Nanotechnology is an industry that has recently begun to offer breakthrough solutions to the world. The incorporation of nanomaterials into thin films, coatings and surfaces leads to new functionalities, completely innovative characteristics and the possibility to achieve multi-functional coatings and smart coatings. The use of nanomaterials also results in performance enhancements in wear, corrosion-wear, fatigue and corrosion resistant coatings.

The term nanocoating refers to nanoscale (i.e. with a thickness of a few tens to a few hundreds of nanometers) thin-films that are applied to surfaces in order create or improve a material’s functionalities. Properties such as antifouling and antibacterial properties, product longevity, thermal insulation, gloss retention, friction reduction, dirt and water repellency, hardness, corrosion resistance, flame retardancy, ultraviolet radiation stability, improved energy efficiency, anti-graffiti, self-cleaning, moisture absorbing, and chemical and mechanical properties are improved significantly using nanomaterials such as carbon nanotubes, graphene and nanoparticulate metal oxides.

Nanomaterials incorporated into coatings and applied onto surfaces improve outdoor durability, wear resistance and toughness properties as well as meeting stringent regulatory and safety requirements. Nanocoatings provide resistance to fluctuations in temperature, as a result, they are popular in products that are impacted by temperature changes and harsh climatic conditions such as aircrafts, ceramic tiles, glass windows, automobiles, etc.

Nanocoatings also provide multiple functionalities in a single coating such as substrate adhesion, corrosion protection, enhanced colour effects and surface functionality/activity. Nanocoatings offer significant benefits for applications in the aerospace, defense, medical, marine, and oil industries, have driven manufacturers to incorporate multi-functional coatings in their products.

Self-cleaning, dirt and water repellent nanocoatings

A surface is not simply the physical division between an object and its environment; it fulfils a range of functions of its own which often play a crucial part in product design. Surfaces are supposed to feel good to the touch and to look good for as long as possible, be easy to maintain and not be spoiled by dirt, water stains or fingermarks. Traditional coating materials often do not stand the test of the increased demands made on materials today. In recent years however, advances have been made using methods ascribed to nanotechnology.

Nanocoatings also have been developed to protect buildings against pollution or to impregnate fabrics to thwart certain chemical weapons.

Antibacterial nanocoatings

Developing strategies to combat antibiotic-resistant bacteria is a major application area for nanocoatings. For instance, researchers have coated nanoparticles with a layer of antibiotics. Owing to chemical affinity, the resulting nanopharmaceutical acts only on the pathogens and is inert to the organism.

In another proof-of-concept study with mice, scientists have shown that a novel coating they made with antibiotic-releasing nanofibers has the potential to better prevent at least some serious bacterial infections related to total joint replacement surgery.

Researchers also have shown that anti-adhesive nanofilm patches that are developed from naturally occurring biomaterials can prevent destructive bacterial biofilm from forming on metal surfaces when they are immersed in water and other damp environments.

Anti-corrosion applications

Given the huge economic incentives, corrosion prevention and protection is a major business. The advanced materials that are being developed and used in modern industries require increasingly sophisticated coatings for improved performance and durability.

Nanocoatings also provide corrosion resistance, this increases the durability and lifespan of the metals where they are applied. For example, nano coatings are commonly applied on air craft parts as they are highly susceptible to corrosion.

Some research features graphene as a promising novel surface coating that can be used to minimize metallic corrosion under harsh microbial conditions. Other scientists have developed self-healing anticorrosion nanocoatings as alternative to toxic chromium. Another novel active protective nanocoating is able to indicate when corrosion processes start under the coatings or in different defects; it thus acts as a sensor.

Anti-friction and tribology applications

What happens when a fluid is brought in contact with a solid surface – the process of ‘wetting’ – has intrigued physicists and material engineers for a long time. In physical terms, the process of wetting is driven by the minimum free energy principle – the liquid tends to wet the solid because this decreases the free energy of the system. Understanding these mechanics, and using nanotechnology to structure surfaces to control wetting, has a far-reaching impact for many objects and applications in our daily lives: anti-sticking pans; low-friction coatings for engine parts; more comfortable contact lenses; better prosthetics; and self-cleaning, anti-fouling or anti-corrosion materials.

Tribologists – scientists who study friction, wear, and lubrication – are using graphene and other carbon nanomaterials to fabricate low-friction surfaces.

Historically, the use of Teflon (the anti-stick coating you find in many pans and pots) in bearings has been limited due to a poor wear life and low adhesion to bearing components. Novel thin, low-friction nanoparticle coating eliminates these weaknesses. A major area for non-stick nanocoatings is in the comsumer industry. Ever got frustrated by the amount of ketchup left in the bottle? No more! Nanocoatings leave no waste behind.

The water-based nanocoatings developed by a Texas A&M researcher can add fire and UV-light protection and chemical recognition capabilities to uniforms, reported in August 2021

Funded by the North Atlantic Treaty Organization (NATO), Jaime Grunlan, the Leland T. Jordan ’29 Chair Professor in the J. Mike Walker ’66 Department of Mechanical Engineering at Texas A&M University, is applying water-based nanocoatings to military clothing, adding protective properties like fire and UV-light protection, as well as chemical recognition capabilities.

Military clothing is made from a variety of textiles such as cotton, wool and synthetic blends. When adding a protective property, the initial benefits of the material are generally lost. “The reason we like cotton is its soft texture, just like we use nylon because it’s strong,” Grunlan said. “If the cotton is given flame-resistance properties, the fiber itself is modified, and the cotton will stiffen. Similarly, nylon exposed to a flame resistance treatment will weaken. Changing its structure essentially takes away its valuable intrinsic properties.”

Grunlan has developed a water-based, nontoxic solution that can add properties without changing the inherent structure of the clothing. A piece of clothing is dipped into a curated solution with a positive charge, extracted, then placed into a solution with a negative charge. The attraction of the opposing charges bonds the chemicals, creating a microscopic nanocoating that adheres to the clothing’s surface in an imperceptible layer.

This technique, commonly referred to as pad-dry processing, can be duplicated with various solutions, creating multiple layers with each new deposition. Each solution is tailored specifically to add certain qualities to the fabric. “For UV protection, we would add zinc oxide or titanium dioxide,” Grunlan said. “It’s the same ingredients you’d find in sunscreen. By mixing the right formula, we can optimize the clothing’s serviceability.”

In this case, he will be creating materials that are both flame retardant and provide protection against UV (ultraviolet) light. An additional, unique aspect of the design is chemical recognition. If the nanocoating is exposed to a hazardous substance, the material will change colors.

“Chemical warfare is increasingly becoming a threat,” Grunlan said. “Many chemicals or gases cannot be seen in the air. For that reason, we’re focused on detection based upon a color change, which will notify the user of the chemical agent, allowing them time to react quickly.”

The water-based composition of the solution contributes significantly to its multifunctionality. By not altering the fibers, the textile remains conformal and seemingly unaffected by the nanocoatings. This also makes the solution environmentally benign and cost-effective. Historically, chemical treatments to clothing have been frowned upon, as they have been linked to sickness and ailments. However, the water-based nature of this solution negates this problem, making it safe for widespread usage.

Grunlan hopes to extend this technology outside of military clothing to other areas that could benefit from protective clothing, such as children’s sleepwear or oil field uniforms. He and his collaborators from North Macedonia and Serbia, Igor Jordanov from Ss. Cyril and Methodius University, andMaja Radetic from the University of Belgrade, hope to eventually create technology that can reject chemicals or kill chemicals on contact. The use and success of the layer-by-layer technique opens new avenues and applications for this emerging technology.

Other high-tech nanocoating applications

Experimental physicists have developed a nanocoating with superconducting properties. Below about -200°C these materials conduct electricity without loss, levitate magnets and can screen magnetic fields. The particularly interesting aspect of this work is that the research team has succeeded in creating superconducting nanowires that can be woven into an ultra-thin film that is as flexible as cling film. As a result, novel coatings for applications ranging from aerospace to medical technology are becoming possible.

A nanocoating made from carbon nanotubes that, when layered around an aluminum-conductor composite core power transmission line, reduces the line’s operating temperature and significantly improves its overall transmission efficiency. A novel nanocoating for aircraft engines may triple service life and reduce fuel consumption. In order to extend the life of fruits and vegetables and preserve them for longer refrigeration, researchers developed an edible nanocoating with added functional ingredients applied to freshly cut foods.

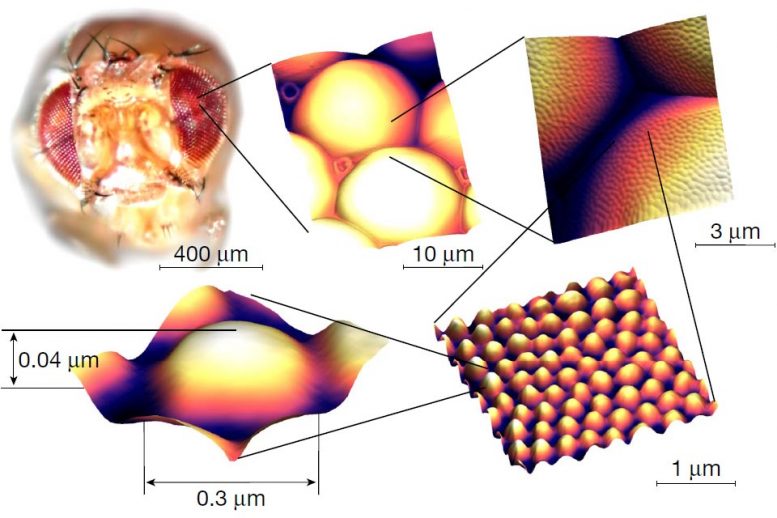

Scientists Replicate Self-Cleaning Anti-reflective Nanocoating of Insects’ Eyes

Scientists from Russia and Switzerland have probed into nanostructures covering the corneas of the eyes of small fruit flies. Investigating them the team learned how to produce the safe biodegradable nanocoating with antimicrobial, anti-reflective, and self-cleaning properties in a cost-effective and eco-friendly way. The protection coating might find applications in diverse areas of economics including medicine, nanoelectronics, automotive industry, and textile industry. The article describing these discoveries appears in Nature.

The craft of nanocoating meets demands in various fields of economics. It can wrap up any flat or three-dimensional structure, and, depending on the task, give it anti-reflective, antibacterial, and hydrophobic properties, including self-cleaning. The latter, for example, is a very important feature for expensive reusable overnight ortho-k lenses that correct the eyesight. Similar anti-reflective coatings are already known though created by more complex and costly methods. They are being used on the panels of computers, glasses, paintings in museums can be covered with them in order to exclude reflection and refraction of light.

“We are able to produce the nanocoating in any required quantity given that its design is more cost-effective compared to the modern methods of manufacturing similar structures. The work with natural components requires no special equipment nor significant energy consumption and constraints of chemical etching, lithography, and laser printing,” Vladimir Katanaev explains, the head of the research and Head of the Laboratory of Pharmacology of Natural Compounds in the School of Biomedicine of FEFU.

“The development has broad applications. For example, it could be the structural dying of textiles that would change the color depending on the angle of view. It is possible to create a disguise coat based on metamaterials, an antibacterial layer for medical implants, and a self-cleaning coating for contact lenses and windshields. We also believe that if we reinforce the nanocoating, it might be utilized as a basis of flexible miniature transistors prototypes designed for modern electronics.”

Scientists managed to rebuild the corneal coating of small fruit flies via direct and reverse bioengineering methods. First, they took the protective layer apart into its constituent components, which turned out to be retinin (protein) and corneal wax (lipids) and then reassemble it under room temperature conditions, covering glass and plastic surfaces. According to Vladimir Katanaev, any other types of materials can be nanocoated too. Combinations with different types of wax and genetic manipulations of the retinin protein allow the design of highly diverse and complex functional nanocoatings.

The scientist explains that the mechanism underlying the formation of the protective nanostructures on the corneas of Drosophila flies is a self-organizing process, described by Alan Turing back in 1952 as a reaction-diffusion mechanism. That is consistent with the mathematical modeling performed during the research. This mechanism is also responsible for the patterns forming, for example, on the fur of a zebra or a leopard. The nanostructures that protect the corneas of Drosophila eyes are the first established example of Turing patterns at the nanoscale.

In the course of the research project, scientists made a detailed characterization of the properties of retinin, as this protein has been little studied so far. It turned out that this initially unstructured protein forms a globular structure when interacting with corneal waxes. Thus, scientists took a look deep into the biophysical nature of the self-organization abiding to the Turing model, highlighting an important molecular process likely at the core of the self-organization – the initiation of the protein structuring.

At next stages, the research team aims at developing a model of three-dimensional nanostructuring (with nano-funnels, nanocolumns, nanorolls within the layer of the coating), also based on the Turing mechanism. This work would lie at the very frontier of modern scientific knowledge and can have promising fundamental and technological consequences.

Nanocoatings in Aerospace and Defense

New advances in Nano structured coatings offer the potential for significant improvements in engineering properties of aero components as well as space components. The potential benefits include higher hardness, wear-resistance, erosion-resistance, abrasion-resistance, oxidation and corrosion-resistance, self cleaning, anti-ice, and flame-retardent coating applications.

Aerospace companies and some goverment agencies are starting to use, or investigate the use of nanocoatings to add special characteristics to aircraft frames, interior components, engine parts, and other component surfaces, which can can benefit from the improved properties of nano-coatings.

Maintenance cost can be reduced through the use of nanocoatings, this is due to the extended life-span of the coatings and the increased on-the-wing time resulting from a longer lasting coating. This is particularly true in military aviation, but also in general and commercial aviation.

Military equipment and personnel must withstand some of the most demanding environments on earth. Nanostructured coating technology enables, for example, military aircraft and turbine powered vehicles and equipment to operate uninterrupted for longer by withstanding these extreme conditions. Scratch resistant coatings have been applied in aircraft cockpits.

The US Army is conducting extensive R&D designed to lead to the development of nanomaterials systems for military applications incorporating unique properties such as self-repair, selective removal, corrosion resistance, sensing, ability to modify coatings’ physical properties, colorizing, and alerting logistics staff when tanks or weaponry require more extensive repair. Major advances enabled by nanotechnology include the development of military grade active sensing packages to detect damage (corrosion, substrate integrity, etc.) and environmental conditions (i.e. radiation, chemicals, temperature, gases, strain, etc.).

Nanoscale thermal barrier coating systems are under development by the US Army and Air Force for aircraft surfaces (metal and fiberglass) that are exposed to moderate short-duration heating; high temperature hard environments in military vehicles; and in military gas turbine engines to increase component life and engine performance.

The harsh marine environment is one of the main drivers of ongoing maintenance costs for shipowners, whether it’s repairing steel damage caused by saltwater corrosion or removing barnacles and other wildlife that attach themselves to hulls, creating drag that reduces fuel efficiency. Across all industries in the US, corrosion costs alone are estimated at more than $1tn a year.

Innovations in nano-scale material science have led to the creation of anti-corrosion coatings that are enhanced at the molecular level. Ohio-based Tesla Nanocoatings offers a two-coat anti-corrosion system formulated with carbon nanotubes (CNTs), tiny rope-like carbon structures that can stretch without breaking, making applications easier – with two coats rather than three with many traditional anti-corrosion paints – and longer-lasting.

In March 2019, Michigan-based Nanovere Technologies won the Corrosion Innovation of the Year award at the National Association of Corrosion Engineers’ annual conference for its Nano-Clear coating, which contains 3D nanostructured polymers with a high crosslink density to improve protection and longevity.

Nanotechnology could also help solve the issue of marine biofouling by creating coatings that are adapted to provide no purchase for wildlife on ship hulls, without releasing harmful copper into the environment. Although this application is still developing and coming up with a specialised coating that can also withstand ocean forces is a challenge, academic centres such as the Ober Group at Cornell University are developing promising nano-materials for the task.

Nanocoating Market

The global nanocoatings market reached a value of US$ 5.9 Billion in 2019. he global nanocoating market is expected to reach an estimated $15.8 billion by 2025 and it is forecast to grow at a CAGR of 24.5% from 2020 to 2025. The major growth drivers for this market are increasing demand for nanocoating in end use industries due to superior functional properties and performance benefits over conventional coatings.

Nanocoating refers to very fine, thin layers of polymeric chemical substances that are used to impart specific chemical and physical characteristics to a substrate surface. This includes corrosion resistance, abrasion resistance, hardness, lubricity, transparency, and ductility. Nanocoatings are predominantly used to alter the hydrophobic and/or oleophobic properties of a surface by adding a protective coating on a substantially small scale of several microns.

Nanocoatings provide a clear, colourless protection that cannot be detected by the naked eye. This maintains a products aesthetic appearance and preserves the natural gloss and transparency of the product. Moreover, nano coated products do not easily accumulate dirt, however, on few occasions when foreign elements such as dust adhere to the surface, they can be easily cleaned.

Nanocoatings are able to provide protection against Ultra Violet (UV) light and resistance against abrasion. This significantly increases the life span of products and makes them ideal for the automotive industry to protect paint surfaces.

Nanocoatings are anti-adhesive and more hygienic as compared to conventional coatings. They prevent the growth of bacteria and microorganisms. Automobiles with nano coatings do not require waxing to maintain their shine. Moreover, they are also environment friendly, non- toxic and breathable, enabling them to be efficiently used on a variety of products as they inhibit damp and mold.

A nanocoating can be produced with utmost precision through a process which involves atomic building blocks, where atoms are deposited in a controlled fashion to produce a layer that conforms uniformly on every distinct feature of the surface. Catalysed by their superior physical and chemical properties the global demand of nano coatings is currently growing robustly in industries such as construction, food, healthcare, automotive, electronics, etc.

Based on the product type, the market has been segmented into anti-microbial, anti-fingerprint, anti-fouling, easy to clean and self-cleaning.

On the basis of end-use, the market has been segmented into construction, food packaging, healthcare, electronics, automotive, marine and others.

Self-cleaning and easy-to-clean, anti-microbial, and anti-fouling nanocoating are the major segments of the nanocoating market by function type. The anti-microbial nanocoating segment is expected to show above average growth during the forecast period due to its increasing usage to maintain a clean, hygienic environment in patient care facilities.

Region-wise, the market has been segmented into North America, Europe, Asia Pacific, Middle East and Africa, and Latin America. North America is expected to remain the largest region and APAC is likely to register the highest growth due to rising demand for nanocoating in the automotive, consumer electronics, and growing awareness of anti-microbial nanocoating for the healthcare industry.

Some of the key players being BASF, Bio-Gate, Buhler, Nanogate, PPG Industries, AdMat Innovations, Cima NanoTech, CG2 NanoCoatings, Cleancorp, Ecological Coatings, Eikos, Inframat, Integran Technologies, Nanofilm, Nanomech, Nanovere Technologies, Nanophase Technologies, P2i, Surfix and Tesla NanoCoatings, Adaptive Surface Technologies Advanced Materials-JTJ S.R.O., Alexium, Inc., Applied Nano Surfaces, Asahi Glass Co., Ltd., Cytonix LLC, Dry Surface Technologies LLC, DSP Co., Ltd., EonCoat, LLC, Green Millenium, Inc., Ionics Surface Technologies, Metal Estalki, Metashield, Nanopool GmbH, Nanto Protective Coating, Opus Materials Technology, P2i Ltd., qLayers, Quantiam Technologies, Inc., QuatCare LLC, Sciessent LLC, SuSoS AG, Surfactis Technologies SAS, Surfix BV, Tesla Nanocoatings, Toto etc.

References and Resources also include:

https://www.nanowerk.com/nanocoatings.php

https://ship.nridigital.com/ship_jul20/nanotechnology_shipping#popup-location-2

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis