Metamaterials are artificially structured materials designed to control and manipulate physical phenomena such as light and other electromagnetic waves, sound waves and seismic waves in unconventional ways, resulting in exotic behavior that’s not found in nature. They are predicted to be able to protect the building from earthquakes by bending seismic waves around it, Similarly, tsunami waves could be bent around towns, and sound waves could be bent around a room to make it soundproof.

Metamaterials (i.e., engineered electromagnetic structures), are poised to disrupt industries, create entirely new markets, and change society. The ability to design and fabricate materials with new functionalities opens the door to a new world of possibilities. They can be tailored to either augment the functionality of existing devices or create new devices with superior performances. Metamaterials are utilized in various devices including Sensors, Superlensing, Cloaking, and Light emitting diodes. Metamaterials are utilized across various applications, including high frequency battle field communication, sensor detection, improving ultrasonic sensors, solar power management, and high gain antennas and also in various remote aerospace applications.

Although the application of metamaterials is very wide, the traditional design method requires the designer to repeatedly perform complex numerical calculations on the structure being designed. This process consumes huge time and computing resources. Therefore, it is urgent to find new ways to simplify or even replace traditional design methods.

Researchers are increasingly using computer models to predict how light will interact with metamaterials. However, it’s hard to predict which metamaterial will produce a desired property. Scientists used machine learning techniques to analyze databases of information. The computer program predicted the ideal metamaterial design for absorbing low-energy light. Conventional models would have taken more than two thousand years to find the best metamaterial. In contrast, the machine learning program calculated the solution in twenty-three hours.

Computational and theoretical materials science is playing an increasingly important role in advancing the search for novel materials and understanding the properties of existing ones. Computational research uses complex models in a variety of ways, all of which advance materials science and engineering. Modern computational hardware and software enable faculty to create “virtual laboratories,” where materials are tested and properties predicted computationally. “Problems that used to take years to solve can now be solved in a month,” says Srikanth Patala, a materials science and engineering researcher at NC State.

Researchers are also employing various machine (or statistical) learning methods to accelerate the discovery of new materials. The materials discovery process can be significantly expedited and simplified if we can learn effectively from available knowledge and data. Recently, researchers at Northwestern University used AI to figure out how to make new metal-glass hybrids 200 times faster than they would have doing experiments in the lab.

Machine learning is emerging as an important tool for advancing fundamental science. In this research, scientists Duke University used a type of machine learning known as a deep neural network to model how artificial materials (metamaterials) would absorb infrared light. The scientists designed a metamaterial that absorbs many wavelengths of infrared light but emits very few. This approach may enable scientists to develop practical thermophotovoltaic devices. These devices create electricity from heat instead of light.

Computer models of infrared optical absorption and emission from a metamaterial were used to fabricate novel metamaterials. The final design was a square array of cylindrical silicon pillars with varying radii and heights. To choose the geometric details, scientists trained a deep neural network with 18,000 individual simulations of potential designs. The network then modeled a much larger set of metamaterial designs. Because this approach was nearly one million times faster than the modeling software that was used to train the neural network, the authors were able to calculate the properties of every relevant metamaterial design in only twenty-three hours. After calculating the optical properties of all possible designs, a search algorithm selected the best design. These new techniques significantly increase the viability of more complex all-dielectric metasurface designs and provide opportunities for the future of tailored light-matter interactions.

Machine learning for metamaterial design

The extraordinary properties of mechanical metamaterials stem from their architecture, or internal structure, rather than their chemical composition. These properties can go beyond (=”meta”) their ingredient materials, and vigorous activities have recently produced programmable and exotic material properties as well as unprecedented mechanical functionalities such as shape-morphing and self-folding. However, understanding how these properties emerge and how we can rationally design metamaterials remain major challenges: how and why mechanical metamaterials function is not well understood, and the design of metamaterials is mostly based on creativity, heuristics and trial-and-error

As a cross-disciplinary field, machine learning covers many disciplines including life sciences, computer sciences, and psychology, it has been working to use computers to imitate and implement human learning processes to acquire new knowledge or skills. The basic principle of machine learning can be simply described as the use of computer algorithms to obtain the correlation among a large amount of data or to predict the rules among similar data and finally achieve the purpose of classification or regression. Until now, many machine learning algorithms have been applied to the designation of metamaterials and have achieved significant results, including genetic algorithms, linear regression algorithms, and shallow neural networks.

As the structure turns more and more complex and the changes in the structure become more diverse, problems will require more time to solve. At the same time, the highly nonlinear nature of the problems makes it difficult for simple machine learning algorithms to obtain accurate predictions. In addition, to design a matching metamaterial structure for a specific electromagnetic effect requires designers to try and perform complex numerical calculations on the structure. These processes will consume a tremendous amount of time and computing resources.

As one of the most outstanding algorithms in the field of machine learning, deep learning has made world-renowned achievements in various related fields such as computer vision, feature extraction, and natural language processing. At the same time, successes in other non-computer related fields are numerous, including many basic disciplines such as life sciences, chemistry, and physics. Therefore, applying deep learning to the design of metamaterials is also a hot research direction at present, and many outstanding works have appeared

Machine learning finds new metamaterial designs for energy harvesting

In Sep 2019, Electrical engineers at Duke University reported to have harnessed the power of machine learning to design dielectric (non-metal) metamaterials that absorb and emit specific frequencies of terahertz radiation. The design technique changed what could have been more than 2000 years of calculation into 23 hours, clearing the way for the design of new, sustainable types of thermal energy harvesters and lighting. The study was published online on September 16 in the journal Optics Express.

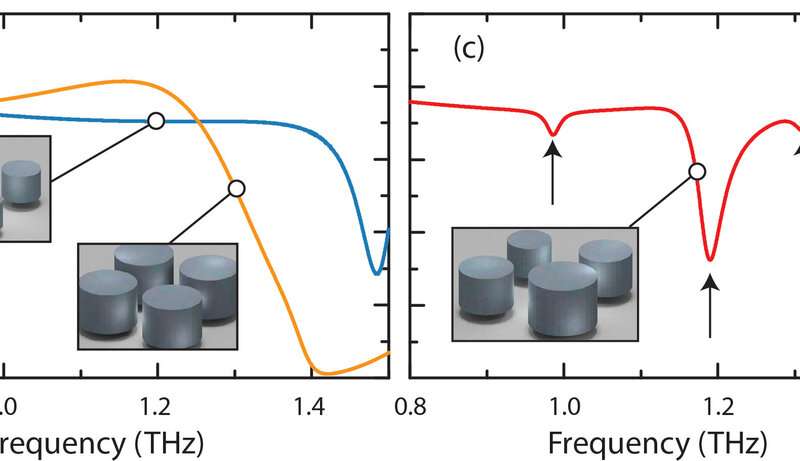

Metamaterials are synthetic materials composed of many individual engineered features, which together produce properties not found in nature through their structure rather than their chemistry. In this case, the terahertz metamaterial is built up from a two-by-two grid of silicon cylinders resembling a short, square Lego. Adjusting the height, radius and spacing of each of the four cylinders changes the frequencies of light the metamaterial interacts with. Calculating these interactions for an identical set of cylinders is a straightforward process that can be done by commercial software. But working out the inverse problem of which geometries will produce a desired set of properties is a much more difficult proposition.

Because each cylinder creates an electromagnetic field that extends beyond its physical boundaries, they interact with one another in an unpredictable, nonlinear way. “If you try to build a desired response by combining the properties of each individual cylinder, you’re going to get a forest of peaks that is not simply a sum of their parts,” said Willie Padilla, professor of electrical and computer engineering at Duke. “It’s a huge geometrical parameter space and you’re completely blind—there’s no indication of which way to go.”

One way to find the correct combination would be to simulate every possible geometry and choose the best result. But even for a simple dielectric metamaterial where each of the four cylinders can have only 13 different radii and heights, there are 815.7 million possible geometries. Even on the best computers available to the researchers, it would take more than 2,000 years to simulate them all. To speed up the process, Padilla and his graduate student Christian Nadell turned to machine learning expert Jordan Malof, assistant research professor of electrical and computer engineering at Duke, and Ph.D. student Bohao Huang.

Malof and Huang created a type of machine learning model called a neural network that can effectively perform simulations orders of magnitude faster than the original simulation software. The network takes 24 inputs—the height, radius and radius-to-height ratio of each cylinder—assigns random weights and biases throughout its calculations, and spits out a prediction of what the metamaterial’s frequency response spectrum will look like.

“The initial predictions won’t look anything like the actual correct answer,” said Malof. “But like a human, the network can gradually learn to make correct predictions by simply observing the commercial simulator. The network adjusts its weights and biases each time it makes a mistake and does this repeatedly until it produces the correct answer every time.” To maximize the accuracy of the machine learning algorithm, the researchers trained it with 18,000 individual simulations of the metamaterial’s geometry. While this may sound like a large number, it actually represents just 0.0022 percent of all the possible configurations. After training, the neural network can produce highly accurate predictions in just a fraction of a second.

Even with this success in hand, however, it still only solved the forward problem of producing the frequency response of a given geometry, which they could already do. To solve the inverse problem of matching a geometry to a given frequency response, the researchers returned to brute strength.

Because the machine learning algorithm is nearly a million times faster than the modeling software used to train it, the researchers simply let it solve every single one of the 815.7 million possible permutations. The machine learning algorithm did it in only 23 hours rather than thousands of years. After that, a search algorithm could match any given desired frequency response to the library of possibilities created by the neural network. “We’re not necessarily experts on that, but Google does it every day,” said Padilla. “A simple search tree algorithm can go through 40 million graphs per second.”

The researchers then tested their new system to make sure it worked. Nadell hand drew several frequency response graphs and asked the algorithm to pick the metamaterial setup that would best produce each one. He then ran the answers produced through the commercial simulation software to see if they matched up well.

With the ability to design dielectric metamaterials in this way, Padilla and Nadell are working to engineer a new type of thermophotovoltaic device, which creates electricity from heat sources. Such devices work much like solar panels, except they absorb specific frequencies of infrared light instead of visible light. Current technologies radiate infrared light in a much wider frequency range than can be absorbed by the infrared solar cell, which wastes energy. A carefully engineered metamaterial tuned to that specific frequency, however, can emit infrared light in a much narrower band.

“Metal-based metamaterials are much easier to tune to these frequencies, but when metal heats up to the temperatures required in these types of devices, they tend to melt,” said Padilla. “You need a dielectric metamaterial that can withstand the heat. And now that we have the machine learning piece, it looks like this is indeed achievable.”

Acoustic metamaterials and machine learning beat the diffraction limit, reported in August 2020

A system that reconstructs and classifies acoustic images with far smaller features than the wavelength of sound they emit has been developed by Bakhtiyar Orazbayev and Romain Fleury at the Swiss Federal Institute of Technology in Lausanne. Their technique beats the diffraction limit by combining a metamaterial lens with machine learning and could be adapted to work with light. The research could lead to new advances in image analysis and object classification, particularly in biomedical imaging.

The diffraction limit is a fundamental constraint on using light or sound waves to image tiny objects. If the separation between two features is smaller than about half the wavelength of the light or sound used, then the features cannot be resolved using conventional techniques. One way of beating the diffraction limit is to use near-field waves that only propagate very short distances from an illuminated object and carry subwavelength spatial information. Metamaterial lenses have been used to amplify near-field waves, allowing them to propagate over longer distances in imaging systems. However, this approach is prone to heavy losses, resulting in noisy final images.

In their study, Orazbayev and Fleury improved on this metamaterial technique by combining it with machine learning – through which neural networks can be trained to discover intricate hidden structures within large, complex datasets. The duo first trained a neural network with a database of 70,000 variations of the digits 0-9. They then displayed the digits acoustically using an 8X8 array of loudspeakers measuring 25 cm across, with the amplitude of each speaker representing the brightness of one pixel. In addition, they placed a lossy metamaterial lens in front of the speaker array, consisting of a cluster of sub-wavelength plastic spheres . These structures acted as resonant cavities, which coupled to the decaying near-field waves to amplify them over long distances.

With an array of microphones placed several metres away, Orazbayev and Fleury picked up the amplitudes and phases of the resulting waves, which they fed into two separate variations of their neural network: one to reconstruct the images, and the other to classify specific digits. Even when the most subtle features of the displayed digits were 30 times smaller than the wavelength of sound emitted by the speakers, the algorithms were able to classify images they had never seen before to within an accuracy of almost 80%.

Orazbayev and Fleury now hope to implement their technique using light waves. This will allow them to apply their neural networks to cellular-scale biological structures; quickly producing high-resolution images with little required processing power. If achieved, such a technique could open new opportunities for biomedical imaging, with potential applications ranging from cancer detection to early pregnancy tests.

The research is described in Physical Review X.

References and Resources also include:

https://phys.org/news/2019-09-machine-metamaterial-energy-harvesting.html

https://physicsworld.com/a/acoustic-metamaterials-and-machine-learning-beat-the-diffraction-limit/

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis