In military terminology, a missile is a guided airborne ranged weapon capable of self-propelled flight usually by a jet engine or rocket motor. Missiles have five system components: targeting, guidance system, flight system, engine, and warhead. Missiles come in types adapted for different purposes: surface-to-surface and air-to-surface missiles (ballistic, cruise, anti-ship, anti-tank, etc.), surface-to-air missiles (and anti-ballistic), air-to-air missiles, and anti-satellite weapons.

Missiles are powered by an engine, generally either a type of rocket engine or jet engine. Rockets are generally of the solid-propellant type for ease of maintenance and fast deployment, although some larger ballistic missiles use liquid-propellant rockets. Jet engines are generally used in cruise missiles, most commonly of the turbojet type, due to its relative simplicity and low frontal area.

Long-range missiles may have multiple engine stages, particularly in those launched from the surface. These stages may all be of similar types or may include a mix of engine types − for example, surface-launched cruise missiles often have a rocket booster for launching and a jet engine for sustained flight.

Missile material requirements

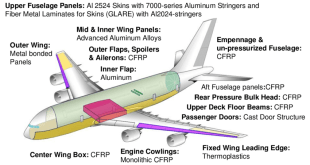

Some of the important factors during material selection are their High Specific Strength or strength to weight ratio. Materials with the highest specific strengths are typically fibers such as carbon fiber, glass fiber and various polymers, and these are frequently used to make composite materials (e.g. carbon fiber-epoxy)

High Specific modulus is a material’s property consisting of the elastic modulus per mass density of a material. It is also known as the stiffness to weight ratio or specific stiffness. The utility of specific modulus is to find materials which will produce structures with minimum weight, when the primary design limitation is deflection or physical deformation, rather than load at breaking—this is also known as a “stiffness-driven” structure. Many common structures are stiffness-driven over much of their use, such as airplane wings, bridges, masts, and bicycle frames.

High-temperature properties of the material, good corrosion resistance, high fracture toughness, Stiffness or deformation characteristics, easy fabricability, and reliable quality.

Some special requirements are High Pressure, High Temperature, Thermo-Structural needs, Soft Magnets. HED Permanent Magnets, Bi-metallics, Opto-Electronics and Electro-Optics.

Some of the types of materials required are Structural Metallic Materials, Composite Materials, Thermo-Structural Materials, Thermal Protection Materials, Special Materials, and Chemicals.

Aerodynamic calculations and flight predictions involve lengthy and numerous calculations and procedures and are more mathematical and theoretical in nature. The aerodynamic engineer is more of a theoretician and requires a powerful imagination to visualize the flight conditions. Hardware oriented engineers may not ‘enjoy’ such a nature of table and desk work after ‘living’ with the actual hardware’s. However, wind tunnel tests for simulation of flight conditions using missile models or full-scale ones, the experience of which may be comparable to actual flight tests of rockets, ejection mechanisms, separation systems and a score of other components and their behavior which one can actually ‘see’ and gain an easier appreciation.

Missile Materials

Alloys of magnesium, aluminium, titanium, and maraging steel are extensively used for airframe and propulsion systems. Airframe and propulsion systems of Missiles are generally made from aluminium and its alloys, steel, magnesium, and titanium. The major concern is the strength-to-weight ratio of the material. Higher this ratio the better.

Structural metallics

i) 15 CDV6 : Low carbon steel used in solid rocket motor case.

ii) M250 : Maraging steel with high strength and high toughness used in booster solid rocket motor case.

iii) Titanium alloy: (Ti-6Al-4V) used in high pressure gas bottles .

iv) Aluminium Alloys: used in liquid propellant tanks, engine components, airframe in Reusable Launch Vehicles. Types: AA 2219, AA2014, AA6061.

v) Magnesium/ Mg ‐Lithium alloys: used in upper stage structure like payload adopter, avionic decks, equipment bay structure.

vi) Powder metallurgy products: used in nozzle throat for bi‐propellant control thrusters.

Composites

Polymer materials and carbon-carbon composites are major nonmetallic materials.

i) Carbon F / Kevlar F – Epoxy Resin : used in solid motor case, pressure vessel, interstages,

payload adopter.

ii) Carbon C / Silica C – Phenolic Resin : used in ablative liners, nozzle throat inserts.

Thermo- Structural

i)Carbon Fibre/ Silicon Carbide Ceramic Matrix Used in nose-cap of heat-shield, leading edge

and control surface of RLV.

ii) SiC F/SiC Ceramic Matrix Composite: used in high temperature / hot structures

Thermal protection System

i) Carbon/Carbon Composite: used in nozzle throat, nosecone ( SiC Coating).

ii) Silica tiles: (Silica Fibre in Si gel ) used in space shuttle and SRE (capsule )mission.

iii) Polyurethane foam insulation for cryogenic propellant tanks and subsystems.

iv) Flexible Reusable Surface Insulation-FRSI Blanket / felt with Teflon coating used in

leeward surface of RLV.

Special Materials

Development of high purity electronic materials like silicon, indium, phosphorus, Cu clad materials, photo resists and epoxies are very important

i) Soft magnetic alloy: Fe-Co-V : used in torque motor in spacecraft.

ii) HED permanent magnet: Sm-Co : used in gyroscope, inertial navigation, guidance & control system, reaction momentum wheel in spacecraft.

iii) Bimetallics: (SS-Al and SS-Ti)used in Cryosystem for assembly of dissimilar items.

iv) Opto-electronics: used in photo sensors and photo diodes and photo voltaic devices for power generation in satellites.

v) Electro-optics: used in High resolution imaging in Spacecrafts.

On account of the high temperatures encountered by missiles flying at supersonic speeds and needs for lighter materials, newer materials are coming into usage. Fibre-reinforced plastics (FRP) like the carbon-carbon variety, graphite compounds, molybdenum, beryllium, etc.

Chemicals

i) Different coating materials are used for protection and imparting certain characteristics to surfaces, potting of connectors.

ii) Variety of adhesives/ bonding agents are used in processing, installation of sensors, assembly and integration operations.

iii) Most of these chemicals are polymers.

Rocket motor cases

Material selection is a very critical design decision, which has a profound influence on the entire development program for rocket motor cases. In the selection process, the main performance parameters and the most appropriate fabrication technology with proven processes must be considered.

Radome

Future missile systems require more aggressive trajectories, operational capability in adverse weather and improved radar performance. This has led designers to consider high temperature composites (i.e. CMCs) in place of traditional monolithic ceramics for missile radomes. Compared to monolithic ceramics, CMCs offer improved strength and toughness coupled with graceful failure permitting their use in more demanding aerothermal and weather environments.

Maraging steel and D6AC are found to be the preferred materials for rocket motor cases for critical missions. HSLA steels are appropriate for less-critical applications, in which rocket motor cases are required in very large numbers (e.g., flow-formed AISI 4130 motor cases). For the selection of an appropriate manufacturing method, the major parameters considered are dimensional accuracy, cost of production, minimum material waste, and flexibility in design.

Non-Eroding Nozzle Materials

The operational environment within high-performance rocket motors is very severe, especially in the throat region. Hot-walled materials may be required to operate at temperatures that approach 6000°F in a very aggressive thermal-chemical environment. Non-eroding throat insert materials can significantly improve the overall performance of the rocket motor compared to an eroding throat.

Suitable non-eroding materials must meet the four following requirements:

- High melting temperature

- High resistance to mechanical erosion

- High resistance to chemical erosion

- Thermal shock resistance

Most materials that satisfy the first three requirements are inherently plagued with poor thermal shock resistance. It has been demonstrated through detailed analytical and experimental efforts, including test motor firings, that innovative designs are achievable in which the selected throat insert materials are capable of performing exceptionally well within these extreme environments when properly designed, fabricated, and assembled.

References and Resources also include:

http://www.m-r-d.com/wpr/our-work/advanced-missile-components/

https://webstor.srmist.edu.in/web_assets/srm_mainsite/files/files/MATERIALS%20FOR%20R&M.pdf

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis