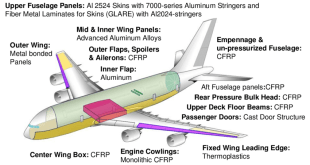

Recent advances of high power solid state lasers promises necessary laser power levels required for the Directed Energy Weapons (DEW) systems. However, inefficiencies of the laser components still generate too much waste heat to be managed by conventional liquid cooling systems, especially in an airborne platform where compactness, light-weight and energy-efficiency are the primary requirements. The DEW systems typically operate in a pulse mode generating very high peak heat that exceeds the capacities of conventional cooling systems. A heat storage system can be a solution to manage such highly transient heat loads and improve system performance without relying on oversized cooling systems.

The laser in weapon is made by stacking many laser bars which are cooled traditionally by a “microchannel” cooler, in which water is rapidly circulated through channels within the heatsink. But the small bore of the microchannels (tens of microns) makes it easy for them to be clogged by particulates. Thus, the water must be stringently conditioned and filtered, and large, heavy, high pressure pumps must be employed to circulate it rapidly enough to achieve the required level of cooling in these traditional bars.

Furthermore, traditional diode bars are usually placed directly on the heatsink in order to achieve good thermal contact. However, this makes the microchannel cooler part of the electrical circuit, thus necessitating the use of deionized water in order to avoid a short circuit. This imposes yet another requirement that increases cost and complexity.

Thermal management is collecting heat in one location and then transporting it to a place where it can be safely rejected. A typical system will consist of some kind of cold plate (or liquid-cooled enclosure) and a plumbing system that will move the liquid or liquid/vapor mix to where the heat exchanger is located.

The heat exchanger can be a simple radiator (in the case of a liquid-to-air heat exchanger) or something more complex such as a liquid-to-liquid heat exchanger. Any system solution is totally dependent upon the platform and the environment. Components are needed to collect (cold plates); move (pipes, connectors, and pumps), and dissipate (heat exchangers) the heat. Therefore, designing an efficient and SWaP (size, weight, and power ) focused solution requires a wide-ranging portfolio of components and systems experience as well as the engineering know-how and design flexibility to tackle today’s highly complex thermal management challenges.

Conventional heat storage systems have used Phase Change Materials (PCMs) such as paraffin wax. Phase Change Materials (PCMs) store thermal energy during the phase change from solid to liquid, since the latent heat from melting or freezing is at least 1-2 orders of magnitude higher than the energy stored by the specific heat.

PCM systems typically suffer from low thermal conductivities and consequently have to use bulky host structures of high thermal conductivity materials for heat transfer enhancement. In addition, the PCMs’ low heat storage density requires excessively large system volumes to meet the DEW heat storage system requirements.

In contrast, the metal hydride systems can provide superior volumetric heat storage capacity as compared to the PCMs. For example, Ca0.2 M0.8Ni5, a commercial hydride, has a heat storage density of 853.3MJ/m³ in raw material condition, while paraffin (Calwax 130), a common organic PCM has a heat storage capacity of 177.5MJ/m³. The greater volumetric heat storage capacity of metal hydride material means more compact design than conventional Phase Change Material (PCM) systems. Other exclusive advantages of the metal hydride system are fast thermal response time and active heat pumping capability required for precision temperature control and on-demand cooling.

Metal hydrides are the binary combination of hydrogen and a metal or metal alloy. Metal hydrides have been used in many industrial applications such as battery electrode material, hydrogen storage medium and heat pump system

Metal hydride systems

In contrast, the metal hydride systems can provide superior volumetric heat storage capacity as compared to the PCMs. For example, Ca0.2 M0.8Ni5, a commercial hydride, has a heat storage density of 853.3MJ/m³ in raw material condition, while paraffin, a common organic PCM has a heat storage capacity of 177.5MJ/m³.

The greater volumetric heat storage capacity of metal hydride material means more compact design than conventional Phase Change Material (PCM) systems. Other exclusive advantages of the metal hydride system are fast thermal response time and active heat pumping capability required for precision temperature control and on-demand cooling.

The compressor-driven metal hydride heat storage system consists of a metal hydride reactor (metal hydride heat storage/heat exchanger unit), a hydrogen compressor and a hydrogen container. The metal hydride system temporarily stores the laser waste heat during the short heat storage period and later dissipates the stored heat over the relatively long regeneration period.

The metal hydride system consisted of three separate loops: a water coolant loop (in blue), a hydrogen loop (in red) and compressed air loop (in green dash). The hydrogen loop included a metal hydride reactor, a hydrogen compressor and a hydrogen container.

Heat Storage Systems

Typical operation for the solid state laser DEW systems requires two main operations: (1) “heat storage” for lasing and (2) “regeneration” for thermal recovery. The metal hydride system temporarily stores the laser waste heat during the short heat storage period and later dissipates the stored heat over the relatively long regeneration period. The solid state laser systems use the laser gain materials of slab shape which dissipate the high heat flux heat (>100W/cm²) during a short lasing. During the lasing, the laser slab temperature should be maintained within allowable maximum spatial and temporal variations to avoid any harmful thermal stresses leading to mechanical fracture, as well as to enhance the laser optical output.

During the “heat storage”, the liquid cooling loop acquires the heat load from a laser heat source and transports and stores the heat into the metal hydride where the dehydriding (endothermic) reaction takes place. Then, the released hydrogen during the dehydriding reaction is compressed by a mechanical compressor and stored in a hydrogen container.

During the subsequent “regeneration” after the heat storage is complete, the entire system needs to be recovered to the initial condition. During the regeneration, the compressor drives the stored hydrogen back to the metal hydride where the hydriding (exothermic) reaction takes place and the heat is removed by the liquid cooling loop. After the regeneration completes, the system is ready for next cycle.

The inefficiencies of the laser components still generate too much waste heat to be managed by conventional liquid cooling systems, especially in an airborne platform where compactness, light-weight and energy-efficiency are the primary requirements. The DEW systems typically operate in a pulse mode generating very high peak heat that exceeds the capacities of conventional cooling systems. A heat storage system can be a solution to manage such highly transient heat loads and improve system performance without relying on oversized cooling systems.

Atomics’ Advanced Power Systems Division developed an advanced thermal energy storage device capable of cooling directed energy weapons (DEW).

The 3 megajoule device is the first large scale module capable of storing heat at a high rate as required for DEW. “We are very pleased with its performance, which shows that it can store heat at an average rate of 230 kilowatts. To put it into perspective, it’s the equivalent of melting about 20 pounds of ice in 13 seconds,” said Dr. Paul Clark, Manager, Advanced Power Systems of General Atomics.

Heat is stored in the 35 kilogram module by melting a wax-type phase change material. These materials, by themselves, cannot support the high heat transfer rate and must be combined with other materials to enhance their thermal properties and make them work.

Thermal management is one of the many challenges of DEW, which produce tremendous amounts of waste heat. Rejecting heat from these systems in real time is not practical, making thermal energy storage a necessity. High power lasers and high power microwave systems will both benefit from this technology.

The PCM systems typically suffer from low thermal conductivities and consequently have to use bulky host structures of high thermal conductivity materials for heat transfer enhancement. In addition, the PCMs’ low heat storage density requires excessively large system volumes to meet the DEW heat storage system requirements.

References and resources also include:

https://www.1-act.com/metal-hydride-heat-storage-technology-for-directed-energy-weapon-systems/

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis