Introduction: The Hypersonic Revolution

Hypersonic flight—defined as speeds exceeding Mach 5, or 3,836 mph (6,200 km/h)—has moved from the realm of science fiction to the forefront of aerospace engineering. Central to this leap is scramjet, or supersonic combustion ramjet, propulsion: a technology capable of transforming military power, redefining space access, and even revolutionizing commercial travel.

The implications are staggering. A passenger jet could one day travel from New York to Beijing in just two hours. Military forces could launch instant-strike missiles capable of penetrating any existing defense network. Reusable spaceplanes could slash the cost of putting satellites into orbit. These possibilities are not just theoretical—industry breakthroughs over the past decade have moved hypersonic systems from lab experiments to near-operational weapons. With China, Russia, and the United States locked in a high-stakes hypersonic arms race, the pace of development is accelerating, and the strategic consequences are profound.

How Scramjets Work: The Science of Hypersonic Speed

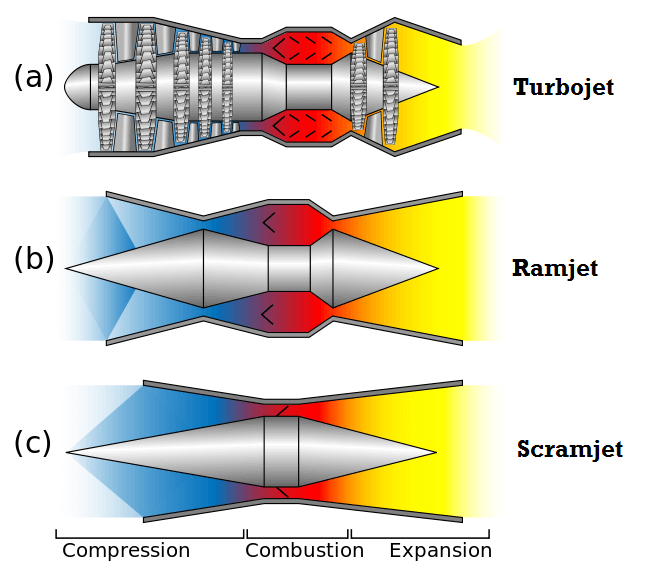

Scramjets, or Supersonic Combustion Ramjets, are a class of air-breathing engines designed to operate at hypersonic speeds—typically between Mach 5 and Mach 15. Unlike turbojets, which rely on turbines to compress air, or ramjets, which slow incoming airflow for combustion, scramjets allow supersonic airflow to pass directly through the engine without deceleration. This eliminates the need for moving parts, making them lighter, more reliable, and far more efficient than rocket engines for sustained high-speed flight.

Because scramjets draw in atmospheric oxygen instead of carrying onboard oxidizers, they significantly reduce weight and improve fuel efficiency—two critical advantages for both range and speed. Their performance sweet spot lies in the upper stratosphere, between roughly 66,000 and 98,000 feet, where oxygen levels and reduced drag enable optimal combustion. Below this range, extreme aerodynamic heating threatens the airframe; above it, oxygen becomes insufficient for engine operation.

This combination of speed, efficiency, and simplicity positions scramjets as a transformative technology for next-generation aerospace systems, from hypersonic military aircraft to reusable spaceplanes. By offering a cost-effective alternative to rocket propulsion for certain missions, they hold the potential to revolutionize both atmospheric and near-space transportation.

Scramjets vs. Traditional Jet Engines

| Engine Type | Max Speed | Key Limitation |

|---|---|---|

| Turbojet | ~Mach 2.5 | Relies on turbines, fails at high speeds |

| Ramjet | ~Mach 4 | Needs supersonic airflow, loses efficiency past Mach 5 |

| Scramjet | Mach 5–15 | Air-breathing, no moving parts, ultra-efficient |

Challenges and technological Breakthroughs driving Scramjet Revolution

Scramjet technology operates best in a narrow performance envelope—typically between Mach 5 and Mach 6—within a flight corridor located in the stratosphere, at altitudes of 66,000 to 98,000 feet. Stray too high, and oxygen levels drop below what’s needed for combustion; fly too low, and aerodynamic drag and intense heating can overwhelm the airframe.Balancing these factors requires precision in aerodynamics, propulsion, and materials engineering.

Compounding the challenge, aerodynamic drag increases with the square of velocity, meaning that doubling speed quadruples drag—demanding ever more powerful and efficient engines. Beyond Mach 5, the harsh operating conditions within the engine, characterized by high speed, shear, and inhomogeneous temperature and pressure distributions, present formidable challenges. To maintain optimal engine operation, the air must remain at supersonic speed inside the engine, a defining feature of scramjets.

Unlike conventional engines, scramjets cannot operate effectively below about Mach 3.5, which means they need a separate propulsion system—often a disposable rocket—to accelerate them to operating speed. This limitation has spurred research into combined-cycle engines, such as turbine-based combined cycles (TBCCs), which use gas turbines for takeoff and acceleration before transitioning to scramjet mode.

Scramjet propulsion faces limitations due to lower component efficiencies, the complexity of the combustion process, energy density of fuels, and the challenge of cold starting the engine. Increasing the flow-through time for air molecules within the combustor is a key goal to ensure sufficient time for fuel and oxidizer combustion.

Moreover, achieving fuel ignition within milliseconds, maximizing energy output, and minimizing aerodynamic drag have been critical design priorities in scramjet development. One of the most persistent challenges lies in fuel selection. Early concepts explored highly energetic fuels such as triethylaluminum, but their extreme toxicity limited practical application. Liquid hydrogen was later tested for its exceptional performance potential; however, its highly reactive nature and demanding cryogenic storage requirements made it impractical for most operational scenarios. Today, hydrocarbon-based fuels—similar to conventional jet fuel—are the preferred choice due to their relative safety, ease of storage, and compatibility with existing fueling infrastructure. Notably, a major Chinese breakthrough in scramjet technology, achieving a sustained 10-minute burn, was linked to an in-depth study of hydrocarbon fuel state transitions and their influence on stable supersonic combustion.

The extreme conditions of supersonic and hypersonic flight—where temperatures can exceed 4,000 °C—demand engineering solutions at the very edge of materials science and thermodynamics. Chinese researchers, including Dr. Fan, have pioneered precision fuel distribution techniques to manage and dissipate intense heat loads while maintaining combustion stability. One of the most pressing concerns is flameout, which can occur when rapid maneuvers disrupt airflow into the engine. Addressing such real-world challenges requires extensive live flight testing, yet access to high-enthalpy wind tunnels—essential for replicating these conditions on the ground—remains limited and highly competitive.

Various concepts, such as turbine-based combined cycles and rocket-based combined cycles, have been explored to operate hypersonic vehicles from zero Mach number, enabling dual-mode scramjets. The most practical concept currently is the turbine-based combined cycle, which involves using a gas turbine or turbojet engine for takeoff and acceleration before transitioning to scramjet operation. Even once at speed, engineers must contend with extreme thermal loads, unstable airflow, and the need to keep combustion supersonic without causing the engine to “unstart.”

In the race for materials capable of surviving these extreme conditions, carbon composites have emerged as indispensable. These lightweight yet ultra-resilient materials can endure both the searing heat and the punishing mechanical stresses of hypersonic flight, making them ideal for next-generation airframes and thermal protection systems.

Thermal management is one of the toughest obstacles. At hypersonic speeds, both internal combustor temperatures and external aerodynamic heating can exceed the limits of most metals. This has driven innovation in advanced ceramics, superalloys, and active cooling techniques—such as circulating cryogenic fuel through engine walls before combustion. The scramjet’s inlets and nozzles also present major design challenges, needing variable geometry to handle a wide range of speeds while surviving ultra-high temperatures.

Meanwhile, advances in compact, high-efficiency heat exchangers are proving critical in controlling thermal loads during sustained hypersonic operation. These systems not only preserve engine integrity but also maintain optimal combustion conditions, ensuring the scramjet operates at peak efficiency even in the most extreme environments.

Despite decades of difficulty, major milestones have been achieved. NASA’s X-43 program demonstrated scramjet-powered flight in the early 2000s, the U.S. Air Force’s X-51A Waverider sustained Mach 5 flight for 210 seconds in 2013, and India’s DRDO successfully tested its Hypersonic Technology Demonstrator Vehicle (HSTDV) at Mach 6 in 2020. These successes prove the concept works, but the next breakthrough—achieving sustained operational flight of 10 minutes or more—remains the critical hurdle. Meeting that goal will require continued advances in materials science, propulsion integration, and precision aerodynamics, pushing the boundaries of what’s possible in high-speed flight

Rotating detonation engines, additive manufacturing, and AI-driven design are converging to push hypersonic capabilities further.

Rotating Detonation Engines (RDEs) have emerged as a promising technology for achieving high velocity and fuel economy in hypersonic flight. These engines operate by creating a shockwave within a thin, cylindrical chamber, allowing for a higher burn rate compared to conventional combustion engines. RDEs operate by burning fuel at an exceptionally high rate, thanks to the use of shockwaves to compress and ignite fuel and air. This results in increased thrust, making them ideal for pushing aircraft to hypersonic speeds efficiently. The combustion chamber’s small size contributes to the increased pressure and potentially offers a 5 to 10 percent improvement in gas mileage.

Artificial intelligence is adding yet another dimension to scramjet evolution. AI-driven computational fluid dynamics (CFD) models and machine learning algorithms are now accelerating design cycles, enabling real-time optimization of fuel injection, combustion stability, and aerodynamic performance. This data-driven approach is pushing hypersonic systems closer to operational maturity.

The advent of additive manufacturing (3D printing) has brought a paradigm shift to scramjet production. By enabling the fabrication of intricate, thermally optimized internal geometries that were once impossible with traditional machining, engineers can now fine-tune airflow and fuel mixing for superior performance and durability. According to experts such as Urzay, these innovations not only enhance operational efficiency but also slash production lead times and costs. L3Harris’ 3D-printed scramjet combustors, for example, are already proven in both rocket engines and flight tests, making large-scale production both faster and cheaper.

More than 14 years have passed since the first X-51A WaveRider—powered by a scramjet engine built by Aerojet Rocketdyne (now part of L3Harris Technologies)—made hypersonic history with the longest-ever supersonic combustion ramjet-powered flight. In the years since, industry has not only refined propulsion technology but also built the production capacity needed to field operational hypersonic systems.

L3Harris has demonstrated its scramjet capabilities through the Hypersonic Air-breathing Weapon Concept (HAWC) program and is advancing additive manufacturing through efforts such as GAMMA-H. The company’s mature scramjet engine incorporates 3D printing to reduce production time by over 75%, manufacturing costs by 75%, and component counts by 95% compared to first-generation designs. Digital engineering further streamlines the design process, cutting costs and accelerating development cycles.

Military Applications: The New Arms Race

Hypersonic scramjet propulsion represents a game-changer in modern warfare. These systems promise unmatched speed, agility, and range—allowing militaries to strike distant targets within minutes rather than hours.

Hypersonic weapons fall into two primary categories: hypersonic cruise missiles and hypersonic glide vehicles (HGVs). Unlike conventional ballistic missiles, which follow a high, predictable arc, HGVs are boost-glide systems—launched on a rocket to hypersonic speeds, then detaching to skim through the atmosphere at low altitude. This unpredictable flight path makes them far more difficult to detect, track, and intercept.

Scramjet-powered hypersonic cruise missiles take a different approach, using advanced air-breathing engines to maintain blistering speeds at relatively low altitudes. This combination of sustained velocity and terrain-hugging flight renders them elusive even to cutting-edge missile defense systems, pushing the limits of current tracking and interception technology.

The military potential of scramjets is clearest in the development of Hypersonic Glide Vehicles (HGVs) and hypersonic cruise missiles. HGVs like China’s DF-ZF and Russia’s Avangard are launched via rockets, then glide unpredictably through the atmosphere at speeds exceeding Mach 20—making interception nearly impossible. Hypersonic cruise missiles, such as the U.S. HAWC and Russia’s Zircon, rely on scramjets to sustain speeds of Mach 5–9 within the atmosphere while flying at low altitudes to evade radar.

Under the U.S. National Hypersonics Initiative 2.0, hypersonic weapons are being developed with four key priorities: scalable manufacturing, constant innovation, workforce development, and expanded test capabilities. L3Harris has invested heavily in facilities, automation, and advanced 3D-printing to meet large-scale production demands. Its dual-mode air-breathing scramjet can operate as both a subsonic-combustion ramjet and a hypersonic scramjet, supporting a wide range of missions from strike to missile defense.

Hypersonic Capabilities Comparison (2023)

By 2023, hypersonic weapons had moved from experimental concepts to a defining feature of next-generation military competition. China’s DF-17, equipped with the DF-ZF hypersonic glide vehicle, has been operational since 2020, capable of reaching speeds over Mach 10 and striking targets 1,800–2,500 km away. Russia has deployed the 3M22 Zircon hypersonic cruise missile on its warships, boasting speeds near Mach 9 and a range of 1,000 km. The United States is testing two distinct approaches: the AGM-183A ARRW, an air-launched boost-glide system capable of Mach 20 over 1,600 km, and the scramjet-powered HAWC, which exceeds Mach 5 with a 1,000 km reach.

India, meanwhile, is positioning itself as an emerging player. Its Hypersonic Technology Demonstrator Vehicle (HSTDV) achieved Mach 6 in a successful 2020 test, laying the groundwork for indigenous capabilities. The nation is also collaborating with Russia on the BrahMos-II, a scramjet cruise missile expected to reach Mach 7 over 600 km. Together, these developments underscore the rapid global push toward hypersonic speed, where reaction times are measured in minutes, and traditional missile defense systems risk being rendered obsolete.

| Country | Key System | Type | Speed | Range | Status |

|---|---|---|---|---|---|

| China | DF-17 (w/DF-ZF HGV) | Hypersonic Glide Vehicle | Mach 10+ | 1,800–2,500 km | Operational since 2020 |

| Russia | 3M22 Zircon | Hypersonic Cruise Missile | Mach 9 | 1,000 km | Deployed on warships (2023) |

| U.S. | AGM-183A ARRW | Air-Launched Boost-Glide | Mach 20 | 1,600 km | Testing (2023) |

| U.S. | HAWC | Scramjet Cruise Missile | Mach 5+ | 1,000 km | Successful tests (2022) |

| India | HSTDV | Scramjet Tech Demonstrator | Mach 6 | N/A | Successful test (2020) |

| India | BrahMos-II* | Scramjet Cruise Missile | Mach 7 | 600 km | Under development |

(*Joint development with Russia)

The U.S. Defense Intelligence Agency notes that such capabilities could dramatically alter the balance of power by enabling rapid global reach, precision engagement, and the ability to penetrate advanced air defenses. Yet, the very advantages that make hypersonics so appealing also fuel concerns over destabilizing arms races, challenges to existing arms control treaties, and the urgent need for clear international norms to govern their use.

The Workforce and Testing Imperatives

A sustained hypersonic program requires not only advanced technology but also a skilled workforce. L3Harris supports STEM education in more than 400 communities and collaborates with 19 colleges and universities to inspire future aerospace engineers through programs in robotics, coding, and space technology.

Testing remains a bottleneck. Demand for high-speed test facilities has never been higher, and the U.S. Department of Defense is working to expand capacity. L3Harris contributes to this effort through its air-breathing hypersonic test facility in Orange County, Virginia, enabling faster validation of designs and reducing time from prototype to deployment.

The Future: Hypersonic Spaceplanes and Global Reach

Looking ahead, the same propulsion technology powering hypersonic missiles could soon be applied to spaceplanes and intercontinental passenger aircraft. Reaction Engines Ltd.’s SABRE engine aims for single-stage-to-orbit flight, while China’s Tengyun spaceplane targets suborbital passenger service by 2035. Hypersonic passenger jets could make Sydney to London in under four hours, though challenges in safety, cost, and infrastructure remain.

Yet the absence of any binding international agreement on hypersonic weapons raises the risk of escalation. As the technology matures, nations face the dual challenge of reaping its benefits while preventing destabilizing arms races.

Conclusion: The Hypersonic Era Has Arrived

Scramjets are no longer experimental—they are operational, tested, and moving into production. The United States, China, and Russia are racing to integrate hypersonic systems into their arsenals, with industry leaders like L3Harris pushing the boundaries of propulsion, materials, and manufacturing.

The pillars of the National Hypersonics Initiative 2.0—scalable production, innovation, workforce development, and robust testing—are in place. The next step is commitment: delivering operational hypersonic systems into the hands of warfighters while shaping the global norms that will define how they are used. The future of warfare, space access, and even global travel is now moving at hypersonic speed.

References and Resources also include:

https://www.createdigital.org.au/scramjet-super-fast-experimental-engine-no-moving-parts/

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis