Innovation knows no bounds, and the world of materials engineering is no exception. Among the most exciting developments in recent years is the emergence of mechanical metamaterials, which are reshaping the way we perceive and utilize materials. With their unique properties, engineered structures, and limitless potential, mechanical metamaterials are unlocking boundless possibilities across multiple industries. In this article, we will explore the remarkable properties, diverse types, and wide-ranging applications of these extraordinary materials.

For centuries, the development of materials has solely relied on the modifications of its composition to alter mechanical properties. Despite being effective, it usually takes more than a decade for a newly discovered material to be in the market. Researchers have found new way to develop new materials via Mechanical metamaterials. They are artificial structures with mechanical properties defined by their structure rather than their composition. Their mechanical properties can be designed to have values which cannot be found in nature

They can be seen as a subset to the rather well-known family of metamaterials, which are artificially structured materials designed to control and manipulate physical phenomena such as light and other electromagnetic waves, sound waves and seismic waves in unconventional ways, resulting in exotic behavior that’s not found in nature. They are often also termed elastodynamic metamaterials and include acoustic metamaterials as a special case of vanishing shear.

In the recent years, metamaterials with unprecedented mechanical behaviors such as negative Poisson’s ratio, twisting under uniaxial forces, and negative thermal expansion are also realized. This paves a new pathway for a wide variety of multifunctional applications, for example, in energy storage, biomedical, acoustics, photonics, and thermal management. They are predicted to be able to protect the building from earthquakes by bending seismic waves around it, Similarly, tsunami waves could be bent around towns, and sound waves could be bent around a room to make it soundproof.

On the other hand, numerous materials found in nature often exhibit intriguing properties unachievable with conventional materials. These natural materials, particularly cellular materials, have evolved over the course of several million years such that they developed an optimized architecture which could span over multiple hierarchies across different length scales. For instance, the highly complex porous architecture of a bone core consisting of intricately-shaped ligaments and density gradients allows it to achieve a much higher structural efficiency compared to most of the synthetic cellular materials developed by humans, which possess significantly less sophisticated architectures and are far from ideal.

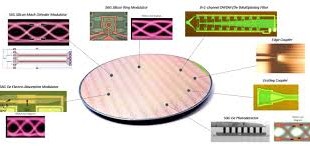

Although the concept of incorporating architecture into materials may not seem new, the recent developments in advanced manufacturing technologies such as additive manufacturing (AM), also known as 3D printing, has enabled the fabrication of cellular materials with complex architectures across several length scales, with feature sizes down to the nanometer scale for a wide range of materials.

Properties of Mechanical Metamaterials:

In the past decade, mechanical metamaterials have garnered increasing attention owing to its novel design principles which combine the concept of hierarchical architecture with material size effects at micro/nanoscale. This strategy is demonstrated to exhibit superior mechanical performance that allows us to colonize unexplored regions in the material property space, including ultrahigh strength‐to‐density ratios, extraordinary resilience, and energy absorption capabilities with brittle constituents.

The mechanical response of natural materials can generally be investigated with respect to four elastic constants, i.e. the Young’s modulus E for strength, the bulk modulus B and shear modulus G for rigidity, the deformation resistance K for stiffness, and the Poisson’s ratio v for deformability between strains.

The moduli of natural materials generally denote the mechanical properties while the stiffness is about the relationship between force (load) and displacement (deformation). For the recoverable deformations in the elastic regime, the Hooke’s law is used to describe the linearly continuous relationship between stress and strain under the small deformation assumptions, which treats stress as force per area and strain as displacement per length. Due to fact that the deformation resistance tends to push the deformed body back to its original configuration, natural materials have positive material properties such as positive stiffness that displacement is in the same direction as the applied force, and positive Poisson’s ratio that the elongation (or shortening) in the loading direction results in the shortening (or elongation) in the transverse direction.

- Negative Poisson’s Ratio: One of the most intriguing properties of mechanical metamaterials is their ability to exhibit a negative Poisson’s ratio. Unlike conventional materials, which contract in the lateral direction when compressed longitudinally, materials with a negative Poisson’s ratio expand laterally. This counterintuitive behavior enables increased resistance to fracture and enhanced energy absorption. Recent studies have demonstrated that certain natural materials (e.g. 2D materials graphene) can exhibit negative Poisson’s ratio. In particular, a negative Poisson’s ratio was obtained due to the normal-auxeticity mechanical phase transition of the graphene films subjected to the uniaxial tension

- Negative Stiffness: Mechanical metamaterials can also possess negative stiffness, meaning they exhibit a softening response to applied forces. This property can be harnessed to create materials that are highly flexible and resilient, with the ability to absorb impacts and vibrations.

- Ultra-Lightweight: Metamaterials can be engineered to have intricate architectures with hollow structures or micro-lattice designs. These structures result in materials that are incredibly lightweight while maintaining sufficient strength and structural integrity. The combination of lightweight and strength makes them ideal for aerospace applications and other industries where weight reduction is critical.

- Tunable Mechanical Properties: Another remarkable aspect of mechanical metamaterials is their tunability. By adjusting the geometry, arrangement, or composition of the constituent elements, the mechanical properties of the material can be finely tuned. This versatility allows for tailoring the material’s response to specific needs, such as adjusting its stiffness, elasticity, or damping characteristics.

Another benefit to the mechanical properties of materials, typically known as the “size-effect”, exhibited in certain nanomaterials where decreasing the size of a material down to the nanoscale allows them to exhibit unusual properties, such as increase in strength compared to its bulk counterpart, also known as the “smaller is stronger” trend in materials. Altering the topology of mechanical metamaterials such that it exhibits unique and tailorable properties (e.g., tunable stiffness, negative Poisson’s ratio, negative compressibility, vanishing shear modulus) arising from rationally engineered deformation mechanisms is possible as well.

Along with the improvement in computational methods developed over the years, mechanical metamaterials, which utilize the synergy between topology, material composition and in some cases, “size-effect” in nanomaterials, have the potential to produce novel materials

with unprecedented properties that approaches the theoretical limits of materials and could be optimized for specific industrial applications across multiple disciplines.

For deeper understanding of mechanical metamaterials please visit: Mechanical Metamaterials: From Fundamentals to Futuristic Applications

A. Metamaterial types based on Structural characteristics

Since their promising mechanical response is primarily due to the microstructures, many researchers categorises mechanical metamaterials with respect to the structural characteristics of the microstructures including the lattice metamaterials, cellular metamaterials, chiral metamaterials, and origami metamaterials.

Lattice or Cellular Metamaterials

Lattice metamaterials, which consist of periodic arrangements of unit cells in two or three dimensions, share similarities with the lattice structure of crystals. These cellular materials can be found in various natural forms such as cork, wood, coral, sponge, and honeycomb.

Lattice structures are highly efficient in terms of structure-to-weight ratio, making them suitable for weight-critical applications in aerospace engineering, automobiles, armors, and rotor blades. In addition to their mechanical properties, lattice metamaterials have gained interest in exploring their physical, chemical, and biological characteristics.

The mechanical response of micro/nanoscale lattice metamaterials is influenced by the cellular architectures and their density, making the geometry and assembly of the unit cells crucial. Recent advancements in computer-aided techniques have enabled the design, optimization, and prediction of mechanical responses for lattice metamaterials, opening doors to novel applications.

With the rapid evolution of 3D printing technology, precise control over lattice geometry at different scales, ranging from sub-μm to cm, has become possible. These advancements have facilitated the fabrication of ultralight, ultra-stiff, and ultra-strong lattice structures, further enhancing the progress in lattice metamaterial research.

Chiral Metamaterials

Chiral metamaterials exhibit non-superimposable mirrored configurations, created by incorporating left- or right-handed substructures such as chiral hexagons. These metamaterials often feature regular polygons and chiral ligaments, resulting in chiral or anti-chiral connections between two-dimensional unit cells. The unique mechanical behavior of chiral metamaterials is characterized by negative stiffness or negative Poisson’s ratio.

To achieve controllable mechanical performance, chiral metamaterials can be fabricated using functional materials like composites or shape memory polymers. Numerical approaches have been employed for response-oriented inverse design and optimization of chiral metamaterials.

Origami Metamaterials

Origami metamaterials are two-dimensional structures created by folding planar films in elegant patterns and shapes, inspired by the art of paper folding known as origami. Different origami strategies, including the Miura-ori pattern, non-periodic Ron Resch pattern, and square twist pattern, have been utilized.

By utilizing origami as basic building blocks, metastructures with enhanced flexibility, deformability, and compactness can be achieved. The dynamic folding patterns of origami also give rise to unique metamaterials, such as bio-origami hydrogel scaffolds or specific buckled surfaces. Kirigami, a special type of origami involving cutting regular sheets, focuses on forming two-dimensional structures.

Highly Porous Materials

Highly porous materials, composed of metals, ceramics, or polymers, belong to a significant subcategory of functional materials due to their remarkable mechanical properties. These materials, assembled with cellular microstructures, offer excellent thermal connectivity and high internal surface area, making them suitable for applications such as heat dissipation, thermal insulation, packaging, and comfort design.

The mechanical performance of highly porous materials is heavily influenced by the morphology and arrangement of cellular units, including factors like orientation, size, and shape. Computer-aided techniques have been employed for modeling, topological optimization, and prediction of mechanical behavior in highly porous materials.

Mechanical Metamaterial types based on Function

Mechanical metamaterials can be categorized based on their functions and properties. One such category is acoustic or phononic metamaterials, which are artificial composite materials that exhibit unique acoustic properties not found in natural materials. These materials are designed with closely spaced constituent elements of specific geometrical and mechanical characteristics.

Acoustic metamaterials can have properties such as negative effective bulk modulus, negative effective mass density, or double negativity, which allow for applications such as acoustic subwavelength imaging, superlensing, negative refraction, and transformation acoustics. Acoustic waves are longitudinal waves that propagate through adiabatic compression and decompression, and their properties are described by quantities such as sound pressure, particle velocity, particle displacement, and sound intensity.

Another category of mechanical metamaterials is materials with negative Poisson’s ratio, also known as auxetic materials. These materials exhibit the unusual behavior of expanding in directions orthogonal to the applied load when compressed along a particular axis. They can concentrate themselves under compressive loads to better resist the load and become stiffer and stronger as the load amplitude increases. Auxetic materials offer advantages in terms of shear resistance, indentation resistance, fracture toughness, and sound and vibration absorption, with potential applications in aerospace and defense.

Metamaterials with negative longitudinal and volume compressibility transitions are designed to undergo contraction when tensioned or expansion when pressured, contrary to the behavior of ordinary materials. These materials exhibit negative responses along the direction of the applied force and can be distinguished from materials with negative transversal response, such as those with negative Poisson’s ratio.

Pentamode metamaterials are three-dimensional structures that behave like fluids despite being solids. They have finite bulk but vanishing shear modulus, making them hard to compress but easy to deform. These metamaterials have potential applications in transformation elastodynamics and elastodynamic cloaking.

Cosserat and micropolar metamaterials are used when the unit cells of typical metamaterials are not centrosymmetric. They require an effective description using chiral micropolar elasticity or Cosserat elasticity, which combines translational and rotational degrees of freedom and exhibits behavior similar to optical activity.

Willis materials are based on the local set of equations proposed by Willis to describe the elastodynamics of inhomogeneous materials. These materials exhibit coupling between stress, strain, and velocity, as well as between momentum, strain, and velocity. Hyperelastic cloaking and invariance involve using pre-stressed hyperelastic materials and the theory of “small on large” for elastic wave propagation through pre-stressed nonlinear media. These mechanisms have been employed in elastic wave cloaking and phononic media.

These different types of mechanical metamaterials have unique properties and functions, offering opportunities for various applications in fields such as acoustics, structural engineering, and materials science.

Acoustic / phononic metamaterials

Acoustic metamaterials, also known as phononic metamaterials, are artificial composite materials that possess unique acoustic properties not found in natural materials. By carefully arranging closely spaced constituent elements, these materials exhibit features such as negative effective bulk modulus and negative effective mass density.

They have applications in areas like acoustic subwavelength imaging, superlensing, and negative refraction. Acoustic waves, which propagate through adiabatic compression and decompression, are described by quantities like sound pressure, particle velocity, and displacement. Longitudinal waves are waves that have the same direction of vibration as their direction of travel. Acoustic waves travel with the speed of sound which depends on the medium they’re passing through. According to the oscillation frequency, acoustic waves have been classified to different fields that cover the audio, ultrasonic and infrasonic frequency range, or seismic waves at much larger scale which are waves of energy travelling through the Earth’s layer.

Acoustic metamaterials can manipulate wave speed and produce propagating waves with extremely high, zero, or negative speeds.

Materials with negative mass density and positive bulk modulus or positive mass density and negative bulk modulus are called single-negative materials, which excel in sound absorption. In such materials, propagating waves cannot be sustained, leading to exponential decay of any acoustic wave within them. Consequently, these materials excel in sound absorption, making them superior sound absorbers. Overall, acoustic metamaterials offer exciting possibilities for manipulating sound and have implications for various scientific and engineering fields.

Materials with negative Poisson’s ratio (auxetics)

Poisson’s ratio defines how a material expands (or contracts) transversely when being compressed longitudinally. While most natural materials have a positive Poisson’s ratio (coinciding with our intuitive idea that by compressing a material it must expand in the orthogonal direction), a family of extreme materials known as auxetic materials can exhibit Poisson’s ratios below zero. Poisson’s ratio which is approximately 0.5 for rubber and 0.3 for glass and steel.

Materials with negative Poisson’s ratio, also known as auxetic materials, exhibit a unique behavior where they expand in directions orthogonal to the applied load when compressed along a particular axis. This is contrary to the behavior observed in most natural materials, which contract in the orthogonal direction when compressed longitudinally. The Poisson’s ratio, defined as the ratio between the negative transverse and longitudinal strains, characterizes this behavior.

Auxetic materials can be found in nature or fabricated, often possessing a low-volume microstructure that imparts the extreme properties to the bulk material. Some examples of auxetic structures include inverted hexagonal periodicity cells and certain origami folds like the Miura fold and zigzag-based folds.

This unusual behavior of auxetic materials offers several advantages. They can concentrate themselves under compressive loads to better resist the applied force and become stiffer and stronger as the load amplitude increases. Studies have demonstrated that auxetic materials exhibit improved mechanical properties, including shear resistance, indentation resistance, and fracture toughness, compared to conventional materials. Additionally, they possess excellent sound and vibration absorption properties, making them potentially valuable in aerospace and defense applications.

However, the fabrication of materials with auxetic properties presents a significant challenge. It often involves embedding intricate structures within a host matrix, which complicates the manufacturing process. Recent research has shown that instability-induced pattern switches in porous elastomeric structures with simple initial microstructures can lead to auxetic behavior. Furthermore, the shape of the holes in the structure plays a crucial role in controlling compaction and achieving a negative Poisson’s ratio. Circular holes are not optimal, and careful design of the pore shape can significantly improve the compaction of the system.

Insights gained from numerical exploration and parametric studies serve as valuable guidelines for the practical fabrication of auxetic materials with desired properties for various applications.

Metamaterials with negative longitudinal and volume compressibility transitions

In a closed thermodynamic system in equilibrium, both the longitudinal and volumetric compressibility are necessarily non-negative because of stability constraints. For this reason, when tensioned, ordinary materials expand along the direction of the applied force. It has been shown, however, that metamaterials can be designed to exhibit negative compressibility transitions, during which the material undergoes contraction when tensioned (or expansion when pressured). When subjected to isotropic stresses, these metamaterials also exhibit negative volumetric compressibility transitions

Metamaterials with negative longitudinal and volume compressibility transitions have the unique ability to contract when subjected to tension and expand when under pressure, contrary to the behavior observed in ordinary materials. In a closed thermodynamic system in equilibrium, traditional materials exhibit positive longitudinal and volumetric compressibility due to stability constraints. However, metamaterials can be specifically designed to achieve negative compressibility transitions.

These metamaterials display a distinctive negative response along the direction of the applied force, setting them apart from materials that exhibit negative transversal response, such as those with negative Poisson’s ratio. During tension, these metamaterials undergo contraction, while they expand when subjected to isotropic stresses.

The design and engineering of metamaterials with negative longitudinal and volume compressibility transitions offer intriguing possibilities. By manipulating the arrangement, composition, and mechanical properties of the constituent elements at a microscopic level, it becomes possible to achieve this unique behavior. These metamaterials hold potential for various applications, including advanced engineering structures, actuators, energy absorption systems, and innovative devices for pressure and force sensing.

Efforts to understand and further enhance the properties of these metamaterials are ongoing. Research focuses on optimizing the material’s microstructure, exploring novel fabrication techniques, and investigating the underlying physical mechanisms driving the negative compressibility transitions. Continued advancements in this field may unlock new opportunities for developing materials with tailored and unconventional mechanical responses, paving the way for future technological breakthroughs.

Pentamode metamaterials or meta-fluids

Pentamode metamaterials, also known as meta-fluids, are unique three-dimensional structures that exhibit fluid-like behavior despite being solid materials. These metamaterials possess a finite bulk modulus but a vanishing shear modulus, which means they are resistant to compression but easily deformable. In other words, they can be described as hard to compress but easy to deform, resembling the behavior of fluids.

From a mathematical perspective, pentamode metamaterials have an elasticity tensor with only one non-zero eigenvalue and five vanishing eigenvalues, hence the name “pentamode” (referring to the five vanishing eigenvalues).

Although the concept of pentamode structures was initially proposed in 1995 by Graeme Milton and Andrej Cherkaev, it took until early 2012 for them to be fabricated and realized experimentally. The theoretical understanding of pentamode metamaterials suggests that they can serve as fundamental building blocks for creating materials with arbitrarily tailored elastic properties.

Anisotropic versions of pentamode structures are particularly interesting for applications in transformation elastodynamics and elastodynamic cloaking. These structures offer the potential for manipulating and controlling the propagation of elastic waves, allowing for the development of innovative devices and technologies with unique properties.

Further research and development in the field of pentamode metamaterials are focused on exploring different fabrication techniques, optimizing their performance, and investigating their potential applications in areas such as acoustics, seismic protection, vibration control, and wave manipulation. By harnessing the extraordinary properties of pentamode metamaterials, scientists and engineers aim to unlock new opportunities for designing materials with unprecedented mechanical characteristics and functionalities.

Cosserat and Micropolar Metamaterials

Cosserat and micropolar metamaterials provide an alternative approach to describing the mechanical behavior of certain metamaterials that exhibit non-centrosymmetric unit cells. While Cauchy elasticity is commonly used to characterize metamaterials, it may not capture the full range of their effective behavior in such cases.

Chiral micropolar elasticity, also known as Cosserat elasticity, offers a more comprehensive description for these metamaterials. It incorporates the coupling of both translational and rotational degrees of freedom, allowing for a more accurate representation of their mechanical response. In static situations, micropolar elasticity demonstrates an equivalent behavior to optical activity, further emphasizing its suitability for characterizing non-centrosymmetric metamaterials.

By considering the coupling between translational and rotational degrees of freedom, micropolar metamaterials can exhibit unique mechanical properties not captured by traditional elastic models. This includes the ability to respond to mechanical stimuli in unconventional ways, leading to enhanced functionality and performance. Micropolar metamaterials have the potential to find applications in areas such as advanced materials, structural engineering, and mechanical systems where non-centrosymmetric behavior is desired or advantageous.

Further research and development in the field of Cosserat and micropolar metamaterials aim to explore their design principles, fabrication techniques, and potential applications. By leveraging the enhanced capabilities provided by micropolar elasticity, scientists and engineers strive to develop innovative metamaterials with tailored mechanical responses, enabling advancements in various fields of engineering and technology.

Willis materials

Willis materials, as originally proposed by Willis in the late 1970s and early 1980s, provide an alternative framework for describing the elastodynamics of inhomogeneous materials. In 2006, Milton, Briane, and Willis demonstrated that the correct invariant form of linear elastodynamics aligns with the local set of equations put forth by Willis. This approach deviates from the traditional Navier’s equations and introduces unique couplings between stress, strain, and velocity, as well as between momentum, strain, and velocity.

Unlike conventional elastic materials, Willis materials exhibit coupling effects that are not typically observed. This coupling arises due to the inhomogeneous nature of these materials, introducing a non-symmetric stress distribution. While invariance of Navier’s equations can be achieved through transformation theory, it necessitates the presence of materials with non-symmetric stress, making the study of Cosserat materials relevant in this context, as mentioned earlier.

The theory behind Willis materials has been further developed and expanded upon in the work by Norris and Shuvalov, providing a solid foundation for understanding their behavior and characteristics. By incorporating these principles, researchers can explore the unique mechanical responses and functionalities offered by Willis materials.

Studying Willis materials opens up possibilities for designing and engineering materials with tailored elastodynamic properties. These materials can exhibit unconventional and desirable behaviors, making them potentially useful in various applications. Further research aims to advance the understanding of Willis materials, refine their theoretical frameworks, and explore practical techniques for fabricating and utilizing these materials in engineering and technological domains.

Hyperelastic cloaking and invariance

Hyperelastic cloaking and invariance, based on pre-stressed hyperelastic materials, provide an alternative approach to achieving non-symmetric stress distributions. This mechanism relies on the concept of “small on large,” which refers to the propagation of elastic waves through pre-stressed nonlinear media. The principles of hyperelastic cloaking and invariance were established in two papers published in the Proceedings of the Royal Society A in 2012, and since then, they have found applications in various fields, particularly in elastic wave cloaking and phononic media.

By employing pre-stressed hyperelastic materials, it becomes possible to manipulate the propagation of elastic waves and achieve cloaking effects. These materials exhibit nonlinear behavior under mechanical deformations, and when appropriately designed and controlled, they can redirect and manipulate the paths of elastic waves. The concept of hyperelastic cloaking involves utilizing these pre-stressed materials to guide and steer elastic waves around an object, rendering it invisible to the waves. This cloaking mechanism offers potential applications in fields such as structural engineering, seismic protection, and medical imaging.

Furthermore, the principle of invariance in hyperelastic cloaking ensures that the cloaking effect remains robust under various conditions and is not affected by changes in the incident waves or material properties. This invariance property is crucial for practical applications, as it guarantees the effectiveness and reliability of the cloaking mechanism in real-world scenarios.

Since the publication of the seminal papers in 2012, researchers have been exploring and expanding upon the concept of hyperelastic cloaking and invariance. Numerous studies have investigated different designs, materials, and wave frequencies to optimize and extend the capabilities of hyperelastic cloaking. This research has led to advancements in elastic wave manipulation, including the development of novel techniques for wave steering, focusing, and filtering.

The field of hyperelastic cloaking and invariance continues to evolve, with ongoing efforts aimed at improving the efficiency, versatility, and scalability of the cloaking mechanisms. Future research will likely explore new material compositions, innovative design strategies, and practical implementation techniques to further enhance the potential applications of hyperelastic cloaking and invariance in various scientific, engineering, and technological domains.

Mechanical Metamaterial Applications

Mechanical metamaterials are revolutionizing various industries, from aerospace and energy storage to biomedical applications, acoustics, photonics, and thermal management. These innovative materials with engineered properties and unique structures are unlocking boundless possibilities and transforming the way we approach technological challenges.

Aerospace: The aerospace industry demands materials that are lightweight, yet strong and durable. Mechanical metamaterials provide a solution by offering exceptional strength-to-weight ratios and superior mechanical properties. These materials can be designed to withstand extreme conditions, such as high temperatures, vibrations, and impacts. They have the potential to revolutionize aircraft components, leading to enhanced fuel efficiency, improved structural integrity, and increased payload capacities.

Energy Storage: Efficient energy storage systems are crucial for renewable energy integration and the electrification of various sectors. Mechanical metamaterials show promise in this field by enabling the development of advanced energy storage devices. By designing metamaterial structures with high porosity, large surface areas, and excellent electrical conductivity, it becomes possible to create supercapacitors and batteries with enhanced energy density, faster charging capabilities, and longer lifespan.

Biomedical: In the realm of biomedical applications, mechanical metamaterials offer exciting prospects. Their unique mechanical properties can be tailored to mimic biological tissues and structures, making them ideal for implants, tissue engineering, and drug delivery systems. Mechanical metamaterials can provide the necessary flexibility, strength, and biocompatibility required for successful biomedical interventions. Additionally, these materials can be designed to respond to external stimuli, such as temperature or pH changes, enabling targeted drug release and personalized therapies.

Acoustics: Controlling sound waves and manipulating acoustic properties are essential in various industries, including architecture, transportation, and communication. Mechanical metamaterials offer unprecedented opportunities for acoustic engineering. By designing metamaterial structures with precise geometries and specific arrangements, it becomes possible to create materials with extraordinary sound-absorbing or sound-amplifying properties. This opens up possibilities for designing quieter environments, enhancing soundproofing materials, and developing advanced acoustic devices.

Photonics: Photonics, the science and technology of light, is another field benefiting from mechanical metamaterials. These materials can manipulate light in extraordinary ways, enabling the creation of devices with unprecedented optical properties. Metamaterials can be designed to bend light around objects, creating invisibility cloaks, or to manipulate light at the nanoscale, leading to advancements in imaging, sensing, and telecommunications. Their ability to control light opens up new frontiers in optics and holds promise for the development of next-generation photonic devices.

Thermal Management: Efficient thermal management is crucial in many industries, including electronics, energy systems, and transportation. Mechanical metamaterials can revolutionize heat transfer and thermal insulation. By engineering metamaterial structures with tailored thermal properties, it becomes possible to create materials that are excellent conductors, insulators, or even capable of directing heat flow in specific directions. This enables the development of high-performance heat sinks, thermal barriers, and thermoelectric devices, enhancing energy efficiency and system reliability.

Recent Breakthroughs in Mechanical Metamaterials

- In 2023, Chinese researchers have achieved a breakthrough in nanolattice metamaterials using a combination of nickel and titanium. This advanced technology allows for ultra-high energy absorption capabilities. The unique architecture of the nanolattice structure enables efficient dissipation of mechanical energy, making it ideal for impact-resistant applications. Nanolattice is a new class of mechanical metamaterials with characteristic sizes on the nanoscale. Due to size effects, geometrical configuration, and material selection, the mechanical properties of this type of porous materials are very different from those of bulk materials. Given its even better mechanical properties with lighter weight, nanolattice is expected to bring revolutionary applications in the field of high-performance functional materials in the future. This development has significant implications for protective gear, vehicle components, and infrastructure protection. The research was conducted by Chinese scientists and published in Physical Review Letters.

- In 2022, researchers at the University of California, Berkeley, developed a new type of mechanical metamaterial that can absorb sound waves with unprecedented efficiency. The metamaterial is made up of a series of interconnected tubes that are arranged in a specific pattern. When sound waves hit the metamaterial, they are absorbed by the tubes and converted into heat. The metamaterial is so efficient at absorbing sound that it can reduce noise levels by up to 99%.

- In 2021, researchers at the University of Texas at Austin developed a new type of mechanical metamaterial that can bend and twist in ways that are impossible for natural materials. The metamaterial is made up of a series of interconnected beams that are arranged in a specific pattern. When the metamaterial is subjected to a force, the beams bend and twist in a way that allows the metamaterial to absorb energy and resist damage. The metamaterial is so strong that it can withstand forces that would crush or shatter natural materials.

- In 2020, researchers at the Massachusetts Institute of Technology developed a new type of mechanical metamaterial that can change its shape in response to an electric field. The metamaterial is made up of a series of interconnected plates that are arranged in a specific pattern. When an electric field is applied to the metamaterial, the plates move in a way that changes the shape of the metamaterial. The metamaterial can be used to create a variety of devices, such as robots, sensors, and actuators.

University of California, Irvine Team creates new ultralightweight, crush-resistant tensegrity metamaterials, in March 2021

In March 2021, a team of engineers from the University of California, Irvine, and the Georgia Institute of Technology created a new class of ultralightweight, crush-resistant metamaterials using the principle of tensegrity. Tensegrity structures consist of rigid bars integrated into a flexible mesh of tethers, resulting in self-tensioning truss structures. The team employed a direct laser writing technique to construct elementary cells and assembled them into larger supercells. Computational modeling and laboratory experiments demonstrated that these metamaterials exhibited homogenous deformation behavior without localized overstress or underuse.

Compared to conventional lattice arrangements, the tensegrity metamaterials showed a 25-fold enhancement in deformability and significantly higher energy absorption capabilities. The researchers achieved the first physical implementation and performance demonstration of these metamaterials, which were conceptualized by co-author Julian Rimoli at Georgia Tech. The idea for creating tensegrity-based metamaterials originated from the discovery that tensegrity structures could withstand severe deformation without collapsing, observed during the development of structural configurations for planetary landers.

Unlike traditional nano-architected materials that often fail due to localized deformation, the compressive members of tensegrity architectures are isolated from each other and only connected by tensile members. As a result, instability in compressive members can only propagate through tensile load paths, preventing catastrophic failure caused by localized damage. Tensegrity metamaterials offer an unprecedented combination of failure resistance, energy absorption, deformability, and strength, surpassing other lightweight architectures. The research lays the groundwork for the design of superior engineering systems, such as reusable impact protection systems and adaptive load-bearing structures.

https://www.youtube.com/watch?v=Wm0enwmGYe4

University of Missouri researchers have developed a new Lattice metamaterial to help buildings withstand the ground shockwaves from earthquakes

The longitudinal and sheer energy waves produced by an earthquake travel through the ground and can destroy buildings miles from the epicentre. Preventing that damage requires a solution that can withstand these multidirectional waves travelling through a solid material but that is also flexible.

Researchers at the University of Missouri have developed a lattice-type metamaterial that can help buildings withstand ground shockwaves caused by earthquakes. The material is designed to be flexible and capable of withstanding multidirectional waves traveling through solid structures. Led by Dr. Guoliang Huang, the team created a polar metamaterial that can bend waves and vibrations, providing protection for objects wrapped in the material, such as buildings or vehicles.

The metamaterial was fabricated using 3D printing and has potential applications in defense, including protecting mechanical parts from vibrations and offering flexible protection for soldiers and equipment against blast energy. The research, funded by the US Army Research Office, was published in Physical Review Letters, a journal of the American Physical Society. Future plans include dynamic testing of the material to further evaluate its performance.

The US Army Research Office funds the research, which has clear defence applications, including protection against vibration in mechanical parts, such as aircraft or submarine engines, and flexible protection for soldiers and equipment against blast energy. Two papers on the research, ‘Polar metamaterials: a new outlook on resonance for cloaking applications’ and ‘Physical realization of elastic cloaking with a polar material’, were published in Physical Review Letters, a journal of the American Physical Society.

Conclusion

Mechanical metamaterials represent a realm of materials engineering that transcends traditional materials’ limitations. Their unique properties, including negative Poisson’s ratio, negative stiffness, and ultra-lightweightness, open up a wide range of possibilities for innovative applications.

Whether it’s in aerospace, energy, biomedical, or other fields, mechanical metamaterials offer the potential to transform industries by providing materials with exceptional characteristics and tailored mechanical responses.

These materials with their exceptional properties and unique structures are propelling innovation, pushing the boundaries of what is possible in technology and paving the way for a future of advanced and sustainable solutions. As research and development in this field continue to evolve, we can anticipate even more groundbreaking applications and transformative outcomes in the years to come.

References and Resources also include:

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis