Smart materials or Active materials or Functional materials are designed materials that have diverse, dynamic features that enable them to adapt to the environment. They have one or more properties that can be significantly changed in a controlled fashion by external stimuli, the stimulus and response may be mechanical, electrical, magnetic, optical, thermal, or chemical.

Smart materials are used to construct smart structures. A smart structure (a.k.a. intelligent structure, adaptive structure, and functional structure) is defined as a structure that is able to sense external stimuli such as pressure, velocity, density, or temperature change. It can process the information and respond in a controlled manner in real time. A smart structure is a system containing multifunctional parts that can perform sensing, control, and actuation; it is a primitive analogue of a biological body.

Apart from the use of better functional materials as sensors and actuators, an important part of a “smarter” structure is to develop an optimized control algorithm that could guide the actuators to perform required functions after sensing changes. Many types of actuators and sensors such as piezoelectric materials, shape memory alloys (SMA) (alloys that can remember their original shapes), electrostrictive and magnetostrictive materials, and fiber optics are being considered for various applications.

Numerous examples already exist. In recent MADMEC competition, a team of PhD students, developed a hydrogel that can be added to the surface of windows, making them switch from transparent to opaque in response to temperature. The hydrogel relies on a custom mixture of polymers that turns opaque as it absorbs heat — up until about 34 degrees Celsius — and then turns transparent and releases heat in response to cooling temperatures. “On a cold day, it’s going to be clear, and on warmer day, if it gets really hot out, it’s going to become opaque,” said team member Seth Cazzell, a PhD student in DMSE. “What we have is this passive, self-shading device that responds to ambient temperature.” Another US university project developed liquid crystal technology where liquid crystal display intensity. changes instantly according to the external light intensity.

Programmable materials offer many possibilities in defense. These materials could change their strength, size, impact properties, or overall shape in response to changing operational requirements. There include morphing wings in UAVs or hypersonic vehicles which change their shape to change their aerodynamic profile according to the mission. Another example is Antenna that uses metamaterials or engineered materials to modify its radiation pattern, change the band/frequencies in which it transmits, or direct the beam at a specific target.

Manufacturing of Smart, Multifunctional and programmable materials

In the world of structural design there are three primary ingredients to develop a structure: constitute materials the structure will be comprised of, manufacturing and assembly of the constitute materials to produce parts and connections, and design of the structure to meet functional requirements. For smart structure and system, the material should be able to withstand higher load and the weight of the materials should be minimum. In the regard of less weight requirement aluminum and magnesium alloy and composites plays major role.

However, developing Smart materials and products have many challenges like novel fabrication techniques (e.g. dispersion, alignment); in-process metrology; material characterization and in-situ monitoring; yield optimization; accelerated life tests to determine material durability and techniques to advance disassembly and recovery at end of life.

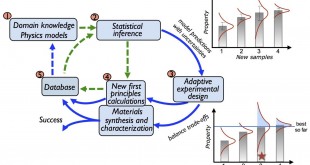

Development of smart or multifunctional materials not only require determining materials behavior, but also manufacturing strategies to design and use the materials to produce multifunctional structures. From understanding material behavior and development of predictive models, analysis tools/instruments are required to establish process parameters for manufacturing of multifunctional materials and structures.

Some of the technologies are composite manufacturing technologies, specifically within the fields of additive manufacturing, fusion bonding of thermoplastic composites, automated fiber placement of thermoplastic composites, and vacuum assisted resin transfer molding (VARTM). Therefore researchers are applying new technologies such as 3D printing, self-assembly and CRISPER for manufacturing these smart materials.

Thus, printed smart materials is an area of increasing interest due to low-cost fabrication, simple integration into devices and possibility of obtaining multifunctional materials over large and flexible areas. The impact of printable smart and multifunctional materials span from the areas of sensors and actuators, to energy generation and storage and tissue engineering applications, among others.

In 2020, Researchers from Texas A&M and the U.S. Army created synthetic materials with morphing abilities that can be 3D printed and self-heal within seconds.

By tweaking the chemistry of a single polymer, researchers at Texas A&M University and the U.S. Army Combat Capabilities Development Command Army Research Laboratory have created a family of synthetic materials that range in texture from ultra-soft to extremely rigid. The researchers said their materials are 3D printable, self-healing, recyclable and naturally adhere to each other in air or underwater. Their findings are detailed in the May 2020 issue of the journal Advanced Functional Materials.

“We have made an exciting group of materials whose properties can be fine-tuned to get either the softness of rubber or the strength of load-bearing plastics,” said Svetlana Sukhishvili, professor in the Department of Materials Science and Engineering and a corresponding author on the study. “Their other desirable characteristics, like 3D printability and the ability to self-heal within seconds, make them suited for not just more realistic prosthetics and soft robotics, but also ideal for broad military applications such as agile platforms for air vehicles and futuristic self-healing aircraft wings.”

Synthetic polymers are made up of long strings of repeating molecular motifs, like beads on a chain. In elastomeric polymers, or elastomers, these long chains are lightly crosslinked, giving the materials a rubbery quality. However, these crosslinks can also be used to make the elastomers more rigid by increasing the number of crosslinks. Although previous studies have manipulated the density of crosslinks to make elastomers stiffer, the resulting change in mechanical strength was generally permanent.

“Crosslinks are like stitches in a piece of cloth, the more stitches you have, the stiffer the material gets and vice versa,” Sukhishvili said. “But instead of having these ‘stitches’ be permanent, we wanted to achieve dynamic and reversible crosslinking so that we can create materials that are recyclable.”

The researchers focused their attention on the molecules involved in the crosslinking. First, they chose a parent polymer, called prepolymer, and then chemically studded these prepolymer chains with two types of small crosslinking molecules — furan and maleimide. By increasing the number of these molecules in the prepolymer, they found that they could create materials stiffer. In this way, the hardest material they created was 1000 times stronger than the softest.

However, these crosslinks are also reversible. Furan and maleimide participate in a type of reversible chemical bonding. Put simply, in this reaction, furan and maleimide pairs can “click” and “unclick” depending on temperature. When the temperature is high enough, these molecules come apart from the polymer chains and the materials soften. At room temperature, the materials harden since the molecules quickly click back together, once again forming crosslinks. Thus, if there is any tear in these materials at ambient temperatures, the researchers showed that furan and maleimide automatically re-click, healing the gap within a few seconds.

The researchers noted that the temperatures at which the crosslinkers dissociate or unclick from the prepolymer chains are relatively the same for different stiffness levels. This property is useful for 3D printing with these materials. Regardless of whether they are soft or hard, the materials can be melted at the same temperature and then used as printing ink. “By modifying the hardware and processing parameters in a standard 3D printer, we were able to use our materials to print complex 3D objects layer by layer,” said Frank Gardea, research engineer in the United States Army Research Laboratory and a corresponding author on the study. “The unique advantage of our materials is that the layers that make up the 3D part can be of vastly different stiffness.”

As the 3D part cools to room temperature, he said, the different layers join seamlessly, precluding the need for curing or any other chemical processing. Consequently, the 3D-printed parts can easily be melted using high heat and then recycled as printing ink. The researchers also noted that their materials are reprogrammable. In other words, after being set into one shape, they can be made to change into a different shape using just heat. In the future, the researchers plan to increase the functionality of their new materials by amplifying its multifaceted properties outlined in the current study.

Optomec Breakthrough in 3D Printing Enables Micron-scale Smart Structures

Optomec, a leading global supplier of production grade additive manufacturing systems for 3D printed electronics and 3D printed metals, today announced its Aerosol Jet Technology can enable 3D polymer and composite structures to be printed at the micron scale with embedded electronics. This breakthrough has significant potential to reduce the cost and size of next-generation products used in the electronics and bio-medical industries.

This new capability is enabled by combining Optomec’s proven Aerosol Jet solution for fine feature printing with a proprietary in-situ curing capability for rapid on-the-fly solidification. Unlike other high resolution 3D printing approaches that deposit material globally, ie: in a powder bed, and then cure locally to define a pattern, the Optomec method relies on both local deposition and local curing. This makes the process more economical, in terms of material consumption, but is also key to enabling the highest resolution features available.

“This breakthrough in 3D printing technology extends additive manufacturing to the creation of micron scale, free-form polymer structures and smart devices,” said Mike O’Reilly, Optomec Director Aerosol Jet Product Management. Early adopter customers have already developed innovative applications for smart devices and micro-fluidic applications. “We continue to place emphasis on innovation such as Aerosol Jet 3D micro-structure printing to address our customer’s next generation product development challenges.”

Using this process high aspect ratio, free-form 3D structures can be printed at the micron-scale, without the need for support structures, from materials including photopolymers and certain composites.

Additionally, the resulting structures can be metallized with conformal 3D conductive traces and printed functional components, such as antennas and sensors, to create fully functional 3D components all in one manufacturing machine. This direct digital approach optimizes the fabrication process, reducing manufacturing steps and material usage making Aerosol Jet 3D micro-structure printing a cost-effective, green technology.

Aerosol Jet 3D micro-structure printing is capable of ultra-high resolutions with lateral features sizes down to 10 microns, and lateral and vertical build resolutions from 1 micron to 100 nanometers respectively. Aspect ratios of more than 100:1 have been achieved. Additionally, such 3D micro-structures can be printed onto existing components and products, such as semiconductor chips, medical devices or industrial parts.

MIT Engineers 3D print materials with networks of sensors directly incorporated

MIT researchers have developed a method for 3D printing materials with tunable mechanical properties, that sense how they are moving and interacting with the environment. The researchers create these sensing structures using just one material and a single run on a 3D printer as reported in August 2022.

The researchers focused their efforts on lattices, a type of “architected material,” which exhibits customizable mechanical properties based solely on its geometry. For instance, changing the size or shape of cells in the lattice makes the material more or less flexible.

While architected materials can exhibit unique properties, integrating sensors within them is challenging given the materials’ often sparse, complex shapes. Placing sensors on the outside of the material is typically a simpler strategy than embedding sensors within the material. However, when sensors are placed on the outside, the feedback they provide may not provide a complete description of how the material is deforming or moving.

Instead, the researchers used 3D printing to incorporate air-filled channels directly into the struts that form the lattice. When the structure is moved or squeezed, those channels deform and the volume of air inside changes. The researchers can measure the corresponding change in pressure with an off-the-shelf pressure sensor, which gives feedback on how the material is deforming. By measuring how the pressure changes within these channels when the structure is squeezed, bent, or stretched, engineers can receive feedback on how the material is moving.

The method opens opportunities for embedding sensors within architected materials, a class of materials whose mechanical properties are programmed through form and composition. Controlling the geometry of features in architected materials alters their mechanical properties, such as stiffness or toughness. For instance, in cellular structures like the lattices the researchers print, a denser network of cells makes a stiffer structure.

This technique could someday be used to create flexible soft robots with embedded sensors that enable the robots to understand their posture and movements. It might also be used to produce wearable smart devices that provide feedback on how a person is moving or interacting with their environment.

“The idea with this work is that we can take any material that can be 3D-printed and have a simple way to route channels throughout it so we can get sensorization with structure. And if you use really complex materials, then you can have motion, perception, and structure all in one,” says co-lead author Lillian Chin, a graduate student in the MIT Computer Science and Artificial Intelligence Laboratory (CSAIL).

NASA’s INSPACE

Furst, professor of chemical and biomolecular engineering and principal investigator of NASA’s InSPACE (Investigating the Structures of Paramagnetic Aggregates from Colloidal Emulsions) project are creating smart materials based on self-assembly, having small building blocks that come together and arrange on their own to rapidly manufacture themselves.

The InSPACE project is using magnetorheological (MR) fluids in microgravity environment of space to study self-assembly. Under Earth’s gravity, the magnetic particles are usually sitting against the bottom of their container, and the friction may prevent the chains from warping the way they do in space.

References and Resources also include:

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis