“Electronics have dramatically changed the way we live, conduct business, communicate, and educate. Visions of the future foretell of ubiquitous computing and sensing. However, the environments in which electronics can reliably operate are limited. In consumer applications, typical operating temperatures range from -40° to 85°C. The “wider” military temperature range is only -55° to 125°C,” writes R. WAYNE JOHNSON, Ph.D., professor, at Auburn University.

Many industries are calling for electronics that can operate reliably in harsh environments, including extremely high temperatures. Traditionally, engineers had to rely on active or passive cooling when designing electronics that must function outside of normal temperature ranges, but in some applications, cooling may not be possible—or it may be more appealing for the electronics to operate hot to improve system reliability or reduce cost. This choice presents challenges that affect many aspects of the electronic system, including the silicon, packaging, qualification methodology, and design techniques.

One hurdle to studying extreme environments is the heat. Silicon-based semiconductors, which power our smartphones and laptops, stop working at about 300 degrees C. As they heat up, the metal parts begin to melt into neighboring semiconductor and don’t move electricity as efficiently.

The development of electronics that can operate at high temperatures has been identified as a critical technology for the next century. Increasingly, engineers will be called upon to design avionics, automotive, and geophysical electronic systems requiring components and packaging reliable to 200 °C and beyond. Now, ICs and supporting components designed and qualified to operate in these environments are available, saving engineering time and lowering the risk of failure However, successful system development efforts hinge on a firm understanding of the fundamentals of semiconductor physics and device processing, materials selection, package design, and thermal management, together with a knowledge of the intended application environments.

High-Temperature Applications

Inside an engine, temperatures reach up to 1000 degrees C, and the outer surface of a piston is 600 degrees C. Current technology to monitor and optimize engine performance can’t handle this heat, introducing error because measuring devices have to be placed far away from the pistons. Electronics designed to survive the intense conditions of space could be placed next to the engine’s pistons to directly monitor performance and improve efficiency. “You just put the sensor right in the engine and get much better information out,” said Suria. Other fiery, high pressure earth-bound environments that would benefit from these robust electronics include oil and gas wellbores, geothermal vents, aircraft engines, gas turbines and hypersonic structures.

The oldest, and currently largest, user of high-temperature electronics (>150°C) is the downhole oil and gas industry. In this application, the operating temperature is a function of the underground depth of the well. Worldwide, the typical geothermal gradient is 25°C/km depth, but in some areas, it is greater. The applications for high-temperature electronics in the downhole industry can be quite complex. First, during a drilling operation, electronics and sensors steer the drilling equipment and monitor its health. Finally, during the completion and production phases, electronic systems monitor pressure, temperature, vibration, and multiphase flow—and actively control valves. Meeting these needs requires a complete signal chain of high-performance components . System reliability is of utmost importance, as the cost of downtime due to equipment failure can be quite severe. A failed electronics assembly on a drill string operating miles underground can take more than a day to retrieve and replace—and the rate for operating a complex deep-water offshore rig is of the order of $1M per day!

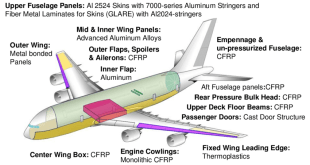

Besides the oil and gas industries, other applications, such as avionics, are emerging for high-temperature electronics. The aviation industry now has a growing movement toward the “more electric aircraft” (MEA). Part of this initiative seeks to replace traditional centralized engine controllers with distributed control systems. Centralized control requires large, heavy wire harnesses with hundreds of conductors and multiple connector interfaces. Moving to a distributed control scheme places the engine controls closer to the engine , reducing the complexity of the interconnections by a factor of 10, saving hundreds of pounds of aircraft weight, and increasing the reliability of the system (estimated in part as a function of connector pin count (per MIL-HDBK-217F)).

The trade off, however, is that the ambient temperature, in close proximity to the engine, ranges from –55°C to +200°C. Although electronics can be cooled in this application, it is undesirable for two reasons: cooling adds cost and weight to the aircraft, and, most importantly, failure of the cooling system could lead to failure of the electronics that control critical systems.

Another aspect of the MEA initiative is to replace hydraulic systems with power electronics and electronic controls to improve reliability and reduce maintenance costs. The control electronics ideally need to be very close to the actuators, which again produce a high-ambient-temperature environment.

The automotive industry provides another emerging application for use of high-temperature electronics. As with avionics, the auto industry is migrating from purely mechanical and hydraulic systems to electromechanical or mechatronic systems. This requires locating sensors, signal conditioning, and control electronics closer to heat sources.

The maximum temperature and exposure time varies by vehicle type and location of the electronics on the vehicle. For example, higher integration of electrical and mechanical systems, such as collocation of the transmission and transmission controller, could simplify the manufacture, test, and maintenance of automotive subsystems.5 Electric vehicles and hybrid-electrics require power electronics with high energy density for converters, motor controls, and charging circuits that are also associated with high temperatures.

Hypersonic flights, re-entry, and propulsion vehicles, regardless of their design, require maneuverability of materials against high temperature erosion in excess of 2400°C. “It’s all about the heat,” said hypersonics expert Brad Leland. At speeds of Mach 5 and higher, aerodynamic friction can heat an aircraft’s exterior enough to melt steel. Advanced materials, recently in development, are necessary.

ICs Designed and Qualified for High Temperature

Fortunately, recent IC technology has produced devices that can operate reliably at elevated temperature with guaranteed data sheet specifications. Advances have been made in process technology, circuit design, and layout techniques. Managing many key device characteristics is crucial for successful, high-performance operation at elevated temperatures. One of the most important and well-known challenges is posed by increased substrate leakage current. Some others are decreased carrier mobility, variation in device parameters, such as VT, β, and VSAT, increased electromigration of metal interconnects, and decreased dielectric breakdown strength.6 Although standard silicon can operate well beyond the military requirement of 125°C,7 leakage in standard silicon processes doubles for every 10°C increase, making it unacceptable for many precision applications.

Trench isolation, silicon-on-insulator (SOI), and other variations on the standard silicon process greatly decrease leakage and enable high-performance operation to well above 200°C. Wide-band-gap materials, such as silicon carbide (SiC), raise the bar even higher; silicon carbide ICs have operated at up to 600°C in laboratory investigations. However, SiC is an emerging process technology, and, currently, only simple devices such as power switches are commercially available.

Packaging Considerations

The IC package must also withstand stresses imposed by harsh environments. Plastic packages, although the industry standard, have historically only been rated to 150°C for sustained use. With recent interest in high-temperature applications, investigations have shown that this rating can stretch to 175°C but only for relatively short durations. Depending on package construction, 175°C is the point at which some materials, such as the molding compound, exceed the glass-transition temperature. Operating above TG can cause significant mechanical changes in key parameters, such as CTE and flexural modulus, and lead to failures such as delamination and cracking from the increased thermal strain.

For this reason, hermetic ceramic packages are preferred for high-temperature applications. The hermetic seal provides a barrier to the moisture and contamination ingresses that cause corrosion. Unfortunately, hermetic packages are normally larger, heavier, and significantly more expensive than their plastic counterparts. In applications with less extreme temperature requirements (<175°C), plastic packages may be preferred to conserve PCB area, reduce cost, or provide better vibration compliance. For systems requiring hermetic packaging and high component density, high-temperature multichip modules may be an appropriate solution. However, this solution requires that known good dice be available.

High-Temperature Organic Electronics

By blending two organic materials together, researchers at Purdue University could create electronics that withstand extreme heat. This new plastic material could reliably conduct electricity in up to 220 degrees Celsius (428 F), according to a paper published Thursday in the journal Science.

“Commercial electronics operate between minus 40 and 85 degrees Celsius. Beyond this range, they’re going to malfunction,” said Jianguo Mei, an assistant professor of organic chemistry at Purdue University. “We created a material that can operate at high temperatures by blending two polymers together.”

One of these is a semiconductor, which can conduct electricity, and the other is a conventional insulating polymer, which is what you might picture when you think of regular plastic. To make this technology work for electronics, the researchers couldn’t just meld the two together – they had to tinker with ratios.

“One of the plastics transports the charge, and the other can withstand high temperatures,” said Aristide Gumyusenge, lead author of the paper and graduate researcher at Purdue. “When you blend them together, you have to find the right ratio so that they merge nicely and one doesn’t dominate the other.”

The researchers discovered a few properties that are essential to make this work. The two materials need to be compatible to mixing and should each be present in roughly the same ratio. This results in an organized, interpenetrating network that allows the electrical charge to flow evenly throughout while holding its shape in extreme temperatures.

Most impressive about this new material isn’t its ability to conduct electricity in extreme temperatures, but that its performance doesn’t seem to change. Usually, the performance of electronics depends on temperature – think about how fast your laptop would work in your climate-controlled office versus the Arizona desert. The performance of this new polymer blend remains stable across a wide temperature range.

Extreme-temperature electronics might be useful for scientists in Antarctica or travelers wandering the Sahara, but they’re also critical to the functioning of cars and planes everywhere. In a moving vehicle, the exhaust is so hot that sensors can’t be too close and fuel consumption must be monitored remotely. If sensors could be directly attached to the exhaust, operators would get a more accurate reading. This is especially important for aircraft, which have hundreds of thousands of sensors.

“A lot of applications are limited by the fact that these plastics will break down at high temperatures, and this could be a way to change that,” said Brett Savoie, an assistant professor of chemical engineering at Purdue. “Solar cells, transistors and sensors all need to tolerate large temperature changes in many applications, so dealing with stability issues at high temperatures is really critical for polymer-based electronics.”

The researchers will conduct further experiments to figure out what the true temperature limits are (high and low) for their new material. Making organic electronics work in the freezing cold is even more difficult than making them work in extreme heat, Mei said.

The study was financially supported by awards from the Purdue University Startup fund, the Office of Naval Research Young Investigator Program and the National Science Foundation CAREER program, which were made available to Mei.

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis