave filters.

- New Superconducting Materials: In 2019, scientists predicted the existence of hydrogen-rich compounds that could potentially conduct electricity without resistance at temperatures up to 200°C, under extremely high pressure conditions. These materials offer unique possibilities for energy transmission and storage.

- Room-Temperature Superconductors: In 2020, researchers at the University of Rochester achieved a groundbreaking milestone by creating a material exhibiting superconductivity at room temperature. This achievement has the potential to revolutionize energy transmission, computer systems, and various technological applications.

- Graphene: Scientists have also explored the potential of double layers of graphene to conduct electricity without resistance. By adjusting the twist angle between the layers or using specific production methods, flat band areas in the electronic structure of graphene were identified, which could support superconductivity.

- Miniaturized High-Field Magnets: National MagLab developed a small, compact coil-based magnet in 2019 that generated a world-record 45.5 tesla magnetic field. This innovation opens up possibilities for smaller, more efficient magnets with applications in particle detectors, nuclear fusion reactors, and medical diagnostics.

- Advancements in Superconducting Materials: The use of advanced superconducting materials like REBCO (Rare Earth Barium Copper Oxide) has led to magnets that can carry more current and operate at higher temperatures than traditional niobium-based superconductors. These materials are crucial for achieving stronger magnetic fields and reducing heat dissipation.

- Ambient Pressure Superconductivity: In 2023, researchers at the University of Rochester achieved superconductivity at ambient temperature (69 degrees Fahrenheit) and relatively high but practical pressures of 10 kilobars using nitrogen-doped lutetium hydride (NDLH). This discovery holds the promise of practical applications of superconductivity at less extreme conditions.

- “Reddmatters” Superconductors: In December 2020, a new class of high-temperature superconductors called “reddmatters” was discovered, capable of conducting electricity without resistance at temperatures up to 15 degrees Celsius. These superconductors have the potential to revolutionize energy storage, transportation, and computing, although they require further study for stability at ambient pressure.

Recent Breakthrough

University of Rochester

In March 2023, University of Rochester researchers achieved a historic milestone by creating a superconducting material that operates at both a relatively high temperature and a lower pressure suitable for practical applications. The material, called nitrogen-doped lutetium hydride (NDLH), was found to exhibit superconductivity at a temperature of 69 degrees Fahrenheit and a pressure of 10 kilobars (approximately 145,000 pounds per square inch, psi).

This achievement is significant because it represents a step toward achieving “ambient superconductivity,” where superconducting materials can function under everyday conditions. While the pressure involved (145,000 psi) might seem high compared to sea level pressure (about 15 psi), it is within the range of strain engineering techniques used in chip manufacturing.

In a related development, the University of Rochester researchers had previously discovered a class of high-temperature superconductors known as “reddmatters” in December 2020. These superconductors, composed of copper oxide, carbon, and oxygen, exhibited resistance-free electrical conductivity at temperatures up to 15 degrees Celsius. However, it’s important to note that these reddmatters still required high-pressure synthesis techniques and were not yet stable at ambient pressure, necessitating further research for practical applications in fields such as energy storage, transportation, and computing.

Korea University

In July 22nd 2023, Sukbae Lee, Ji-Hoon Kim and Young-Wan Kwon — three scientists from Korea University in Seoul — published a research paper that many said could change the world as we know it.

Within the past decade, the appearance of new materials that superconduct at relatively balmy temperatures, but only under extreme pressures, has brought a slight yet significant alteration in the quest. To be truly grail-like, a newly synthesized superconductor cannot merely carry electrical current without resistance at room temperature. It must also do it at ambient pressure for it to have practical applications beyond the laboratory – such as levitating trains, efficient power lines or cheaper MRI machines.

Physicists in Korea have reported a potential breakthrough in the quest for room-temperature, ambient-pressure superconductors. In a not-yet-peer-reviewed paper titled “The First Room-Temperature Ambient-Pressure Superconductor,” researchers at the Quantum Energy Research Centre (Q-Centre) in Seoul claim that a modified form of the mineral lead apatite exhibits signs of superconductivity under everyday conditions, including resistance-free current flow, the Meissner effect (expulsion of magnetic fields), and critical transition temperatures.

To strengthen their claims, the researchers published another paper providing more details on the material’s synthesis and demonstrated the Meissner effect in a video. However, experts have urged caution, highlighting potential issues with the data presented. One physicist questioned whether the levitation demonstrated in the video could be solely attributed to superconductivity, as other phenomena could cause levitation.

Another concern was raised about discrepancies in the data presented in the two papers, particularly regarding magnetic susceptibility. The scientific community will need to await further research and replication of these findings to confirm the legitimacy of this potential room-temperature superconductor. Despite the excitement, scientists remain cautious, emphasizing the need for independent verification before confirming a groundbreaking discovery in superconductivity.

These developments represent significant strides in the field of superconductivity, with potential applications ranging from power transmission to medical diagnostics and beyond. Researchers continue to explore new materials and conditions to further advance the practical utility of superconductors.

Challenges and Future Directions

Superconductors have come a long way since their discovery in 1911, and the field of high-temperature superconductors continues to evolve rapidly. Despite the tremendous progress made in the field of high-temperature superconductivity, significant challenges remain. One of the major obstacles is the high cost of manufacturing and cooling these materials. Researchers are actively working on finding more cost-effective and practical solutions to make HTS technologies more accessible.

Additionally, a deeper understanding of the underlying physics of high-temperature superconductors is needed to unlock their full potential. New materials with even higher transition temperatures and improved performance are also actively sought after.

While challenges like cost-effective manufacturing and achieving room-temperature superconductivity remain, researchers are making significant strides. If room-temperature superconductors become a reality, they could reshape entire industries, from energy transmission to transportation, electronics, and beyond.

Conclusion

High-temperature superconductors have redefined our understanding of superconductivity and opened up a world of possibilities for energy-efficient technologies and innovations. As scientists continue to investigate the materials and technologies behind HTS, we can expect to see even more groundbreaking applications that push the boundaries of what is possible in the realm of superconductivity.

As scientists continue to investigate and experiment with various materials and technologies, we stand on the precipice of transformative advancements that could change the way we power our world, travel, and conduct research. Superconductors are no longer confined to the frigid temperatures of their early days; they are reaching new heights and temperatures, promising a future where energy efficiency and innovation know no bounds.

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis