Introduction

As we venture into the limitless expanse of space with aspirations of exploration and colonization, spacecraft face an unprecedented set of challenges. Beyond Earth’s protective embrace, these vessels must endure extreme temperature fluctuations that range from searing heat in direct sunlight to bone-chilling cold in the shadows of celestial bodies.

Spacecraft, the intrepid voyagers of the cosmos, are essential tools in our quest for space exploration and eventual colonization. These advanced machines are composed of intricate systems designed to endure the rigors of the space environment. Among the most crucial components is the Thermal Control Subsystem (TCS). While often overshadowed by other systems, TCS plays a pivotal role in ensuring the physical integrity and operational efficiency of spacecraft. This article delves into the world of spacecraft thermal control, highlighting its critical significance for the future of space exploration and colonization.

Spacecraft are man-made machines that operate in space. An orbiting spacecraft is normally referred to as a satellite, although it is manmade as opposed to a natural satellite like our moon. A spacecraft is typically subdivided into two major parts, the payload and the bus. Where the mission can be defined as the purpose of the spacecraft and is usually identified as the payload part of the spacecraft (e.g. scientific instruments, communications). The thermal control subsystem and other subsystems (e.g. attitude control, electrical power, structures) are part of the bus.

Just as human body has a temperature range that it feels comfortable say 70°F to 72°F, most spacecraft components also have a range which must be maintained in order to protect the reliability of the components. Thermal control is what allows maintaining the satellite‘s (or another space system) temperatures within set parameters during its lifetime. Thermal control is also what keeps the specified temperature stability for delicate electronics or optical components so as to ensure that they perform as efficiently as possible. Controlling the level of temperature of equipment, payloads, satellites and launchers is essential during all phases of a space mission to protect flight hardware and to guarantee the optimum performance and success of the mission.

Navigating the Cosmic Thermalscape

Space Thermal Environment

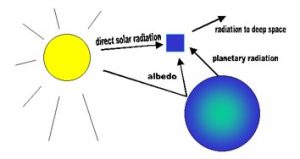

Thermal control issues can have serious impacts to the spacecraft’s mission. Knowledge of both external and internal heat sources must be included in design considerations in order to maintain thermal balance.

The primary sources of externally generated heat for earth-orbiting spacecraft are direct sun, reflected sun from the earth, and infrared (IR) energy emitted from the earth. The spacecraft operating environment largely depends on its orbit type, which is primarily driven by its intended mission. Other parameters also influence the thermal control system design such as the spacecraft’s altitude, orbit, attitude stabilization, and spacecraft shape.

The three common earth-orbiting satellite types are geosynchronous orbit (GEO), highly elliptical orbit (HEO), and low earth orbit (LEO). of the thermal control system. LEO satellites have an altitude of less than one thousand miles. Satellites in HEO can have a wide range of altitudes for perigee (lowest altitude) to apogee (highest altitude). GEO satellites, orbiting about the equator at some small angle (inclination angle), have an altitude of ≈ 23,000 miles above earth. At this altitude, satellites have the same period of rotation as the earth, appearing fixed relative to earth.

LEO orbit’s proximity to the Earth has a great influence on the thermal control system needs, with the Earth’s infrared emission and albedo playing a very important role, as well as the relatively short orbital period, less than 2 hours, and long eclipse duration. Small instruments or spacecraft appendages such as solar panels that have low thermal inertia can be seriously affected by this continuously changing environment and may require very specific thermal design solutions.

GEO satellites, orbiting about the equator at some small angle (inclination angle), have an altitude of ≈ 23,000 miles above earth. In this 24-hour orbit, the Earth’s influence is almost negligible, except for the shadowing during eclipses, which can vary in duration from zero at solstice to a maximum of 1.2 hours at equinox. Long eclipses influence the design of both the spacecraft’s insulation and heating systems. The seasonal variations in the direction and intensity of the solar input have a great impact on the design, complicating the heat transport by the need to convey most of the dissipated heat to the radiator in shadow, and the heat-rejection systems via the increased radiator area needed.

Satellites in HEO orbits can have a wide range of apogee and perigee altitudes, depending on the particular mission. Generally, they are used for astronomy observatories, and the TCS design requirements depend on the spacecraft’s orbital period, the number and duration of the eclipses, the relative attitude of Earth, Sun and spacecraft, the type of instruments onboard and their individual temperature requirements.

For direct sun, the amount of time the sun is “seen” per orbit by the spacecraft also affects its temperature control abilities, especially when extended for long periods of time. Each of the orbital types have a cyclical characteristic where the spacecraft goes from light (i.e.

the sun is present) to dark (i.e. cannot “see” the sun). Sometimes, the spacecraft may be in sunlight or darkness for extended periods of time; worst cases are known as 100% sun or minimum sun respectively. Percent sun refers to the amount of sun present during each orbit.

Interplanetary

An interplanetary trajectory exposes spacecraft to a wide range of thermal environments more severe than those encountered around Earth’s orbits. The interplanetary mission includes many different sub-scenarios depending on the particular celestial body. In general, the common features are a long mission duration and the need to cope with extreme thermal conditions, such as cruises either close to or far away from the Sun (from 1 to 4–5 AU), low orbiting of very cold or very hot celestial bodies, descents through hostile atmospheres, and survival in the extreme (dusty, icy) environments on the surfaces of the bodies visited.

For interplanetary space missions, the primary source of external thermal heat is direct sun, secondary is planetary reflected and IR when passing near a planet. This means that most of the time, for interplanetary missions, the heat source intensity will be a function of the spacecraft distance to the sun. Therefore, missions to distant planets (e.g. Jupiter) and further incur very low solar radiances creating an extremely cold spacecraft environment. The challenge for the TCS is to provide enough heat-rejection capability during the hot operating phases and yet still survive the cold inactive ones. The major problem is often the provision of the power required for that survival phase.

Space is a realm of extreme temperatures, where the rules of thermal dynamics differ from those on Earth. Spacecraft must grapple with a range of thermal challenges:

- Intense Solar Radiation: In the relentless embrace of the Sun, spacecraft can be exposed to searing heat, causing temperatures to soar when in direct sunlight.

- Frigid Shadows: On the flip side, drifting into the shadow of celestial bodies plunges spacecraft into bone-chilling cold, endangering sensitive components.

- Internal Heat Generation: Spacecraft generate heat internally from electronic systems and propulsion, adding complexity to temperature control.

- Radiative Heat Exchange: In space, heat cannot be conducted or convected away, necessitating the use of radiation to dissipate excess heat.

Temperature Requirements of Subsystems

Thermal control is essential to guarantee the optimal performance and success of the mission because if a component is subjected to temperatures that are too high or too low, it could be damaged or its performance could be severely affected. Thermal control is also necessary to keep specific components (such as optical sensors, atomic clocks, etc.) within a specified temperature stability requirement, to ensure that they perform as efficiently as possible. Large temperature differences within the satellite are also undesirable because they can lead to thermal expansion or contraction, potentially distorting its structure and thereby result in e.g misalignments of optical systems.

It must cope with the external environment, which can vary in a wide range as the spacecraft is exposed to deep space or to solar or planetary flux, and with ejecting to space the internal heat generated by the operation of the spacecraft itself. Thermal control for space applications covers a very wide temperature range, from the cryogenic level (down to -270 deg C) to high-temperature thermal protection systems (more than 2000 deg C).

Thermal control is absolutely essential for both the physical integrity of the satellite and for its efficient operation because electronic equipment have their optimum performance within a certain temperature range. The satellite’s payload will dictate its operating range. Some instruments with infrared detectors for example require extreme low temperatures. Many components have their lifetimes reduced by sustained high temperatures.

The temperature requirements of the instruments and equipment on board are the main factors in the design of the thermal control system. The goal of the TCS is to keep all the instruments working within their allowable temperature range. All of the electronic instruments on board the spacecraft, such as cameras, data-collection devices, batteries, etc., have a fixed operating temperature range. Keeping these instruments in their optimal operational temperature range is crucial for every mission. Some examples of temperature ranges include

Batteries, which have a very narrow operating range, typically between −5 and 20 °C.

Propulsion components, which have a typical range of 5 to 40 °C for safety reasons, however, a wider range is acceptable.

Cameras, which have a range of −30 to 40 °C.

Solar arrays, which have a wide operating range of −150 to 100 °C.

Infrared spectrometers, which have a range of −40 to 60 °C.

In spacecraft design, the function of the thermal control system (TCS) is to keep all the spacecraft’s component systems within acceptable temperature ranges during all mission phases. For instance, a piece of equipment could, if encountering a temperature level that is too high, be damaged or its performance could be severely affected. If a component fails sooner than expected, from excessive overheating for example, the spacecraft’s mission could also be shortened. In space it would hardly be possible to correct such a problem and this is why space thermal control systems – like other space subsystems – need to be properly designed and tested and need to be very efficient and highly reliable.

Thermal Control System

The thermal control subsystem seeks to maintain the overall temperature to an acceptable level but also to obtain the most adequate temperature distribution within the satellite. It is the task of the thermal engineer to manage the distribution of heat within the satellite so as to ensure that the temperature level is adequate for all phases of a mission (launch, transfer orbit, operation in orbit).

- Protects the equipment from overheating, either by thermal insulation from external heat fluxes (such as the Sun or the planetary infrared and albedo flux), or by proper heat removal from internal sources (such as the heat emitted by the internal electronic equipment).

- Protects the equipment from temperatures that are too low, by thermal insulation from external sinks, by enhanced heat absorption from external sources, or by heat release from internal sources.

It includes the interaction of the external surfaces of the spacecraft with the environment. Either the surfaces need to be protected from the environment, or there has to be improved interaction. Two main goals of environment interaction are the reduction or increase of absorbed environmental fluxes and reduction or increase of heat losses to the environment.

- Heat collection includes the removal of dissipated heat from the equipment in which it is created to avoid unwanted increases in the spacecraft’s temperature. Heat transport is taking the heat from where it is created to a radiating device.

- Heat rejection: The heat collected and transported has to be rejected at an appropriate temperature to a heat sink, which is usually the surrounding space environment. The rejection temperature depends on the amount of heat involved, the temperature to be controlled and the temperature of the environment into which the device radiates the heat.

- Heat provision and storage.: Is to maintain the desired temperature level where heat has to be provided and suitable heat storage capability has to be foreseen.

The Indispensable Role of Thermal Control Subsystems

The Thermal Control Subsystem (TCS) emerges as the linchpin in mitigating these extreme thermal fluctuations. Its mission is twofold: safeguarding the structural integrity of the spacecraft and ensuring the efficient operation of onboard systems:

- Innovative Heat Shields and Insulation: TCS employs cutting-edge heat shields and insulation materials to deflect or absorb solar radiation, preventing overheating.

- Radiators: To manage internally generated heat, spacecraft employ radiators—large, reflective surfaces that emit excess heat into space through thermal radiation.

- Thermal Blankets: Multi-layer insulation blankets, featuring reflective outer layers, preserve stable internal temperatures while minimizing heat exchange with space.

- Active Cooling Strategies: Advanced active cooling methods, such as heat pipes and cooling fluids, precisely regulate temperatures in vital components or scientific instruments.

- Phase Change Materials: These materials transition between solid and liquid phases at specific temperatures, absorbing or releasing heat as needed to maintain stability in critical systems.

Active or passive systems

The temperature within a spacecraft is intricately influenced by a delicate equilibrium between various factors, encompassing external solar radiation, albedo effects, planetary heat fluxes, as well as internal heat generation from electronic components, all counterbalanced by the dissipation of heat into the void of deep space. Much like on Earth, heat transfer within a spacecraft adheres to three fundamental mechanisms: convection, conduction, and radiation. However, unlike our planet, space lacks the medium of air for heat transfer due to its vacuum and zero-gravity conditions. Temperature regulation within spacecraft relies on a combination of passive and active thermal management techniques. While traditional thermal control methods have been proven effective on larger spacecraft, adapting and refining these techniques for smaller spacecraft, such as SmallSats, has become crucial in response to the growing interest in miniaturized satellite missions over the past decade.

Passive thermal control system (PTCS) components include:

Passive thermal control systems (PTCS) are a crucial component of spacecraft design, offering an efficient means of temperature regulation without the need for active power input. This approach holds particular significance for spacecraft designers, especially in the context of CubeSat missions, as passive thermal control systems are characterized by their cost-effectiveness, minimal volume and weight requirements, low risk factors, and a proven track record of reliability. The key objective is to minimize the reliance on the electrical subsystem’s power budget, thereby maximizing the available power for the payload’s operation.

Passive thermal control in spacecraft encompasses a diverse range of methods and technologies that collectively ensure effective temperature management. Some prominent examples include Multi-Layer Insulation (MLI), which acts as a protective shield against excessive solar or planetary heating, as well as the chilling effects of deep space. MLI achieves this by employing multi-layered insulation blankets that substantially attenuate the incoming solar heat flux. To efficiently dissipate heat, spacecraft employ radiators that release excess warmth into the frigid vacuum of space, where temperatures can plummet to around -270 degrees Celsius.

Additionally, passive thermal control strategies encompass thermal coatings capable of altering the thermo-optical properties of external surfaces, thermal fillers that enhance thermal coupling at crucial interfaces (such as between electronic components and radiators), thermal doublers that evenly distribute the heat generated by onboard equipment across radiator surfaces, and mirrors like optical solar reflectors (OSR) or secondary surface mirrors (SSM) that bolster external radiator performance while reducing the absorption of solar energy.

In certain planetary and exploratory missions, Radioisotope Heater Units (RHU) play a role in generating heat for Thermal Control Systems (TCS). These multifaceted passive methods collectively ensure the spacecraft’s thermal stability and performance across a variety of challenging environmental conditions.

Additionally, passive methods extend to spacecraft design strategies that manage thermal loads through structural and electrical elements, such as thermally isolated structural joints and circuit board designs optimized for efficient heat conduction away from critical components. These multifaceted approaches collectively ensure effective passive thermal control within the spacecraft.

Optical Solar Reflectors (OSRs)

Optical Solar Reflectors (OSRs) are pivotal components of spacecraft thermal control systems, serving to regulate temperatures on the sun-facing sides of satellites. They accomplish this by reflecting incoming solar radiation while simultaneously emitting internally-generated heat. Traditionally, OSRs have been crafted from quartz tiles, which possess thermo-optical properties and durability but are heavy, fragile, and add to assembly and launch costs. Polymer foil-based alternatives suffer from rapid performance degradation, rendering them unsuitable for missions lasting more than a few years.

In 2018, a groundbreaking development in OSR technology emerged from a collaborative effort involving researchers from the University of Southampton, England. This innovation, known as Metamaterial Optical Solar Reflectors (meta-OSRs), represents a paradigm shift in spacecraft exploration. Meta-OSRs are first-surface coatings applied to the external surfaces of spacecraft, designed not only to reflect most of the optical solar spectrum but also to efficiently radiate infrared heat away from the spacecraft’s surface. This breakthrough material relies on metal oxide, a common material used for transparent electrical contacts, patterned into a metamaterial structure. It possesses a high infrared emissivity while maintaining a low absorption of the solar spectrum. Furthermore, the team behind this advancement showcased a ‘smart’ radiator concept based on their metamaterial design, enabling precise control over the spacecraft’s radiative cooling using another type of metal oxide. With its potential to reduce weight and cost, meta-OSR technology holds promise for revolutionizing the space industry, making it more accessible and efficient for future missions.

Surfaces

In the vacuum of space, heat exchange primarily relies on two mechanisms: radiation and conduction. Within the enclosed confines of a small satellite, heat transfer predominantly occurs through conduction, while interactions with the external environment involve thermal radiation. Effective management of thermal radiation is achieved by selecting materials with specific radiative properties, particularly solar absorptivity (pertaining to wavelengths in the range of approximately 0.3 to 3 µm) and IR (infrared) emissivity (spanning roughly 3 to 50 µm).

Solar absorptivity dictates how much solar energy a spacecraft absorbs when subjected to incident solar flux, while IR emissivity determines the spacecraft’s capacity to release thermal energy into space compared to an ideal blackbody emitter. It also defines the fraction of thermal radiation emitted by IR sources such as the Earth or Moon that is absorbed by the spacecraft surface. These optical properties can be tailored by applying specialized coatings, surface treatments, or adhesive tapes endowed with their own unique coatings.

Thermal control surfaces encompass a wide array of materials, including coatings, paints, and finishes, employed to regulate the emissivity and/or absorptance properties of spacecraft components, both internally and externally. The performance of these surfaces is characterized by the absorptivity-to-emissivity ratio (α / ε), which plays a pivotal role in radiation-based heat transfer. For instance, white paint, characterized by a low α / ε ratio, serves as an efficient heat emitter, while materials with ratios exceeding 1.0, like dark paint, tend to heat up when exposed to sunlight.

Coating

Coatings represent one of the most straightforward and cost-effective techniques within thermal control systems (TCS). These coatings can encompass conventional paints or more advanced chemical formulations, strategically applied to spacecraft surfaces to either enhance or diminish heat transfer. The specific attributes of a coating hinge on its absorptivity, emissivity, transparency, and reflectivity.

Commonly, black and white paints are employed, each offering distinct thermal properties. Most paints exhibit high emittance levels alongside varying absorptance and electrical conductivity characteristics. Black paints, in particular, exhibit the following defining traits: α ≈ ε ≈ 1.0, indicating a nearly perfect thermal equilibrium where absorbed heat is promptly emitted. This renders black paint thermally neutral, making it the preferred choice for most internal spacecraft components. Conversely, external spacecraft surfaces are typically coated with white paint to minimize absorption of solar energy.

However, a notable drawback of coatings is their susceptibility to rapid degradation within the harsh operational environment.

Furthermore, thermal control surfaces play a pivotal role in other TCS methods, such as multi-layer insulation (MLI) blankets and radiators. Aluminized Kapton is a frequently employed material for the external layer of MLI blankets. Surfaces boasting a performance ratio of less than 0.4, like white paints or optical solar reflectors (OSRs), are highly effective as radiators. OSRs encompass materials such as quartz mirrors, silvered or aluminized Teflon, enhancing heat rejection capabilities while minimizing solar energy absorption.

Radiators

Radiators serve as the primary mechanism for heat dissipation on spacecraft, pivotal in maintaining optimal operating temperatures. These devices, characterized by their extensive surface area, are specifically designed to emit heat into the vacuum of space. The sizing of radiators is contingent upon the heat loads generated by onboard systems and the spacecraft’s temperature requirements.

Radiators can take various forms: they may utilize pre-existing spacecraft structural components exposed to space, effectively repurposing them for heat dissipation, or they can be purpose-built components within the thermal control system. Regardless of their form, the core function remains consistent—redirecting internal surplus heat to the radiator for expulsion into space as infrared (IR) radiation, thus ensuring the spacecraft’s temperature regulation.

Surface coatings are a critical aspect of radiator design, as previously discussed. These coatings are engineered to possess high emissivity, with options such as white coatings or optical solar reflectors (OSRs), maximizing heat dissipation efficiency. Furthermore, they should exhibit low absorptivity and strive for stability, safeguarding against thermal degradation inflicted by the rigors of the space environment.

Typically, spacecraft radiators are engineered to reject heat loads ranging from 100 to 350 watts per square meter, stemming from internally generated electronics waste heat. The weight of radiators spans a wide spectrum, from nearly negligible when utilizing an existing structural panel as a radiator, to approximately 12 kilograms per square meter for more substantial deployable radiator configurations and their associated support structures.

Multilayer insulation (MLI)

Multilayer insulation (MLI) plays a vital role in spacecraft thermal control, serving as a passive thermal barrier that shields against incoming solar or infrared radiation and prevents unwanted radiative heat dissipation. This insulation method is prevalent in spacecraft design and is instrumental in regulating temperatures for various components, including electronics, batteries, and biological payloads.

MLI blankets, composed of an outer cover layer, interior layer, and inner cover layer, comprise the core structure of this insulation system. The outer cover layer is chosen for its ability to block sunlight, minimize particulate contamination, and withstand the spacecraft’s environmental conditions, including exposure to UV radiation, atomic oxygen, charged particles, and potential contamination from onboard systems. Materials like fiberglass woven cloth impregnated with PTFE Teflon, PVF reinforced with Nomex bonded with polyester adhesive, and FEP Teflon are commonly employed for the outer layer.

The interior layer, on the other hand, is primarily selected for its low emittance properties, with Mylar aluminized on one or both sides being a prevalent choice. These layers are typically thin to save weight and are perforated to facilitate the venting of trapped air during launch. The inner cover, facing the spacecraft hardware, is designed to protect the delicate interior layers and is often left non-aluminized to prevent electrical shorts. Materials like Dacron and Nomex netting are utilized for this purpose. However, MLI’s delicate nature necessitates caution, especially when used on small satellites, as compression can lead to thermal conductive “short circuits.” As such, MLI is typically more effective on larger spacecraft, and alternatives such as surface coatings are considered for smaller satellite applications. Furthermore, internal MLI blankets that don’t receive direct solar thermal radiation can sometimes be replaced with low emissivity tapes or coatings, offering equivalent performance in a more compact and cost-effective manner. Second-surface silvered FEP tapes, for instance, excel as radiator coatings by reflecting incident solar energy while efficiently emitting the spacecraft’s thermal energy, albeit requiring careful handling and presenting challenges with curved surfaces.

Active thermal control system (ATCS)

In spacecraft design, the goal is to maximize the allocation of electrical power to the payload by relying primarily on passive thermal control methods. However, the extreme temperature fluctuations experienced by spacecraft in the harsh environment of space often necessitate the use of active thermal control systems (ATCS) to ensure that critical components can maintain their required operating temperature ranges continuously.

Active thermal control involves a range of methods and technologies that not only regulate temperatures but also require ongoing temperature monitoring across the spacecraft. To facilitate this monitoring, thermistors, electrical components sensitive to temperature changes and resistant to the environment of space, are strategically placed throughout the spacecraft. These thermistors provide real-time temperature data, serving as inputs for the active control system and supporting thermal trend analysis by engineers.

Key components of an active thermal control system (ATCS) include:

- Thermostatically controlled resistive electric heaters, which are employed to elevate the temperature of equipment above its lower operational limit during cold phases of the mission.

- Fluid loops designed to transfer the heat emitted by spacecraft equipment to radiators. These loops can take the form of single-phase loops controlled by a pump or two-phase loops utilizing technologies such as heat pipes (HP), loop heat pipes (LHP), or capillary pumped loops (CPL).

- Louvers, which play a crucial role in adjusting the spacecraft’s heat rejection capability to space based on temperature requirements.

- Thermoelectric coolers, devices used for active cooling in situations where certain components must be maintained at lower temperatures.

These active thermal control measures are essential for ensuring that critical systems and components onboard the spacecraft operate reliably and within their specified temperature ranges, despite the challenging thermal conditions encountered in space.

Heat Pipes

Heat pipes use a liquid-gas phase change to efficiently transfer heat from one location to another over relatively long distances. Most consist of the following components: evaporator, tube, working fluid, capillary wick structure, and a condenser. Heat pipes function by adding heat to one end of the tube at the evaporator, changing the working fluid from a liquid to a gas, and then removing the heat transported to the other end by the condenser, changing the working fluid back into a liquid.

Using this closed two phase system for thermal control, large amounts of heat can be transferred by convection through the sealed heat pipe tube between two end locations. The operating temperature range to be “felt” by the pipe determines the working fluid to be used which must

also be compatible with the material used for the tube. An aluminum tube with an axial groove wick structure, using ammonia as the working fluid has been commonly used for heat pipes.

Pumped Fluid Loops

Like heat pipes, pumped fluid loops (PFLs) can also be used to transfer large amounts of heat, to provide heat transfer cooling by forced convection. Pumped Fluid Loops (PFLs) function as a means to efficiently transfer substantial amounts of heat through forced convection, similar to the cooling principle employed in automotive engines using coolant like antifreeze. In a PFL, a working fluid such as ammonia or water is circulated through tubing, absorbing thermal energy at a heat source and subsequently conveying it to a heat sink through mechanical pumping, analogous to the process of engine cooling and heat dissipation via a radiator in a car.

Louvers

Louvers serve as active thermal control components utilized in various configurations within spacecraft systems. While their primary application involves placement over external radiators, louvers can also regulate heat exchange between internal spacecraft surfaces or be installed on spacecraft wall openings. A fully open louver is capable of rejecting six times as much heat as in its fully closed state, all without the need for power input. The bimetallic, spring-actuated, rectangular blade louver, resembling a venetian blind, is the most commonly employed type. Louver radiator assemblies typically consist of five key elements: a baseplate, blades, actuators, sensing components, and structural elements. Although they offer controlled heat transfer rates, improper orientation toward the sun can lead to high temperatures. In contrast, Second Surface Mirrors, a more advanced alternative, have largely supplanted louvers in the industry. These mirrors, equipped with specific coatings, reflect incident radiation while effectively emitting internal energy, offering a more advanced and efficient approach to thermal control.

Heaters

Heaters play a critical role in spacecraft thermal control systems, serving multiple purposes within the overall design. They are essential for safeguarding components under frigid environmental conditions or compensating for inadequate heat dissipation. Often paired with thermostats or solid-state controllers, heaters provide precise temperature regulation for specific components. Additionally, heaters are employed to raise components to their minimum operating temperatures before activation.

Among the most commonly utilized heaters in spacecraft are patch heaters, which consist of an electrical-resistance element sandwiched between layers of flexible electrically insulating material, like Kapton. These heaters may feature single or multiple circuits, depending on redundancy requirements. Cartridge heaters, on the other hand, are used to warm blocks of material or high-temperature components, such as propellants. These heaters comprise coiled resistors enclosed in cylindrical metallic cases and are embedded into drilled holes within the component to be heated.

Radioisotope heater units (RHUs) offer a distinct heating solution, particularly for missions beyond Jupiter where solar radiance is severely limited. These RHUs, powered by the decay of radioactive materials, supply heat without relying on spacecraft electrical power. Plutonium dioxide is a commonly employed material in RHUs, which are compact and weigh just 42 grams, fitting into a 26 mm diameter and 32 mm long cylindrical enclosure. Although each RHU generates 1 W of heat upon encapsulation, the heat production rate diminishes over time. Notably, the Cassini mission incorporated 117 RHUs to meet its thermal control needs.

The spacecraft thermal control design process is a comprehensive undertaking that involves establishing thermal requirements, analyzing worst-case scenarios for environmental heat loads and power dissipation, and developing control strategies, initially prioritizing passive systems and transitioning to active ones when stringent temperature tolerances or high dissipation requirements dictate. Mathematical modeling plays a pivotal role in simulating satellite thermal behavior, enabling the design to withstand extreme environmental conditions and thermal loads. Rigorous testing, correlation with mathematical models, and adherence to international standards for quality assurance, such as those defined by the European Cooperation for Space Standardization (ECSS), ensure the thermal control system’s effectiveness and reliability. Standards like ECSS-E-30 Part 1 (Thermal Control) and ECSS-E-10-03A (Testing) are pivotal in achieving quality assurance within the project.

Overcoming Challenges and Forging Ahead

As humanity embarks on audacious missions and lays the groundwork for space colonization, the demands on TCS have never been greater. The future of spacecraft thermal control rests on innovative solutions:

- Advanced Materials Revolution: Integration of revolutionary materials like aerogels and advanced composites enhances insulation and augments heat management capabilities.

- Variable Emittance Surfaces: Surfaces that adjust their emissivity empower spacecraft to modulate heat rejection rates based on environmental conditions.

- Synergy of Passive and Active Systems: Seamlessly integrating passive and active cooling systems empowers spacecraft to achieve precise temperature control while conserving energy.

- Miniaturization Mastery: Smaller spacecraft necessitate ingenious TCS designs that optimize efficiency within confined spaces.

The future of thermal control systems in spacecraft holds exciting prospects with the integration of cutting-edge technologies and materials. Composite materials are poised to play a pivotal role, offering lightweight yet robust solutions for thermal management. Advanced passive radiators are expected to enhance heat rejection capabilities, optimizing spacecraft temperature control.

Spray cooling devices, including liquid droplet radiators, represent innovative approaches to dissipating excess heat. Lightweight thermal insulation will continue to evolve, reducing thermal inefficiencies while conserving precious payload space.

Variable-emittance technologies promise adaptable solutions for optimizing heat emission. The incorporation of diamond films, advanced thermal control coatings, microsheets, and spray-on thin films will contribute to enhanced thermal performance. Silvered quartz mirrors and advanced metallized polymer-based films will further bolster heat rejection capabilities, ushering in a new era of spacecraft thermal control efficiency and reliability.

Here are some of the latest breakthroughs in spacecraft TCS

- Phase change materials (PCMs): PCMs are materials that can absorb or release large amounts of heat when they change phase between solid and liquid. PCMs can be used to store or release heat as needed, which can help to regulate the spacecraft’s temperature.

- Variable emittance coatings (VECs): VECs are coatings that can change their emissivity, or ability to emit infrared radiation, in response to changes in temperature. This can help to control the amount of heat that is radiated from the spacecraft, which can help to regulate the spacecraft’s temperature.

- Loop heat pipes (LHPs): LHPs are two-phase heat transfer devices that can transfer large amounts of heat over long distances with very little temperature drop. LHPs can be used to distribute heat evenly throughout the spacecraft, which can help to prevent overheating or overcooling.

These are just a few of the latest breakthroughs in spacecraft TCS. These breakthroughs are enabling the development of new spacecraft that can operate in extreme environments and for long periods of time. This is essential for future space exploration and colonization missions.

Here are some examples of how these breakthroughs are being used in the development of new spacecraft TCS:

- NASA is developing a new PCM-based TCS for the Artemis mission to the Moon. The new TCS will use PCMs to store heat during the day and release heat at night, which will help to regulate the temperature of the spacecraft and the astronauts.

- SpaceX is developing a new VEC-based TCS for its Starship spacecraft. The new TCS will use VECs to control the amount of heat that is radiated from the spacecraft, which will help to regulate the spacecraft’s temperature during launch, landing, and in-space operations.

- Boeing is developing a new LHP-based TCS for its CST-100 Starliner spacecraft. The new TCS will use LHPs to distribute heat evenly throughout the spacecraft, which will help to prevent overheating or overcooling.

Conclusion: Charting the Course to Cosmic Domination

As humanity’s ambitions for space exploration and colonization surge to new heights, spacecraft Thermal Control Subsystems remain unsung heroes in these grand endeavors. They stand as the guardians, ensuring that fragile instruments, vital systems, and the very structures of our cosmic pioneers endure the harshest extremes of the universe. In the ever-expanding frontier of human knowledge and space conquests, spacecraft thermal control shall stand at the forefront of innovation, propelling us toward the final frontier with unwavering resolve and boundless possibilities.

Quality assurance

References and Resources also include:

https://www.nasa.gov/smallsat-institute/sst-soa-2020/thermal-control

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis