The battlefield is a demanding environment. Aerospace and defense applications require robust and reliable communication systems that can withstand harsh conditions, intense vibration, and extreme temperatures. In the dynamic world of aerospace and defense, where reliability is not just a preference but a necessity, the significance of robust and dependable connectors cannot be overstated.

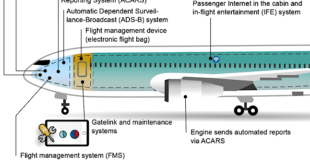

Aerospace & Defense Connectors refer to electrical connectors that are specifically designed and manufactured to be used in aerospace and defense applications. These connectors are critical components as they enable the transmission of electrical power and signals in aircrafts, satellites, missiles, and other defense systems.

These systems form the backbone for a myriad of vital technologies, encompassing satellite communication, electronic warfare, intelligence, missile guidance, radar, hypersonic systems, and more. The continuous evolution of hardware components and interconnect solutions is imperative to meet the high demands of these advanced technologies and ensure their unwavering performance in variable and extreme environments.

Connectors:

Electrical connectors constitute a large portion of the microwave technology manufacturing market. They are conductive devices used to bridge electrical circuits and can serve as permanent joints between microwave components. Microwave connectors often form termination units in coaxial connections and provide housing and circuit board support. Most microwave assemblies use them in 50 or 70 ohm settings.

Some common connector types include:

SMA: The Sub-Miniature Version A (SMA) connector is a coaxial cable device that functions on the multi-megahertz or gigahertz frequency range. The base design has a 4.2-millimeter diameter and can withstand maximum frequencies from 18 to 26 gigahertz. SMA connectors can also be coated with gold or stainless steel plated heads. SMB and SMC connectors are smaller versions of the SMA.

Type N: This is one of the oldest types of coaxial cable connectors suitable for microwave transmissions. N connectors can usually handle between 10 and 12 gigahertz maximum frequency and are most often found in communication and cable television systems.

GPO: A GPO is a type of push-on connector that is typically used when threaded connections are impractical. It has a non-threaded lock design, often coupled with a spring mechanism to improve alignment. GPO connectors are generally easier to apply and remove than other connectors, as they require no additional tools for installation.

Challenges in Aerospace and Defense Connectivity

Aerospace and defense applications demand connectors that go beyond traditional standards. The harsh conditions of these environments, coupled with the need for compact designs and high-frequency capabilities, call for connectors capable of withstanding extreme challenges. From densely packaged signal intelligence systems to electronic warfare operations, the connectors must excel in providing robust and reliable radio-frequency (RF) systems.

However, legacy connector designs like SMP/SMPM (sub-miniature push-on/sub-miniature push-on micro) connectors are falling short of evolving technology demands. Their vulnerabilities to electromagnetic interference (EMI) and electromagnetic compatibility (EMC), coupled with the lack of environmental sealing and the potential for disconnection upon impact, have paved the way for innovative RF interconnect designs. These designs aim to address these challenges more effectively and ensure superior performance in critical operations.

The Evolution of Connector Designs

Traditional connectors often struggle to meet these demands, leading to unreliable performance and potential mission failure. Traditional connectors often face limitations in terms of shielding, environmental protection, and mechanical retention, compromising their performance in critical operations.

In this realm, the emergence of high-performance connectors marks a significant leap forward, promising enhanced durability and consistent performance. Specifically engineered for high peak power at altitude, these new connector types are set to play a pivotal role in the next generation of military communication systems designed to operate in harsh environments.

For instance, the increasing frequency ranges (23 to 60 GHz and beyond) demand faster data transmission rates for quick processing of incoming signals. Printed circuit boards (PCBs) play a crucial role in establishing quick connections between components or between PCBs themselves. Moreover, as aircraft push the limits of speed and altitude, connectors must handle higher power while balancing considerations of weight, size, and power transmission capabilities. Connector designs equipped with materials like boron nitride dielectrics, capable of withstanding extreme temperatures, are being introduced to address these challenges.

Smaller Yet Stronger: The O-Ring Sealed Connector Solution

The latest breakthrough in connector technology introduces smaller-sized, O-ring sealed connector solutions that outperform their SMP/SMPM predecessors. These connectors are specifically engineered to meet the rigorous demands of aerospace and defense applications. The advantages they offer are manifold, contributing to improved shielding, enhanced environmental protection, and superior mechanical retention.

Key Advantages of O-Ring Sealed Connectors:

Retaining the compact form factor of SMPs, these connectors enhance shielding, environmental resilience, and power capabilities across frequencies from DC to 60 GHz. The connectors’ sealed and rugged design equips them to withstand harsh conditions and severe environments, addressing the shortcomings of their predecessors.

- Enhanced Shielding: O-Ring sealed connectors provide superior electromagnetic interference (EMI) shielding, ensuring reliable performance even in highly congested signal environments. This is particularly crucial in applications where signal integrity is paramount, such as electronic warfare systems.

- Improved Environmental Protection: The O-ring sealing mechanism offers robust protection against dust, moisture, and other environmental factors. This is a game-changer in aerospace and defense scenarios where equipment is often exposed to extreme weather conditions and challenging terrains.

- Superior Mechanical Retention: These connectors are designed to withstand intense vibrations and mechanical stresses, ensuring a secure and stable connection. In high-mobility operations or during turbulent flights, the mechanical robustness of these connectors becomes a defining factor in maintaining communication integrity.

Their overlapping insulators prevent signal leakage, meeting standards for EMI, EMC interference, liquid ingress, and salt ingress. The latching mechanism enhances mating retention, making them ideal for high-mobility scenarios.

Applications in Mission-Critical Systems:

The deployment of O-ring sealed connectors extends to various mission-critical systems, including:

- Signal Intelligence: In densely packaged signal intelligence systems, where the accuracy and speed of data transmission are vital, these connectors ensure a reliable and interference-free connection.

- Electronics Intelligence: The intricate nature of electronics intelligence demands connectors that can endure extreme conditions without compromising performance. O-ring sealed connectors rise to the challenge, offering a resilient solution.

- Electronic Warfare (EW) Systems: In EW systems, where the ability to detect, disrupt, and protect against adversarial electronic activities is crucial, the reliability of connectors is non-negotiable. O-ring sealed connectors ensure uninterrupted communication in these high-stakes operations.

Aerospace & Defense Connectors Market

The Aerospace & Defense Connectors Market is set to experience significant growth in the coming years. The increasing demand for new aircraft deliveries, military modernization programs, and the rising need for advanced defense systems are the key factors driving the market. Moreover, technological advancements such as miniaturization, lightweight connectors, and advanced materials are also fueling the market growth.

The market is witnessing a shift towards the development of advanced connectors that can withstand extreme conditions such as high vibrations, shock, temperature variations, and electromagnetic interference. Additionally, the growing trend of electric and hybrid aircraft is creating opportunities for the market, as these aircraft require more complex and specialized connectors for efficient power transmission.

The Aerospace & Defense Connectors market comprises three main types of connectors: Ethylene Propylene Diene Monomer (EPDM), Silicone Elastomers, and Fluoroelastomers. EPDM connectors are known for their excellent heat resistance and electrical insulation properties. Silicone Elastomers offer outstanding temperature resistance, making them suitable for high-temperature applications. Fluoroelastomers provide exceptional chemical resistance and are often used in environments where exposure to chemicals is common. Each type of connector has specific characteristics that make it suitable for different aerospace and defense applications.

The Aerospace & Defense Connectors Market Industry Research by Application is segmented into:

- O-Rings & Gaskets

- Seals

- Profiles

- Hoses

The aerospace & defense connectors market refers to the industry involved in the manufacturing and supply of connectors used in aerospace and defense applications. O-rings & gaskets are essential components used to create a seal in connectors, ensuring leakage prevention and maintaining system integrity. Seals are used to prevent the entry of contaminants or fluids into connectors. Profiles are used to provide mechanical stability or insulation. Hoses are utilized for the transfer of liquids or gases within the connectors, enabling efficient operations in aerospace and defense applications.

Geographically, North America dominates the Aerospace & Defense Connectors Market due to the presence of major aerospace and defense manufacturers in the region. However, Asia Pacific is expected to witness the highest growth during the forecast period, driven by the increasing defense budgets of countries like China and India.

Conclusion:

As aerospace and defense technologies evolve, the demand for connectors capable of withstanding the harshest conditions continues to grow. The advent of smaller-sized, O-ring sealed connector solutions represents a significant leap forward in achieving reliable and consistent performance in critical applications. By addressing challenges related to shielding, environmental protection, and mechanical retention, these connectors are poised to play a pivotal role in shaping the future of aerospace and defense connectivity.

References and Resources also include:

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis