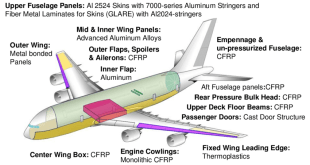

With the rapid development of the aerospace field, fiber-reinforced, resin-based composite materials have gradually replaced traditional metal materials due to their advantages of low density and high strength. An increasingly important innovation in the aerospace industry is the use of composite materials, and they have played a major role in weight reduction. A lower-weight plane is more fuel-efficient because it requires less fuel to propel itself forward. Composites are also incredibly strong and as a result have a higher strength-to-weight ratio, also known as specific strength, than the metals used in making aircraft. In addition, they resist compression and don’t easily break under tension.

Composite materials aren’t prone to corrosion due to harsh chemicals, and they’re resistant to many highly reactive chemicals. They can also handle wide variations in temperature and exposure to severe weather. Another big advantage of composites is their design flexibility: They can be made into just about shape. And a single, oddly shaped piece of composite can replace many pieces made of other materials. That helpful characteristic cuts down on maintenance and so can reduce costs over the lifetime of a plane.

Composites are versatile, used for both structural applications and components, in all aircraft and spacecraft, from hot air balloon gondolas and gliders, to passenger airliners, fighter planes and the Space Shuttle. Applications range from complete airplanes such as the Beech Starship, to wing assemblies, helicopter rotor blades, propellers, seats and instrument enclosures.

Composites are essentially materials made up of 2 or more phases or constituent parts, predominantly plastics reinforced with carbon fibers. They can be formed into various shapes to increase their strength and layered with fibers running in a different directions, to allow designers to form structures with unique properties. The development of next generation composite materials with light-weight and high-temperature resistance will help in designing high-performance, economical aircrafts. Today there are three main types in use: carbon fiber-, glass- and aramid- reinforced epoxy.; there are others, such as boron-reinforced (itself a composite formed on a tungsten core).

Perhaps the biggest disadvantage of composite materials for aircraft and component manufacturers is their higher initial cost compared with metals. The greater cost is largely due to the price of the fibers and the complicated process required to make the finished materials. It can be difficult to tell when the interior structure of a composite aircraft piece has been damaged. That makes inspections difficult and more costly.

Structural fibers such as carbon, glass and aramid fibers have been intensively adopted in high-performance applications.Aramid fibers form an important group of fibers for composite applications. These applications range through light-weight shell structures, protective structures in ballistic applications such as helmets and various shields, protective clothing, and car tires, for instance.

Aramid Properties

Aramid fibre is a man-made organic polymer (an aromatic polyamide) produced by spinning a solid fibre from a liquid chemical blend. The bright golden yellow filaments produced can have a range of properties, but all have high strength and low density giving very high specific strength. All grades have good resistance to impact, and lower modulus grades are used extensively in ballistic applications. Compressive strength, however, is only similar to that of E glass.

Aramid fibers exhibit various surprising properties, such as ultrahigh specific strength and specific modulus, satisfactory high-temperature resistance and insulation, good chemical stability, and good flame retardancy, thereby attracting significant research attention. Aramid main advantages are high strength and low weight. The chain molecules in the fibers are highly oriented along the fiber axis. As a result, a higher proportion of the chemical bond contributes more to fiber strength than in many other synthetic fibers. Aramides have a very high melting point (>500 °C). Aramid’s major characteristics include high strength, high modulus, high toughness, thermal dimensionality stability, low creep and light weight.

Like graphite, it has a slightly negative axial coefficient of thermal expansion, which means aramid laminates can be made thermally stable in dimensions. Unlike graphite, it is very resistant to impact and abrasion damage. It can be made waterproof when combined with other materials like epoxy. It can be used as a composite with rubber retaining its flexibility. High tensile modulus and low breakage elongation combined with very good resistance to chemicals make it the right choice for different composite structural parts in various applications.

Aramid fiber is unique for its inherent “skin-core” structure. The “skin” is constituted of highly crystalline rigid molecular chains, packed up regularly and tightly, arranged along the axial direction of the fiber. The “core” is composed of a large number of rod-shaped macromolecules which depend on hydrogen bond cross-linking. However, the poor compatibility between aramid fibers and resin matrixes, which is due to the inert and smooth surface of the aramid fiber, directly leads to the poor interfacial performance of the composites

On the other side, aramid has a few disadvantages. The fibers absorb moisture, so aramid composites are more sensitive to the environment than glass or graphite composites. For this reason, it must be combined with moisture resistant materials like epoxy systems. Compressive properties are relatively poor too. Consequently, aramid is not used in bridge building or wherever this kind of resistance is needed. Also, aramid fibers are difficult to cut and to grind without special equipment (e.g. special scissors for cutting, special drill bits). Finally, they suffer some corrosion and are degradated by UV light. For this reason they must be properly coated.

Aramid fiber or Nomex® and Kevlar® composite materials used widely in Military and Aerospace

Although most commonly known under its Dupont trade name ‘Kevlar’, there are now a number of suppliers of the fibre, most notably Akzo Nobel with ‘Twaron’. Each supplier offers several grades of aramid with various combinations of modulus and surface finish to suit various applications. As well as the high strength properties, the fibres also offer good resistance to abrasion, and chemical and thermal degradation. However, the fibre can degrade slowly when exposed to ultraviolet light.

The word aramid is the blend of words aromatic and polyamide. Aramid fiber is the strong and heat-resistant synthetic fiber used extensively in military and aerospace applications for ballistic composites and ballistic rated body armor fabric. Aramid fiber has good resistance to solvents, abrasion, has low flammability, it is sensitive to UV radiation, acids and salts, and offers excellent chemical and physical properties at high temperatures.

The commercially branded Dupont™ Nomex® and Kevlar® composite materials belong to the class of aramid fibers. Meta-Aramids (such as Nomex®) are highly resistant to temperature, chemical degradation, and abrasion. A meta-aramid fiber is usually manufactured by spinning in a chemical solution, know as wet spinning. The result is a semi-crystalline fiber with its molecular chain partially oriented along the axis of the fiber. M-aramid fibers generally have a Tenacity of about 5.6g/den, which can compare to Mid-Tenacity nylon and polyester fibers. These fibers are unique in their ability to withstand tensile stress during exposure to flames and temperatures up to 400 deg. C.

Para-aramids (such as Kevlar® and lower cost alternatives) display high tensile strength (the maximum stress that a material can withstand) and modulus behavior(the tendency of a material to deform when force is applied). These fibers are created by the the dry-jet, wet spinning method resulting in a fiber which consists of fully extended liquid crystal chains formed along the fiber axis with a high degree of crystallinity which increases the fiber’s strength. The p-aramid fibers can be manufactured with Tenacity around 23g/den and elongation at break ~3.5%.

Aramid fiber applications are divided into two categories: A) Reinforcement in composites like sport goods, aircraft, military vehicles and many other. B) Fabrics in clothing such as fire protection clothes or bullet proof vests. Para-aramid and meta-aramid fiber is used in protective wear owing to the high resistant properties and outstanding strength-to-weight ratio.

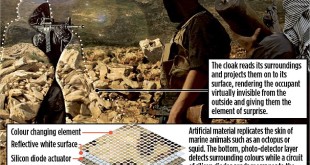

Weight is the most important consideration in the design and manufacture of heavier-than-air machines; researchers and scientists have been continuously striving to improve the lift-to-weight ratio. The same is applicable to defense uniform. Less weight gives the soldiers greater mobility, and thus, allows them the tactical advantage in the battleground or in any hostile situation.

With ever increasing environmental lobbying and the cost of fuel, commercial flying is under constant pressure to improve performance and weight reduction is a key solution in the equation. Furthermore, aircraft maintenance cost can be reduced by eliminating corrosion. Competition exists in the military too, with continuous pressure to increase payload and range, performance characteristics, and survivability. All the above-mentioned factors significantly affect the increase in usage of aramids in aerospace & defense applications. Apart from military, the largest section using aramid fiber is protection and security including private contractors, municipal law enforcement, and private security. It is also used in stab-resistant products, such as protective gloves and helmets.

China develops military-grade fiber with multiple applications

China has developed its own fiber that is strong, light and resistant to heat and corrosion, which can be used to manufacture fire-proof and bullet-proof military equipment. The material can be used to make body armor and other protective components for precision instruments or military hardware, experts said. After 16 years of development, state-owned oil giant Sinopec announced it had developed a type of para-aramid fiber nicknamed “golden silk,” Beijing-based newspaper Science and Technology Daily reported on Saturday. Kevlar is a similar type of material.

The material is a strategic asset to the country and the military, which has wide applications in both civilian and military fields, like the making of cables, optical fibers, frame materials and composite materials, the report said. A standard application for “golden silk” is to make body armor, which weighs only 1.5 kilograms and is many times more efficient than a steel plate in taking and dispersing kinetic energy from bullets and shrapnel. With the fiber, body armor can even block rapid fire from a light machine gun, according to the report.

The material can also be used in the manufacturing of vehicles, ships, aircraft and rocket, as it provides extra structural strength and resistance to harsh environments, said a military expert. Sinopec said in a statement that China used to trail foreign countries in making high-performance fibers, and related technologies were controlled by those countries as they kept inflating the price and banned supply in military use. With the domestically developed technology, the fiber now becomes affordable and is available to the Chinese military and arms industry, the expert said. The development of “golden silk” has broken the blockade of foreign countries and can further boost China’s capability in military equipment development, the company said, noting that the Chinese fiber can be considered as advanced as other similar materials developed globally.

Composite materials market

Based on type, the composites segment contributed to more than three-fourths of the total share in terms of revenue of the global aerospace materials market in 2018, and is estimated to continue its lead position throughout the forecast period. Moreover, this segment is estimated to register the fastest CAGR of 6.9% from 2019 to 2026. This is due to paradigm shift from metals to composite materials in the aerospace industry as composites offer better chemical, mechanical, and physical properties as compared to metals. The research also analyzes segments including metals and plastics.

Based on type of aircraft, the commercial segment held the largest market share of the global aerospace materials market, accounting for more than half of the total market share in 2018, and will maintain its leadership status during the forecast period. This is due to the shift from conventional metals to plastics and composites in commercial aircrafts. However, the space segment is estimated to grow at the highest CAGR of 8.2% from 2019 to 2026, owing to continuous demand for heat resistant and lightweight materials.

The global aramid fiber market is expected to reach USD 2,869.66 million in 2018. The market studied is anticipated to reach USD 3,907.54 million by 2023, registering a CAGR of about 6.37% over the period 2018-2023.

Rising requirement for security and defensive measure and expanding assembling of ballistic scope, such as, bulletproof armours, law enforcement vest, and vehicle reinforcement in military drives the worldwide aramid fiber market. Nonetheless, High manufacturing cost, requirement for huge amount in innovative work and non-biodegradable nature of the material might slowdown the development of the market. Expanding consumption on defence, quick improvement and mechanical advances in transportation, drive for higher fuel productivity and being potential substitute for asbestos and steel empowers the aramid fiber market globally.

Major Key players included in the report are: Teijin Ltd., Yantai Tayho Advanced Materials Co., Toray Chemicals South Korea Inc., Hyosung Corp., Kolon Industries Inc. Huvis Corp., Kermel, SRO Aramid (Jiangzu) Co. Ltd. and China National Bluestar (Group) Co. Ltd.

Yantai Tayho Advanced Materials plans to invest around CNY600 million (US$89 million) in para-aramid fiber plant in China, with an aim to produce nearly 3,000 tons of yarns for civil and military use. The company hopes to start trial production in early 2020. In 2018, Teijin Group in partnership with Snow Peak launched a new material fabric. The material uses Teijinconex neo heatproof material combining fashion and comfort for outdoor use. Going forward the company also plans to introduce new apparel in partnership with Snow Peak.

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis