A miniature UAV or small UAV (SUAV) is an unmanned aerial vehicle small enough to be man-portable. Miniature UAVs range from micro air vehicles (MAVs) that can be carried by an infantryman, to man-portable UAVs that can be carried and launched like an infantry man-portable air-defense system. The term is usually applied to those used for military purposes. SUAVs have been given various definitions among national regulation authorities, ranging from less than 2 kg for Canada to less than 25 kg for the United States. UE’s SESAR prospective for the 2020 Air Traffic Management rules also proposed less than 25 kg, while UK’s CAA stated less than 20 kg.

Militaries are now employing Micro, Mini & Nano UAVs into their operations. MAVs capable of hovering and vertical flight would be used to scout out buildings for urban combat and counter terrorist operations. A MAV could be included in a pilot’s survival kit. A downed pilot could use it to keep track of enemy search parties, or as airborne radio relays to search and rescue units.

For commercial use, drones have to provide much more extended flight time. A longer flight times as well as quick refuelling are the most desirable features enabling the wide range of possibilities of UAVs’ application. Drones may be used, among the others for search and rescue, aerial photography, fire protection, inspection of difficult to access areas, agriculture, police intelligence and others, hence a huge increase in interest of these vehicles are visible.

The choice of the propulsion system is crucial for the usability, sustainability and flight endurance of the aircraft. A system which is too

difficult to manage could lead to unwanted cost as well as less applicability for civilian usage. Sustainability is important in an environmental sense, the goal is to achieve a net zero carbon footprint and not have any other adverse effect on the environment. The flight endurance dictates the amount of time the UAV can remain in the air. The greater the endurance, the less amount of times the UAV is required to land and refuel during an extended mission. Subsequently reducing the cost in addition to increasing operability.

In order to determine the required properties of the propulsion system, one must assess the operating conditions such as: cruise speed, cruise altitude, the total amount of drag and lift affecting the aircraft and the maximum power output required during the flight (e.g. during takeooff/landing).

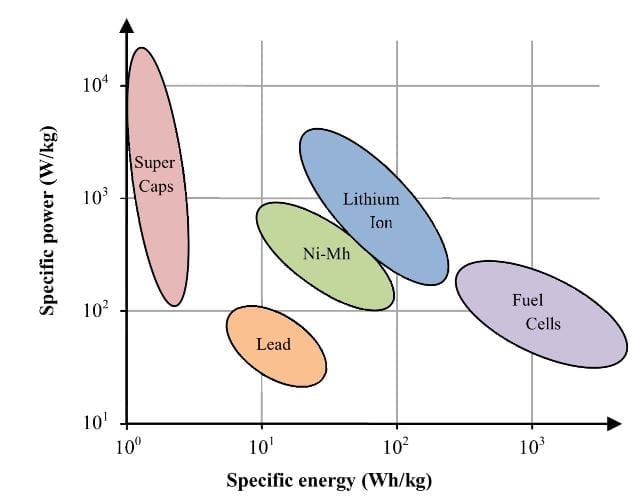

The propulsion system can be split into four parts: The energy source, the storage media, the mechanical energy converter and finally the lift/thrust converter. When choosing the specific options for the different parts, the main things to consider from a purely performance standpoint are: the specific energy and the amount of stored energy per weight of the energy source. The fuel storage weight percentage is the percentage of weight that is fuel in the energy storage module. The specific power, the power output per unit of weight for the mechanical energy converter. The efficiency per module is the energy losses at each specific point of the propulsion system and what percentage amount of energy is lost for the entire system altogether, from the energy storage to converter.

The specific energy is the amount of energy per weight of the energy source, in units J/kg: the higher the specific energy the more fuel can be supplied before reaching the maximum take-off weight. The density of the fuel is the amount of mass per volume of the energy source, in units kg/m3 and higher density enables the fuel to occupy less space. In small UAVs this property is very relevant since there is often a very

limited amount of space on board. The purpose of the Energy Storage is to have as high percentage fuel weight as possible in order to reduce the overall weight of the propulsion system. It is also important that the energy source and storage be able to exert the required operational power. The ultimate goal of the propulsion system is combining high power with high energy and low weight.

As engine designs reduce in size, design tolerances such as clearances and flow leakages/losses do not scale proportionally. The rotational speeds of turbomachinery also increases as engine designs become smaller. This makes it challenging to produce small engine designs that provide the desired efficiency and system life. In addition to producing thrust, engines are relied upon to supply the power for the various electronic and mechanical systems onboard the aircraft. As engine designs become smaller and UAV application capabilities expand, the percentage of produced engine power allocated to offtakes is expected to grow. The compact size of small engine designs also pose unique thermal management challenges. Affordable controls-based solutions to maintain tighter clearances, reduce flow losses, extend engine life, and ensure the efficient offtake of power and thermal management are necessary to help meet overall engine design and efficiency goals. Researchers are developing new engine technology, new designs, or even new fundamental research and propulsion concepts for these new classes.

Small UAV propulsion systems

A useful operational MAV would need a lightweight, highly efficient engine with a power source with high energy density. Electric motors were becoming available that met the requirement, but power sources were more troublesome. Lithium batteries were marginal. New compact fuel cells were in development but weren’t expected to be available for several years.

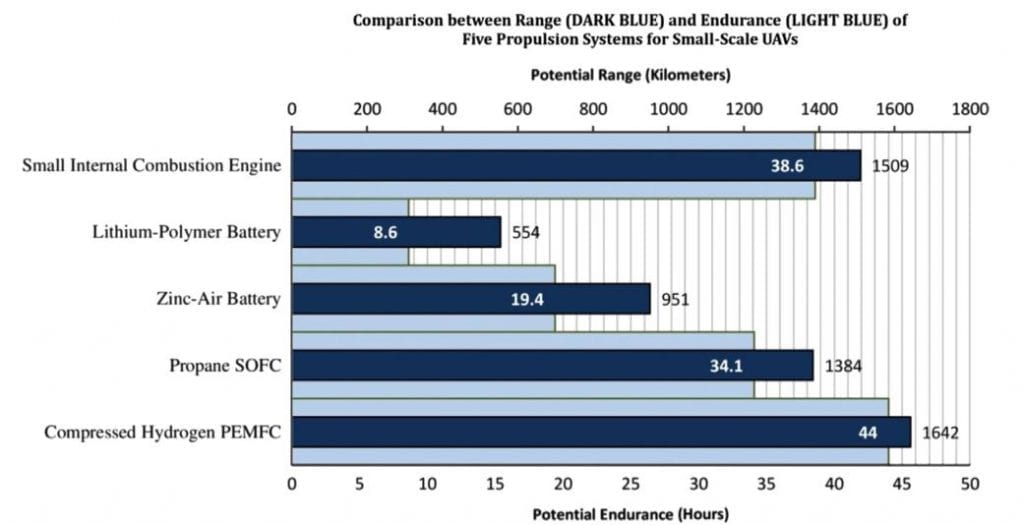

A battery system has more than 70% efficiency, a fuel cell system has a 45% efficiency and a combustion engine is able to ramp it up by 40% – which is why drones use battery-powered systems such as Lithium polymers and Lithium ion batteries. Fuel cells are a power source offering a significantly higher energy density than the best lithium-ion batteries that are typically used in the propulsion of drones.

In a fuel cell, the chemical energy is converted into electrical energy in a direct way – while the conventional electricity generation consists of a three-stage energy conversion process (chemical to thermal, thermal to mechanical and mechanical to electric). Hence, the most suitable fuel cell types are the PEMs (Proton Exchange Membranes) and their advantageous features of the PEM fuel cells include the high power density, fast start-up times, high efficiency, low operating temperature as well as the ease of safety in handling.

Hydrocarbons

Hydrocarbons are chemicals comprised of hydrogen and carbon. The most common hydrocarbons are biofuels, gasoline and jet fuel. Jet fuel has the specific energy of 43 MJ/kg and energy density of 35 MJ/L which allows for good endurance during flights. Biofuels and gasoline

have around the same range of specific energy and energy density as jet fuel.

Lithium-Polymer Batteries

Lithium-Polymer (LiPo) batteries have a very low specific energy ranging from 0.36-0.72 MJ and a energy density of 0.5-1.5 MJ/l, but tend to have a higher specific power of about 200 W/kg. With these properties, LiPo batteries meet the required operational power very easily for small air crafts, the issues arises with energy capacity. Since the specific energy is at such a low level for a LiPo battery, powering an aircraft for an extended period of time using solely LiPo batteries would lead to a very high aircraft weight.

Ultra-Capacitors

Ultra-Capacitors have the benefits of having a very high specific power, high efficiency, a very fast charging rate in addition to a very long lifetime. In comparison to LiPo batteries, Ultra-capacitors have a 10x higher specific power, slightly higher efficiency, faster recharge rate at

the cost of only having one-tenth of the specific power of batteries. It is therefore more suitable to use an ultracapacitor where high influxes of power are required for short amounts of time.

Solar Cells

Solar cells are the best energy source in an endurance aspect since it can supply energy for an undetermined amount of time (until component failure) with the sole requirement of the weather being sunny. The energy production from the solar cells is completely clean in an environmental sense as well. There are two major issues with solar cells when implementing it into UAV technology, the first being the weather requirements. It is only possible for solar cells to produce energy when struck by direct sunlight, making the system obsolete during nighttime or cloudy weather. The second issue is the design requirements. Unlike other energy sources volume is not the main issue with solar cells, instead it is the surface area. In order to achieve the surface area required to produce the operational power for the UAV, one must design the fuselage and the airfoil specifically to have high surface area in order for solar cells to be attached.

Hydrogen

Hydrogen has a very high specific energy of 120 MJ/kg, but suffers heavily in regards to energy density. It is converted into energy by using a PEMFC (Protonexchange / polymer electrolyte membrane fuel cell). PEMFCs function by converting hydrogen and oxygen into water vapour, creating an electric potential as a consequence. PEMFCs have a relatively low specific power output compared to batteries, but make up with higher specific energy with the combination of a hydrogen storage which allows for a higher flight endurance. The efficiency of the fuel cell is about 40-60 % depending on the operating conditions, the losses stem from hydrogen simply not reacting inside the fuel cell.

The fuel cell itself requires a constant stream of pure hydrogen from a hydrogen source and oxygen from the nearby air to function, and its only by-product is water which is simply released back into the atmosphere in the form of vapour. The fuel cell also operates at a relatively low temperature of only 50-100 degrees Celsius and does not require any greater amount of cooling compared to an ICE. The electric potential created by the PEMFC is then used in an electrical engine to create torque for the the thrust converter. The PEMFC suffers from a very slow transient response time creating issues when the operational power changes quickly.

By far the most efficient storage tank material is that of composite material, they can reach a gravimetric effiiency of 15 %. Steel cylinder tanks in comparison only have a gravimetric efficiancy of 1-3 %. Liquid hydrogen is also an available option, being able to achieve 40 % gravimetric efficiency. An issue with liquid hydrogen is the losses due to evaporation, almost half of the total hydrogen stored on board is evaporated during the flight. With the losses from the fuel cell, this leads to only 25 % of the hydrogen actually being used. At 300 bar the compressed hydrogens energy density reaches 2.25 MJ/l which is low, but reasonable, while liquid hydrogen has an energy density of 8.5 MJ/l

Hydrogen is not found naturally and has to be produced for usage. The current main way to produce hydrogen is through natural gas reforming. The process converts methane into hydrogen and carbon dioxide through a two chain process, first converting the methane + water into carbon monoxide and hydrogen, then the carbon monoxide + water into carbon dioxide and hydrogen.

Electrical Engine

Electrical engines have high efficiency, typically around 90 %. They benefit from having a lower thermal and audial noise in comparison to the internal combustion engine, in addition to having a very low maintenance requirement. Electrical engines also have a very fast transient response, being able to quickly change the power output to satisfy the demand required power during acceleration or deceleration.

Hybrid Alternatives

Combining the high specific energy of fuel cells and hydrogen with the high specific power of batteries or ultracapacitors to create a propulsion system with high specific energy, power and low weight in addition to being environmentally friendly. The main idea consists of the fuel cell powering the aircraft during cruise, while the batteries/capacitors function as auxiliary power to the engine during the moments where a higher power consumption is required, such as during take off. The engine of choice for a hybrid propulsion system is the electrical

engine.

Microturbine Propulsion Systems Introduced for sUAS

The use of micro-jet and micro-turbine engines, are more and more seen in today’s technology. One particularly intriguing option for both propulsion and power was a button-sized silicon microturbine (“jet”) engine developed by Dr. Al Epstein at MIT during the 1990s. Silicon was actually a good structural material at such scales, though increasing operating temperature would have dictated use of silicon carbide.

UAV Turbines micropropulsion systemUAV Turbines, Inc. (UAVT), a developer of microturbine technology, has announced the introduction of its Monarch RP family of microturbine engines, which will provide defense and commercial partners with reliable, quiet, and powerful propulsion systems. Designed for Group 3 and 4 Unmanned Aerial Vehicles (UAVs), the Monarch engines can run on heavy fuel of varying qualities. The Monarch RP has passed all critical tests in the cell, working through its operating cycle repeatedly, and for extended times. As a result, UAVT is now working with a commercial airframe partner to conduct ground testing.

“After several years of intense effort, our talented team of engineers has developed a complete, turnkey microturbine propulsion system for Group 3 and 4 UAVs that is unique in both utility and function,” said Kirk Warshaw, CEO of UAV Turbines. “Throughout the design process, we focused on creating the world’s first reliable, lightweight, high-performance microturbine engine for small aircraft that runs on heavy fuel. As we have matured the design, we now recognize that a microturbine in this category has limitless possibilities across the propulsion spectrum.”

The Monarch RP microturbine was carefully designed to outperform conventional reciprocating engines in several ways:

Monarch RP will provide more time in the air and less time being serviced on the ground with upwards of a 2,000 hour increase in operation time between overhauls when compared to available Class 3 engines. Monarch RP’s variable pitch propeller will enable UAVs to climb faster and reach greater dash speeds, enabling greater performance and efficiency in both commercial and military aircraft.

The reliability of Monarch RP eliminates the need for extra engines for a single aircraft. The flexibility to run efficiently on all types of heavy fuels, such as jet fuel, makes Monarch RP safer and more convenient than engines running on volatile aviation gasoline. Monarch RP generates useful on-board electrical power that is 2-3x greater than what is produced by conventional engines.

“The Monarch RP propulsion systems changes the game for unmanned flight,” said William T. “Tim” Crosby, MG (R) Chairman of UAVT’s Board of Advisors. “The U.S. Military is in critical need of a reliable heavy fuel engine that ensures our troops consistently have the support of their UAVs when they need them. The successful evolution and testing of the Monarch RP propulsion systems proves that reliability, added safety, and efficiency is possible and will soon be available to the warfighter in a variety of platforms.

Novel Drone and Propulsion System Doubles Flight Time

Small drones have limited flight time due to their heavy batteries and relatively inefficient propellers requiring the small drone’s battery has to be regularly recharged or replaced for longer missions. His design, marketed through his start-up Flybotix, uses just two propellers and an algorithm-based stabilization mechanism, giving his drones “the aerodynamic performance of a helicopter and the mechanical stability of a quadcopter.”

A drone’s flying time is proportional to its size—the smaller the machine, the less time it can spend in the air, as Bouabdallah says “Drones with four rotors are highly stable, making them reliable and easy to use.” But as these drones get smaller, their propellers become increasingly inefficient. That, combined with their limited battery capacity, explains their abbreviated flying times.

One solution could be to use a completely different kind of propulsion system – for example, by reducing the number of propellers from four to two engineers can make each propeller longer and the rotor more efficient. This will also reduce the amount of power required, meaning the same-sized battery could run for a longer time. However up until now, drones with two propellers were generally less stable and harder to manipulate. Bouabdallah’s design employs a ring-like structure—around 30 centimetres in diameter—in which the propellers are stacked on top of each other in the centre and turn in opposite directions. His drones look more like flying saucers than the conventional drone designs one is used to seeing.

Conventional helicopters use a complicated transmission system that enables pilots to control the blades and maintain the aircraft’s pitch- but this system is heavy, cumbersome and requires a considerable amount of maintenance. Bouabdallah’s drones can be piloted just as easily as quadcopters, using a conventional remote-control device, thanks to another innovation of his drones’ stabilization mechanism. However, Bouabdallah has developed an algorithm that offsets the two rotating forces and serves the same function as a helicopter’s transmission system.

Additionally, Bouabdallah’s drone has a unique transmission system and foam covering its outer ring, so can bounce off of obstacles without breaking. The first application that Flybotix will target is inspecting dangerous or hard-to-reach areas. Encouraged by the immense positive feedback on their technology while in China last month the team made some promising contacts and are hoping to launch their drones in the Chinese market soon.

Military Adopts AI to Help Drones Stay in Flight Longer

As the U.S. military’s reliance on aerial drones for surveillance and reconnaissance has increased, an interesting tactical problem has arisen: the drones’ batteries inevitably get depleted, limiting what they can be used for, or worse, rendering them incapable of completing their missions. One solution being pursued is using ground-based autonomous vehicles that can be sent out to recharge the depleted batteries of battlefield aerial drones. The U.S. Army is funding research now underway that will allow teams of small unmanned aircraft systems (sUASs) to descend to unmanned ground vehicles (UGVs) to autonomously recharge so they can resume their missions.

The U.S. Army’s Combat Capabilities Development Command (CCDC) Army Research Laboratory (ARL) is funding a four-year, $8-million cooperative agreement with the University of Illinois Chicago to develop critical propulsion and power technologies for powering future sUASs. Part of the work includes the development of artificial intelligence/machine learning (AI/ML) algorithms to enable sUASs to find optimal route planning to autonomously return to UGVs for recharging. The adoption of AI/ML by the military has been driven by the need for autonomous control of drone routes to the UGVs, which includes extending the operational range and time on mission.

The challenge is that the sUASs with current battery technologies have about 26 minutes to conduct a flight mission and return to their home before they lose power, which would require soldiers to carry a few thousand batteries on missions, said Dr. Mike Kweon, program manager for the ARL’s Versatile Tactical Power and Propulsion Essential Research Program. “Without solving how to handle the energy demand, all other advanced technologies using artificial intelligence and machine learning will be useless for the Army,” said Kweon. “On the battlefield, we do not have luxury to replace batteries for hundreds of UAVs and recharging them for hours.”

Researchers are currently exploring recharging options as well as developing several AI/ML algorithms to enable small drones such as quadrotors to find optimal routes as well as to monitor and improve power management. How it works: Small drones will use a battery power sensor to turn on one of the three LED lights (green, yellow, and red) in response to the status of battery power. The green light will indicate the drone’s battery is within the optimal level. The yellow light will turn on when the power falls below the optimal level, and the red light will indicate that the drone will have no power in a few seconds or minutes. When the battery sensor falls below the optimal level, the drone will autonomously descend and hover over a charging port on a UGV for wireless recharging.

The number of drones that can wirelessly recharge from the same UGV at the same time depends on the off-platform wireless power transfer technology capabilities, said Kweon. “Off-platform wireless charging means that the sUASs are charged away from the UGVs,” he explained. “The distance is also a design parameter.” Kweon noted that the researchers are performing operational impact analysis for a number of UASs for recharging under different mission situations. They also are considering a variety of recharging options. “In the near-term we use lithium-ion batteries modified for fast six-minute recharging,” said Kweon.

The drones will carry cameras for intelligence, surveillance, and reconnaissance (ISR) — a common mission for small drones in the U.S. Army — and for use in rescue missions. All images can be sent to the command control for situational awareness and decision-making. As for the UGVs, they are small multi-purpose equipment transport (SMET), which “will have a propulsion system either powered by an engine or a hybrid system” along with a charging pad, explained Kweon. He noted that further details about the UGVs cannot be discussed.

The team of researchers are working on several AI/ML algorithms. The algorithm under development at the University of Illinois Chicago will primarily focus on finding the optimal (shortest) route to an UGV for recharging. The algorithm uses unsupervised learning to collect route data and to learn from it without human supervision.

Kweon’s program also is responsible for energy and power management, including autonomous recharging. Similar features of the routing algorithm will be applied to the energy/power management algorithms. “The [energy/power management] algorithms will have multiple sub-models,” said Kweon. “The purpose of the algorithms is to monitor energy level; predict the energy/power required for the mission that takes into consideration the mission profile, environment, and other factors, and to communicate with UGVs to find optimal timing and routes to return for recharging.” Accuracy is important for an efficient and effective mission as well as not to lose the asset, he added. “These algorithms will be programmed and integrated into the extensive autonomy stack for autonomous operation,” Kweon said.

The ARL also is developing AI-enabled algorithms to autonomously maneuver a drone when hit by a bird and other flying objects. The drone must be able to quickly return to the original path or take an alternate route while in the air. In addition, one of the major objectives of the Artificial Intelligence for Maneuver & Mobility Essential Research Program (AIMM ERP) at the Army Laboratory Research is to develop algorithms for UGVs to move autonomously off-road. “Drones need to find an optimized path to get to UGVs when it needs to recharge to continue the mission. In the contested area, the paths can be complicated,” Kweon said. “The drones also need to find the most optimal path while minimizing energy use during return.”

References and Resources also include:

https://dronebelow.com/2018/10/23/challenges-of-fuel-cells-use-in-small-drone-propulsion/

https://www.eetimes.com/military-adopts-ai-to-help-drones-stay-in-flight-longer/#

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis