Introduction

Innovation, reliability, and military readiness are essential pillars for the success of any modern military force. The convergence of advanced technologies and the concept of digital twins has paved the way for a transformative revolution in the military landscape. Digital twins, the virtual replicas of physical systems or processes, are driving innovation, enhancing reliability, and revolutionizing military readiness in unprecedented ways. In this article, we will explore how digital twins are reshaping the military sector, their impact on innovation and reliability, and the future implications for military readiness.

What are Digital Twins

The Fourth Industrial Revolution, also known as Industry 4.0, is blurring the boundaries between the digital and physical worlds. Smart technologies like global connectivity, big data, machine learning, and virtual reality are driving this revolution. At the forefront of Industry 4.0 is Digital Twin technology, which combines these applications and has become a vital component.

A digital twin is a virtual replica of an object, system, or entity that evolves in real-time along with its physical counterpart through data collected by connected sensors. By mapping the data onto the virtual model, crucial information about the physical entity’s performance and behavior in the real world can be accessed.

Developers and analysts use digital twins in labs to understand the behavior of real-world systems. The virtual and physical worlds are paired, allowing for data analysis, system monitoring, problem prevention, new opportunity development, and future planning through simulations. Digital twins serve as testing grounds to simulate scenarios and provide predictive alerts, improving reliability and reducing costs.

The concept of digital twins originated in 2002 and was pioneered by NASA, who used mirrored systems to aid the rescue of Apollo 13. NASA now employs digital twins to develop recommendations, roadmaps, and advanced vehicles and aircraft.

Digital twins are transforming industries by bridging the gap between the physical and digital realms, enabling proactive problem-solving, enhancing reliability, and unlocking new possibilities for innovation.

For in-depth understanding on Digital Twins technology and applications please visit: Building a Better World with Digital Twins: An Introduction to the Technology and its Applications

Digital twin technology

Digital twins serve as virtual replicas of physical devices, products, or entities, leveraging data, machine learning, and software analytics to create dynamic models that evolve in sync with their real-life counterparts.

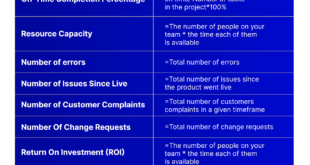

The implementation of digital twin technology encompasses a combination of cutting-edge technologies, including the Internet of Things (IoT), machine intelligence, and cloud connectivity. This convergence has made it cost-effective to implement digital twins on a large scale across various industries. A digital twin comprises three key components: a data model, a set of analytics or algorithms, and a set of executive controls. It combines real-time simulation of system dynamics with executive control capabilities.

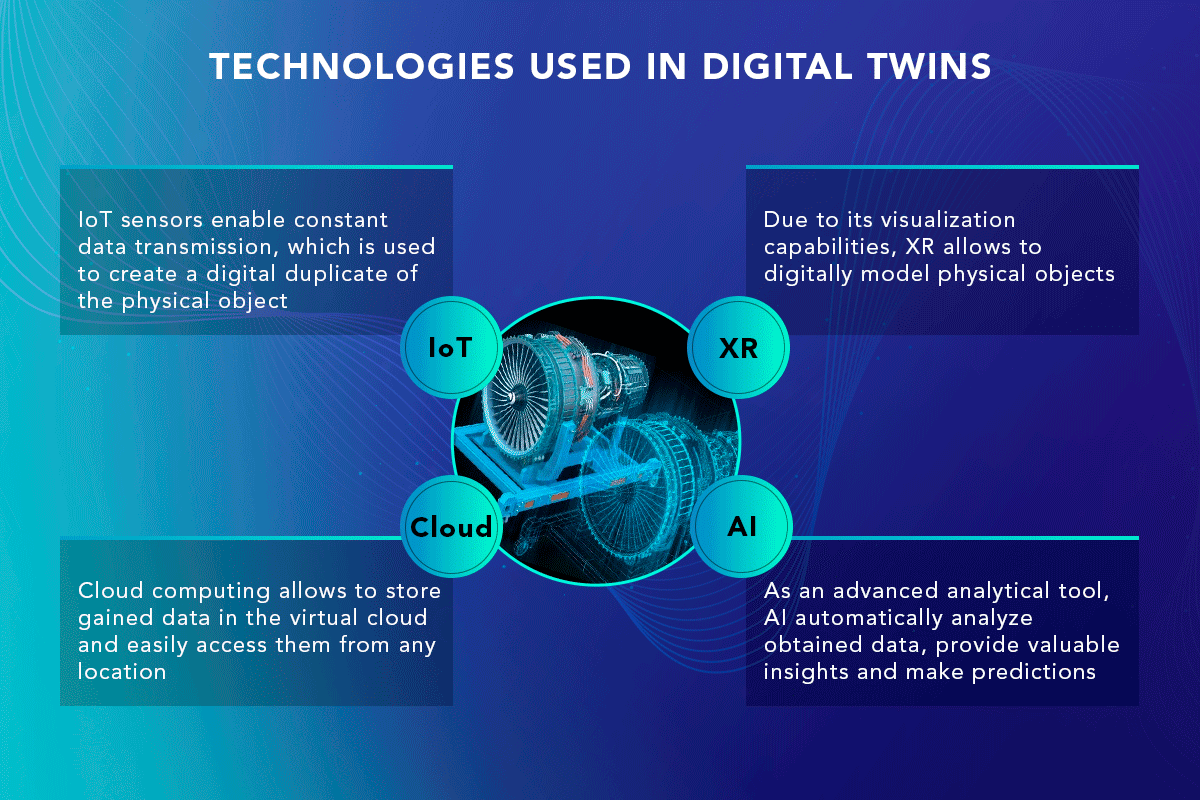

The Internet of Things (IoT) plays a vital role in digital twin applications. IoT involves collecting data from real-world objects through sensors, which is then used to create a digital replica of the physical object. This digital representation can be analyzed, manipulated, and optimized, providing valuable insights. IoT enables the connection of a virtual representation with a physical object in real-time, ensuring constant updates and synchronization.

Extended Reality (XR) is a visualization technology that allows for the creation of digital representations of physical objects. XR capabilities empower digital twins to digitally model real-world objects, enabling users to interact with virtual content. Multiphysics modeling tools are employed to collect data and create mathematical representations of systems and components.

Designing digital twins with virtual reality (VR) capabilities enhances the design process by providing immersive views and natural interaction. VR simulations can be run in real-time, enabling designers to observe the product’s behavior and appearance before production. This facilitates rapid-paced design iterations. Moreover, in scenarios such as remote surgeries, VR-enabled digital twins can be coupled with robotics, allowing surgeons to perform operations based on the virtual representation of a patient’s organ.

Cloud computing technology plays a crucial role in digital twin applications by providing efficient storage and accessibility of large volumes of data over the internet. Storing data in the virtual cloud enables easy access from any location, facilitating data management and analysis.

Digital twins are already empowering organizations to understand changing customer preferences, customize products, and deliver higher-quality solutions more rapidly. However, the potential of digital twins can be further realized.

Artificial intelligence (AI) serves as a powerful analytical tool, automatically analyzing acquired data and offering valuable insights. It can make predictions about outcomes and provide suggestions to avoid potential problems. Leveraging machine learning, predictive analytics tools build a comprehensive virtual understanding of the physical product.

Cognitive computing enhances the capabilities of digital twins, incorporating technologies like natural language processing, machine learning, object/visual recognition, acoustic analytics, and signal processing. These features augment traditional engineering skills and expand the scope of digital twin applications.

The fusion of machine learning and digital twins fosters accelerated growth in innovative ideas. Machine learning algorithms applied to digital twins can generate countless variations, uncovering patterns, solutions, and creative ideas that may elude human intuition.

For example, leveraging cognitive capabilities to enhance testing, a digital twin can identify which product tests should be conducted more frequently or retired. Cognitive digital twins transcend the limitations of human intuition, enabling the design and refinement of future machines on an individualized basis. This personalized approach replaces the outdated “one-size-fits-all” model, catering to specific needs and requirements.

In conclusion, digital twin technology, bolstered by the IoT, extended reality, cloud computing, artificial intelligence, and cognitive computing, is revolutionizing industries. With continuous advancements, digital twins hold immense potential for optimizing processes, driving innovation, and delivering customized solutions for the benefit of businesses and end-users alike.

Accelerating Innovation

Digital twins are becoming a driving force behind innovation in the military domain. By creating virtual replicas of complex military systems such as aircraft, vehicles, or even entire bases, military engineers and designers gain valuable insights into the performance and behavior of these systems. With real-time data streaming from sensors and other sources, digital twins provide a comprehensive understanding of system operations, enabling engineers to identify optimization opportunities, detect potential issues, and develop innovative solutions.

Through virtual simulations, military engineers can test new technologies, evaluate alternative designs, and conduct risk-free experiments. This accelerates the innovation cycle by reducing the time and costs associated with physical prototyping. Digital twins facilitate the exploration of new concepts, materials, and strategies, leading to the development of more advanced and efficient military systems.

Enhancing Reliability

Reliability is paramount in military operations, where the lives of soldiers and the success of missions depend on the performance of equipment and systems. Digital twins play a crucial role in enhancing reliability by continuously monitoring and analyzing real-time data from physical assets. By comparing the behavior of the digital twin with the real system, any deviations or anomalies can be quickly identified, allowing for proactive maintenance and predictive analysis.

With predictive analytics, digital twins can forecast potential failures or performance degradation, enabling proactive maintenance schedules and minimizing downtime. This proactive approach reduces the chances of unexpected system failures during critical missions and enhances the overall reliability of military assets. By harnessing the power of digital twins, military forces can maximize the availability and operational effectiveness of their equipment while minimizing risks and associated costs.

Revolutionizing Military Readiness

Military readiness encompasses the preparedness, agility, and effectiveness of armed forces to fulfill their missions and respond to emerging threats. Digital twins have the potential to revolutionize military readiness by providing real-time situational awareness, training simulations, and mission planning capabilities.

Digital twin models can integrate data from various sensors, intelligence sources, and simulations, creating a comprehensive operational picture for military commanders. This enhances situational awareness, allowing decision-makers to make timely and informed choices. Furthermore, digital twins enable the creation of virtual training environments, where soldiers can simulate complex scenarios and practice their skills in a risk-free setting. These training simulations can replicate real-world conditions, improving readiness and reducing training costs.

In addition, digital twins aid in mission planning by providing accurate and up-to-date information about the physical environment, enemy positions, and logistical considerations. This enables military planners to optimize routes, allocate resources effectively, and devise strategies based on the most accurate and current data available.

Digital twin Applications

Digital twin technology has revolutionized various industries, delivering valuable benefits and transforming processes. In the defense and maritime sectors, digital twins optimize operations, modernize fleets, track ship parts, and enable predictive maintenance. This technology ensures the reliability and performance of machines and systems crucial for war zones or critical space missions.

Smart city programs leverage digital twins to model and optimize traffic flows, automate port operations, and improve overall efficiency. For example, in cities like Portland, digital twins are used to simulate and manage traffic, while Rotterdam is developing a digital twin of its port to enhance automation and operational effectiveness.

In the healthcare industry, digital twins have significant potential. Philips has developed the Heart Model, a digital representation of the human heart that assists clinicians in diagnosing cardiac images faster and with fewer variations than traditional methods. The ultimate goal is to create a digital twin of the human body, enabling advancements in cardiology, oncology, pulmonology, neurology, and other medical disciplines.

Manufacturing and product development industries benefit from digital twin technology by improving productivity and efficiency. Companies like GE use digital twins in their “digital wind farm” to analyze data from each turbine and optimize performance. Digital twins facilitate the design, testing, and refinement of products, enabling more innovative and customized solutions.

The automotive industry has embraced digital twins, with Tesla utilizing this technology for each car it produces. Continuous data collection from sensors allows the physical car to communicate with its digital twin, enabling software updates to improve performance and address specific issues. Insights from digital twins inform engineers and designers, leading to advancements in future product iterations.

Aerospace companies, such as Rolls-Royce, employ digital twins to monitor and maintain aero engines. Virtual copies of engines equipped with sensors collect real-time data transmitted to their digital twins. This enables predictive maintenance and the ability to study and simulate extreme operational scenarios, resulting in enhanced reliability and reduced downtime.

Digital twins also have applications in training and maintenance. They provide virtual environments for training simulations and distance learning, allowing personnel to gain confidence and expertise before performing tasks on actual aircraft. This approach reduces maintenance issues caused by repetitive work on operational aircraft.

Digital twins, as part of comprehensive digital models, are the foundation for connected products and services. Embracing digital twin technology allows companies to adapt to changing business landscapes and gain a competitive edge. By leveraging digital twins, organizations can enhance operations, maintenance, and the development of more reliable and efficient solutions.

Military applications

Digital twin technology holds great potential for military applications, offering significant advantages in maintenance regimens, testing methodologies, and overall system efficiency. Military leaders recognize the importance of digital twins in adapting to emerging threats and leveraging artificial intelligence for future testing processes.

Projects like VADIS, carried out by the University of Nottingham and Electroimpact, showcase how digital twins can enhance production in the aircraft assembly line. By measuring and updating a digital model based on real-time data, the construction process can be adjusted for specific components, leading to improved quality and reduced assembly time.

The digital thread, a seamless strand of data stretching from product requirement to retirement, is a crucial element in the digital twin architecture. It serves as the backbone for the digital twin, often supported by product lifecycle management software, manufacturing execution software, IoT platforms, CAD tools, and predictive analytics tools. This integrated approach ensures the comprehensive management and utilization of digital twin capabilities.

Maintenance and readiness are critical challenges for military forces, and digital twins offer solutions in these areas. By shifting from routine maintenance to as-needed repairs, digital twins can optimize maintenance processes and improve system availability. For example, the Navy faces difficulties in maintaining its legacy systems, and digital twins have the potential to address these issues and enhance overall operational readiness.

The Air Force has also embraced the digital thread concept to enhance its acquisition process and the performance of weapons systems. By streamlining resolutions of performance issues, identifying maintenance needs, and effectively managing risk, the Air Force can realize substantial benefits throughout the entire lifecycle of aircraft and weapons systems.

In summary, digital twin technology brings significant advantages to military applications, including improved maintenance, enhanced testing methodologies, streamlined production processes, and optimized system performance. By leveraging digital twins, military organizations can overcome challenges, improve readiness, and ensure the efficient utilization of resources.

Army Using Digital Twins to Breathe new Life into Aging Helicopter Fleet

The U.S. Army is leveraging digital-twin technology to enhance the sustainment and logistics of its aging fleet of Black Hawk helicopters. In collaboration with the U.S. Army Aviation and Missile Command, the Strategic Capabilities Office, and Wichita State University, researchers at the National Institute of Aviation Research are creating a virtual model, or digital twin, of a UH-60L Black Hawk helicopter. By disassembling an airframe and capturing a 3D scan of each structural part, the digital twin will enable the acquisition of out-of-production parts and the utilization of advanced techniques like additive manufacturing for component production.

The digital twin initiative aims to improve readiness across the Army’s UH-60 fleets while reducing operation and sustainment costs. By providing parts that are obsolete, low-volume, or in small quantity, the digital twin technology opens new opportunities for ensuring fleet readiness. Additionally, it allows for more efficient airworthiness assessments and streamlined evaluation and modifications through coordination with the Combat Capabilities Development Command Aviation and Missile Center’s Systems Readiness Directorate. This digital transformation brings key technical data for the Army’s utility workhorse, the Black Hawk helicopter, into the digital age, enhancing efficiency and effectiveness in maintenance and modifications.

Navy Optimizing Shipyards With Digital Twin Technology

The U.S. Navy is implementing digital twin technology as part of its Shipyard Infrastructure Optimization Program (SIOP) to modernize its aging public shipyards. With dry docks and buildings over a century old, the Navy recognized the need to optimize infrastructure to improve performance and productivity. The SIOP program, launched in 2018, focuses on creating digital replicas, or digital twins, of the shipyards using modeling and simulation technology. Siemens Government Technologies was selected to develop digital twins for each of the four yards involved in the program.

The digital twin models allow the Navy to analyze and optimize workflow, layout, and operations within the shipyards. By identifying opportunities for efficiency, the Navy aims to streamline processes and reduce costs. The program involves extensive data collection and analysis, and the Navy plans to continuously refine the models to incorporate new information and functionality.

While digital twin technology has been employed in ship construction yards overseas, its application in ship repair yards is relatively new. Private ship repair yards, although smaller and with limited investment capabilities compared to construction yards, can also benefit from digital twin technology. However, the challenge lies in the significant investment of software and time required for implementing digital twins.

Overall, the Navy’s utilization of digital twin technology within the SIOP program aims to revitalize and optimize its shipyards, improving efficiency and productivity in ship maintenance and repair operations.

US Navy use digital twins for electronic warfare assets

The US Naval Air Systems Command (NAC) has implemented digital twin modeling for its Airborne Electronic Attack Systems Program (PMA-234). Digital twins are virtual models of physical objects that can be used in computer simulations. The adoption of digital twin technology will allow the NAC to improve readiness, explore new capabilities, and expedite training for the program.

The PMA-234 Chief Engineer Christie Agamaite explained how a digital twin can aid in troubleshooting. “There is a plethora of signals from a platform and an integrated system. If you are using a digital twin, you can vary those signals at myriad different rates and see the resultant behaviours in real-time. The resultant behaviours are where we find the problems.”

The PMA-234 has been working with an industry partner to develop digital twin technology for the past six months. The initial testing of the technology focused on the pod interface unit of the ALQ-99 Tactical Jamming System, an older technology that converts analog signals to digital signals.

The use of digital twins enables the team to test and troubleshoot system behaviors in real-time, providing insights for improvements and upgrades before investing in new hardware. The implementation of digital twins enhances resiliency, efficiency, adaptability, and autonomy within the NAC’s systems, contributing to accelerated learning and development.

Air Force turns to digital twin technology

The U.S. Air Force is leveraging digital twin technology to design, test, and develop weapons more efficiently. After successfully using digital twinning for its Boeing-Saab ET-7 Red Hawk jet trainer, the Air Force plans to create an online Colosseum where defense companies can virtually test their systems against each other. This approach eliminates the need for physical prototypes and enables faster and more cost-effective evaluation of designs.

The Colosseum, part of the Air Force Research Lab’s Golden Horde program, will facilitate regular competition events focusing on various technology areas. To participate, vendors must adhere to a Government Reference Architecture, ensuring data standards and defining interfaces for seamless integration within the Colosseum’s framework.

By employing digital twin technology, the Air Force aims to advance networked, collaborative, autonomous systems such as swarming drones and sophisticated weaponry capable of identifying and attacking targets independently. The Golden Horde program is part of the Air Force’s Vanguard initiative, which prioritizes cutting-edge research projects that have the potential to deliver new capabilities to warfighters rapidly.

Air Force Research Laboratory: Where Digital Twins Soar into Reality

The Air Force Research Laboratory (AFRL) is at the forefront of a digital revolution, employing digital twins to transform aircraft and weapons development. These high-fidelity virtual counterparts, fueled by vast datasets and cutting-edge technologies, empower researchers to optimize designs, refine prototypes, and evaluate performance with unprecedented accuracy.

From the Colosseum, a simulated arena for pitting virtual weapons systems against each other, to AFWERX’s virtual proving ground for autonomous vehicles, AFRL is pushing the boundaries of digital twin applications. This approach unlocks significant advantages:

- Early-stage Optimization: Iterate designs rapidly within the digital realm, identifying weaknesses and refining performance before incurring the expense of physical prototypes. Imagine testing thousands of wing configurations in a simulated wind tunnel, optimizing aerodynamic efficiency before a single rivet is laid.

- Predictive Maintenance: Monitor digital twins in real-time to predict equipment failures and optimize maintenance schedules. Envision sensors feeding data back to the virtual model, flagging potential issues before they become critical emergencies.

- Enhanced Training: Immerse pilots and ground personnel in simulated scenarios using digital twins of aircraft and environments. Think virtual dogfights honing combat skills or practice missions in hyper-realistic replicas of hostile terrain, all within the safety of a computer-generated world.

However, harnessing the full potential of digital twins requires a robust underlying infrastructure. High-performance computing, real-time data transfer, and secure data management are critical to handling the immense data streams generated by these complex virtual models. As AFRL pioneers this frontier, their success hinges on building a digital backbone capable of supporting the soaring ambitions of digital twins.

By investing in cutting-edge technology and embracing advanced data analytics, AFRL can ensure that digital twins take flight, revolutionizing Air Force capabilities and ushering in a new era of agile, data-driven innovation.

Conclusion

Digital twins are revolutionizing the military landscape by accelerating innovation, enhancing reliability, and transforming military readiness. The ability to create virtual replicas of physical systems and processes offers unprecedented opportunities for military forces to optimize their operations, improve the performance of their equipment, and enhance their overall readiness. As technology continues to evolve, we can expect digital twins to play an increasingly pivotal role in shaping the future of military innovation, reliability, and preparedness. By embracing this transformative technology, armed forces can gain a significant competitive advantage in an ever-changing and complex global security landscape.

References and Resources also include:

https://www.avm-mag.com/army-using-digital-twins-to-breathe-new-life-into-aging-helicopter-fleet/

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis