The Internet of Things is an emerging revolution in the ICT sector under which interconnecting physical objects communicate with each other and/or with humans over the internet in order to offer a given service. IoT devices consist of sensors, processing, and communications subsystems that require power which can be provided by batteries, but even sub-Watt sensing assets require large, heavy batteries to operate for extended periods of time.

IoT applications require smart, integrated, miniaturised and low-energy wireless nodes, typically powered by non-renewable energy storage units (batteries). Batteries are considered conventional energy sources yet suffer from several limitations, such as limited lifespan and power efficiency as well as limited energy storage capacity, which necessitates frequent recharging.

In most situations, devices are remotely deployed, so that maintenance may be either inconvenient or impossible. Therefore, a need raises for nodes that not only exchange data wirelessly but also, often, operate maintenance-free over their whole predicted lifetime. This aspect poses constraints as batteries have a limited lifetime and often their replacement is impracticable. This leaves system designers with two options: either let the battery determine the life of the sensor or create a strategy for replacing sensor batteries.

Researchers are considering multiple ways to solve the energy challenge of Internet of Things and Military IoTs. One of solution is to develop low-power and energy efficient electronics. Fraunhofer’s researchers and many other including DARPA, are focussing on the development of ‘wake-up receivers’. These devices use ultra-low currents to monitor wireless sensor networks and only fire up components from a sleeping state when they are required to handle an incoming request or instruction.

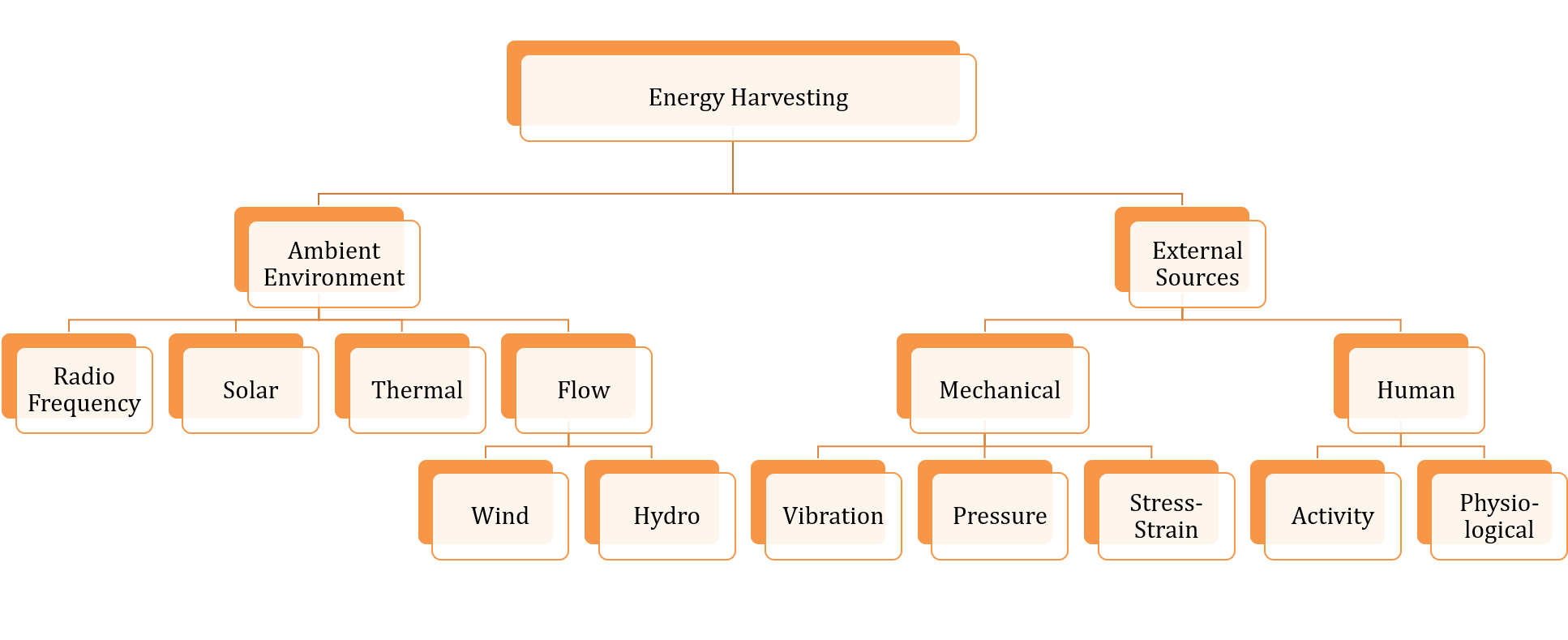

Energy Harvesting (EH), also known as Energy Scavenging (ES), literally means to extract energy from the surrounding environment and convert it into electric power.

Researchers are exploring Energy harvesting technologies to tackle these issues. Energy harvesting is the process of collecting the wasted energy from the surrounding such as heat, sound, vibration and the other sources to generate electricity.

Advancements in technology have driven improved efficiency and cost in energy harvesting, especially with solar-based methods. However, solar is not viable in many cases and is highly dependent on environmental conditions.

Advantages of Energy Harvesting Devices

Energy harvesting in industrial IoT can offer various advantages over wired or battery-powered IoT devices.

Some of the advantages are listed below:

Energy harvesting devices have several advantages in industrial IoT applications. Some of these include:

- Self-sustainability: Energy harvesting devices can convert ambient energy sources into usable power, allowing IoT sensors to operate independently of external power sources. Industrial IoT hardware with Energy Harvesting eliminates the need for running wires to devices. This ensures a hassle-free deployment with a simple Plug & Play feature.

- Cost-effectiveness: By eliminating the need for batteries or external power sources, energy harvesting devices can reduce the overall cost of an IoT system.

- Reliability: Energy harvesting devices can provide a reliable power source for IoT sensors, even in remote or difficult to access locations.

- Flexibility: Energy harvesting devices can convert a variety of energy sources into usable power, allowing for flexibility in the design and deployment of IoT systems.

- They are a promising solution to power Industrial IoT, especially in remote, hard-to-reach, or unsafe areas where maintenance of devices is not desirable or perhaps even feasible.

- Durability: Energy harvesting devices are often more robust and durable than traditional power sources, making them well-suited for industrial environments.

- Environmental-friendly: Energy harvesting devices can help to reduce the environmental impact of IoT systems by reducing the need for batteries or other non-renewable energy sources.

It facilitates businesses or organizations to drive digital transformation, which was previously unaffordable due to the high energy, installation, and upkeep costs of IoT devices. Industrial IoT devices require ultra-low power, which makes Energy harvesting devices compact in nature. IoT devices with Energy Harvesting can provide myriad benefits to the consumers as well the environment due to their ability to replace existing energy sources while maintaining the full functionalities of the devices.

Power and energy requirements of SNs

The Connected IoT devices may be simple sensing nodes (SNs) in a network or may be sensing and actuating elements of complex nets, and are being more and more deployed in the most diverse fields, from medical diagnostics to security, from predictive maintenance to environmental safety—not to forget their use for energy saving in buildings.

In general terms, SNs share with conventional sensors their capabilities (a) to measure one or more quantities (chemical, physical, electrical, environmental, etc.) and (b) to convert such a measurement into an electric signal. However, SNs further (c) store information temporarily, (d) elaborate it, and then finally (e) transmit data to some remote logging/processing station and/or to other nodes in the network.

With a few exceptions (mostly related to some self-heated chemical sensors ) and despite often sophisticated local computational capabilities, the most power-demanding SN operational step is data transmission. This enables large classes of widely differentiated devices to be analyzed along.

While SN power consumption in sleep mode is relatively small (typically in the order of 10 μWor less), during the duty cycle power requirements surge to≈1mW over a time span of about 2 s (listening and transmit times). Frequency of data transmission largely varies. While event-driven transmission is customary only in alarm sensor networks, in most cases data exchange is time-driven, occurring from every minute to every some hours. This largely reduces the average power requirements of the SN.

The power requirements and energy consumptions per connection for SNs depends on operating commercial data transmission protocols. Since transmission events may occur with widely different frequencies, power sources are requested to provide average powers ranging from some tens of microwatts (Bluetooth connection occurring every hour) to a few tenth of watts (WiFi connection occurring every second). Thus, energy and average power requirements are to be assumed to span more than four orders of magnitude.

An additional feature more and more often met in SNs is their capability of locally processing information. Processors, either single-core or multi-core microcontroller units (MCUs), are embedded in the SN. As anticipated, the engineering effort has led to develop ultra-low power processors, with power consumptions down to 15mW(in their active state). Furthermore, MCUs spend most of their time in sleep mode, so that, unless the application requires a high computational workload, average power requirements remains negligible compared to radio transmission.

Military Requirements

The military is also adopting IoT technologies. Analogous to IoT, Military internet of things (MIOT) has been defined that comprises of multitude of platforms, ranging from ships to aircraft to ground vehicles to weapon systems. The US Army’s modernization priority for Network Command, Control, Communications and Intelligence (NC3I), requires a variety of sensing assets capable of intelligent, autonomous and reliable processing and communications.

The battlefield environment and hence Military Internet of things are constrained by power consumption. Military IoT devices are likely to be powered by batteries or solar power, and charged on-the-move from solar panels, trucks, or even by motion while walking. In either case, they should last for extended periods of time (at least for the duration of the mission). Therefore, devices and sensors need to be power-efficient.

US Army seeks Novel Energy Harvesting Technology for Unattended Sensors

In addition, RF methods for Internet of Things (IoT) devices that harvest wifi/bluetooth signals are only applicable to a small sub-set of use cases. Such sensing assets are often located in close-proximity to strong 50 or 60 Hz electric and magnetic-fields produced by conductors providing power to loads or overhead power lines. These devices are ideally sustained by power extracted from these fields, enabling extended operation, although energy-harvesting from any ubiquitous source would enable in-situ placement of low-power sensing devices with no need for energy-related maintenance.

The goal of this effort is to determine the feasibility, develop concepts and demonstrate novel technology for harvesting 10-100 mW of power (average) in close proximity to energized conductors or overhead power lines. Viable energy-harvesting methods for low-frequency fields do not currently exist to provide enough power in a form factor suitable for the majority of unattended sensing applications. The development of this technology would greatly expand the number of viable permanent installation points for a future Army network of assets, and ensure minimal maintenance with respect to the powering of the devices.

Low-power sensing devices typically consume 10-100 mW, depending on the application, which informs the amount of harvesting needed to operate the sensors indefinitely. Harvesting technology capable of sustaining sensing assets in the majority of emplacement scenarios near powered conductors (e.g., high/low-temp, day/night/indoors) will enable unattended operation and eliminate the logistical difficulties of wiring power or swapping batteries.

The Phase I effort will research concepts and determine the technical feasibility of harvesting energy in close proximity to overhead power lines or powered conductors. This effort should identify and define the physics of energy harvesting to be explored and the enabling technologies to capture and store that energy. The research will include studies on the effects of indoor and outdoor environments on the technology, to include extreme temperatures. The theoretical limits of energy extraction for form factors up to a maximum volume of 100 cm3 (no dimension to exceed 15 cm), factoring in all known/expected losses, will be determined. A successful technology design will be capable of producing at least 10 mW consistently in a 100 cm3 volume or less. This effort will produce a conceptual design for a harvesting technology that can be demonstrated in the Phase II effort.

Energy Harvesting technologies

Energy harvesting is the collection of energy from ambient operating environmental energy sources, which is then used to power wireless IoT devices. It is the process of converting some form of ambient energy into power for a device.

Energy harvesting for many unattended technologies must be dependable in a variety of environments, especially indoors where sun exposure is unlikely. Energy harvesting is a natural fit for powering sensors that are not easily accessible — behind the walls of a smart home, for instance, or embedded in the structure of a bridge to monitor its integrity.

The general architecture of an energy-harvesting industrial IoT Sensor consists of harvesters that convert available energy to electrical energy. The energy captured may be used directly by the sensor or can be stored for later use. Generally, rechargeable batteries or supercapacitors are used for storing energy.

Energy harvesting can be defined as the direct transformation of ambient energy (mechanical, solar, thermal, wind, fluid flow, etc.) to electrical energy using a particular material or transduction mechanism. Several energy harvesting materials exist, each with a unique conversion mechanism that can be employed for energy harvesting. Some of the most common energy harvesting materials include photovoltaics (solar panels) to convert solar energy to electric energy, thermoelectrics (thermoelectric generators) to convert temperature differentials into electrical energy, and electromechanical transducers (piezoelectrics, electrostatic generators) to convert mechanical vibration energy into electrical energy.

Mechanical vibration energy is common in many environments where energy harvesting can be beneficial. Vibration energy may exist due to the surrounding environment (i.e. wind, fluid flow), and also due to operational conditions (e.g. rotating machinery).

There are transducers, which make the conversion from some type of ambient energy to usable, electrical power; power-management integrated circuits (PMICs), which, among other things, do the power conversion that’s required for the energy load; and storage, such as batteries or supercapacitors that store the harvested energy.

The ambient scattered energy can typically be attributed to four different sources:

Vibration/motion

The common vibration to electric power conversion methods for EH-MEMS are basically three: piezoelectric, electromagnetic and electrostatic. It was demonstrated that piezoelectric EH-MEMS can reach output power levels in the range of 10–50 µW for typical environmental vibrations, or even of more than 100 µW for large accelerations . An issue to be addressed concerns sensitivity enhancement of EHs in vibration frequency ranges available in the environment, typically up to 2–4 kHz. Non-linear elastic behaviour and multi-modality seem two promising strategies to extend the operability of MEMS vibrating EHs, , writes JacopoIannacci

Thermal energy

Pyroelectric materials such as AlN generate electrical charges on their surfaces when undergo temperature changes. Although AlN is widely characterised against its electrical, mechanical and piezoelectric properties for actuation and sensing applications in MEMS/NEMS, i.e. NanoElectroMechanical-Systems, devices, only few publications discuss pyroelectric properties. Successful operation of thermoelectric EHs in combination with phase change materials powered wireless nodes in aircrafts .

Ambient light

Beside innovative EH-MEMS, high power densities are achievable with commercial transducers such as miniaturised Photovoltaic (PV) cells. The advantage is the availability of manageable voltages in very limited footprints. Since research in this field is rather mature, the current activities in developing zero-power HW platforms that encompass PV cells are based on the incorporation of EHs as Commercial Off The Shelf components (COTS).

Everactive’s ultra-low-power integrated circuits

Now the startup Everactive has developed industrial sensors that run around the clock, require minimal maintenance, and can last over 20 years. The company created the sensors not by redesigning its batteries, but by eliminating them altogether. The key is Everactive’s ultra-low-power integrated circuits, which harvest energy from sources like indoor light and vibrations to generate data. The sensors continuously send that data to Everactive’s cloud-based dashboard, which gives users real time insights, analysis, and alerts to help them leverage the full power of industrial IoT devices.

“It’s all enabled by the ultra-low-power chips that support continuous monitoring,” says Everactive Co-Chief Technology Officer David Wentzloff SM ’02, PhD ’07. “Because our source of power is unlimited, we’re not making tradeoffs like keeping radios off or doing something else [limiting] to save battery life.”

Everactive offers its sensors as part of a wider service that incorporates wireless networks and data analytics. The company’s sensors can be powered by small vibrations, lights inside a factory as dim as 100 lux, and heat differentials below 10 degrees Fahrenheit. The devices can sense temperature, acceleration, vibration, pressure, and more. The company says its sensors cost significantly less to operate than traditional sensors and avoid the maintenance headache that comes with deploying thousands of battery-powered devices. For instance, Everactive considered the cost of deploying 10,000 traditional sensors. Assuming a three-year battery life, the customer would need to replace an average of 3,333 batteries each year, which comes out to more than nine a day.

By saving on maintenance and replacement costs, Everactive customers are able to deploy more sensors. That, combined with the near-continuous operation of those sensors, brings a new level of visibility to operations. “[Removing restrictions on sensor installations] starts to give you a sixth sense, if you will, about how your overall operations are running,” Calhoun says. “That’s exciting. Customers would like to wave a magic wand and know exactly what’s going on wherever they’re interested. The ability to deploy tens of thousands of sensors gets you close to that magic wand.” With thousands of Everactive’s steam trap sensors already deployed, Wentzloff believes its sensors for motors and other rotating machinery will make an even bigger impact on the IoT market.

Beyond Everactive’s second generation of products, the founders say their sensors are a few years away from being translucent, flexible, and the size of a postage stamp. At that point customers will simply need to stick the sensors onto machines to start generating data. Such ease of installation and use would have implications far beyond the factory floor. “You hear about smart transportation, smart agriculture, etc.,” Calhoun says. “IoT has this promise to make all of our environments smart, meaning there’s an awareness of what’s going on and use of that information to have these environments behave in ways that anticipate our needs and are as efficient as possible. We believe battery-less sensing is required and inevitable to bring about that vision, and we’re excited to be a part of that next computing revolution.”

Thermoelectric generators (TEGs)

Thermoelectric generators (TEGs) are energy harvesting devices that convert a temperature difference into electrical energy. They consist of a thermoelectric module, which is made up of thermoelectric materials such as bismuth telluride, and a heat exchanger. When a temperature difference is applied across the thermoelectric module, it generates a voltage, which can be used to power an electronic device.

TEGs are often used in applications where there is a large temperature difference, such as waste heat recovery in industrial processes or automotive systems, and in remote or inaccessible areas where conventional power sources are not available. TEGs are well known to be highly reliable, with lifetimes often largely exceeding those of the devices they power. As such, TEGs have found extended applications in mission-critical contexts (e.g. as power sources in outer space probes).

The efficiency of TEGs is typically low, around 5-7%, so they are most often used in combination with other energy harvesting technologies.

EM and RF

EM (electromagnetic) and RF (radio frequency) energy harvesting involves the conversion of electromagnetic waves into electrical energy. This is typically done by using an antenna to capture the EM or RF energy and then converting it into direct current (DC) energy using a rectifier circuit. The captured energy can then be stored in a storage device, such as a battery or capacitor, and used to power electronic devices. Applications of EM and RF energy harvesting include powering wireless sensors and other low-power electronic devices, such as those used in IoT (Internet of Things) networks.

RF-based EH consists in converting into DC power the ambient RF energy (e.g. digital TV, 3G-4G, WiFi). In such rechargeable devices, an antenna picks up radio waves, which induce an alternating current. This is passed along to a diode, which converts the signal into a direct current that can charge a capacitor. The challenge is that the effective charging range is only a few metres and diodes are not very efficient. For example, the signal strength needed to generate useful power far exceeds the signal strength a wifi router needs to maintain a strong connection.

The ambient light provides the highest power levels to be harvested. However, the situation changes drastically when passing from outdoor to indoor environments, as the harvested power density drops from 10 mW/cm2 down to 10 μW/cm2. This makes indoor ambient light sources comparable with vibration/motion and thermal energy sources in their less favourable context, i.e. human (4 μW/cm2 and 30 μW/cm2, respectively).

MIT Researchers develop Photovoltaic-Powered Sensors For The ‘Internet Of Things’

MIT researchers have designed photovoltaic-powered sensors that could potentially transmit data for years before they need to be replaced. To do so, they mounted thin-film perovskite cells — known for their potential low cost, flexibility, and relative ease of fabrication — as energy-harvesters on inexpensive radio-frequency identification (RFID) tags. The cells could power the sensors in both bright sunlight and dimmer indoor conditions. Moreover, the team found the solar power actually gives the sensors a major power boost that enables greater data-transmission distances and the ability to integrate multiple sensors onto a single RFID tag.

In a pair of papers published in the journals Advanced Functional Materials and IEEE Sensors, MIT Auto-ID Laboratory and MIT Photovoltaics Research Laboratory researchers describe using the sensors to continuously monitor indoor and outdoor temperatures over several days. The sensors transmitted data continuously at distances five times greater than traditional RFID tags — with no batteries required. Longer data-transmission ranges mean, among other things, that one reader can be used to collect data from multiple sensors simultaneously. Sai Nithin Kantareddy, a PhD student in the MIT Auto-ID Laboratory said, “This work is basically building enhanced RFID tags using energy harvesters for a range of applications.”

Depending on certain factors in their environment, such as moisture and heat, the sensors can be left inside or outside for months or, potentially, years at a time before they degrade enough to require replacement. That can be valuable for any application requiring long-term sensing, indoors and outdoors, including tracking cargo in supply chains, monitoring soil, and monitoring the energy used by equipment in buildings and homes.

The idea, then, was combining a low-cost power source with low-cost RFID tags, which are battery-free stickers used to monitor billions of products worldwide. The stickers are equipped with tiny, ultra-high-frequency antennas that each cost around three to five cents to make. RFID tags rely on a communication technique called “backscatter,” that transmits data by reflecting modulated wireless signals off the tag and back to a reader. A wireless device called a reader — basically similar to a Wi-Fi router — pings the tag, which powers up and backscatters a unique signal containing information about the product it’s stuck to.

The researchers’ sensor consists of an RFID tag built on a plastic substrate. Directly connected to an integrated circuit on the tag is an array of perovskite solar cells. As with traditional systems, a reader sweeps the room, and each tag responds. But instead of using energy from the reader, it draws harvested energy from the perovskite cell to power up its circuit and send data by backscattering RF signals.

In recent attempts to create self-powered sensors, other researchers have used solar cells as energy sources for internet of things (IoT) devices. Traditional solar cells, for instance, are bulky and expensive to manufacture, plus they are inflexible and cannot be made transparent, which can be useful for temperature-monitoring sensors placed on windows and car windshields. They’re also really only designed to efficiently harvest energy from powerful sunlight, not low indoor light. Perovskite cells, on the other hand, can be printed using easy roll-to-roll manufacturing techniques for a few cents each; made thin, flexible, and transparent; and tuned to harvest energy from any kind of indoor and outdoor lighting.

First battery-free cellphone makes calls by harvesting ambient power

Researchers at the University of Washington in the US demonstrated a batteryless smartphone which can run on power harvested either from ambient radio signals or light. According to Shyam Gollakota, associate professor in the university’s Paul G Allen School of Computer Science & Engineering, this could be the first functioning mobile phone to consume almost zero power: “To achieve the really, really low power consumption that you need to run a phone by harvesting energy from the environment, we had to fundamentally rethink how these devices are designed,” he says.

The battery-free cellphone takes advantage of tiny vibrations in a phone’s microphone or speaker that occur when a person is talking into a phone or listening to a call. An antenna connected to those components converts that motion into changes in standard analog radio signal emitted by a cellular base station. This process essentially encodes speech patterns in reflected radio signals in a way that uses almost no power.

To transmit speech, the phone uses vibrations from the device’s microphone to encode speech patterns in the reflected signals. To receive speech, it converts encoded radio signals into sound vibrations that that are picked up by the phone’s speaker. In the prototype device, the user presses a button to switch between these two “transmitting” and “listening” modes.

The team designed a custom base station to transmit and receive the radio signals. But that technology conceivably could be integrated into standard cellular network infrastructure or Wi-Fi routers now commonly used to make calls.The battery-free phone does still require a small amount of energy to perform some operations. The prototype has a power budget of 3.5 microwatts. The UW researchers demonstrated how to harvest this small amount of energy from two different sources. The battery-free phone prototype can operate on power gathered from ambient radio signals transmitted by a base station up to 31 feet away. Using power harvested from ambient light with a tiny solar cell — roughly the size of a grain of rice — the device was able to communicate with a base station that was 50 feet away.

UCLA researchers and colleagues have designed a new device that creates electricity from falling snow.

UCLA researchers and colleagues have designed a new device that creates electricity from falling snow. The first of its kind, this device is inexpensive, small, thin and flexible like a sheet of plastic. The researchers call it a snow-based triboelectric nanogenerator, or snow TENG. A triboelectric nanogenerator, which generates charge through static electricity, produces energy from the exchange of electrons. Findings about the device are published in the journal Nano Energy.

“The device can work in remote areas because it provides its own power and does not need batteries,” said senior author Richard Kaner, who holds UCLA’s Dr. Myung Ki Hong Endowed Chair in Materials Innovation. “It’s a very clever device—a weather station that can tell you how much snow is falling, the direction the snow is falling, and the direction and speed of the wind.”

“Static electricity occurs from the interaction of one material that captures electrons and another that gives up electrons,” said Kaner, who is also a distinguished professor of chemistry and biochemistry, and of materials science and engineering, and a member of the California NanoSystems Institute at UCLA. “You separate the charges and create electricity out of essentially nothing.”

“Snow is already charged, so we thought, why not bring another material with the opposite charge and extract the charge to create electricity?” said co-author Maher El-Kady, a UCLA postdoctoral researcher of chemistry and biochemistry. Silicone—a synthetic rubber-like material that is composed of silicon atoms and oxygen atoms, combined with carbon, hydrogen and other elements—is negatively charged. When falling snow contacts the surface of silicone, that produces a charge that the device captures, creating electricity.

“While snow likes to give up electrons, the performance of the device depends on the efficiency of the other material at extracting these electrons,” he added. “After testing a large number of materials including aluminum foils and Teflon, we found that silicone produces more charge than any other material.”

About 30 percent of the Earth’s surface is covered by snow each winter, during which time solar panels often fail to operate, El-Kady noted. The accumulation of snow reduces the amount of sunlight that reaches the solar array, limiting the panels’ power output and rendering them less effective. The new device could be integrated into solar panels to provide a continuous power supply when it snows, he said.

The device can be used for monitoring winter sports, such as skiing, to more precisely assess and improve an athlete’s performance when running, walking or jumping, Kaner said. It also has the potential for identifying the main movement patterns used in cross-country skiing, which cannot be detected with a smart watch. It could usher in a new generation of self-powered wearable devices for tracking athletes and their performances.

It can also send signals, indicating whether a person is moving. It can tell when a person is walking, running, jumping or marching. The research team used 3-D printing to design the device, which has a layer of silicone and an electrode to capture the charge. The team believes the device could be produced at low cost given “the ease of fabrication and the availability of silicone,” Kaner said. Silicone is widely used in industry, in products such as lubricants, electrical wire insulation and biomedical implants, and it now has the potential for energy harvesting.

Energy harvesting has been attracting attention as a technology that is capable of replacing or supplementing a battery with the development of various mobile electronics. In environments where stable electrical supply is not possible, energy harvesting technology can guarantee an increased leisure and safety for human beings.

ULP electronics for power conversion, management and storage

Next challenges for EH are miniaturisation and integration with active electronics, opening up the floor to massive exploitation of semiconductor and Microsystem technologies. Shrinking down dimensions from macro- to micro-domain brings a dowry of pros and cons. First, devices’ footprint scaling down means reducing harvested power, it looking at first sight as a limiting constraint. Nonetheless, if supply of low-power and ULP electronics is less and less demanding (as mentioned above), on the other hand, development of micro-fabrication technologies enables to enhance EHs’ conversion efficiency.

Given the concurrent growing need for integrated and miniaturised wireless sensors/actuators nodes, capable of energy autonomy and multiple functionalities, as well as provided with more on-board smart capabilities, in recent years MEMS, i.e. MicroElectroMechanical-Systems (EH-MEMS), and semiconductor-based EH has been attracting significant attention in the research and scientific community and is now indicated as an enabling technology for the IoT paradigm.

Design of µ-power converters with high efficiencies and ultra-low intrinsic power consumption is of extreme interest. Some works investigated Complementary Metal Oxide Semiconductor (CMOS) technology as a viable solution for different types of sources. A µ-power converter for thermoelectric EHs was designed to consume less than 2 µW . Further reductions to the sub-µW range are significantly boosting applications of EH.

Some works in literature focus on CMOS multi-source power converters for EH, as e.g. in Bandyopadhyay and Chandrakasan, where heterogeneous transducers are handled with a few µW power consumption. An example of integration of microelectronic substrates, MEMS, and µ-packaging is reported in Aktakka and Najafi. There is a growing interest for electronic interfaces operating in the sub-threshold region, where minimum voltage remains currently limited to a few hundreds mV. The harvested energy should also be efficiently stored in low-volumes and made available upon user application demands. Super-capacitor technology and nanostructured electrochemical batteries hold the promise of significant improvements.

Ambient Photonics Demonstrates Low-Light Energy Harvesting Technology for More Sustainable IoT at CES 2023

Showcasing its novel low-light energy harvesting solar technology, Ambient will display proof-of-concept prototypes across a range of IoT, smart home, smart retail and industry 4.0 devices in partnership with the world’s leading IoT manufacturers.

“As we pioneer a new indoor energy harvesting market from the ground up, we recognize the importance of a proven, repeatable methodology for integrating energy harvesting technology into devices,” said Ambient CEO Bates Marshall. “Our mission at CES is to demonstrate this model and show how manufacturers are quantifiably reducing emissions while at the same time developing products that support sustainable living for consumers.”

Ambient’s expert engineers will share the design considerations, performance benefits and carbon lifecycle analyses of integrating its award-winning high power density PV cells into devices.

Wiegand energy harvester opens new windows to the Internet of Things.

UBITO, a member of the FRABA family of technology companies, has announced a breakthrough in its development of Wiegand technology as an energy source for smart sensors. After more than two years of effort at FRABA’s R&D center in Aachen (Germany), a research team has demonstrated a prototype of a wireless sensor powered by Wiegand technology that could participate in an ‘Internet of Things’ (IoT) network.

The project involved the development of an exciting new Wiegand Harvester capable of capturing enough energy to power the sensor’s electronics package, including a high-efficiency ultra-wide-band radio transmitter. This achievement—a world’s first—helps to position Wiegand technology (which collects energy from movements of an external magnetic field) beside established energy harvesting techniques such as solar, piezo, or thermo-electrics as an energy source for sensor nodes in the emerging Internet of Things (also known as Industry 4.0).

Wiegand devices and demonstrating the possibility of self-powered sensors that could detect events and transmit data wirelessly to an IoT network. The R&D project was conducted by specialists from FRABA and Aachen’s University for Applied Science, with financial support from the German Ministry of Education and Technology. The project team succeeded in producing a new “Wiegand Harvester”—a device that could generate over fifty times more energy than commercial Wiegand sensors. Best continues: “This level of output makes it possible to dream of energy self-sufficient sensors that can communicate data wirelessly over a significant distance.”

The team chose a window sensor system for a practical demonstration of an IoT sensor node powered by Wiegand-harvested energy. Two Wiegand harvesters and their associated electronics were mounted on the window, with bar magnets mounted on the frame. The harvesters, made up of a 21 mm long pieces of Wiegand wire surrounded by a copper coil, are the size of an AAA battery (d=7.5 mm). Whenever the window is opened or closed, the harvesters pass the magnets, triggering abrupt magnetic polarity changes in the Wiegand wires. The amount of energy delivered is largely independent of how quickly or slowly the window is moved – a key benefit of Wiegand technology. The current pulses induced by these polarity reversals generate about 10 microjoules of energy. A key goal had been achieved: the amount of energy captured was sufficient to activate a microcontroller and collect a reading from a temperature sensor built into the system. The team added an ultra-wide-band (UWB) transmitter module that could transmit 134 bytes of data to a receiving station 60 m away. This lab demonstration, which marks a milestone towards self-sufficient Wiegand-based IoT sensor nodes, was presented in April at EnerHarv 2022 in the USA.

References and resources also include:

http://www.sciencedirect.com/science/article/pii/S1018364717303579

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis