Nanomaterials are chemical substances or materials that are manufactured and used at a very small scale. Nanomaterial is defined as a, ‘material with any external dimension in the nanoscale (size range from approximately 1 – 100 nm) or having internal structure or surface structure in the nanoscale’. Nanomaterials are developed to exhibit novel characteristics compared to the same material without nanoscale features, such as increased strength, chemical reactivity or conductivity.

Nanostructures have the capacity to disrupt a number of industries and they can revolutionize material science, medicine and battery technology to name just a few. If we can truly harness nanomaterials then almost every facet of modern life will change, from the clothes we wear to our water filtration system. It’s one of those breakthroughs that really could change everything. So the potential is immense, but nanostructures are complex to produce in usable form. Scaling them up to a workable size has caused issues with the structural integrity, performance and consistency.

Three-dimensional (3D) nanoprinting, a class of nanoscale additive manufacturing techniques, is attracting increasing interest because it offers novel possibilities for designing and fabricating nanoscale components and devices. Additive manufacturing is a way of making 3-D objects by building up material, layer upon layer, with the guidance of a digital design. The processes are engineered to use material more efficiently, give designs more flexibility and produce objects more precisely. Above all, they make things quickly. Applying 3D printing concepts to nanotechnology could bring similar advantages to nanofabrication – speed, less waste, economic viability – than it is expected to bring to manufacturing technologies.

Metamaterials extend the capabilities of conventional materials in devices by making use of geometric features arranged in repeating patterns at scales smaller than the wavelengths of energy being detected or influenced. New developments in 3-D printing technology are making it possible to create many more shapes and patterns of metamaterials, and at ever smaller scales. In the study, researchers at the Nano Lab at Tufts describe a hybrid fabrication approach using 3-D printing, metal coating and etching to create metamaterials with complex geometries and novel functionalities for wavelengths in the microwave range.

There are wide ranging applications of 3D printed nanotechnology, In 2013, American researchers managed to 3D print extra efficient batteries the size of a grain of sand, by using ink containing Lithium ion nanoparticles! It’s easy to imagine such batteries being used in nanoelectronics, like very small cameras. Another application is in filtration systems: with Nanoscribe’s machine it is possible to create nanofluidic filters inside channels that are only a micrometer wide. In the future using Printable electronics we shall be able to develop 3D printing flexible screens or flexible batteries, that are so thin they can be rolled up and fit in a pocket!

Researchers have produced many 3D printers capable of fabricating nanomaterials. Materials scientists based at the Massachusetts Institute of Technology new approach for the 3D printing of nanofiber meshes. Nanofibers being produced on a large scale and of good quality, with little variation with the diameters of the fibers produced. Diameter control is important since the performance of the fibers dependent upon their diameter.

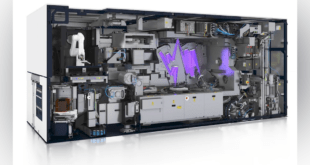

Jan Torgersen created a 3D printer which is able to produce nano-scaled objects suitable for numerous applications in photonics, surface modifications and biomedical engineering. It’s currently the fastest of its kind and brings the technology closer to industrial applications. The company Nanoscribe applies stereolithography to the nanoscopic world. With their Photonic Professional GT machine, they can create objects as small as only a few microns.

DARPA is looking for combat 3D printers which can print ultra-strong materials based on nanomaterials that small infantry units can use for a variety of tasks in urban combat, such as erecting obstacles, fortifications and camouflage.

Researchers 3-D print metamaterials with novel optical properties

A team of engineers at Tufts University has developed a series of 3-D printed metamaterials with unique microwave or optical properties that go beyond what is possible using conventional optical or electronic materials. The fabrication methods developed by the researchers demonstrate the potential, both present and future, of 3-D printing to expand the range of geometric designs and material composites that lead to devices with novel optical properties. In one case, the researchers drew inspiration from the compound eye of a moth to create a hemispherical device that can absorb electromagnetic signals from any direction at selected wavelengths. The research was published in April 2019 in the journal Microsystems & Nanoengineering, published by Springer Nature.

For example, they created an array of tiny mushroom shaped structures, each holding a small patterned metal resonator at the top of a stalk. This particular arrangement permits microwaves of specific frequencies to be absorbed, depending on the chosen geometry of the “mushrooms” and their spacing. Use of such metamaterials could be valuable in applications such as sensors in medical diagnosis and as antennas in telecommunications or detectors in imaging applications.

Other devices developed by the authors include parabolic reflectors that selectively absorb and transmit certain frequencies. Such concepts could simplify optical devices by combining the functions of reflection and filtering into one unit. “The ability to consolidate functions using metamaterials could be incredibly useful,” said Sameer Sonkusale, professor of electrical and computer engineering at Tufts University’s School of Engineering who heads the Nano Lab at Tufts and is corresponding author of the study. “It’s possible that we could use these materials to reduce the size of spectrometers and other optical measuring devices so they can be designed for portable field study.”

The products of combining optical/electronic patterning with 3-D fabrication of the underlying substrate are referred to by the authors as metamaterials embedded with geometric optics, or MEGOs. Other shapes, sizes, and orientations of patterned 3-D printing can be conceived to create MEGOs that absorb, enhance, reflect or bend waves in ways that would be difficult to achieve with conventional fabrication methods.

There are a number of technologies now available for 3-D printing, and the current study utilizes stereolithography, which focuses light to polymerize photo-curable resins into the desired shapes. Other 3-D printing technologies, such as two photon polymerization, can provide printing resolution down to 200 nanometers, which enables the fabrication of even finer metamaterials that can detect and manipulate electromagnetic signals of even smaller wavelengths, potentially including visible light.

“The full potential of 3-D printing for MEGOs has not yet been realized,” said Aydin Sadeqi, graduate student in Sankusale’s lab at Tufts University School of Engineering and lead author of the study. “There is much more we can do with the current technology, and a vast potential as 3-D printing inevitably evolves.”

Nanotribological printing – a novel 3D nanotechnology fabrication technique

Three-dimensional (3D) nanoprinting, a class of nanoscale additive manufacturing techniques, is attracting increasing interest. Achieving high fidelity multilayer material deposition has become one of the major challenges in focused electron beam induced deposition (FEBID) technology. While researchers have already developed several techniques such as 3D-printing nanostructures using high-speed atomic force microscopy AFM, achieving high fidelity multilayer material deposition and obtaining sufficiently robust mechanical properties remain significant challenges. Also, these existing techniques for additive nanoscale patterning typically require specialized equipment and usually yield patterns only with a limited set of materials or under a limited set of conditions.

In new work, reported in Nano Letters (“Nanotribological Printing: A Nanoscale Additive Manufacturing Method”), researchers describe a novel nanoscale additive manufacturing technique termed Nanotribological Printing (NTP), which creates structures through tribomechanical and tribochemical surface interactions at the contact between a substrate and an atomic force microscope probe, where material pattern formation is driven by normal and shear contact stresses.

Tribology is concerned with the study of friction, lubrication and wear. Tribochemistry can be defined as the chemical reactions that occur between the lubricant/environment and the surfaces under boundary lubrication conditions. Nanotribological Printing advances the field of nanomanufacturing by providing a versatile and easily accessible method for creating complex (multi-material) nanostructures, with high precision and uniquely superior mechanical properties.

“Our research was chiefly motivated by the observation of surface films that are known to form under macroscale tribological conditions, i.e. applied normal and shear stress – and the question of whether similar growth could be achieved with nanoscale contacts,” Dr. Harman Khare, the paper’s first author, tells Nanowerk. “In macroscale observations, these films serve to either reduce friction or improve wear resistance through superior mechanical properties. In our work, we demonstrate that surface patterns can similarly be created at the nanoscale to exhibit superior mechanical properties, which can be used in applications well-beyond improvements in friction and wear.”

This novel additive manufacturing technique, based on standard atomic force microscopy, allows the creation of nanoscale structures and patterns with tunable microstructure, thickness, and lateral dimensions. Fundamentally, the team, led by Prof. Robert W. Carpick at the University of Pennsylvania, demonstrates how applied normal and shear tribological stresses can induce chemical and physical surface interactions that result in patterning.

In addition, they also demonstrate that the patterns that are created by NTP retain their microstructural identities and mechanical properties.

The ink used for this 3D-printing process consists of molecules or nanoparticles dispersed in a suitable fluid within which the AFM probe is submerged. This is typically achieved by using an AFM fluid cell.

The choice of liquid carrier is determined primarily by the solubility and dispersion stability of ink units. During sliding, the molecules or nanoparticles in the ink are entrained into the contact at the leading edge of the AFM probe. Once within the contact, applied normal and shear stresses result in surface-mediated tribochemical or tribomechanical interactions between multiple ink units, as well as ink units and the substrate, leading to the formation of stable surface-bound solidified structures.

“There are two aspects of this research that are quite exciting,” Khare points out: “One, we are able to generate structures at the nanoscale additively, using only applied pressure and, sometimes, some heat. This is unusual in its relative simplicity to other additive nanolithography methods that require special working environments or operation conditions.” “Secondly” he adds, “the structures we are able to create exhibit remarkable mechanical properties. We report on measured moduli and hardness of structures created through NTP that approach values normally seen in bulk materials.”

This technique has the potential to enable additive nanomanufacturing of mechanically robust structures, which in addition to certain thermal, electronic or optical functionality, are uniquely able to also withstand applied normal and shear stresses. Practical applications of this technique could be in the fields of nanophotonics, sensors and wear-resistant nanoscale coatings. The team is currently investigating other potential material systems which could be used for ink materials in this technique. They are also pursuing methods to optimize and improve rates of patterning to increase throughput.

“One of the key challenges for this method, which also motivates the future direction of our research is scalability and throughput,” Carpick concludes. “Given the serial nature of patterning in an AFM, patterning of large areas is intrinsically time-consuming and slow. We are currently investigating novel methods to improve patterning throughput using Nanotribological Printing.”

Researchers at Virginia Tech 3D print metallic nanomaterials

Researchers at Virginia Tech have potentially cracked a conundrum that has tormented the scientific community and created a viable method to produce usable metallic nanomaterials. Of course, 3D printing provided the answer and this really could change the world we live in.

Now Xiaoyu Zheng’s team at Virginia Tech has made a major breakthrough and produced metallic nanostructures that are flexible, strong and exceptionally light. It is 400% more flexible than typical ceramic or metallic foams with far superior electrical conductivity and much greater flexibility.

Before now, we simply did not know how to produce lattices with the right resolution and build volume. So the structures and their functionality were inherently compromised. The team at Virginia Tech have found a way to employ digital light processing on a large area to get round the issues with scaling the process up that faced traditional stereolithography.

“Creating 3D hierarchical micro features across the entire seven orders of magnitude in structural bandwidth in products is unprecedented,” he explained. “Assembling nanoscale features into billets of materials through multi-leveled 3-D architectures, you begin to see a variety of programmed mechanical properties such as minimal weight, maximum strength and super elasticity at centimeter scales.”

In a solar panel, this nanostructure can collect photovoltaic energy throughout the structure, rather than just on the surface. This new material could be built in a way to replicate the mechanical properties of bone and any number of other organic materials. Any industry that requires strong, lightweight materials could use this technology and it has applications that range from aerospace through to agriculture.

Now it has been published in the Nature Materials journal, their paper has caused quite a stir. Entitled Multiscale Metallic Metamaterials, the study was effectively a collaborative effort as the Lawrence Livermore National Laboratory was also involved.

Current Graphene production techniques simply don’t exploit this incredible compound, so when it is produced in a 3D form it doesn’t live up to its full potential. It’s still impressive and has found its way into clothing and other materials, but we haven’t truly mastered it yet.

This discovery could prove to be the missing link and give us the technology to truly exploit Graphene, as well as change the way we look at a number of other elements and compounds.

DARPA wants to provide Infantry personnel with 3D printers which can print nanomaterials on demand

The modern infantry frequently have to perform combat-engineering tasks such as erecting or dismantling fortifications and obstacles, but it’s only the combat engineers who get the specialized heavy vehicles and equipment, and that gear tends to be tactically awkward and of limited availability. “Currently, small units are obliged to use theater (i.e., large formation) scale items such as protective barriers, ribbon or float bridges, structures formed from prefabricated concrete and other materials, qualified personal armor kits, as well as heavy equipment transporters and installers,” DARPA notes.

“The materials used in these items often limit performance, are heavyweight, and can have unintended consequences. For example, heavy armor reduces urban mobility, which can adversely impact a squad or platoon’s survivability when operating in close quarters.”

Rapunzel aims to take advantage of the new era of nanotech, where materials made of microscopic nanotubes can create nanomaterials that are lightweight but incredibly strong. “Recent advances in materials and additive manufacturing—such as the development of bulk printed nanotube/metal composites—are synergistic and suggest that a new era of rapidly generated, custom structures constituted of super-strength materials is at hand,” DARPA says.

The intended users are individual soldiers, fire teams and squads. In effect, DARPA wants to give combat infantry the equivalent of combat 3-D printers, by using nanomaterials that can be quickly shaped into any desired structure.

Rapunzel will focus on devising new materials and engineering systems in four areas: mobility to allow U.S. troops to maneuver on an urban battlefield, countermobility to erect obstacles in cities, concealment to camouflage friendly troops and installations, and survivability to protect soldiers, vehicles and civilians. Rapunzel will also use four types of materials: particles, fibers and filaments, films, and engineered origami (folded deployable structures).

“Can non-material science specialists within small units identify and assess material content and usability?” DARPA asks. Can they handle “immediate material formation, real-time fabrication processes, and instant testing/certification?”

References and Resources also include:

https://3dprintingindustry.com/news/solved-nanomaterials-problem-87653/

https://nationalinterest.org/blog/buzz/darpa-wants-turn-infantry-instant-combat-engineers-31237

https://www.nanowerk.com/spotlight/spotid=51476.php

https://phys.org/news/2019-04-d-metamaterials-optical-properties.html

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis