The past few years have seen the introduction of a number of wearable technologies, from fitness trackers to smart watches but with the increasing use of smart textiles, wearables are set to become ‘disappearables’ as the devices merge with textiles. Unlike today’s ‘wearables’ tomorrow’s devices will be fully integrated into the the garment through the use of conductive fibres, multilayer 3D printed structures and two dimensional materials such as graphene.

Smart Textiles are a new generation of materials and systems with interesting multifunctional properties which, given their ability of being integrated into uniforms and platforms. Smart fabric is a traditional fabric with added interactive functionality such as power generation or storage, sensing, radio frequency functioning, human interface elements and/or assistive technology.

The purpose of smart fabrics is to provide added value to the wearer, whether that be for pleasure, performance, or safety. Smart fabrics—also called electronic textiles, e-textiles, smart garments, and intelligent fabrics—have some type of digital component embedded in them. The technology is incorporated into the fabric through various methods, such as conductive fibers and multi-layer 3D printing.

The integration of IoT sensors in smart clothes to determine the presence and level of hazardous gas in the environment and allow the military to mitigate the harm caused by hazardous gases efficiently. Acellent Technologies Inc., a US-based company, in collaboration with the US Army, developed the SmartArmor system that can be used for the in-service monitoring of the health of body armor structures. The system is specially designed to monitor a personal body armor comprising of SMART layer and software to increase the safety of the soldiers in a combat zone. Since clothing is the first layer of protection for the wearer and forms an important protective measure in defense operation against combat and environmental hazards, this segment is expected to witness highest growth during the forecast period.

Smart or Intelligent fabrics have even now become advanced to be able to sense and respond to a stimulus in their environment. These second-generation smart textiles accommodate sensors that can sense the external environmental changes and actuators, which act in accordance to the stimuli sensed. For example, rather than simply delivering heat when activated, an intelligent fabric will respond to ambient room temperatures or a person’s body temperature to cycle heating on or off as required to maintain a temperature set point.

Other applications include diagnostic fabrics that monitor vital signs and send information directly to a smartphone app that recommends the appropriate response action, or protective fabrics with active functional coatings that change color to warn their wearers of the presence of an environmental contaminant. Recently, Samsung has received a patent for smart T-shirts, equipped with sensors that can track and monitor the lungs’ functionality of wearers and provide advice through smartphones.

Intelligent fabrics require not only the core performance function, but also Closed-loop control combining sensors that collects information from the environment and actuators for responding to input from that sensor to close the loop. Smart textiles have applications in medical, sports, personal protective equipment, geo-protection, military, and aerospace sectors, where sensing and monitoring are already used and would only be made more efficient if integrated with textiles.

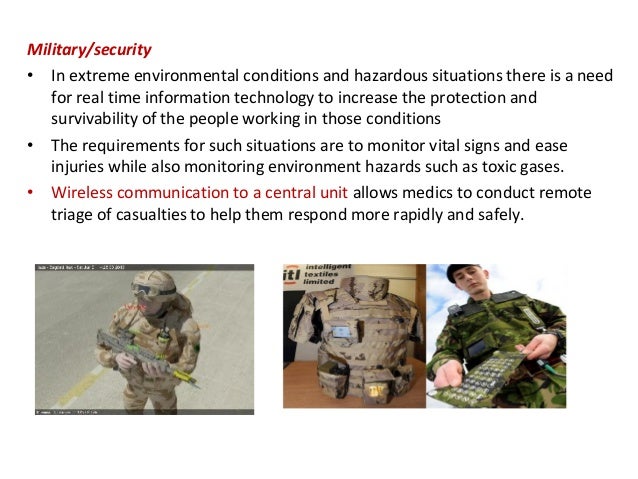

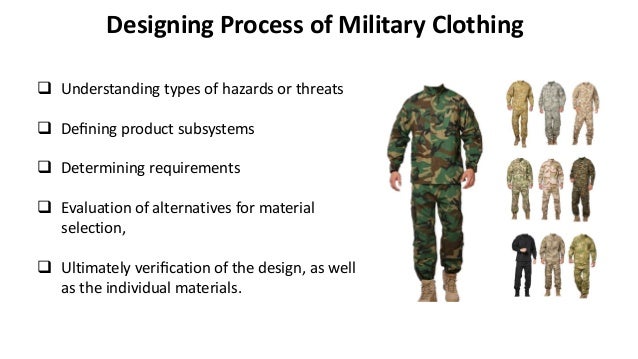

The growing need for supportive and performance-enhancing garments has led to the rapid induction of smart textiles in the military sector. Governments across the world are focusing on equipping their soldiers with sophisticated military clothing that enhances soldiers’ performance during combat operations.

Military Requirements

Military clothing is an important part of a combat soldier’s performance and plays a significant role in their protection. This becomes even more important when they are deployed under rugged circumstances and demanding conditions. Operation of Armed Forces personnel in harsh military terrains for extended tenure period necessitates protection from elements and battle hazards. Harsh military terrains can be Mountain environment characterized by treacherous terrains with extreme cold and hypoxia, Deserts characterized by extreme heat stress, Depths of underwater that can pose life threatening situation in case of a distressed submarine, Aviation hazards (such as deadly G-forces faced by fighter pilots during G-manoeuvres and fire hazards that may result from crash) etc.

Harsh military terrains exert profound effects on the physical and physiological performance of the soldiers and can impart serious health hazards on inadequately protected soldiers resulting in mission failure and avoidable loss of lives. The operation of military personnel in harsh terrains for extended tenure necessitates protection from elements and battle hazards.

Biological and chemical agents continue to pose severe threats because of their broad defensive and offensive potential. Recently, the threat of bioterrorism increased due to the concerns that non-state armed actors, such as terrorists and militia groups, could use biological agents to target air, water sources, food supplies, and other vital infrastructures. Furthermore, toxins and microbiological materials also pose a great threat to the mental health of the troops, which could affect the success of any military operations.

Clothing being the first layer of protection for the wearer, forms an important protective measure in military operation against combat and environmental hazards. Smart Textiles For Military improve performance of soldiers offering them more mobility and fast connectivity. While allowing the soldiers to carry out their operations smoothly; these textiles safeguard the army personnel from visual and infrared light as well as heat and sweat.

Smart and Intelligent textiles not only increase performance of soldiers, but also add various other functionalities that have never been realised before. The various functionalities where intelligent textiles are making inroads include health monitoring, communication (both wired and wireless), enhanced mobility, survivability, reduction of heat stress, reduction of logistic burdens, camouflage and signature management.

Some of the recent functionalities achieved by integration of e-textiles include physiological status monitoring, wearable power supplies, and sensing of environmental conditions as well as the detection of chemical and biological threats.

Constant technological innovations in this market have led to an added range of functionalities and capabilities to smart textiles used in the military sector. Also, manufacturers are developing smart textiles that have the potential for physiological and locational monitoring and energy harvesting.

Military Smart and Intelligent Textiles

Many countries are now investigating the application of various electronic devices integrated into textiles for military use. The special programme “Soldiers of the Future” was launched by the United States in the 1990s and investigated the benefits of smart textiles for soldiers. Two different training and education initiatives have been sponsored by North Atlantic Treaty Organization (NATO) on the application of advanced textiles for civil protection and defence.

In 2018, EDA launched a project, called STILE, “Smart TextILEs in defence: looking at the soldiers of the future”. This project was assigned to a consortium led by the Spanish AITEX research institute, in collaboration with two Portuguese organisations, CITEVE and INEGI. It’s objective was to come up with a proof of concept, integrating various functionalities such as signature management, monitoring of environmental parameters and CBR threats, flame retardancy, water and dirt repellence and anti-mosquito solution, physiological monitoring, temperature regulation, and communication and wireless exchanging data.

Signature management and Cloaking

A textile to provide a multispectral camouflage, with special focus on visual, Near InfraRed and thermal spectra, aiming at decreasing the visibility of the soldier in combat zones, in both static and moving positions.

Japanese scientist at the University of Tokyo has been developing a hi-tech cloak. This invisible cloak is developed by nanoparticles that reflect light, which makes the wearer look invisible. There’s a camera fitted on the back the of the cloak which records whatever happens behind the wearer and projects the image on the front of the cloak, creating the illusion that makes wearer looks invisible.

Monitoring of environmental parameters and CBR threats.

Several sensors integrated in the combat uniform in order to detect the presence of hazardous agents in the environment surrounding the soldier. The integration of IoT sensors in smart clothes to determine the presence and level of hazardous gas in the environment and allow the military to mitigate the harm caused by hazardous gases efficiently.

Smart fabric can detect and protect against toxic gases

Scientists from Dartmouth College in New Hampshire are developing smart fabrics that can detect the presence of hazardous gases as well as protect the wearer from their effects. The SOFT e-textile uses metal-organic frameworks (MOFs) to improve detection and protection from toxic chemicals. Known as SOFT (Self-Organised Framework on Textiles), the material is flexible and conductive, yet porous and washable. According to the Dartmouth team, the fabric is capable of real-time gas detection. It’s envisaged that the material would be worn by military and emergency services personnel in conjunction with a haz-mat suit, alerting the user to a breach in the primary barrier.

“By adding this fabric to a protective suit, sensors can alert the user if a chemical is penetrating the hazardous-material gear,” said Katherine Mirica, an assistant professor of chemistry at Dartmouth College. “This is not just passive protection, the textile can actively alarm a user if there is a tear or defect in the fabric, or if functional performance is diminished in any other way.”

The smart fabric works by using textile-supported electronic sensors based on materials known as metal-organic frameworks, or MOFs. In their research, published in the Journal of the American Chemical Society, the Dartmouth team showed that the material could identify the exhaust pollutant nitric oxide, as well as the poisonous and corrosive hydrogen sulphide. The researchers claim that the textiles can not only sense these gases, but are also capable of capturing and filtering the dangerous toxins.

“Metal-organic frameworks are the future of designer materials, just like plastics were in the post-WWII era,” said Mirica. “By integrating the MOFs into our SOFT devices, we dramatically enhance the performance of smart fabrics that are essential to safety and security.” While the technology requires further development before it can be used in wearable systems, the researchers believe the fabrication method has the potential to be extended into other systems, producing a range of new smart textiles with tunable properties.

Improved mobility.

The main aim of the smart textiles is to reduce the weight of the electronic gadgets, battery pack and connecting cables so as to improve survivability of soldier at war fields. The smart multifunctional textile system taking into account parameters such as ergonomics, homogeneous distribution of weight, wearers’ comfort, modularity, freedom of movement, and functional properties based on a body mapping study aiming at defining specific functionalities for each body area (such as flexibility, compression, and ventilation areas). Wearable electronic components, the most flexible, light and miniaturized elements were selected.

Flame retardancy, water and moisture repellence and anti mosquito solution.

Textile fibres and materials with flame retardant properties to avoid exposure to heat and flame. Other functionalities, such as water and moisture repellence and anti-mosquito were incorporated using the most innovative functional finishing technologies, by means of thermochromics formulations, colour fastness tests to washing cycles, and colour fastness tests to light.

The US military is making uniforms with built-in bug spray

Future US military uniforms could grant protection against disease-carrying mosquitoes by having insect repellent embedded within the fabric itself. Testing by military researchers has shown that specially manufactured nylon fibres can provide slow release of repellents for at least three days, more than the 8-to-12-hour protection provided by spraying common insect repellents such as DEET or picaridin on clothing and skin.

Physiological monitoring.

The monitoring of certain physiological parameters of the soldiers was carried out by means of specific sensors located in the inner layer of the smart multifunctional textile system, in contact with the body skin. The special stretching and flexible properties of the electrodes enabled the obtaining of a comfortable solution, without the need of hard and rigid elements. Thus, sensors capable of measuring parameters such as heart rate and respiration rate were integrated in the textile substrate through the use of conductive textiles and printed electronics techniques.

Temperature regulation.

A system capable of regulating the thermal comfort of the soldier, adapting to the weather conditions and considering the physical activity carried out needs to be incorporated to the combat uniform. This solution included both heating and cooling effects. Smart textiles are being integrated with adaptive insulation property to enhance warmth in military clothing, sleeping bags, and blankets.

Communication and wireless exchanging data.

All the sensors integrated in the smart multifunctional textile system are capable of sending the registered data via wireless networks, enabling the monitoring of different parameters related to the state of the soldier in the combat field. In the same way, the various electronic solutions can be adjusted, activated or deactivated from the control centre located in a smartphone. The information is shown by means of a mobile app that was ad hoc developed to show the valuable information in a user-friendly and intuitive way.

BAE joins ITL to deliver a revolutionary piece of new wearable technology which can turn clothing into networked technology

BAE has entered into exclusive partnership with world-leading e-textiles developer, Intelligent Textiles Limited (ITL), to deliver a revolutionary piece of new wearable technology which can turn clothing into networked technology. Broadsword® Spine® is an e-textile based layer that when added to a user’s clothing creates an invisible electronic network and power supply, by using conductive fabrics instead of wires and cables. With the innovative network, users can plug vital electronic devices straight into their vest, jacket or belt and have them instantly hooked into power and data via USB – all delivering an estimated 40 per cent weight saving per user versus alternative solutions.

“The problem a soldier faces at the moment is that he’s carrying 60 AA batteries [to power all the equipment he carries],” said Thompson. “He doesn’t know what state of charge those batteries are at, and they’re incredibly heavy. He also has wires and cables running around the system. He has snag hazards – when he’s going into a firefight, he can get caught on door handles and branches, so cables are a real no-no.”

Working together, our Company and ITL will be ready to deliver these lightweight devices to personnel including the armed forces, fire and rescue services and law enforcement, all of whom rely on carrying electronic equipment and having a durable power supply for long periods of use. Broadsword® Spine® is also designed to be robust enough to operate in the harshest environments, including being resistant to water, fire, humidity and shock – and can be easily recharged in the field via in-vehicle charging points or through simple battery replacements.

Wireless Charging

BAE Systems has created its Broadsword range of devices that revolve around a vest called Spine. Spine uses so-called e-textiles to wirelessly charge military equipment – and this energy use can be monitored using a smartphone app. Eight devices can be plugged in and charged at any one time, and the vest’s electrically conductive yarns can also be used to charge other gadgets wirelessly. BAE’s inductive seat charger transfers energy from a vehicle to the vest and all of this energy use can be monitored using a smartphone app.

The squaddies’ uniform was thus turned into a power- and data-distribution system containing a single battery pack, eliminating trailing wires and the need to spend 40 minutes at the end of each day checking whether the AA cells need replacing. The grant also allowed them to make the technology less conspicuous, using electromagnetic screening to prevent soldiers being detected by enemy troops while wearing their super-charged uniform.

Spine was developed by the London-based defence firm with Surrey-based Intelligent Textiles Design. It can power up and transfer data to and from equipment such as radios, cameras, smart helmets and torches, as well as smart weapons – effectively working as a portable hotspot.

Ballistic protection

Current research on military textiles includes the improvement in the ballistic protection level (which is the primary requirement), and the developments of new designs with integrated sensors and embedded sensing technologies in clothing, backpacks or tents for other functionalities. Acellent Technologies Inc., a US-based company, in collaboration with the US Army, developed the SmartArmor system that can be used for the in-service monitoring of the health of body armor structures. The system is specially designed to monitor a personal body armor comprising of SMART layer and software to increase the safety of the soldiers in a combat zone.

Smart Textile Technology

Smart Textiles now refers to materials capable of perceiving stimuli from the external environment and reacting to mechanical, thermal, and chemical manipulations by modifying their structure automatically or by detecting physiological and environmental data to transfer them to subjects capable of interpreting and using them.

A great deal of research is being carried out by military/defence research laboratories worldwide in collaboration with industries to develop technical textiles incorporating suitable smart material finishes for the alleviation of the dangers associated in the combat terrain. In April 2016, the University of Massachusetts and Institute for Soldier Nanotechnology were granted USD 75 million by the US Department of Defense, for the development of smart textiles.

Extended Cold weather clothing ensemble, High Altitude Pulmonary Oedema chambers, Anti-G suits, Flame retardant overalls, Submarine Escape Sets, Chemical warfare protection ensemble, liquid cooled garment for protection against hyperthermia etc., are fabricated from variety of technical textiles having special material properties.

Active smart textiles have the shape memory property and are chameleonic, water-resistant, vapor permeable and absorbing, and heat storage and thermos regulated fabrics. The camouflage technique that these textiles offer has prompted several countries to focus on the R&D of fiber optics, thermal sensitive materials, photosensitive materials, conductive polymers, and chemical-responsive fabrics.

Nano-materials, nano-biotechnology, and nano-electronics, electronic components such as actuators, control units, and sensors, are embedded into smart textiles. Flexible conductive materials such as conductive yarns and polymers, optical fibers, stainless steel wires, carbon nanotubes, piezoelectric materials in interaction with electronic devices are now inserted into clothing in a non-invasive way

Smart coatings — which may include CNT, resins or polymers — can be designed to deliver unique functionality and performance characteristics, including conductivity, bacterial resistance or sensing capabilities. Many smart coatings, including Battelle’s CNT conformal coating, can be added to a textile via the same methods used for more traditional coatings, including knife coating, transfer, Zimmer coating, roll-to-roll and spray coating.

US Army, Navy spin hollow microfiber filled with picaridin for insect-repellent textiles, reported in Jan 2022

A team of Army and Navy research scientists have engineered a hollow microfiber filled with the insect repellant picaridin. The hollow “core-shell” nylon fibers were created by coaxial electrospinning, according to their newly published U.S. patent application.

The problem with existing insect-repellent clothing (permethrin-treated) is that the liquid repellants eventually evaporate or get washed out. Others have tried to solve the problem by mixing DEET into the polymer base before it’s processed into fibers, or grafting DEET to the fibers. Another approach is microcapsules of insect repellent, which are imparted onto a material to provide long-term repellency with improved water resistance. But coating fabrics can change the way they feel.

The encapsulation of insect repellent (i.e. picaridin) into textile fibers via a bottom-up approach affords the potential to create fabrics and garments that exhibit a similar feel of existing fabrics, while also exhibiting superior performance. Incorporation of the active materials into the core of the fibers will greatly enhance the durability of these functionalities to laundering, especially when compared with surface treatments, strongly reducing the current health hazards present for surface treated fibers and increasing their environmental sustainability.

The insect repellent fibers have the potential to greatly reduce environmental and health risks during their lifecycle by 1) Increasing the longevity of functionalities after laundering, 2) Reducing direct skin contact of active additives by encapsulation within the core of a benign material, and 3) Generating fibers from which textiles and garments could be designed with functionalities localized and limited only to the areas in which they are needed.

In this work, picaridin was incorporated into nylon-6,6 nanofibers via monofilament and coaxial electrospinning. Compared to a monofilament construction, the sheath component of a coaxial fiber would aid in protecting additives in the core for more durable fabrics and act as a diffusion barrier for extended-release applications. The sheath material offers the opportunity to tune diffusion rates based on composition and afford additional control through the modulation of thickness.

Military Smart Textile market

The smart textiles for the military market is anticipated to grow at a CAGR of 26.14% during the 2021 – 2026 period, the textiles market size is expected to reach US$ 5.55 billion by 2025. In addition to the traditional demand for PPE – personal protective equipment (masks, gloves, shoes, clothing), the Covid19 pandemic has given further impetus to the development and diffusion of Smart Textiles.

The military & defence segment is estimated to hold the largest market share in 2019. Smart textiles, by sensing the hazardous environmental conditions, enhance the performance & safety of defence force and help them in rapidly responding to any casualties. Smart textiles for the military have evolved over time with the addition of several features to enhance their functionality. Governments around the world have given high importance on equipping their soldiers with the latest firearms. This importance by the governments has created a demand that has helped the growth of the global smart textiles market in the military sector.

BAE Systems, one of the key vendors in the market offers a wide range of products and security. The company, in collaboration with leading e-textiles developer ITL, has developed Broadsword Spine — a modern, wearable technology that can substitute for the heavy portable data and power supplies that are generally carried by military personnel.

Smart Textiles for Military Market is advancing rapidly with constant technological innovations that have led to an added range of functionalities and capabilities to smart textiles used in the military sector. Today, Integrated with adaptive insulation property smart textiles output intensified warmth in fabrics used in military sectors such as military clothing, sleeping bags, and blankets.

- The growing military spending and territorial issues between various countries are propelling the investments towards augmentation of the technologies for their armed forces. Such investments are focused on the development and deployment of advanced smart textiles for their military personnel, which is expected to propel the growth of the market.

- Currently, companies and research facilities are focusing on the various categories of technology-enabled fibers, such as dual-channel data transfer capable fibers, color-changing fibers, and fibers that can store electricity. Also, textile-based materials equipped with nanotechnology and electronics play a key role in the development of technologically advanced military uniforms and materials. The growing emphasis on the integration of such technologies into military textiles is expected to bolster the market prospects during the forecast period.

- The incorporation of stealth materials that can completely conceal the presence of military personnel is expected to accelerate the growth of the market in the coming years.

Worldwide militaries & defense sectors are striving to have their soldiers equipped with the latest firearms and micro electronic materials embedded in lightweight, sophisticated military clothing that enhances soldiers’ performance during battle or war operations. Leverage to this, governments across the world are fully convinced and emphasize upon camouflage optimization of their military personnel which has augmented the uptake of smart textiles in the military sectors.

Geographical Outlook

The Americas have dominated the global market and occupied the maximum market share. The security requirements of the Americas are rising considerably with the increasing threats from various militant groups along with territorial disputes. Such security concerns have prompted countries like the US, Canada, Mexico, and other Latin American nations to increase their focus on offering the soldiers wearables equipped with electronic devices to boost their situational awareness. The need for protective clothing for the troops and the measures adopted to equip them with enhanced high-tech products will further contribute to the growth of the market in the Americas.

The Asia-Pacific houses some of the largest importers of arms such as India, Australia, China, South Korea, etc. Due to the ongoing territorial issues and geographical tensions in the region, the countries in the region are rapidly increasing their military spending.

China and India are two of the world’s largest defense spenders with USD 261 billion and USD 71.1 billion military spending in 2019, respectively. The increase in defense spending is propelling the investments towards the development and deployment of smart textiles for the military personnel.

As of November 2020, China has shortlisted nearly two dozen private companies to supply advanced unmanned weaponry and graphene clothing to the People’s Liberation Army (PLA) regiments deployed along with the long high-altitude border areas with India. The Chinese armed forces are also looking for advanced logistics support equipment like portable solar chargers, smart warm clothing made of graphene, and portable oxygenators to fuse its military needs with the technology available in the civilian sector. However, the adoption is not without its constraints and criticism associated with the lower security protocols that may threaten an entire operation due to hostile capture or manipulation of transmitted data.

Hence, since 2015, China has imposed a ban on the use of smart wearables in the PLA Army and deemed the use of wearables with internet access, location information, and voice-calling functions should be considered a violation of confidential regulations when used by military personnel. This may limit the adoption of smart textiles and associated wearables in the region to a certain extent.

Indian Army, the second largest in the world, requires 18.6 million modular bullet-proof jackets and is open for tenders for 10 years. The budget allocated for this procurement is about USD 150 million, with provisions for a vest modernization program. This offers a great opportunity for military textile vendors to explore and produce in-house capabilities and products for soldiers, thus driving the military smart textiles market.

The smart textiles for military market is fragmented due to the presence of many players in the market like the presence of universities and research organizations in Europe and North America. Some of the prominent players in the market are BAE Sytems plc, Texas Instruments Incorporated, Tennessee Acquisition Holding BV, Dupont de Nemours Inc., and Schoeller Textil AG. The companies are partnering with the governments and armed forces to develop specifically tailored products for their military personnel.

The major players of this market include Advanced Fabric Technologies, BeBop Sensors, Directa Plus, DuPont, Intelligent Textiles, and Outlast Technologies, Globe Manufacturing Company, BAE systems, Intelligent Textiles Ltd., , Midé Technology, Ohmatext, Textronics, Lockheed Martin Corp., Gentherm Inc., Schoeller Technologies AG, Texas Instruments Inc., E.I. DuPont De Nemours and Co., Milliken & Company, Outlast Technologies LLC, Noble Biomaterials Inc, W.L Gore & Associates and Outlast Technologies.

References and Resources also include:

https://www.eda.europa.eu/docs/default-source/eda-factsheets/factsheet_stile

https://finance.yahoo.com/news/smart-textiles-military-market-growth-101800653.html

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis