Introduction:

In the world of nanofabrication, precision and control are paramount. The ability to manipulate matter at the atomic and molecular scale has opened up a realm of possibilities in various fields, from electronics to medicine. One technique that has been instrumental in pushing the boundaries of nanotechnology is Electron Beam Lithography (EBL). In this article, we will delve into the fascinating world of EBL, unravel its working principles, explore its applications, and understand why it has become a revolutionary tool in nanofabrication.

Microelectronics, with its functional and cost-effective electronic devices, has transformed various aspects of our lives. With advancements in fabrication methodologies, microelectronics has expanded into non-electronic areas such as micro-actuators, micro-sensors, and even DNA probes. This technological progress has led to the emergence of nanotechnology, where nanoscale devices, known as “nanodevices,” are obtained through top-down miniaturization.

Nanotechnology, which involves controlling matter atom by atom or molecule by molecule, has opened up new possibilities in creating functional materials and devices with unique properties. Nanofabrication techniques operate at the nanoscale, bridging the gap between macroscopic products and individual atoms or molecules. Two approaches, bottom-up synthesis and top-down miniaturization, are employed to create nanoscale structures.

Nanolithography techniques play a vital role in top-down nanofabrication. Techniques like Electron Beam Lithography, Nanoimprint Lithography, X-ray Lithography, and Extreme Ultraviolet Lithography are used to achieve precise patterns at the nanoscale. Among these methods, EBL stands out for its ability to focus and control electron beams onto different substrates. The resolution of EBL can be extended to the sub-nanometer region with appropriate resist materials.

For in-depth understanding on Nanofabrication technology and applications please visit: Nanofabrication: The Science and Applications

The Basics of Electron Beam Lithography:

Electron Beam Lithography is a high-resolution patterning technique that utilizes a focused beam of electrons to create patterns on a substrate with extreme precision. Unlike traditional lithography methods that use light, EBL employs a beam of accelerated electrons, allowing for much finer features and higher resolution.

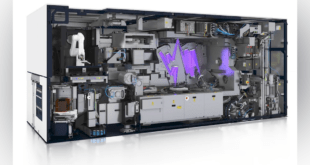

The core components of an EBL system, including the electron source, beam control, and patterning stage, work in unison to achieve sub-10 nanometer resolution.

How Does Electron Beam Lithography Work?

Electron Beam Lithography involves several key steps. First, an electron beam is generated using an electron source, typically a heated tungsten filament or a field emission gun. The electron beam is then focused and shaped using electromagnetic lenses and apertures, which control the beam’s size and intensity. The shaped beam is then scanned across the surface of the substrate, where it interacts with a resist material. The resist material’s properties are altered by the incident electrons, enabling the creation of patterns.

In EBL, a beam of electrons is scanned across a substrate that is coated with a thin layer of resist. The resist is a material that changes its solubility properties when exposed to electrons. Areas of the resist that are exposed to the electron beam become more soluble, while areas that are not exposed become less soluble. The resist is then developed, which removes the soluble areas, leaving behind a pattern of exposed resist.

By precisely controlling the position of the electron beam using computer control, arbitrary structures can be written onto a surface, transferring digital images directly onto the desired substrate.

Unleashing the Power of Nanofabrication:

Over the years, EBL has made significant advancements. Researchers have successfully focused electron beams to less than 1 nm, pushing the boundaries of resolution in nanofabrication. EBL was initially used for research and prototype nanoelectronic devices, but its precision and nanolithographic capabilities have made it the preferred tool for creating masks for other advanced lithography methods. Its applications span various fields, including semiconductor device fabrication, photonic devices, and the development of advanced sensors and optoelectronic devices.

The exceptional resolution and precision of Electron Beam Lithography have opened up a world of possibilities in various fields. EBL finds extensive applications in semiconductor device fabrication, where it is used to create nano-scale features such as transistors, interconnects, and capacitors. It is also crucial in the development of photonic devices, microelectromechanical systems (MEMS), and nanoelectromechanical systems (NEMS). EBL has enabled researchers to explore novel materials, study quantum phenomena, and develop advanced sensors, optoelectronic devices, and biomedical tools.

Here are some examples of how Electron Beam Lithography (EBL) is being utilized in various industries today:

- Semiconductor Industry: EBL plays a crucial role in the semiconductor industry by fabricating the intricate patterns required to create transistors and other components of semiconductor devices. The precise control offered by EBL enables the creation of nanoscale features that are essential for high-performance integrated circuits.

- Medical Industry: In the medical field, EBL is used to fabricate medical devices with specific functionalities. It allows for the production of implants and surgical tools with intricate geometries and tailored surface properties. This enables improved performance, biocompatibility, and integration with biological systems.

- Materials Science: EBL is widely used in materials science research to fabricate materials with unique properties. By precisely controlling the deposition or removal of material at the nanoscale, EBL enables the creation of structures such as nanowires, nanotubes, and quantum dots. These materials exhibit novel electronic, optical, and mechanical properties, opening up new possibilities for advanced technologies and devices.

- Photonics and Optoelectronics: EBL finds applications in the development of photonic and optoelectronic devices. It enables the fabrication of complex photonic structures, such as waveguides, resonators, and photonic crystals, which are essential for manipulating light at the nanoscale. EBL also plays a role in creating nanoscale features for the integration of light-emitting devices, photodetectors, and optical sensors.

- Nanoelectronics and Quantum Computing: EBL is instrumental in the fabrication of nanoelectronic devices and circuits. It allows for the precise positioning and patterning of nanostructures, such as quantum dots and nanowires, which are key building blocks for future quantum computing architectures. EBL’s ability to create custom designs and tailor device properties contributes to advancements in quantum information processing.

These examples highlight the versatility and significance of Electron Beam Lithography across various industries. Its capability to create nanoscale structures with exceptional precision and control has paved the way for breakthroughs in semiconductor technology, healthcare, materials science, photonics, and emerging fields like quantum computing. EBL continues to push the boundaries of nanofabrication, enabling the development of innovative devices and systems with enhanced functionalities.

Advantages and Challenges:

Electron Beam Lithography offers numerous advantages over other lithography techniques. Its exceptional resolution allows for the creation of intricate patterns and structures at the nanoscale. EBL also provides high flexibility and versatility, enabling the production of custom designs and prototypes.

Here are some of the disadvantages of EBL:

However, EBL does come with certain challenges, such as limited throughput, high equipment costs, and the need for a controlled environment to minimize beam scattering and contamination.

Complexity: EBL is a complex technique that requires a high level of expertise to operate. The equipment is also expensive, which can make it prohibitive for some applications.

Time-consuming: EBL can be time-consuming to produce patterns. This is because the electron beam must be scanned across the substrate one line at a time. For complex patterns, this can take a significant amount of time.

Radiation damage: EBL can cause radiation damage to the substrate. This is because the electron beam can knock electrons out of atoms in the substrate, which can create defects in the material. This can reduce the performance of the substrate or even make it unusable.

In addition to these disadvantages, EBL can also be difficult to scale up for mass production applications. This is because the electron beam can only scan a small area at a time, which limits the throughput of the process.

Despite these disadvantages, EBL is a powerful technique that can be used to produce patterns with high resolution and precision. As the technology continues to develop, we can expect to see even more innovative applications for EBL in the future.

Future Directions and Innovations:

As technology continues to advance, Electron Beam Lithography is also evolving. Researchers are constantly working on improving system performance, increasing throughput, and reducing costs. Advances in electron optics, new resist materials, and parallel processing techniques are paving the way for even more precise and efficient nanofabrication. Furthermore, hybrid approaches, such as combining EBL with other lithography methods, are being explored to harness the strengths of multiple techniques.

Conclusion:

Electron Beam Lithography has revolutionized nanofabrication by providing researchers and engineers with an unprecedented level of control and precision. Its ability to create intricate patterns at the nanoscale has opened up new frontiers in various scientific disciplines. As the technology advances, we can expect to see even more groundbreaking applications and discoveries fueled by the power of Electron Beam Lithography. With each new development, the boundaries of what is possible in nanofabrication continue to expand, promising a future full of exciting possibilities.

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis