Quantum dot lasers are revolutionizing precision light technology, enabling breakthroughs in communication, medicine, and consumer electronics.

In the ever-evolving world of photonics, quantum dot lasers are emerging as a transformative technology. By combining the unique properties of quantum dots with advanced semiconductor laser designs, these devices offer unmatched efficiency, stability, and precision. As industries demand ever faster, smaller, and more reliable light sources, quantum dot lasers are becoming central to applications ranging from next-generation telecommunications to medical diagnostics and even consumer electronics.

Introduction to Quantum Dots

Quantum dots are nanoscale semiconductor particles, typically just 2–10 nanometers in diameter, that behave like artificial atoms. Because of a phenomenon known as quantum confinement, the electrons inside these tiny structures are restricted in all three dimensions, creating discrete energy levels. When excited, they emit exceptionally pure light whose color depends not on the material itself but on the dot’s size. This unique property allows precise control over light emission, making quantum dots invaluable across fields ranging from ultra-vivid displays and medical imaging to secure quantum communication.

Building on these properties, researchers developed quantum dot lasers—a revolutionary class of photonic devices that outperform traditional semiconductor lasers.

Quantum Dot Lasers: A Leap Beyond Conventional Designs

Lasers have long been at the heart of modern technology, from powering global communication networks to enabling precise surgical tools and advanced sensing systems. Yet, as demands for higher efficiency, greater stability, and miniaturization continue to rise, conventional semiconductor lasers are reaching their limits. This has opened the door for quantum dot lasers—a new generation of photonic devices that harness the unique properties of nanoscale materials to overcome many of the shortcomings of traditional designs.

Traditional semiconductor lasers—whether based on bulk materials or quantum wells—face inherent challenges in efficiency, thermal stability, and wavelength control. Quantum dot lasers overcome these barriers by embedding nanoscale quantum dots within the laser’s active region. These dots act like “artificial atoms,” fully confining electrons and holes in all three spatial dimensions. This confinement creates discrete, quantized energy states rather than continuous energy bands, fundamentally changing how carriers interact. They exhibit superior temperature stability, since carrier confinement reduces sensitivity to thermal fluctuations.

When confined electrons recombine with holes inside a quantum dot, they emit photons at sharply defined energies, giving the laser precise control over its emission wavelength. Because of this quantization, fewer carriers are needed to reach the threshold for lasing, significantly reducing power requirements. The result is a laser with higher efficiency, narrower spectral linewidths, and superior thermal stability compared to conventional semiconductor lasers. Finally, their broad gain spectra allow tunable operation across multiple wavelengths, making them adaptable to diverse environments and technologies.

Key Applications of Quantum Dot Lasers

Since their theoretical foundations in the 1980s and commercial progress in the 1990s, quantum dot lasers have matured into practical, high-performance technologies. Today, they are driving advances in telecommunications, medical imaging, LiDAR, and consumer electronics. As manufacturing techniques continue to improve, their role is expected to expand even further, positioning quantum dot lasers as the next dominant platform for precision light sources.

Optical Communications

Quantum dot lasers are transforming fiber-optic communication systems through their superior performance characteristics. These lasers naturally emit at the crucial telecommunications wavelengths of 1.3 µm and 1.55 µm, which correspond to the lowest loss transmission windows in optical fibers. Their narrow linewidth and stability make them ideal for dense wavelength division multiplexing (DWDM) systems that pack multiple data channels into a single fiber. Major telecommunications companies are adopting quantum dot lasers to enable next-generation networks capable of 100Gbps and beyond transmission speeds.

The technology is particularly valuable for coherent optical communication systems used in long-haul networks. Quantum dot lasers maintain signal integrity over thousands of kilometers while consuming less power than conventional options. Their compatibility with silicon photonics platforms is enabling new integrated optical circuits that combine lasers, modulators, and detectors on single chips. This integration promises to revolutionize data center interconnects and bring unprecedented speed and efficiency to cloud computing infrastructure.

Medical Imaging & Surgery

In the medical field, quantum dot lasers are enabling new diagnostic and therapeutic capabilities. Their precise wavelength control and beam quality make them ideal for minimally invasive surgical procedures where accuracy is paramount. Surgeons can perform delicate operations with reduced thermal damage to surrounding tissues, leading to faster patient recovery times. The lasers’ stability ensures consistent performance throughout lengthy procedures.

For diagnostic applications, quantum dot lasers enhance advanced imaging techniques like optical coherence tomography (OCT). Their narrow spectral output improves OCT resolution, allowing doctors to detect early signs of disease with greater confidence. Researchers are developing multispectral imaging systems that use multiple quantum dot lasers to identify different tissue types and detect biochemical changes associated with conditions like cancer. These systems promise to revolutionize early disease detection and precision medicine.

LiDAR & Sensing Systems

The unique properties of quantum dot lasers make them exceptionally well-suited for light detection and ranging (LiDAR) applications. Autonomous vehicles benefit from their eye-safe operation at high power levels, enabling longer detection ranges while meeting safety standards. The lasers’ temperature stability ensures reliable performance in varying environmental conditions, from freezing winters to scorching summers.

Industrial and environmental sensing applications leverage quantum dot lasers’ precise wavelength control. Gas detection systems can target specific molecular absorption lines with unprecedented accuracy, enabling leak detection and air quality monitoring with few false alarms. In manufacturing, quantum dot laser-based metrology systems provide nanoscale measurement capabilities for quality control in semiconductor fabrication and precision engineering.

Consumer Electronics

Quantum dot laser technology is beginning to transform consumer products, particularly in display and projection systems. Their pure, stable colors and high brightness make them ideal for next-generation displays that surpass current LED and OLED technologies. Augmented reality devices benefit from the lasers’ small size and efficiency, enabling more compact and power-efficient designs.

The technology is enabling new categories of consumer products, including ultra-compact laser projectors that fit in smartphones while delivering cinema-quality images. Future applications may include holographic displays and ultra-high-definition projection systems for home theaters. As manufacturing costs decrease, quantum dot lasers could become standard in many consumer electronic devices.

Enabling Technologies

Silicon Photonics Integration

One of the most significant developments in quantum dot laser manufacturing is their integration with silicon photonics platforms. Researchers have developed hybrid integration techniques that combine III-V semiconductor quantum dots with silicon waveguides and circuits. This approach leverages the mature silicon manufacturing infrastructure while benefiting from the superior optical properties of III-V materials.

The integration challenge involves overcoming the lattice mismatch between silicon and traditional quantum dot materials. Various solutions have been developed, including direct bonding techniques and the growth of buffer layers that accommodate the crystal structure differences. Successful integration enables the creation of complete photonic integrated circuits that combine quantum dot lasers with modulators, detectors, and electronic control circuits on a single chip.

Colloidal Quantum Dots

While most commercial quantum dot lasers use epitaxially grown dots, solution-processable colloidal quantum dots are emerging as an alternative for visible wavelength applications. These quantum dots can be synthesized through chemical methods and deposited using relatively simple techniques like inkjet printing or spin coating. Although currently less efficient than their epitaxial counterparts, colloidal quantum dot lasers offer advantages for flexible electronics and low-cost applications.

Recent breakthroughs in surface passivation and charge transport in colloidal quantum dots have significantly improved their performance. Researchers have demonstrated electrically pumped lasing from colloidal quantum dots, bringing the technology closer to commercial viability. This development path could lead to printable quantum dot lasers for flexible displays, wearable devices, and other novel applications where traditional semiconductor lasers cannot be used.

Current Technical Challenges

Despite their impressive advantages, quantum dot lasers still face several technical hurdles that must be addressed for wider adoption. Manufacturing costs remain significantly higher than for conventional laser diodes, primarily due to the complex growth processes and lower production yields. While MBE and MOCVD technologies continue to improve, further refinements are needed to make quantum dot lasers cost-competitive for high-volume applications.

Reliability testing and lifetime validation present another challenge. The long-term performance of quantum dot lasers under continuous operation needs more extensive characterization, particularly for demanding applications like undersea communications cables where maintenance is extremely costly. Researchers are working to better understand degradation mechanisms and develop more robust device structures.

Expanding the wavelength range of quantum dot lasers remains an active area of research. While excellent performance has been achieved in the near-infrared spectrum, developing efficient quantum dot lasers for ultraviolet and far-infrared wavelengths would open new application possibilities. This requires breakthroughs in materials science to create quantum dots with the appropriate bandgap energies while maintaining good optical properties.

Manufacturing Breakthroughs in Quantum Dot Lasers

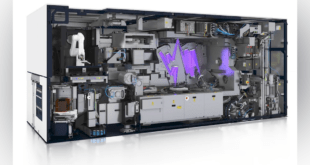

The path from laboratory prototypes to widespread adoption of quantum dot lasers depends heavily on advances in manufacturing. Two main fabrication techniques—molecular beam epitaxy (MBE) and metal-organic chemical vapor deposition (MOCVD)—have driven the field forward, each playing a distinct role in balancing precision with scalability.

Molecular Beam Epitaxy (MBE): Precision Engineering

MBE has long been the gold standard for producing high-quality quantum dot structures. By depositing atoms in an ultra-high vacuum, this technique allows researchers to control quantum dot size, composition, and density at the atomic level. Such precision is essential, since these parameters directly determine the optical properties of the resulting lasers. Recent improvements in MBE include advanced strain-engineering methods that minimize lattice mismatch defects between semiconductor layers. These refinements yield nearly defect-free quantum dots, improving reliability and extending device lifetimes—critical factors for commercial deployment.

Metal-Organic Chemical Vapor Deposition (MOCVD): Scalable Mass Production

While MBE excels at precision, it is slow and expensive, limiting large-scale production. MOCVD has emerged as the practical alternative for manufacturing quantum dot lasers at scale. By using chemical precursors in a controlled reactor environment, MOCVD enables rapid, uniform deposition of quantum dot layers. Modern reactors are equipped with in-situ monitoring systems, giving engineers real-time control over growth conditions and ensuring consistent performance across batches. This scalability makes MOCVD especially attractive for high-demand applications such as optical communications.

ETRI’s Cost-Effective Manufacturing Breakthrough

A major leap in production economics has been achieved by South Korea’s Electronics and Telecommunications Research Institute (ETRI). Their team developed an advanced MOCVD process to fabricate indium arsenide/gallium arsenide (InAs/GaAs) quantum dot laser diodes that operate at the key 1.3 µm wavelength used in fiber-optic networks. Remarkably, this process reduces manufacturing costs to just one-sixth of traditional methods, while maintaining world-class performance.

The breakthrough replaces costly indium phosphide (InP) substrates with more affordable gallium arsenide (GaAs), which are less than one-third the price, without compromising laser quality. Devices produced with this method have demonstrated continuous operation at temperatures up to 75 °C—a record for MOCVD-grown quantum dot lasers. By combining cost savings with superior performance, ETRI’s approach addresses one of the biggest barriers to widespread commercialization. The institute is now working to optimize the process for reliability and transfer the technology to domestic optical communication companies through its semiconductor foundry network, accelerating adoption and boosting competitiveness in global markets.

Future Development Directions

The most promising near-term development is the creation of quantum dot lasers monolithically integrated on silicon substrates. This would dramatically reduce costs by allowing fabrication in standard CMOS foundries. Several research groups have demonstrated proof-of-concept devices, with commercial viability expected within the next few years. Such integration would be transformative for silicon photonics, enabling complete optical systems on chip for data centers and high-performance computing.

Another important direction is the development of electrically pumped visible-light quantum dot lasers. While optically pumped versions have been demonstrated, creating efficient electrically driven devices remains challenging. Success in this area would enable new applications in displays, projectors, and biomedical devices. Recent progress in materials engineering and device architecture gives reason for optimism about near-term breakthroughs.

Researchers are also working to push modulation speeds beyond 100 GHz, which would make quantum dot lasers even more attractive for high-speed communications. This involves optimizing the carrier dynamics in quantum dots and reducing parasitic effects in device structures. Combined with their inherent temperature stability, such high-speed quantum dot lasers could become the standard for next-generation optical networks.

Conclusion

Quantum dot lasers represent a major leap in precision light technology. Their combination of efficiency, stability, tunability, and potential for cost-effective mass production makes them a cornerstone of the next generation of photonics. From powering global communications and enabling early disease detection to driving consumer innovations, quantum dot lasers are not just an incremental improvement—they are a transformative technology shaping the future of light.

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis