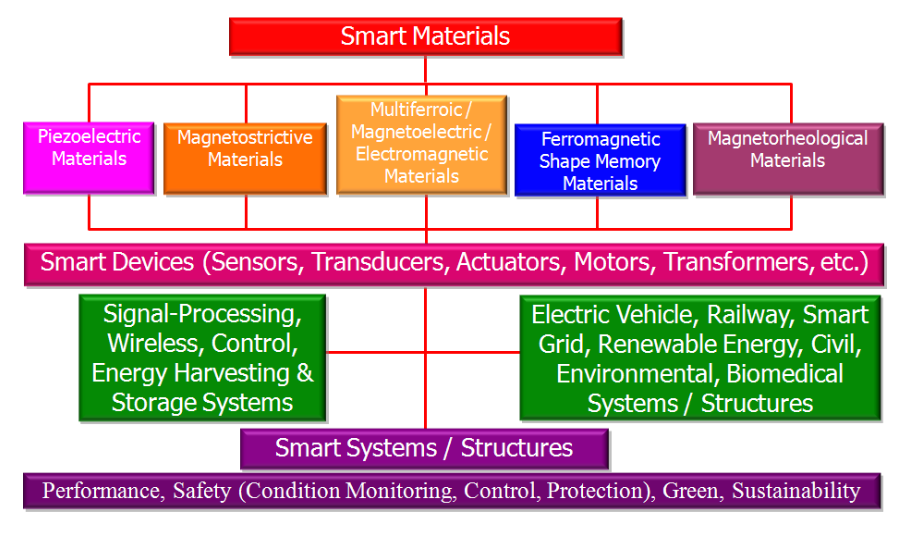

Smart materials or Active materials or Functional materials are designed materials that have diverse, dynamic features that enable them to adapt to the environment. They have one or more properties that can be significantly changed in a controlled fashion by external stimuli, the stimulus and response may be mechanical, electrical, magnetic, optical, thermal, or chemical.

Smart materials include self-healing materials, coatings with damage sensing, chemical sensing, friction changing, hydrophobicity changing capabilities, and also materials with several “smart” capabilities. They derive smart properties from structural patterning, often at the micro- or nanoscale, of already known material chemistries.

The multifunctional materials and composites achieve high functionality area, which intendeds to improve processes and products, creates several avenues to increase sustainability, and makes a direct and positive impact on economic growth, environment, and quality of life. They have tremendous potential to impact new system performance by reducing size, weight, cost, power consumption, and complexity while improving efficiency, safety, and versatility.

Smart materials are used to construct smart structures. A smart structure is a system containing multifunctional parts that can perform sensing, control, and actuation; it is a primitive analogue of a biological body. Smart structures are an integration of sensors, actuators, and a control system. Apart from the use of better functional materials as sensors and actuators, an important part of a “smarter” structure is to develop an optimized control algorithm that could guide the actuators to perform required functions after sensing changes.

Leif Asp, a professor at Chalmers University of Technology in Sweden described some of the work he is engaged in to develop carbon fibre composites for vehicles where the frame itself takes on energy storage functions. These structural batteries could mitigate against the usually high load battery masses bring to devices, but as Leif points out their development relies on a large team of researchers from a wide range of disciplines

Numerous examples already exist. In recent MADMEC competition, a team of PhD students, developed a hydrogel that can be added to the surface of windows, making them switch from transparent to opaque in response to temperature. The hydrogel relies on a custom mixture of polymers that turns opaque as it absorbs heat — up until about 34 degrees Celsius — and then turns transparent and releases heat in response to cooling temperatures. “On a cold day, it’s going to be clear, and on warmer day, if it gets really hot out, it’s going to become opaque,” said team member Seth Cazzell, a PhD student in DMSE. “What we have is this passive, self-shading device that responds to ambient temperature.” Another US university project developed liquid crystal technology where liquid crystal display intensity. changes instantly according to the external light intensity.

There have been predictions that by 2025 there can be as many as 100 billion connected IoT devices or network of everyday objects as well as sensors that will be infused with intelligence and computing capability while controllable via the Internet. These devices may include food items, home appliances, plant control systems, equipment monitoring and maintenance sensors, industrial robots, and personal devices such as smart watches, digital glasses and fitness monitoring products. Smart materials and structures are one of the enabling technologies of this intelligent future.

Military and aerospace also have large demand for smart materials and devices including smart self-repair, smart clothing such as cloaking suits, winglets in aeroplanes that adapt automatically to changing flight conditions and adaptive hull structures for ships. The technology has been used in the head up displays of fighter pilot helmets to enable them to see the visual display even under conditions of rapid change in light intensity like going from bright sunlight into cloud or from cloud into bright sunlight. Smart materials could change shape to unfold a solar panel on a space satellite without need of a battery-powered mechanical device.

Smart Materials and Devices

Mostly, “smart” materials are embedded in systems whose inherent properties can be favorably changed to meet performance needs. There are four of these aspects of which at least one is incorporated in a functional smart-material based device: smart materials can be sensors or actuators, they can be controlled or they can have biomimetic characteristics, according to Seung-Bok Choi of Department of Mechanical Engineering, Inha University, Incheon, South Korea.

Sensors are either bonded to the surface of a structural material or are embedded within a smart material to produce an electric signal proportional to the static or dynamic changes in the structural material.

Actuators are typically excited by an external stimulus, such as electricity, in order to change the stiffness and damping properties in a controlled manner. The control capability permits the dynamic behavior of the material to respond to an external stimulus according to a prescribed control algorithm associated to microprocessors.

Biomimetic characteristics are inspired by biological patterns in order to equip materials with the possibility of self-diagnosis, self-repair, and self-degradation of a broad range of structural materials.

Smart materials and structures have widespread applications in

- Materials science: composites, ceramics, processing science, interface science, sensor/actuator materials, chiral materials, conducting and chiral polymers, electrochromic materials, liquid crystals, molecular-level smart materials, biomaterials.

- Sensing and actuation: electromagnetic, acoustic, chemical and mechanical sensing and actuation, single-measurand sensors, multiplexed multimeasurand distributed sensors and actuators, sensor/actuator signal processing, compatibility of sensors and actuators with conventional and advanced materials, smart sensors for materials and composites processing.

- Optics and electromagnetics: optical fibre technology, active and adaptive optical systems and components, tunable high-dielectric phase shifters, tunable surface control.

- Structures: smart skins for drag and turbulence control, other applications in aerospace/hydrospace structures, civil infrastructures, transportation vehicles, manufacturing equipment, repairability and maintainability.

- Control: structural acoustic control, distributed control, analogue and digital feedback control, real-time implementation, adaptive structure stability, damage implications for structural control.

- Information processing: neural networks, data processing, data visualization and reliability.

Classes of Smart Materials

The most promising materials with the above features are piezoelectric materials, magnetostrictive materials, magnetorheological (MR) fluids, electroactive polymers (EAPs), shape memory alloys, and electrostrictive materials.

Piezoelectric materials are materials that produce a voltage when stress is applied. Since this effect also applies in the reverse manner, a voltage across the sample will produce stress within the sample. Suitably designed structures made from these materials can therefore be made that bend, expand or contract when a voltage is applied. Piezoelectric materials are being used for contact sensors for alarm systems and in microphones and headphones.

Magnetorheological fluids are smart suspensions of soft magnetizable particles in non-magnetic liquid medium whose phase and rheological properties can be altered by an external magnetic field. They are commercially applied in a broad spectrum of areas due to their field-tunability. Shock absorbers, brakes, clutches, seismic vibration dampers, control valves, and precision polishing are just a few examples to illustrate their use.

Electroactive polymers are polymer-based composites in which electronic or ionic properties are embedded. EAPs exhibit a large displacement in response to external stimuli and hence can offer operational similarity to biological muscles. This is the reason why EAP materials have a really promising future in biologically inspired actuators.

They may drive various mechanisms for manipulation and mobility including microrobots, micro flying objects, tactile, and animatronic devices. Generally, the EAPs are divided into two major categories based on their activation mechanisms: electronic (driven by electric field or Coulomb forces) and ionic (involving mobility or diffusion of ions).

In 2015, University of bristol developed Artificial Camouflaging Skin

Researchers from the University of Bristol have created an artificial skin based on electroactive dielectric elastomer, a soft, compliant smart material, mimicking the biological chromatophores responsible for camouflaging of the squid. Chromatophores are small pigmented cells embedded on cephalopods skin which can expand and contract and that work together to change skin colour and texture.

Aaron Fishman, Visiting Fellow in Engineering Mathematics, said: “Our ultimate goal is to create artificial skin that can mimic fast acting active camouflage and be used for smart clothing such as cloaking suits and dynamic illuminated clothing.”The cloaking suit could be used to blend into a variety of environments, such as in the wild. It could also be used for signalling purposes, for example search and rescue operations when people who are in danger need to stand out.”

In 2016, WSU Researchers developed shape-changing smart material

Washington State University researchers have developed a unique, multifunctional smart material that can change shape from heat or light and assemble and disassemble itself. This is the first time researchers have been able to combine several smart abilities, including shape memory behavior, light-activated movement and self-healing behavior, into one material. They have published their work in ACS Applied Materials & Interfaces (http://pubs.acs.org/doi/pdf/10.1021/acsami.6b04374).

The work is led by Michael Kessler, professor and Berry Family director and in the WSU School of Mechanical and Materials Engineering (MME), and Yuzhan Li, MME staff scientist, in collaboration with Orlando Rios, a researcher at Oak Ridge National Laboratory.

The team worked with a class of long-chain molecules, called liquid crystalline networks (LCNs), which provide order in one direction and give material unique properties. The researchers took advantage of the way the material changes in response to heat to induce a unique three-way shape shifting behavior. They added groups of atoms that react to polarized light and used dynamic chemical bonds to improve the material’s reprocessing abilities. “We knew these different technologies worked independently and tried to combine them in a way that would be compatible,’’ said Kessler.The resulting material reacts to light, can remember its shape as it folds and unfolds and can heal itself when damaged. For instance, a razor blade scratch in the material can be fixed by applying ultraviolet light. The material’s movements can be preprogrammed and its properties tailored.

New Shape-shifting smart materials could cut fuel burn reported in 2018

A group of new smart materials discovered by researchers at Texas A&M University and their colleagues has the potential to significantly improve the efficiency of fuel burn in jet engines, cutting the cost of flying. The materials, which could also reduce airplane noise over residential areas, have additional applications in a variety of other industries.

The discovery is based on bringing together two relatively new areas of materials science involving metal alloys, or metals composed of two or more elements. The first area involves shape-memory alloys, “smart” materials that can switch from one shape to another with specific triggers, in this case temperature. Picture a straight metal rod that is bent into a corkscrew. By changing the temperature, the corkscrew turns back into a rod and vice versa.

“What excites me is that we have just scratched the surface of something new that could not only open a completely new field of scientific research, but also enable new technologies,” said Dr. Ibrahim Karaman, Chevron Professor I and head of the university’s Department of Materials Science and Engineering.

Many potential applications for shape-memory alloys involve extremely hot environments like a working jet engine. Until now, however, economical high-temperature shape memory alloys, (HTSMAs), have only worked at temperatures up to about 400 degrees Celsius. Adding elements like gold or platinum can significantly increase that temperature, but the resulting materials are much too expensive, among other limitations.

Karaman, while working on a NASA project with UTRC and colleagues, began this research to address a specific problem: controlling the clearance, or space, between turbine blades and the turbine case in a jet engine. A jet engine is most fuel-efficient when the gap between the turbine blades and the case is minimized. However, this clearance has to have a fair margin to deal with peculiar operating conditions. HTSMAs incorporated into the turbine case could allow the maintenance of the minimum clearance across all flight regimes, thereby improving thrust specific fuel consumption.

Another important potential application of HTSMAs is the reduction of noise from airplanes as they come in to an airport. Planes with larger exhaust nozzles are quieter, but less efficient in the air. HTSMAs could automatically change the size of the core exhaust nozzle depending on whether the plane is in flight or is landing. Such a change, triggered by the temperatures associated with these modes of operation, could allow both more efficient operation while in the air and quieter conditions at touchdown.

Karaman and his colleagues decided to try increasing the operating temperatures of HTSMAs by applying principles from another new class of materials, high-entropy alloys, which are composed of four or more elements mixed together in roughly equal amounts. The team created materials composed of four or more elements known to form shape-memory alloys (nickel, titanium, hafnium, zirconium and palladium), but purposefully omitted gold or platinum.

“When we mixed these elements in equal proportions we found that the resulting materials could work at temperatures well over 500 degrees C — one worked at 700 degrees C — without gold or platinum. That’s a discovery,” said Karaman. “It was also unexpected because the literature suggested otherwise.”

How do the new materials work? Karaman said they have ideas on how they operate at such high temperatures, but do not have solid theories yet. To that end, future work includes trying to understand what is happening at the atomic scale by conducting computer simulations. The researchers also aim to explore ways to improve the materials’ properties even further. Karaman notes, however, that many other questions remain. This joint project between UTRC and Texas A&M was funded by the NASA Leading Edge Aeronautics Research initiative.

In 2020, AFRL repairs next generation composite materials with light

Scientists at the Air Force Research Laboratory and Hanyang University are developing smart structural composites that are robust and photothermally responsive, enabling next generation composite materials that are repairable with the application of light sources.

This is a joint collaboration between the United States and South Korea with participation of AFRL and Hanyang University through collaborative sponsorship of the Air Force Office of Scientific Research and the National Research Foundation of Korea.

“This partnership has helped us to leverage resources and accelerate our technology development,” said Professor Youngjong Kang of Hanyang University.

“We are developing an evolving and transformative materials technology that enables real-time system readiness and cost savings in the area of system sustainment and electromagnetic interference (EMI) shielding,” said Dr. Dhriti Nepal, Research Materials Engineer, of AFRL.

The structural damage repair in traditional epoxy composites is time-consuming and labor-intensive. Component downtime during repair also adds to loss of squadron readiness, in addition to excessive labor-intensive repair cost.

Traditional epoxy thermosets are infusible and unable to be remolded. It is nearly impossible to repair without completely replacing the entire component.

The development of smart photothermally activated composites repair via light activation adaptable to non-invasive (practically eliminating human touch labor) provides a significant breakthrough in sustainment of aircraft systems. This enables exceedingly low-cost repair.

This technology and EMI shielding have the potential to transition the research to system applications to meet warfighter needs.

Vitrimer materials, otherwise known as a class of plastics derived from thermosetting polymers, is one solution to providing a material that will alleviate issues related to mechanical repair. Vitrimer properties can be tailored to incorporate electrospray ionization (high voltage applied to a liquid to create an aerosol) shielding.

“Prime aerospace industry members see an immediate need for this technology for significant cost savings and boosted system readiness,” said Dr. Ajit Roy, Principal Material Research Engineer, of AFRL. “We are excited to experiment on the development of new generation nanoparticles incorporated into composites to meet application requirements for filled elastomer (a semi-flexible polymer that is added in between structural components to fill component gaps and to provide electrical connectivity) and EMI shielding.

To coincide with the development, Dr. Yixin Ren and Dr. Amber Hubbard of AFRL recently participated in a “Science as Art Competition” at the 2020 Spring Materials Research Society meeting. Ren’s “Carbon Nano Shish Kabob,” showing carbon nanotubes’ growth on carbon fibers, was awarded in the top 50 of the competition. Hubbard’s “(Thermoplastic) Flower in the Sun,” showing a system that can transform films into 3D shapes based on a photothermal response, won second place. Fundamental technical challenges remain to be worked to make the technology insertion to Air Force systems happen; however, a cohesive and productive multidisciplinary team is in place to advance this important and scientifically relevant technology.

References and Resources also include:

http://www.technavio.com/report/global-metals-and-minerals-piezoelectric-smart-materials-market

http://news.mit.edu/2016/materials-science-innovation-display-madmec-1012

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis