According to the University of Maryland’s Global Terrorism Database, there were a total of 143 attacks – 35 biological, 95 chemical, and 13 radiological – using CBRN weapons across the world from 1970 to 2014. The relative ease with which malicious actors could obtain many of the materials and know-how and wide range of dissemination techniques makes them appealing to extremist groups. Biological weapons achieve their intended effects by infecting people with disease-causing microorganisms and other replicative entities, including viruses, infectious nucleic acids and prions. The chief characteristic of biological agents is their ability to multiply in a host over time.

CBRN defence remains an indispensible part of the strategic security preparedness of all nations. CBRN protection includes identifying threats and hazards and preventing or mitigating the effects of CBRN environments. Protective measures include individual protective equipment, detection devices, contamination mitigation technology as well as medical countermeasures. To be resilient, we must be able to respond quickly and effectively to all emerging threats with the appropriate resources including decontamination technologies.

The environmental impact of incidents involving Chemical Warfare Agents (CWAs) can be long-lasting and requires meticulous and expert decontamination by chemical operations specialists. The clean-up process also takes considerable time, as has been evidenced in the case of the Novichok nerve agent attack in Salisbury, UK in March 2018. Nearly two months after the incident, a total of nine key sites connected to the attack remain under guard behind high-security barriers while they await specialist decontamination.

DEFRA’s Chief Scientific Advisor, Ian Boyd, is chair of the decontamination science assurance group explains, the decontamination of each site will involve testing to categorise the level of residual contamination, followed by the removal of affected items, chemical cleaning and then further retesting. The clean-up crews are also expected to take soil samples for further analysis.

Vehicle Contamination

Vehicle contamination becomes a key concern in military operations. When chemical weapons first made their military debut in 1915, warfare was largely an affair dominated by infantry foot soldiers, and artillery was towed by horses. Warfare in the modern era relies heavily on armoured and unarmoured vehicles. Artillery systems are towed by vehicles or are self-propelled. Vast logistical trains of trucks support modern armies in the field. Aircraft have numerous military uses. All of these are vulnerable to contamination.

Various surfaces and materials on vehicles could absorb liquids and actually make them more persistent than they would normally be in the ambient environment. Persistent contamination could cause injuries long after an attack, as substances desorb out of vehicle exteriors or interiors. Vehicle crews and passengers could be forced to wear cumbersome protective clothing, thus degrading their operational capability. Loss in operational capacity due to the operational necessity of wearing CBRN protection is a strong motivator in military decontamination planning. No artillery crew wants to spend hours or days in full kit while conducting fire missions.

Contaminated vehicles could spread contamination from the site of an attack, thus contaminating roads, airfields or supply routes. Vehicle crew or passengers could inadvertently transfer contamination when they leave a vehicle. Driving to a designated decontamination site is likely to spread contamination. The decision as to where and when to conduct decontamination needs to account for the operational imperatives of ongoing combat operations, while also understanding that decontamination is best done quickly and nearby, rather than much later and far away.

Military Decontamination

For military there are two type of decontamination, operational and thorough. “The purpose of thorough decon is to get you completely clean so you can go back to the motor pool, go back to the (forward operating base), go back wherever you need to go,” said 1st Lt. Brendan Hales, platoon leader for 3rd Platoon, 44th Chem. Co. during a CBRN decontamination training. “The purpose of operational decon is to quickly get all the decontaminants off so you can turn around and go back into the fight.” Thorough decon is both the most effective type of decon and is the most resource intensive. Operational decon requires less resources, but physically removes only surface contamination.

The thorough decon site consists of four main areas: the predecon staging area, the detailed equipment decon (DED), the detailed troop decon (DTD), and the postdecon assembly area. The chemical unit leader selects all four areas based on operational guidance, road network, available cover and concealment, and water supply. The predecon staging area is used by the contaminated unit to ready themselves for DED and DTD operations. The DED is the process of removing, neutralizing, or reducing contamination on interior and exterior surfaces of equipment to negligible risk. The DTD is the process of decontaminating individual fighting equipment to negligible risk and removing contaminated MOPP gear from soldiers. The postdecon assembly area is the location where vehicle and soldiers exiting the DED and DTD are linked up prior to their movement from the decon site.

A limiting factor that must be considered when planning any decontamination operations is the availability of water. A typical vehicle will require 500 gallons of water during detailed equipment decon. The actual amount of water required will vary by vehicle and its condition.

Under the current methods of material decontamination, platforms and personnel would have to leave the fight and use vast amounts of water and resources to be rendered safe. When deployed, the decontamination slurry will provide more efficient and effective decontamination for vehicles and equipment on the battlefield.

While it was designed for water filtration, the researchers have other applications in mind. Griggs and Mattei-Sosa think it can make construction materials stronger and Medina has been looking at using it for decontamination, as a wipe or a “bandage,” to bind contaminants.

Decontamination technologies

There are numerous technical and operational approaches to vehicle decontamination. A classic approach to decontamination is neutralisation. Some authorities call this detoxification. This approach uses chemical substances, often in solution with water, to react with chemical or biological agents on a vehicle. The ionising radiation emitted by radiological particles is not inactivated by chemistry, so these methods apply only to chemical and biological contaminants. A wide variety of chemical substances have been used over the years for these purposes. Many are chlorine-based, such as hypochlorite bleaches. Acids and peroxides have often been used as well. In the USA there is interesting work being done on specific enzymes to increase the vulnerability of specific categories of chemical agent to reaction with water. In general, the various neutralisation solutions often require removal after use, generally by rinsing with water.

Another approach is removal. Decontamination by removal generally involves water, often with soaps or detergents, which can be generic or proprietary. Full decontamination of large combat systems like tanks can take hundreds of gallons of water per vehicle and an extensive amount of labour. Decontamination by removal may be aided by soaps, detergents, surfactants, chelating agents and other such products. Thick, greasy, or oily contaminants, such as mustard or VX, may require scrubbing to come off a vehicle. Decontamination of a company or battalion of combat vehicles can easily tie up dozens of specialists and take many tonnes of water. Indeed, water logistics are often a critical component of CBRN decontamination plans, and some environments, such as deserts, will have limited availability of water for decontamination.

In practice, there is significant overlap between neutralisation and removal techniques. Warm soapy water is, in effect, both a removal agent and a neutralisation agent for many types of threats. Many chemical warfare agents react with water over time. A large number of commercially available neutralisation chemicals are, in effect, cocktails that include detergents and surfactants and such to help removal as well as neutralisation.

It should be noted that some approaches in the past have used other creative methods than water for removal. Some approached have utilised large air blowers, even dismounted jet engines. The Soviet Union developed a jet engine mounted on a truck, called the TMS-65. It is still occasionally seen in Russia and other former Soviet states. Such an approach may work, but stands the risk of creating a significant downwind vapour hazard by volatilising persistent chemicals. In the past, even more creative approaches had been tried. In the early 1990s, the US Army experimented with chlorinated fluorocarbons as a removal agent, but both cost and environmental issues doomed this idea.

Bio-decontamination equipment refers to the equipment, for example, a chamber or a confined box in which cleaning process is performed. Decontamination might be finished by physical means, synthetic or science based strategies. Disinfecting with physical means includes strategies, for example, thermal, high weight techniques and others. Decontamination by synthetic substances includes utilization of oxidizing operators, surfactants for balance of concoction waste and others. Science based disinfection techniques include utilization of enzymatic frameworks, counterfeit microscopic organisms and others.

Decontamination is one of the main focal points of enhanced CBRN training, using Dismount Recon Sets Kit and Outfits (DRSKO) and practicing on pig carcasses is a major stepping stone. CBRN specialists conduct this training annually to provide the Marines with a realistic scenario to hone their skills within their Military Occupational Specialty (MOS). “This is a completely different environment than we are used to,” said Cpl. Tyler Chapman, a CBRN specialist with Headquarters Battalion, 2d MARDIV. “Pig skin is very similar to that of humans. So, it truly prepares us for the decontamination of a Marine if the case was to arise.”

The decontamination process is precise and thorough. From the time a pig reaches the decontamination line to the time it exits, everything is done in a specific manner. One mistake can lead to failure in the training. “It is a step-by-step process that is extremely detailed,” said Lance Cpl. Scott Elliott, a CBRN specialist with Headquarters Battalion, 2d MARDIV. “We start by monitoring the pigs with various tools to search for radiation as well as possible chemicals. The cleaning process is in depth; we scrub the pigs while monitoring to see if radiation levels decrease. Once we find we have cleared all the loose radiation, we then know our job is done.”

While the Marines take precaution to protect themselves from dangerous chemicals, there is always the possibility of a Marine getting contaminated with an unknown substance in effect. Knowing how to quickly and adequately go through the decontamination process is not only important training for the Marines, but is also a necessary lifesaving skill set.

Recently UK Military developed Microsoft’s HoloLens 2 based device, the most advanced mixed reality wearable device on the market, to create an innovative and experiential learning experience for decontamination, to remove the threat of soldiers getting infected .

Graphene oxide tech developed, patented by US Army

Concern that the U.S. military could run out of water while washing tanks and trucks exposed to chemical and biological weapons has led to development of a new water recycling system built by the U.S. Army Engineer Research and Development Center’s Environmental Laboratory. It solves the problem by filtering out the bad stuff, which allows the wastewater to be reused or dumped.

Known as the Decontamination Effluent Treatment System, it can filter up to 600 gallons of wash water per hour, according to Victor Medina, a research engineer in the Army lab. But an offshoot of Medina’s work has led to a new filter membrane made of graphene oxide, a unique material with a tendency to self-assemble in layers, creating narrow channels that are perfect for filtering water.

While graphene oxide is great as a filter, it’s also really expensive, around $250 per gram expensive, so the researchers wanted a way to recycle it to lower production and lifecycle costs. Using chitosan, which is made of crustacean shells and is relatively inexpensive, the researchers were able to bind the graphene oxide into a recyclable membrane.

In September, the Army was granted U.S. Patent 10,414,659 for the recycling idea, and another is pending on the filter membrane itself. Both are available now to U.S. companies for the development of new products, water-related or not.

U.S. Army Lab prepares new decontamination spray technology for field testing

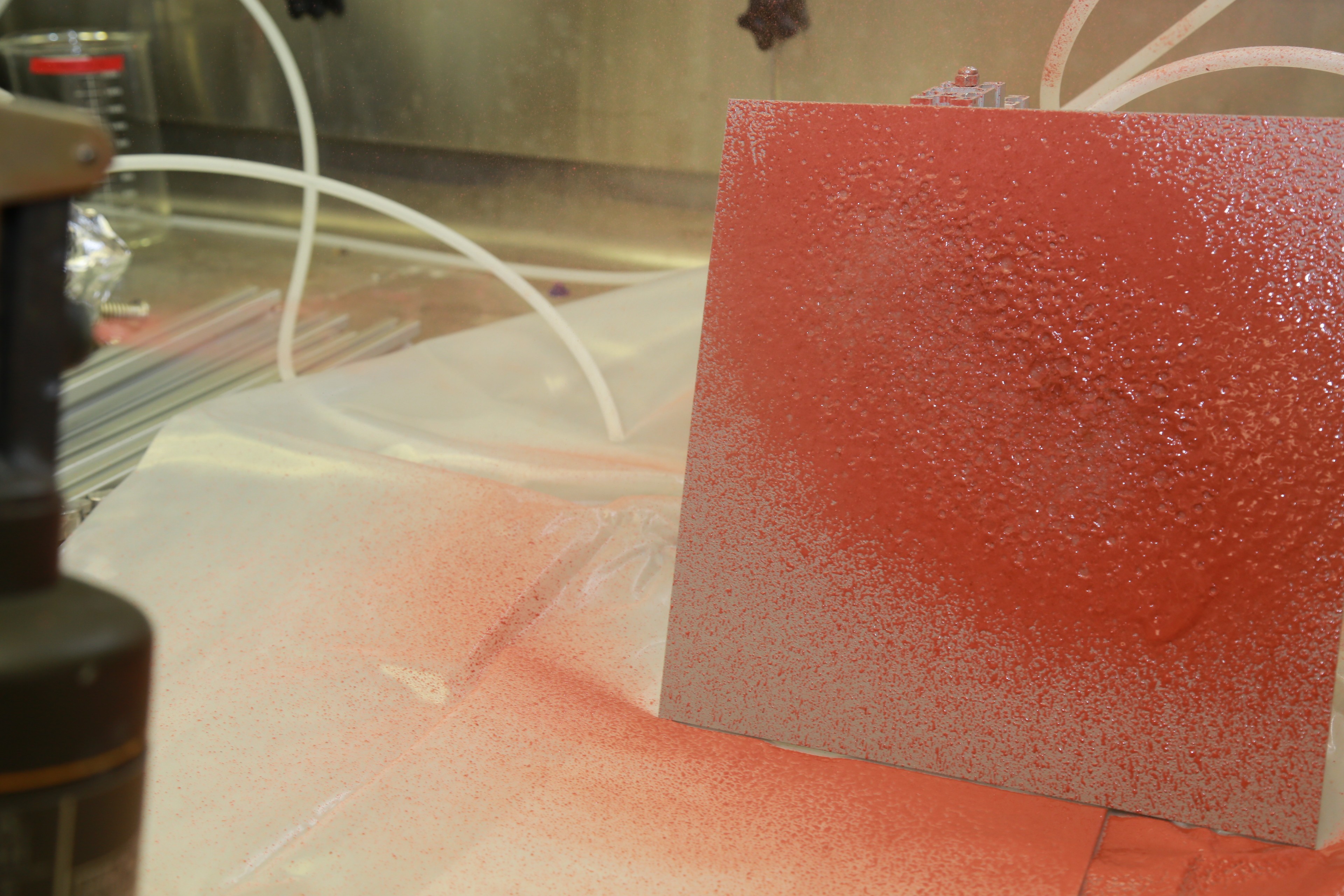

A sprayable decontamination slurry, developed by scientists at the U.S. Army Edgewood Chemical Biological Center is entering the next stage of its development and will soon be tested on a larger scale beyond the laboratory. The slurry is a highly effective decontaminant and works through multiple mechanisms: hydrolysis and oxidation. The slurry is designed for material decontamination of equipment and vehicles — like the fender of a Humvee — but not skin.

“This is designed for immediate, material decontamination,” said Joseph Myers, a research chemist with ECBC’s Decontamination Sciences Branch. “Theoretically, let’s say there are Soldiers in the field and their Humvee is contaminated with chemical warfare agent. After getting to safety, they can mix up the decontaminant slurry, spray it on the vehicle, and drive back to the base.”

“This new technology will decrease the time and resources needed to respond to an attack, allowing units to maintain their momentum and increase their effectiveness on the battlefield,” explained Maj. John Williams, assistant product manager for science & technology portfolio integration. “Because of the versatility of the slurry and its effectiveness on multiple surfaces, this new technology will enable all future Army systems to operate in a contaminated environment, including new ground and air platforms.”

Resembling a thick paint, the slurry is a solid-liquid hybrid and may require a special sprayer. Myers thinks the sprayer could resemble a pump-action pesticide sprayer or maybe a backpack sprayer similar to a fire extinguisher. In the coming months, the capability will be rigorously vetted to confirm that its laboratory-level efficacy is ensured in the field.

Thus far, Myers is confident in the slurry’s effectiveness. “If you were to apply this as an immediate decon — within 15 to 30 minutes — you let it sit on the material for four hours, you get 99.9 percent removal for blister and nerve agent,” he said. “The slurry achieves this efficacy through its combination of hydrolysis and oxidation.” Some agent can be decontaminated through hydrolysis but not oxidation and vice versa, but by combining the processes, the slurry is more universally effective.

“Zirconium hydroxide works by a process called hydrolysis,” Myers said. “Through the optimization process, we’ve added another chemical into the mix that promotes oxidation. With a blend of hydrolytic and oxidative chemistries, the slurry has the ability to detoxify a wide range of chemical warfare agents.” This blend was identified by experimenting with different ingredients to determine which would be most effective in the laboratory.

“The primary component of this slurry is called zirconium hydroxide,” Myers said. “We took this substance, which is like a fluffy, white powder, and we mixed it in with kerosene, with the assumption that kerosene would be prevalent in the field. Mixed together, the components made a decontamination slurry.”

Myers later found that sulfolane would make a better carrier liquid than kerosene, because it promotes the extraction of agent from materials. When agent is extracted, the slurry’s other ingredients, like zirconium hydroxide, can begin to hydrolyze or oxidize with the agent. “We swapped out the kerosene for a new solvent, sulfolane, and that did a better job of removing agent that soaked into materials,” Myers explained. Sulfolane is a high flashpoint solvent, which makes it logistically favorable for transport, Myers said.

Funded by the Defense Threat Reduction Agency, the capability is a year or two away from being deployed, Myers said. “This has a high probability of being provided to the warfighter,” he said. “It’s highly effective, it’s easy to use, and none of the ingredients are particularly hazardous.”

Mixed reality training solution, developed by KBR in collaboration with Microsoft, has won a prestigious UK industry award for innovation.

For 12 months, KBR’s Government Solutions EMEA Advisory team has been working to create the world’s first mixed reality solution for Chemical, Biological, Radiological and Nuclear (CBRN) medical training for the Defence Medical Services section of the UK Ministry of Defence (MOD), with help from Microsoft. The project won the ‘Visionary Award for Protecting Society and Saving Lives’ at the 16th Institute of Engineering and Technology Innovation Awards, which recognize the people, projects, and organizations transforming our world for the better through engineering and technology.

The project utilizes Microsoft’s HoloLens 2 device, the most advanced mixed reality wearable device on the market, to create an innovative and experiential learning experience, while improving the retention of knowledge and skills. The collaborative team created a unique instructor led solution that gives medical practitioners an immersive and highly realistic training scenario where they can accurately replicate the decontamination, diagnosis, triage and stabilization of a patient exposed to a chemical agent.

“This project epitomises KBR’s vision to design and deliver the future, enhancing our capability in the human performance and training transformation market,” said Andrew Barrie, President, Government Solutions – EMEA. KBR was awarded the contract by the UK MOD to design and run a pilot in April 2019 to prove the technology. Following approval and funding in September 2019, full development of a complete augmented reality training simulation tool using agile software development was completed.

Industry and Market growth

The global Bio-decontamination Equipment market is valued at 100 million US$ in 2017 and will reach 160 million US$ by the end of 2025, growing at a CAGR of 5.6% during 2018-2025. QY Research has come up with a fresh new report on the global bio-decontamination equipment market, which carries the title “Global Bio-decontamination Equipment Market Research Report 2018

High use of bio-decontamination equipment in hospitals and other healthcare institutions due to the rising concerns over the spread of hospital-acquired infection (HAI) is expected to create a whole lot of demand in the market. Rise of the geriatric population that is more susceptible to diseases could also fuel the demand for bio-contamination equipment.

Increasing number of government initiatives, improving awareness about decontamination, and growing investments in the research and development of new bio-decontamination equipment are foretold to benefit the market. Nonetheless, rising number of technological applications of bio-decontamination equipment could create rewarding opportunities in the market. Increasing prevalence of infectious diseases that also affect the young could be another factor augmenting the development of the global bio-decontamination equipment market.

However, economic slowdown, expensive cost of products, and strict government regulations in some countries are anticipated to hamper the growth of the global bio-decontamination equipment market. Moreover, the long lifecycle of bio-decontamination equipment could discourage its adoption in end-use industries.

Followed by Europe, North America is foretold to rank highest in terms of market share. In 2017, it collected a share of more than 47.0%. Europe and the U.S. are observed to provide most of the high-end products in the global bio-decontamination equipment market.

In 2017, nine of the leading companies operating in the global bio-decontamination equipment market accounted for a close to 80.0% share of the market. This shows that the market is a highly concentrated one. JCE Biotechnology, TOMI Environmental Solutions, Fedegari Group, Bioquell, and STERIS Life Science are the top manufacturers of bio-decontamination equipment. Among these, STERIS Life Science leads the global bio-decontamination equipment market. In 2017, it secured a revenue share of over 38.0%.

In the European space, Kärcher (GE) and OWR (GE) continue as market leaders in many markets beyond their own domestic market space. Both Kärcher and OWR provide both equipment (sprayers of all sizes) and chemistry (solutions for removal and neutralisation) for every major CBRN vehicle decontamination requirement. Bioquell (UK) is not a major player in the traditional military vehicle decontamination market, but its peroxide fumigation technology may have extensive use for sensitive equipment and vehicle interiors, given the opportunity. NBC Sys (France) and Hispano Vema (Spain) continue to make products mostly for their own respective domestic markets.

Cristanini (Italy) continues to hold a prize place among decontamination companies, with successful marketing efforts in both military and civil emergency response agencies in dozens of countries. They have two systems of note that represent useful capabilities in vehicle decontamination. The Cristanini Mobile Decontamination Arch is, in effect, the equivalent of a mobile car wash. It is modular and can be assembled in various sizes for different vehicles. It can apply water, or generic cleansing agents, or Cristanini’s own decontamination chemicals. A single arch can use up to 59 litres of water per minute. Thoroughness of decontamination can be modulated by the speed at which vehicles transit through the arch. Several can be set up in series, with one arch applying decontamination solutions from every angle and one or more arches further on to rinse off the vehicles and any remaining residual contamination.

Czechs have inherited much of the Warsaw Pact’s expertise in CBRN operations and continue to provide valuable service in this space. VOP Defence, near Brno, makes several vehicle decontamination systems, including the MDA Small Decontamination Vehicle. Their Linka-08 is configured in an ISO container and can set up a “car wash” style decontamination lane. The Czechs specialise in providing CBRN capability to NATO, so these systems will get seen a fair bit.

In the US CBRN market space, which traditionally accounts for about half of worldwide CBRN expenditures, M26 Joint Service Transportable Decontaminating System Small Scale (JSTDS-SS) has been an old capable system made by DRS Technologies (USA). capable system. Two rival decontamination chemical solutions are now on the US and world market. So-called “Sandia Foam”, first developed by the US Department of Energy’s Sandia National Laboratory, is now licenced for commercial exploitation by private companies. The other major American product of note is called Dahlgren Decontamination Solution. It originated from research starting in 1999 at the US Navy’s research centre in Dahlgren, Viriginia. So-called “Dahlgren” solution, a set of three chemicals which are meant to be dissolved in water, is highly effective at decontaminating chemical and biological agents. It is now licenced to First Line Technologies, a Virginia-based company. This technology won a Federal government prize for “Excellence in Technology Transfer” in 2018.

Canada’s DEW Engineering and Development, based in Ottawa, has developed a combined personnel and vehicle decontamination system. This has been done in partnership with the French firm NBC Sys. This relatively recent system can decontaminate up to four armoured vehicles an hour. At least six systems were procured by the Canadian military, and the Canadian government retains options to buy several more.

References and resources also include:

https://euro-sd.com/2020/02/articles/16043/cbrn-decontamination-of-vehicles/

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis