The effectiveness of anti-tank weapons used by Ukraine against Russian tanks revives old questions as well as generates new ones about armoured fighting vehicles and their future. Oryx, an open-source site tracking military-equipment losses around the world, has reported that Moscow has lost 5,020 military vehicles since the beginning of its invasion. According to the latest figures, 3,202 of those vehicles were destroyed, 103 damaged, 323 abandoned and 1,392 captured by Ukranian troops. Among the Russian losses listed by Oryx, there are 916 tanks, 556 of which are estimated to have been destroyed.

Russia’s army was estimated to have over 12,000 tanks and 20,000 armored fighting vehicles before the war in Ukraine began, far outnumbering Ukraine’s estimated force of an estimated total of over 2,500 tanks and over 2,800 armored vehicles. Since then, it’s been estimated that Russia has already lost over a quarter of its available tanks for its campaign in Ukraine, and rumors have spread about Moscow’s inability to repair its damaged tanks and its capacity to build new tanks.

According to Western military experts, Russian tanks are being destroyed because of a fatal design flaw in the vehicles where troops and ammunition share the same space. In April, CNN reported that Western militaries had known for years about a design flaw within Russian tanks called the “jack-in-the-box effect,” which makes the vehicles highly susceptible to catch fire and explode.

Prior to Russia’s invasion of Ukraine, the struggling Turkish Leopard 2A5s in Syria and American M1A1s against ISIS in Iraq showed that heavily armoured vehicles lack mobility and adaptability and thus struggle in urban settings.

The next-generation armored vehicles will face threats from near-peer and insurgent warfare. Modern main battle tanks and infantry fighting vehicles and their occupants are facing increasing threats from all sides: Rocket Propelled Grenades (RPGs) that are thrown from short distances. Anti-Tank Guided Missiles (ATGMs) that use infrared or radar guidance to attack the tops or engine compartments of vehicles. Mines or improvised explosive devices (IEDs) designed to attack the weaker bottoms of vehicle.

However, the next-generation light-anti tank weapon (NLAW), the FGM-148 Javelin anti-tank missiles system and the Turkish Bayraktar TB2 drone using anti-tank missiles, appear to be quite effective against heavily armoured Russian vehicles. Contributing factors include bad Russian tactics, the failure to establish air superiority and successful and determined Ukrainian ambushes and guerrilla tactics.

The traditional protection technique depends on the amount of armor, has reached a practical limit for today’s threat environments, as main battle tanks and infantry fighting vehicles have reached weights approaching 70 tons. The trend of increasingly heavy less mobile and more expensive combat platforms has limited Soldiers’ ability to rapidly deploy and maneuver in theater and accomplish their missions in varied and evolving threat environments. Moreover, larger vehicles are limited to roads and bridges they are able to travel on, require more logistical support and are more expensive to design, develop, field and replace.

One of the ways to enhance survivability without increasing weight is new lighter armor materials like composites. Composites can be designed to be far stronger than aluminum or steel. Metals are equally strong in all directions. But composites can be engineered and designed to be strong in a specific direction. By using composites to decrease weight, armored vehicles can make more space to carry fuel, ammunition, and crew if needed. Since composites will not rust or suffer from fatigue like its metal counterparts, it also helps drive down lifetime maintenance costs while increasing service life

Another technology being used to enhance the survivability is Active Protection Systems, or APS, that uses sensors and radar, computer processing, fire control technology and interceptors to find, target and knock down or intercept incoming enemy fire such as RPGs and Anti-Tank Guided Missiles, or ATGMs.

The US Army is speeding up development work on its future Modular Active Protection System for combat vehicles. The MAPS is being developed as an open architecture system with a common controller, and will be capable of installation on a variety of ground vehicles. Vehicles slated for use of APS systems are infantry fighting vehicles such as Bradleys along with Stykers, Abrams tanks and even tactical vehicles such as transport trucks and the emerging Humvee replacement, the Joint Light Tactical Vehicle.

Russian Armata T-14 will incorporate several active protection system called Afganit designed to kill incoming missiles before they even strike the tank. Milley also wants a tank that could be driverless, allowing the remaining crew to concentrate on fighting the enemy, or even completely crewless.

The U.S. Army is planning to bring new vehicle protection technologies to the fleet as early as 2020 to include reactive armor tiles, as well as laser warning and signature management capabilities, according to Col. Glenn Dean, the program manager for the service’s Stryker combat vehicle.

The service will also continue its work on advanced reactive armor tiles for Armored Multi-Purpose Vehicle, or AMPV as part of its base vehicle protection. But that advanced technology will be shared across multiple other platforms in the Army’s fleet, Dean said.

The first program will look into signature management capabilities to address “all of the various signatures — visual, infrared, radar, sound, electromagnetic — that a vehicle puts off,” Dean said. The capability will begin to “control and reduce those to reduce the detectability of the platform and its vulnerability to threats,” he added.

Out of the three main technology programs the Army is advancing, signature management is the most mature, according to Dean: “Frankly, we could deploy that next year if we were funded right now. It’s not in the 2019 budget, so we are looking for opportunities.” The Army will also devote effort to a laser warning program “that will provide the ability to detect, identify and then locate laser sources” such as laser range finders or beam-riding anti-tank missiles, Dean noted.

The three programs underway as part of the VPS portfolio are meant to roll out to the fleet before its future Modular Active Protection System, or MAPS, architecture is ready for delivery, Dean said. Depending on the long-term strategy, the Army will decide whether to bring those capabilities into the MAPS architecture.

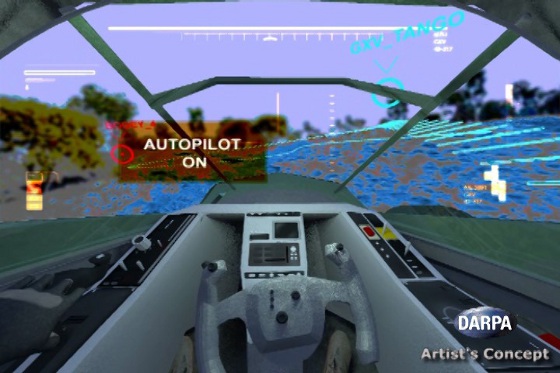

DARPA’s has launched Ground XVehicle Technology (GXV-T) program has developed revolutionary technologies to enable a layered survivability approach, which is not entirely armor-based, against multiple classes of threats to armored vehicles. A layered approach should consist of technologies that: reduce vehicle detection, reduce the likelihood of a vehicle being engaged, reduce the chances of both guided and unguided rounds hitting the vehicle and reduce the effectiveness of modern threats to armored vehicles.

Enhanced 360-degree Awareness with Virtual Windows

Honeywell International demonstrated its windowless cockpit in an all-terrain vehicle (ATV) with an opaque canopy. The 3-D near-to-eye goggles, optical head-tracker and wrap-around Active Window Display screens provide real-time, high-resolution views outside the vehicle. In off-road courses, drivers have completed numerous tests using the system in roughly the same time as drivers in All Terrain Vehicles (ATVs) with full visibility.

Virtual Perspectives Augmenting Natural Experience (V-PANE)

A tactical vehicle offers limited visibility and data for decision-making, especially when moving rapidly through unfamiliar territory. Raytheon BBN Technologies’ V-PANE technology demonstrator fuses data from multiple vehicle-mounted video and LIDAR cameras to create a real-time 3-D model of the vehicle and its nearby surroundings. In a final Phase 2 demonstration, drivers and commanders in a windowless recreational vehicle successfully switched among multiple virtual perspectives to accurately maneuver the vehicle and detect targets of interest during both low- and high-speed travel.

Enhanced Situational Awareness through Unmanned Aerial Vehicle (UAV) integration on a combat turret

CMI Defence is introducing at Eurosatory 2016 a new feature that extends the situational awareness and enhances the indirect firing capabilities of its turrets: the first Unmanned Aerial Vehicle (UAV) integration on a combat turret. This newly developed ability to communicate and interact with a dedicated mission-capable UAV is a world première. CMI Defence has integrated the control of a mini-drone to a weapon system, allowing the direct use of the data coming from its optical payload by the turret crew.

These new features improve the survivability of light armored vehicles and their weapon systems, improve the crew safety (e.g. in urban areas) and reduce collateral damage by a better assessment of the immediate tactical situation. It is a commander’s “direct-in-hand” capability, which complements the traditional Close Air Support and Artillery Support when both are not available.

The new feature allows:

- Better accuracy in indirect firing via the Forward Observer capability of the drone: target localization and designation, first firing assessment and corrective indication in artillery mode, as well as battle damage assessment.

- Reconnaissance and situation awareness at extended distance, complementing the existing capability of the sighting systems of the turrets.

This demonstration integerated Spy’Ranger drone from Thales and their console Spy’C with its Cockerill® 3105HP turret equipped with the advanced 105mm gun . The control software was run in the Turret Network Controller and the Ballistic Computer of the Cockerill® 3105HP turret. The HMI has been adapted to the existing displays used by the crew to facilitate the control of the drone (position, evolution in the theater of operation) and the use of the data coming from the optical gimbal (display of the aerial view).

Signature reduction

Modern armored vehicles, especially tanks and infantry fighting vehicles, have required steadily more significant amounts of power to support ever-improving sensors, communications systems, and other systems, which only increases their thermal signature. Heat builds up in places, such as the suspension and tracks, from normal operation, too, as well as just sitting out in the sun.

This has increased the risk that an opponent with thermal or infrared imaging systems will be able to detect those vehicles faster and at greater distances and then engage or avoid them. These types of optics are increasingly part of the fire control systems on vehicles and man-portable weapon systems, such as anti-tank guided missiles.

Beyond the threat of detection, these thermal signatures also offer something for various guided weapons to home in on. Reducing the heat a vehicle gives off, could make it more difficult for a missile or a bomb with an imaging infrared seeker to spot it and lock on.

Power generation requirements for armored and other ground vehicles are only set to increase in the future, which will require even more efforts to conceal their thermal signatures. The GVCS paint jobs are only one part of a broader effort to address these threats, according to the Army.

The U.S. Army says it has developed a new type of paint for its M1 Abrams tanks and other armored vehicles that can help reduce their infrared signature and make the harder to detect. The coating is also a general improvement over what the service uses now and could have applications well beyond ground vehicles. The Army’s Ground Vehicle Systems Center, the Army Research Laboratory, and the service’s Manufacturing Technology (ManTech) program worked to develop what is officially known as the Ground Vehicle Coating System (GVCS), according to an official news item on Mar. 20, 2019. The paint itself is known as “TALON, ” to lessen the absorption of thermal energy from a vehicle’s heat-generating internal components, such as engines, auxiliary power units, and electronics.

The service says the new paint also simply offers important improvements over the existing Chemical Agent Resistant Coating (CARC) it uses now. As its name implies, CARC’s major improvement over previous paints was its ability to limit the absorption of chemical and biological agents, especially liquids, to speed up the process of decontamination after an attack.

Sensor protection and heat-transfer reduction in one system

Military vehicles are used in support of operations in a wide variety of settings with constantly changing threats and intensity. Since vehicles are most vulnerable while moving, mobile camouflage is a highly important equipment area. With optional Heat Reduction capability further protection is achieved.

Enhanced Mobility

Militaries have requirement to increase ability to traverse complex terrain while achieving a greater operational tempo.

Non-Pneumatic Tire (NPT)

Mobile is also crucial for survivability so that military vehicles will be able to escape at high speed or complete its mission while running on one or two wheels deflated. Airless tires, or non-pneumatic tires (NPT), are tires that are not supported by air pressure. According to soldiers who have driven vehicles fitted with them, the tires are capable of towing 1,000 gallons of water up a mountain or three pallets of ammo and batteries up a steep incline, while handling like normal rubber tires. Humvees have “run flat” tires that continue to roll despite very low air pressure, but “airless tires” are even better.

The technology, “Non-Pneumatic Tire” (NPT), is made of a polymeric web. NPTs keep vehicles moving in any terrain while not being slowed or stopped by punctures, increasing the possibility of escaping from dangerous situations. NPT was originally developed at the University of Wisconsin for the U.S. Army.

Modular

A vehicle with a common chassis with several interchangeable units not only makes it deployable in various combat scenarios, but often also reduces manufacturing costs and the logistical tail on the battlefield. Rheinmetall BAE Systems Land (RBSL) Boxer 8×8 wheeled armoured vehicle can support 16 different configurations with a payload of up to 15 tonnes.

International Institute of Strategic Studies senior fellow for land warfare Ben Barry says: “Taking off a physical module and putting on a new one is very easy in a garage or in an engineering shed during peacetime, but it’s much more difficult in field operations in war.”

Though the Boxer’s configurations can be changed in about an hour with adequate equipment, logistics can still prove difficult. “What do you do with the modules you are not using? How do you carry them around the battlefield, where do you store them? What if the situation changes?” Barry questions.

Rheinmetall seems to have the solution. The Lynx KF41 infantry fighting vehicle unveiled in the summer of 2016 can support five mission modules. However, instead of storing them in containers waiting for deployment, the Lynx modules can be directly deployed in standard ISO containers as standalone solutions and can play an active role in combat operations

Networked with Open Architecture

The future optionally manned fighting vehicle will need the flexibility to be networked with other capabilities across the battlefield, and designed such that capabilities can plug into the vehicle at the forward edge. “The network is almost more important in some ways than building the combat vehicles,” said Maj. Gen. Brian Cummings, program executive officer of ground combat systems.

Networking is an important capability for the Next Generation Combat Vehicles portfolio not only for secure communications and sharing of information, but also control of autonomous or semi-autonomous vehicles that may eventually be incorporated into operational ground

forces, such as OMFV and RCV. Past modernization efforts failed, in part, due to challenges maturing networking capabilities. According to program officials, networked communication is key to connecting the vehicles, and collecting and processing sensor data

Army engineers develop greater lethality, speed to support future combat vehicle

Engineers at Picatinny Arsenal have reached key milestones in developing an advanced armament system that integrates a medium caliber weapon, ammunition, fire control, and sensors to effectively engage targets at extended ranges. The system is designed to demonstrate a decisive lethal punch that enables gunners to make the right firing decision quicker, with greater accuracy, at farther distances, to establish dominance on the battlefield.

The Advanced Lethality and Accuracy System for Medium Caliber (ALAS-MC) is expected to provide superior medium caliber weapon system performance and lethality as compared to currently fielded systems worldwide. Moreover, it is designed to provide greater target standoff, improved precision and accuracy.

Key features of the system include a high explosive airburst munition for optimized effects against personnel targets, behind walls and in the open; an armor piercing munition for optimized effects against materiel targets; integrated fire control enhancements; graphical user interface and enhanced laser rangefinder. Integrated into the design are the 50mm auto cannon, known as the XM913, capable of firing both XM1204 High Explosive Airburst with Trace (HEAB-T), and XM1203 Armor Piercing Fin Stabilized Discarding Sabot with Trace (APFSDS-T) munitions. The HEAB-T and APFSDS-T cartridges were designed and developed by Picatinny engineers and manufactured by General Dynamics Ordnance and Tactical Systems.

“These technologies, coupled with an advanced fire control system, optimize the system’s lethality to maximize the number of stowed kills and provide a lethal capability that will enable overmatch against our pacing threats,” said Robert Tani, Ground Combat Development Team Lead, Medium and Cannon Caliber Munitions Division. Stowed kills is a general term for the estimated amount of kills or damage the ammunition stowed on the vehicle can achieve. The improvement in stowed kills is significantly aided by the enhanced lethality provided by a novel HEAB-T warhead jointly developed between Picatinny engineers and MATSYS, Inc.

The XM913 weapon developed in partnership with Northrop Grumman Defense Systems improves upon traditional chain gun technology. New design improvements will enhance the weapon’s precision and accuracy through optimized mechanical design and advanced weapon control systems.

Picatinny engineers believe that in the future, the HEAB-T will most likely be the standard ammunition, replacing the High Explosive (HE) ammunition in service today that relies solely on a point detonating fuze capability. In contrast, the ALAS-MC HEAB-T uses a fuze that introduces a multimode programmable capability. This flexibility will enable settings of point detonate (PD), point detonate delay (PDD), and Airburst (AB), creating a fundamental change to how the warfighter conducts enemy engagements.

Today, a gunner uses high explosive rounds fired from the 25mm M242, and has to walk rounds into each target to achieve the desired effects. With the HEAB-T, the gunner can depart from this type of engagement. By using airburst mode, the round will be programmed with range to the target–and other important factors–for maximum lethal effect with an order of magnitude fewer shots. “Because of the increased complexity necessary to employ HEAB-T, efforts were focused on developing a much more advanced fire control system, which will enable optimized use of HEAB-T rounds,” said Adam Winters, Program Engineer, Armored Vehicle and Aviation Fire Control Systems.

The ALAS-MC fire control combines sensor data and a scenario based engagement capability/technique using hardware developed with Picatinny engineers and General Dynamics Mission Systems – Canada. This combination provides a number of advantages: optimize lethal effects against typical infantry fighting vehicle (IFV) targets, maximize stowed kills, reduce engagement time, reduce cognitive burden on the warfighter, reduce logistics footprint, and maximize affordability per engagement. As part of the scenario based fire control capability, the advance graphical user interface allows the gunner to select from a set of target icons that match common threats to an infantry fighting vehicle. “Based on the lethal footprint of the round, the fire control is able to automatically select the optimal number of rounds and most effective aim point for each target,” Winters said.

“Another key aspect of the ALAS-MC development is that it is using a development model aimed at future system growth that can be adapted for future technologies that enable multi-role missions,” Fitzpatrick noted. “When considering the potential target sets, ranges, and the lethal effectiveness required to meet future needs, the ALAS-MC team began ground up development of the future 50mm armament system with the intent to provide the warfighter with overmatch and a distinct advantage on the future battlefield,” said Fitzpatrick.

Railguns and Directed Energy Weapons for lethality and Survivability

Military is looking to deploy railguns and laser weapons to enhance lethality. US General Mark Milley said he was looking for a “breakthrough,” not incremental evolution for the US Army’s next tank. He also highlighted two other technologies that could revolutionize armored vehicle design.

* electrically-powered weapons, such as railguns – which use electromagnets to accelerate a solid metal slug to supersonic speeds

* lasers – which fire pure energy at the speed of light

These weapons require Electric power generation systems that can accommodate electric drive and high-power weapon systems and payloads

Survivability through movement of armor

One of the ways DARPA plans to achieve a lighter but more survivable tank is through “active repositioning of armor,” that is vertical and horizontal movement of armor to defeat incoming threats in real time. This results in enhancing the armor effectiveness by increasing the thickness of the armor at the place where missile is expected to hit without incurring the weight and size penalty of increasing the thickness of full armor. Increased threat defeat using conventional armor is prohibitive due to the significant weight burdens associated with increased protection. Any increase in weight has secondary effects such as limited off-road mobility and increased logistics burden.

The US Army has also called for specifications call for a mechanism that can move an armor panel, at least 1-foot-square in size, to a distance of 10 inches horizontally in less than five seconds. The armored panel would be an extra layer of protection attached to the outside of the vehicle, and remotely controlled by the crew.

The army also wants to avoid active protection systems like Israel’s Trophy system that automatically predicts the threat object trajectory and then instantly aims a launcher that fires a canister of ball bearings at high speed directly at the object. This however enhances the risk of injuring nearby infantry that are supposed to be protecting the tank.

Here is the main portion of the Army’s moveable armor proposal:

OBJECTIVE: Develop and demonstrate a model for a mechanism capable of moving an armor panel of at least 1 square foot with an areal density of 100 pounds per square foot (PSF) 10” horizontally in less than 5 seconds. The movement is intended to be repeatable and controlled from the interior of the vehicle and shall not pose harm to dismounted personnel.

DESCRIPTION: Conventional armor solutions currently being integrated are “not adaptable” in providing increased threat capability and protection from a greatly expanded set of threats. A solution is needed for threats that are not feasibly addressed with conventional armor systems. Conventional armor systems are essentially static and unable to respond to unanticipated changes in threats deployed against the system; essentially the army has limited potential to increase the capabilities of current static armor recipes in order to balance size, weight, and performance requirements.

This SBIR topic solicits new, innovative approaches to incorporate mechanisms into an armor system to provide protection against increased threats. For the purpose of this effort the system shall be designed to interface with a 1” plate of Rolled Homogenous Armor (RHA) Plate that represents a surrogate vehicle structure. The mechanism needs to be capable of moving a 100 PSF armor panel 10 inches horizontally in less 5 seconds. The mechanism needs to be able to withstand automotive loading as well as environmental conditions typical of a combat vehicle. The proposal should discuss in detail how the system could be incorporated onto a vehicle platform and what the projected Space, Weight, Power, and cooling (SWAP-C) at the vehicle level.

The proposal shall not include a system that could be describe as an Active Protection System (APS). A system is considered an APS system if any of the two statements apply: 1. A light-weight hit avoidance vehicle defense system which, when integrated on a ground combat vehicle, can detect, track; and then interdict by diversion, disruption, neutralization, or destruction of incoming line-of-sight threat munitions. 2. A system that deploys a counter-measure that does not providing any inherent protection to the vehicle system when the counter-measure does not perform as designed.

References and Resources also include:

http://www.militaryaerospace.com/articles/2016/04/stealthy-vetronics-that-hide-combat-vehicles.html

http://www.army-guide.com/eng/article/article_2968.html

https://www.army-technology.com/analysis/armoured-vehicles-tanks-ukraine-russia-ifv-nlaw-manpad/

https://www.newsweek.com/russia-lost-5k-military-vehicles-ukraine-war-1729590

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis