Material coatings on Ships and Submarine hulls reduce drag, enhance stealth and prevent marine growth, enhancing their durability and performance. Ship manufacturers are increasingly looking towards materials that can improve performance and increase weapons load, while reducing fuel costs, maintenance, and environmental impact. Approximately 80% of the fuel consumed by a ship goes towards maintaining its speed and overcoming hydrodynamic drag. Use of new and advanced materials can help improve the range of military operations performed by naval ships. Advanced materials such as carbon composites and aluminium offer the shipbuilding an opportunity to reduce costs, although they are yet to be explored at full scale. These advanced materials can enhance stealth and speed as well as provide corrosion protection.

The US Navy is already experimenting with omniphobic coatings for its surface ships, submarines, and unmanned underwater vessels. These coatings can repel water and reduce hydrodynamic drag thereby saving fuel costs.

Submarines provide unique warfighting capabilities including a stealthy platform with great range, mobility, endurance, payload potential, and survivability. In many hostile environments, the submarine may be the only survivable platform. Future submarines will offer a significant degree of flexibility and reconfigurability, both internally and through the use of off-board vehicles, sensors, and weapons; they also will accommodate rapidly emerging technology to improve current capabilities and to enable new roles and missions.

Depth is one of the most important and deciding structural design criteria. The pressure hull is the primary structural element of the submarine, and is designed to be able to withstand the external hydrostatic pressure A submarine is designed to withstand the loads generated by underwater detonations (for example, mine explosions, pressures generated by bursting of large underwater gas bubbles). The pressure hull is generally constructed of thick high-strength steel with a complex structure and high strength reserve, and is separated with watertight bulkheads into several compartments.

In addition to steel, various parts of a nuclear submarine are made from other metals, such as copper, aluminum, and brass. Other materials used to manufacture the thousands of components which make up a fully equipped nuclear submarine include glass and plastic. Electronic equipment includes semiconductors such as silicon and germanium. The nuclear reactor that powers the submarine depends on uranium or some other radioactive element as a source of energy.

Hulls are apllied with various coatings for multiple purposes including Superhydrophobic Hull Coatings for reucing drag, stealth coatings to enhance stealth, and Antifoulant surfaces are necessary to prevent the development of slimes (microfouling). Anechoic tiles are rubber or synthetic polymer tiles containing thousands of tiny voids, applied to the outer hulls of military ships and submarines, as well as anechoic chambers..

In 2019, Former employee of Huntington Ingalls Industries, the Virginia-based shipbuilder that helps to construct all of the U.S. Navy’s submarines, sued the company in federal court, claiming that the firm lied about problems with the external coating on Virginia-class attack subs.Ari Lawrence, a former HII engineer, claimed he was fired for raising his concerns about the “anechoic” hull coating, which adheres to a submarine’s metal hull and helps to absorb sound waves, thus minimizing the vessel’s sonar signature.

Virginia-class subs since at least 2006 have suffered problems with their coatings. Official photos have depicted submarines entering and leaving port with noticeable gaps in their coatings, implying that chunks of the sound-absorbing material had peeled off. Lawrence claimed HII falsified testing, inspection results and certifications related to the coatings.

Defense consultant Craig Hooper has studied problems with hull coatings for years. It creates a smoother surface and was thought to be cheaper, faster and more durable. It is designed to be “anechoic,” able to absorb waves of active sonar. It also reduces interior noise, making the boat more difficult to detect by passive or listening methods. “It’s one of these things where it seems deceptively simple,” he said. “But it has a lot of variables.” A submarine is essentially a metal tube that contracts and expands while moving through water at different depths, he said. Older submarines were covered by tiles that can fall off. Virginia-class subs employ a coating applied in large swaths called “mold-in-place, special hull treatment.”

The properly formulated protective coatings are very important to the durability and performance of naval aircraft. Coatings on the hull not only protect against corrosion, but impact the ability of the ship to increase or reduce friction drag, which directly impacts fuel consumption and greenhouse gas emissions. Coatings on exposed surfaces above the waterline and within ship interiors, including ballast and fuel tanks, are also important for protecting assets from corrosion and other forms of degradation.

Meanwhile, ONR is sponsoring efforts by Dr. Anish Tuteja, an associate professor of materials science and engineering at the University of Michigan, to develop an omniphobic coating. The clear coating, which can be applied to many different surfaces, has been shown to be durable and repel most types of liquids, from oil to water to peanut butter. The coating has significant potential to reduce friction drag on ships, submarines, and unmanned underwater vessels. Because up to 80% at lower speeds and 40–50% at higher speeds of a ship’s fuel consumption goes toward maintaining its speed and overcoming friction drag, significantly reducing friction drag would result in reduced fuel consumption or required batter power, saving money and also extending the potential range of operations, according to Dr. Ki-Han Kim, a program officer in ONR’s Sea Warfare and Weapons Department.

The challenge has been to develop an omniphobic coating that is durable enough for use on ship hulls and capable of repelling all of the types of liquid a ship might come in contact with. Simply mixing polymers and fillers with the right properties does not provide the best coating. Tuteja’s team searched through large databases of known chemical substances and evaluated their performance in mixtures using computer models that considered a wide rage of molecular properties. The right combination was identified after investigating hundreds of combinations.

ONR is also sponsoring research into other types of protective coatings, from anti-corrosion systems to coatings that prevent biofouling (the buildup of marine organisms) and ice buildup on ship hulls.

Superhydrophobic Hull Coatings For Submarines

In 2018, University of Michigan reported to be developing could reduce fuel costs for U.S. Navy ships, increasing fuel economy by making it easier for them to cut through water. The new coating could also make ships—especially submarines—faster and quieter.

Researchers at the University of Michigan funded by the Office of Naval Research are trying to develop durable “superhydrophobic” water coatings for ship hulls. Water encounters less friction passing over air bubbles than it does a ship’s hull, so the solution is to cover the hull in literally millions of tiny air bubbles. This reduces drag, which also reduces the amount of energy needed to drive a ship. That means increased fuel efficiency and longer ranges for warships.

According to Anish Tuteja, an associate professor of materials science and engineering at U of M, sixty percent or more of a ship’s fuel is used to overcome drag. A reduction in drag of even just twenty percent would yield significant fuel savings. The university team tried out hundreds of coatings before finding the right, apparently secret, mix. The next step is to make the coating durable enough to last for years submerged, so the Navy doesn’t have to continuously maintain it.

The rubber-like formulation is optically clear and binds tightly to many different types of surfaces. It can be applied by spraying, brushing, dipping or spin-coating and has excellent resistance to scratching and denting. In addition to its potential for reducing friction drag, Tuteja believes the coating could also be used to protect high-value equipment like sensors, radars, and antennas from damage due to harsh weather. Tuteja expects to have the coating available for small-scale military and civilian use within the next couple of years.

In addition to fuel efficiency there are two other potential benefits of a superhydrophobic coating. One is that ships coated with them become a little faster, as the amount of drag decreases. Another potential benefit—also a function of drag reduction—is that ships become quieter. In undersea warfare, quietness is everything, allowing submarines to sneak up on targets and slink away after making their attacks. The U.S. Navy currently covers its submarines with anechoic coatings, rubber or polymer tiles that are affixed to hulls with glue and are designed to reduce detection at certain sonar frequency bands.

Although effective as late as 2017 the Navy was having trouble with its anechoic coatings sloughing off at sea. A superhydrophobic coating on the other hand might be a more durable solution with the added benefit of making the submarine harder to detect by all types of sonar.

In addition to military use, a superhydrophobic coating would also have huge implications for the shipping industry. The coating would lower commercial shipping fuel costs while reducing the amount of fuel used to ship goods worldwide. Unfortunately, once the ONR finally does develop a coating it will likely try to keep it out of the commercial market as long as possible. Like all tech, a superhyphobic coating can equally be applied to Russian, Chinese, and North Korean submarines just like American ones to make their subs quieter—and more deadly.

Australia to develop acoustic materials to improve submarine stealth

The Australian Department of Defence has entered an agreement with universities and industry to develop ways to improve the stealth capabilities of submarines. The three-year collaboration programme was signed by Defence Science and Technology (DST). It seeks to develop new acoustic materials that will make the submarines harder to detect.

Prototype stealth materials will be developed by a team comprising researchers from DST, the University of Melbourne and RMIT University and industry partners QinetiQ and Matrix Composites & Engineering. Chief defence scientist professor Tanya Monro said: “Emerging materials and next-generation platforms are vital to creating sustainable sovereign capability for the navy to support defence’s current and future needs across the maritime domain. “This innovative research has the potential to enhance underwater vehicle survivability, as well as operational effectiveness.” Meanwhile DST scientists have already been working for nearly a decade on understanding and assessing the materials likely to be used in Attack-class construction.

The Collins-class hulls were constructed from a high-tensile micro-alloy created by Swedish specialist steel manufacturer SSAB but subsequently modified for Australian manufacture and produced by Wollongong company Bisalloy Steels, the country’s only producer of high strength quenched and tempered steel plate, and steelmaker Bluescope.

Benefitting from that experience, in February this year Bisalloy received an initial order from Naval Group for 250 tonnes of HLES high performance steel plate as used in the Barracuda class. This will be utilised in the first of up to three qualification phases which will test the company’s ability to maintain quality in production, having earlier demonstrated that its steel meets the relevant specifications. Australia has recently partnered with France’s Naval Group for delivery of an A$50bn ($35bn) future submarine programme.

Biofoulants

Marine growth adds weight and increases drag reducing a vessel’s fuel efficiency – not good in an era of soaring fuel costs. The practical problem for ships is simply that biofilm can add up to 20 percent drag and barnacles over 60 percent. This increases fuel consumption and green house gas emissions. ONR-sponsored biofouling prevention coatings provide an environmentally safe alternative for protecting naval ship hulls, which could also benefit the commercial shipping industry.

The Naval Surface Warfare Center at Carderock estimates that biofouling reduces vessel speed by up to 10 percent. Vessels can require as much as a 40 percent increase in fuel consumption to counter the added drag. For the Navy, that translates into roughly one billion dollars annually in extra fuel costs and maintenance to keep its ships free of barnacles, oysters, algae and other debris.

High-performance naval warships and submarines rely on critical design factors such as top speed, acceleration and hydroacoustic stealth. Previous biofouling prevention methods used toxic coatings, or biocides, to clear barnacle colonies from the ship exteriors. Although effective in the short-term, biocides exact a heavy environmental burden.

“The ultimate solution is to stop the barnacle settlement process before it happens,” says Steve McElvany, Ph.D., program manager for ONR’s Environment Quality program. “We are really trying to look very far forward to get the ultimate solution that’s good for the U.S. Navy and the oceans.”

By studying the environment, researchers are learning from nature how it beats the “crusty fouler” naturally. And that’s where ONR’s investment in biofouling prevention technologies has made significant gains.

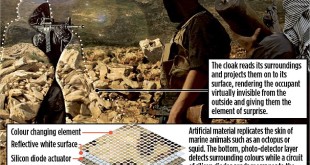

On the East Coast, ONR is funding research at the University of Florida where Anthony Brennan, Ph.D., professor of material science and engineering, has been investigating why some marine animals, such as whales, harbor barnacles and others, such as sharks, stay relatively clean. Brennan discovered that the unique pattern of shark skin contributed to its ability to fend-off microorganisms.

Antifoulant surfaces are necessary to prevent the development of slimes (microfouling) and the attachment of natural marine organisms (macrofouling) on the hull, appendages, and propulsor. The challenge is to identify long-lasting and environmentally acceptable biocides or bioresistant surfaces or other means to inhibit or remove micro- and macrofouling.

With this insight, Brennan started modeling shark skin patterns in his lab. The idea led to the development of a new biomimetic technology called Sharklet, which has shown extremely positive results in inhibiting marine growth. The significance of his work really hit home during a visit to Pearl Harbor. “I saw a Navy ship going by … flowing with green algae,” Brennan said. “I thought that’s why we are doing this research, to stop that biofouling … to give our Navy the ability to perform at a higher level.”

The biodiversity of different ocean environments also creates unique challenges. So, across the country on the West Coast, ONR is working with Dr. Shaoyi Jiang, Boeing-Roundhill Professor at the University of Washington, on biofouling prevention coatings that incorporate zwitterionic or mixed-charge compounds. “The marine environment is very complicated,” said Jiang. “It is as complex as the human body.”

Zwitterionic compounds are stable, alternating perfectly between positive and negative charges, and easy to handle in both laboratory and field tests. They’ve shown excellent resistance to the attachment of biomolecules and microorganisms. The result is that naturally occurring proteins, bacteria, algae, barnacles and tubeworms do not bind to this unique surface.

ONR’s innovation in hull coatings will optimize ship performance with an eye toward environmental stewardship. Inventive biofouling prevention systems will help conserve fuel, minimize the Navy’s carbon footprint, reduce the risk of transporting invasive aquatic species and prevent toxic biocides from entering surrounding environments.

While both the Sharklet pattern and zwitterionic coating inhibit the settlement of barnacles, they also inhibit the growth of bacteria. This unique attribute has applications in hospitals and high-touch areas in healthcare where it is critical to inhibit the survival and transference of bacteria to protect patients from infections. As Brennan says, “this technology spreads beyond the hull of the ship … there is a great opportunity to extend this technology to the public.” Jiang and Brennan acknowledged the open environment and multidisciplinary research approach that the Office of Naval Research and its program managers encourage from principal investigators.

“The ONR program provides an excellent environment and infrastructure for collaborations,” said Jiang. Brennan added, “ONR has brought together biologists, geneticists, chemists, material engineers, chemical engineers, physicists and we end up sharing. It says a lot of our Navy to have that forethought to reach beyond what everybody sees in front of them and go for something new and innovative that will help the Navy and benefit the world.”

Typical Coatings Used in US Navy

Antifouling coatings are applied on top of the anticorrosive on exterior surfaces to prevent marine growth. The underwater hull of submarines are coated with an anticorrosive and antifouling paint system. The anticorrosive component of the coating system protects the substrate from the seawater, while the antifouling paint is necessary to help reduce drag in the water. The anticorrosive and antifouling coating system used should be in accordance with MIL-PRF-23236, Coatings Systems for Ship Structures, MIL-DTL-24441, Paint, Epoxy-Polyamide, General Specification for, and MIL-PRF-24647, Paint System, Anticorrosive and Antifouling, Ship Hull as specified in Submarine Maintenance Standard (SMS) 6310-081-015 – Submarine Preservation and NAVSEA Standard Item (NSI) 009-32.

The exterior hull with SHT (Special Hull Treatment) installed, the David Taylor Research Center paint system (DTRC 2844-1110 and 2844-1109) may be used on the hull beneath and adjacent to SHT surfaces. A coating qualified to MIL-DTL-24631A Navy Formula 187 is applied on top of SHT surfaces.

Specific guidance on the application and repair of nonskid deck paint applied over SHT/MIP-SHT

SSN-688 Class – Technical Handbook for Special Hull Treatment Maintenance and Repair for Submarines: NAVSEA S6360-AD-HBK-010. For Fairing Compound, use NAVSEA Drawing 605-6160358.

SSN-21 Class – Submarine Mold-in-Place Special Hull Treatment a and Repair Manual: NAVSEA S6360-AN-MMA-010/SHT

SSN-774 Class – Maintenance and Repair Manual for Virginia Class Submarine Mold-in-Place Special Hull Treatment: NAVSEA S6360-AV-MMA-010

Surface Preparation

According to NSI 009-32, the underwater hull is considered a critical coated area. To ensure proper coating adhesion, special attention should be paid to surface preparation of this area. All surface preparation work must be accomplished in accordance with NSI 009-32 and Submarine Maintenance Standard (SMS) 6310-081-015 – Submarine Preservation.

Sherwin-Williams marine group offers fast-drying, general maintenance coatings for quick return-to-service to high-solids coatings designed for long-term asset protection. Of particular note is the close collaboration between the company and the Navy to develop novel coating solutions including Fast Clad® ER, an ultra-high-solids, rapid cure, single-coat epoxy that replaced the Navy’s traditional three-step coating practice to enable faster maintenance and a 24-hour return-to-service for ballast and fuel storage tanks and other vessel assets.

In addition, Sherwin-Williams is the primary paint supplier for the new USS Gerald R. Ford (CVN-78) aircraft carrier and for restorations being performed on the USS George Washington (CVN-73) aircraft carrier. The Navy is currently using the company’s SeaVoyage® Copper Free antifoulant coating on the USS Nimitz (CVN-68) to deter fouling of its underwater hull. In addition, Sherwin-Williams has a five-year just-in-time (JIT) coatings contract with four public naval shipyards in Norfolk, Portsmouth, Puget Sound, and Pearl Harbor. The JIT contract enables Sherwin-Williams to manage the shipyards’ coatings inventory and deliver supplies as needed to not only ensure a steady delivery of coatings from local inventory but also reduce onsite storage challenges for the shipyards.

TRI NCC 209 Coating Approved for U.S. Naval Submarine Fleet Usage

The United States Navy approved Texas Research Institute Austin, Inc. (TRI Austin) Non-Conductive Coating (NCC) 209 for use on metal outboard cable connector backshells in its submarine fleet, effective April 15, 2020. The approval was granted by the Navy’s Submarine Maintenance Engineering, Planning and Procurement Activity (SUBMEPP) in Portsmouth, New Hampshire. TRI’s new NCC 209 is a non-metallic cathodic delamination resistant coating for outboard applications on cables and connectors.

“It is a proud achievement to now be able to offer the new TRI NCC 209 to the commercial and Navy customer base, after supporting sales and marketing of our successful plasma spray legacy NCC since 1999,” said Vince Newton, Business Development and Technology Transition Director of TRI’s Applied Technologies (TRI AT), the commercialization and production arm of TRI Austin.

Over the past 20 years, TRI Applied Technologies has successfully brought to market a number of technologies developed by TRI Austin to the fleet and warfighter. These include coatings, adhesives, greases, foams, and composite materials. They serve many industries but are primarily focused on aerospace, military vehicles, naval surface ships, submarines, and the oil and gas industry.

TRI NCC 209 coating outperforms all other NCC systems with peel strengths well beyond any previously displayed. Independent third-party testing results show a bond that survives the harshest corrosive environments over an extended service life of coated parts. TRI NCC 209 reduces the number of failure points, increases reliability, reduces cost, and eases application methods compared to previous NCC systems. “Usage by the Navy will be a slow, gradual build, but has already begun,” said Newton. TRI Applied Technologies has full control of both the chemistry and processing of parts at the new TRI Round Rock facility. This allows TRI to offer the best-performing product on the market while continuing the superior customer service the company has provided over the last two decades.

AMRA Submits Bid For Royal Australian Navy’s Magnetic Treatment Facility

Victorian-based Advanced Magnetic Ranges Australia Pty Limited (AMRA), a joint venture combining the engineering expertise of AMOG with French naval technology specialist ECA Group, has just submitted their bid for the Royal Australian Navy’s Magnetic Treatment Facility, known as project SEA1350 Phase 2.

Project SEA1350 Phase 2 is set to replace an existing deperming facility at Fleet Base West and is seeking an innovative ‘over-run’ solution that will deliver both time and cost savings to the Commonwealth. It replaces the traditional deperming process of wrapping the entire body of a ship or submarine in a massive wire coil and passing electricity through the coil to reduce the magnetic ‘signature’ of the vessel.

The innovative AMRA approach instead uses wire coils laid down on the seabed, supported by a custom-designed subsea structure, through which a specific current form is passed as the vessel moves over the coils. This single day ‘over-run’ process provides a significant operational advantage when compared to the traditional wrapping, which can take up to 10 days.

AMOG CEO, Ben Clark, has confirmed that AMRA’s submission, “Includes an impressive list of Australian subcontractors and SMEs who will ensure that Australian industry content is maximised, whilst delivering the best global technology from ECA Group.” “Safety at sea is a continuous challenge since it is a hostile environment. Beyond the fact that AMRA’s solution is based on a tried, tested and approved method of ship protection through magnetic risk management such as deperming of submarines, our solution is a real technological breakthrough as it simplifies the process and reduces the time required,” added Mr Philippe Novelli, Chief Commercial Officer of the Robotics Division at ECA Group.

References and resources also include

https://phys.org/news/2009-06-hull-coatings-navy-ships-fuel.html

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis