Motor Driver Technology: Enabling the Electrified Future of Aerospace and Automation

From eVTOL aircraft to factory robotics, motor drivers are quietly powering the next wave of innovation.

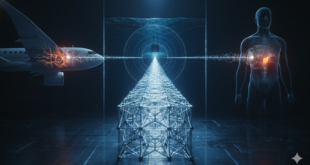

Motor drivers are at the core of modern motion control systems, enabling the precise control of electric motors across a wide range of industries. From industrial automation and robotics to the rapidly evolving aerospace and automotive sectors, motor driver technology is key to achieving higher efficiency, compact designs, and sustainable solutions. As the global push for electrification gains momentum, motor drivers are playing an increasingly pivotal role in powering electric and more electric aircraft (MEA), redefining the future of aviation

What Are Motor Drivers?

An electric motor is an electrical machine that converts electrical energy into mechanical energy. Most electric motors operate through the interaction between the motor’s magnetic field and electric current in a wire winding to generate force in the form of torque applied on the motor’s shaft. Electric motors can be powered by direct current (DC) sources, such as from batteries, or rectifiers, or by alternating current (AC) sources, such as a power grid, inverters or electrical generators. Electric motors produce linear or rotary force (torque) intended to propel some external mechanism, such as a fan or an elevator.

The Role of Motor Drivers in Electrification

Motor drivers serve as the bridge between control electronics and electric motors, managing speed, torque, and direction with precision. In the context of electrification, especially in aviation, motor drivers are essential for electric propulsion systems, actuator control in flight surfaces, landing gear mechanisms, braking systems, and overall power management systems. These advanced drivers are fundamental to optimizing energy use, improving response times, and ensuring the reliability of critical aerospace applications.

In more electric aircraft (MEA), motor drivers are replacing traditional hydraulic and pneumatic systems with electric actuation. This shift significantly reduces the weight of aircraft by eliminating complex hydraulic networks, increases energy efficiency through precise electronic control, and simplifies maintenance requirements. The result is a more reliable, environmentally friendly aircraft design that meets the growing demands for sustainable aviation.

Types of Motor Drivers and Their Applications

A DC motor driver controls the speed and direction of the motor by adjusting the voltage applied to the motor’s terminals. These drivers often use pulse-width modulation (PWM) to control the motor’s speed and torque. Modern DC motor drivers come with integrated features like current sensing and fault protection, making them suitable for a wide range of applications, from household appliances to robotics.

DC motor drivers are commonly used in applications such as actuators, pumps, and HVAC systems. They are known for their high-speed control capabilities and simple design, making them cost-effective solutions for both industrial and aerospace applications. Their ability to manage rapid changes in motor speed and torque makes them ideal for dynamic environments where quick adjustments are critical.

Stepper motor drivers, on the other hand, are preferred in applications that require precise positioning, such as avionics systems, navigation equipment, and robotics. These drivers allow for accurate control without the need for feedback sensors, providing high torque at low speeds.

A stepper motor driver controls the motor in discrete steps, providing accurate positioning and holding torque. These drivers are designed to supply a sequence of signals that rotate the motor in small, fixed steps. Advanced stepper motor drivers also include microstepping capabilities, which allow the motor to take smaller, fractional steps, improving precision and reducing vibration. Their inherent design simplifies control systems, making them suitable for tasks that demand high precision without added complexity.

Brushless DC (BLDC) motor drivers are pivotal in powering drones, electric vehicles, and electric vertical take-off and landing (eVTOL) aircraft. They offer superior efficiency, require minimal maintenance due to the absence of brushes, and deliver smooth, quiet operation through advanced electronic commutation. A BLDC motor driver uses electronic commutation to control the motor’s phases, ensuring smooth operation without the need for brushes. These drivers are typically more complex than DC motor drivers, as they require position feedback and advanced control algorithms to regulate speed and torque effectively. This makes BLDC drivers highly effective in aerospace environments where reliability and performance are paramount.

Hybrid Power Drive (HPD) modules represent the latest evolution in motor driver technology. These modules integrate silicon carbide (SiC) and traditional silicon technology to support high-power actuation systems. They are essential for applications that demand both high efficiency and robust performance, such as electric propulsion systems in next-generation aircraft.

Key Features of Modern Motor Drivers

- Efficiency and Power Handling Modern motor drivers are designed to be highly efficient, converting a minimal amount of electrical energy into heat. This is particularly important for applications requiring continuous operation, such as robotics and electric vehicles. The efficiency of a motor driver directly impacts the overall energy consumption and the motor’s performance. For high-power applications, such as electric aircraft or automotive systems, power handling capabilities of motor drivers are crucial for ensuring reliable and safe operation.

- Integrated Protection Mechanisms Overcurrent, overvoltage, and thermal protection are essential features of motor drivers, especially in demanding applications where failure could result in significant damage. Integrated protection mechanisms safeguard the motor and driver from damage caused by electrical faults. These protections are becoming increasingly sophisticated, with many modern drivers including short-circuit, thermal shutdown, and fault detection mechanisms that improve the system’s reliability.

- Size and Form Factor As motors become smaller and lighter, so too must the motor drivers. Compact and lightweight designs enable the development of more portable and flexible systems, such as electric drones, robotics, and wearable devices. Integration of motor drivers into compact modules allows for reduced space requirements, making them ideal for applications where size is a constraint.

- Smart Motor Control Smart motor drivers are the next step in motion control technology. These drivers include integrated intelligence, such as microcontrollers, sensors, and advanced algorithms, that optimize the performance of the motor. For example, sensorless control techniques enable BLDC motors to operate without the need for external position sensors, reducing complexity and cost. Additionally, advanced motor control algorithms allow for improved torque, speed, and efficiency control, making smart motor drivers ideal for applications like robotics, electric vehicles, and industrial automation.

Emerging Trends in Motor Driver Technology

Wide-bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), are revolutionizing motor driver design, particularly in high-power applications. These advanced materials offer higher efficiency by minimizing power losses during switching, faster switching speeds for high-frequency operations, and improved thermal performance that enhances heat dissipation in compact systems. This makes them ideal for applications like electric propulsion in aviation, where efficiency and reliability are paramount.

Another significant trend is the integration of smart control features within motor drivers. Modern motor drivers are evolving into intelligent systems equipped with embedded microcontrollers that enable real-time monitoring, diagnostics, and predictive maintenance. This advancement allows for proactive management of system health, reducing downtime and maintenance costs, which is particularly beneficial in critical industries like aerospace. Additionally, sensorless control techniques are becoming more prevalent, eliminating the need for external position sensors. This not only reduces system complexity and weight but also improves reliability, as there are fewer components that could potentially fail.

The rise of the Internet of Things (IoT) is also shaping the future of motor driver technology. IoT-enabled motor drivers allow for remote monitoring and control, providing valuable insights into performance and enabling predictive analytics. This capability is transforming fleet management in aviation and enhancing operational efficiency in industrial automation. Furthermore, the development of wireless motor control is gaining momentum, especially in applications like drones and robotics. Wireless solutions reduce the complexity of wiring, lower system weight, and offer greater design flexibility, opening new possibilities for advanced control architectures.

Applications of Advanced Motor Driver Technology

The advancements in motor driver technology are having a profound impact across multiple industries. In the automotive sector, motor drivers are central to electric vehicles (EVs), managing battery systems, power steering, and electric propulsion. Their ability to optimize energy use and deliver precise control contributes to improved vehicle performance and extended battery life.

In aerospace, motor drivers are redefining the design of flight control systems, landing gear actuation, and electric propulsion for eVTOL aircraft. Their compact size, lightweight design, and high efficiency are critical in reducing aircraft weight and enhancing fuel efficiency, supporting the aviation industry’s shift toward more sustainable solutions.

In the field of robotics, motor drivers enable precise control of robotic arms, drones, and automated systems used in manufacturing and logistics. Their high efficiency and reliability are essential for maintaining consistent performance in demanding environments. Industrial automation also benefits from advanced motor drivers, with applications ranging from conveyor systems and CNC machines to smart factories that rely on precision motion control to optimize production processes.

Consumer electronics have not been left behind. High-efficiency motor drivers are now integral to appliances, gadgets, and personal devices, enhancing performance while reducing energy consumption. From high-speed fans and electric shavers to advanced camera gimbals, motor drivers are quietly powering the devices that shape our daily lives.

Latest Advancements in Motor Driver Technology

Case Study: Microchip Technology’s Integrated Actuation Power Solution

One of the most notable advancements in motor driver technology comes from Microchip Technology, which has introduced an integrated actuation power solution combining companion gate driver boards with hybrid power drive (HPD) modules. This cutting-edge technology leverages both silicon carbide (SiC) and silicon semiconductors, offering scalable power solutions ranging from 5 kVA to 20 kVA—ideal for electrification in aerospace applications.

The companion gate driver boards are designed for seamless integration with Microchip’s HPD modules, creating an all-in-one motor drive solution that enhances efficiency and simplifies system design. This scalability allows the technology to be adapted for a wide range of applications, from small unmanned aerial systems (UAS) to high-power systems for electric vertical take-off and landing (eVTOL) aircraft, more electric aircraft (MEA), and fully electric aircraft. The new driver boards are lightweight, compact, and low-profile, optimizing both size and power efficiency, which is critical in aviation where every gram matters.

Moreover, these motor drivers are built to perform reliably across an extreme temperature range from −55°C to +110°C, making them suitable for the harsh operating environments encountered in aerospace applications. Microchip’s technology is not just about powering electric motors—it’s a transformative solution driving the future of electric aviation by reducing dependence on hydraulic systems, enhancing energy efficiency, and improving the reliability of aircraft systems.

Texas Instruments (TI) – High-Efficiency GaN Motor Drivers for Industrial and Automotive Applications

Texas Instruments (TI) has made significant strides in motor driver technology with its GaN (Gallium Nitride) motor drivers, designed to deliver ultra-high efficiency and fast switching performance. TI’s DRV8353 and LMG5200 series are standout products that integrate GaN FETs with smart gate drivers, reducing power losses and thermal stress while enabling higher switching frequencies. This advancement leads to more compact, energy-efficient designs, which are critical in applications like electric vehicles (EVs), robotics, and renewable energy systems.

In the automotive sector, TI’s motor drivers are pivotal for electric power steering, HVAC systems, and traction motors, offering precise control and robust protection features. Their GaN-based technology supports higher voltage operations with improved thermal management, reducing cooling requirements and system complexity. This positions TI’s motor drivers as essential components in both industrial automation and next-generation electric mobility solutions, paving the way for more sustainable and efficient powertrain architectures.

Infineon Technologies – E-Mobility Focus with Advanced SiC-Based Motor Drivers

Infineon Technologies is a key player in advancing motor driver solutions for e-mobility and aerospace applications. Their EiceDRIVER™ family, particularly the EiceDRIVER™ F3 Enhanced series, utilizes silicon carbide (SiC) technology to achieve exceptional power density, efficiency, and thermal performance. These motor drivers are optimized for high-voltage applications, making them ideal for electric aircraft, eVTOLs, and high-performance electric vehicles.

Infineon’s SiC motor drivers support fast switching and high-frequency operations, significantly improving system efficiency while reducing energy losses. This technology is crucial in aviation, where lightweight, compact, and energy-efficient solutions are paramount. Additionally, Infineon’s drivers incorporate advanced safety features, including fault detection and thermal protection, ensuring reliable performance in mission-critical applications. By focusing on SiC innovations, Infineon is helping accelerate the shift toward electrified transportation and cleaner energy systems.

NXP Semiconductors – Smart Motor Control Solutions for Aerospace and Industrial Automation

NXP Semiconductors has introduced the i.MX RT series of crossover MCUs, designed specifically for high-performance motor control applications. These smart motor drivers combine real-time processing capabilities with advanced security features, making them suitable for aerospace, industrial automation, and automotive systems. NXP’s motor control solutions are optimized for precise control of brushless DC (BLDC) motors, permanent magnet synchronous motors (PMSMs), and AC induction motors.

In aerospace, NXP’s motor drivers support electric actuation systems for flight controls, landing gear, and power distribution units in MEA platforms. Their integrated approach combines motor control algorithms, sensor interfaces, and safety protocols into a compact, energy-efficient package. This not only enhances operational efficiency but also simplifies the design process, reducing time-to-market for aerospace and industrial OEMs. NXP’s focus on secure, real-time motor control makes their technology a critical enabler for the next generation of smart, connected systems.

STMicroelectronics – Dual Full-Bridge Motor Drivers for Energy-Efficient Applications

STMicroelectronics has been pushing the boundaries of motor driver technology with its STSPIN32 series, which integrates dual full-bridge drivers with advanced motion control logic. These drivers are designed for energy-efficient applications, including drones, robotics, and industrial automation systems. The integration of control and power stages in a single package reduces the overall footprint, making them ideal for space-constrained applications like UAVs and portable medical devices.

ST’s motor drivers are known for their high efficiency, robust protection features, and flexible control options. They support sensorless field-oriented control (FOC), reducing the need for external sensors while maintaining precise motor control. This makes them cost-effective solutions for applications where weight, efficiency, and reliability are critical. STMicroelectronics continues to innovate in motor control technologies, contributing to the global trend of electrification and smart automation.

Rohm Semiconductor – SiC-Based Motor Drivers for High-Power Automotive and Aerospace Systems

Rohm Semiconductor has been a pioneer in leveraging silicon carbide (SiC) technology to develop high-power motor drivers that meet the demands of electric vehicles, industrial machinery, and aerospace systems. Their BM620xFS series of SiC-based intelligent power modules (IPMs) offers outstanding thermal performance, high switching efficiency, and compact design, making them ideal for applications like EV traction inverters, HVAC compressors, and electric propulsion systems in aviation.

Rohm’s motor drivers feature integrated gate drivers with advanced protection functions, ensuring safe and reliable operation even under extreme conditions. Their SiC technology allows for higher voltage operation with reduced switching losses, significantly improving energy efficiency and reducing system weight—key factors in aerospace and automotive applications. By focusing on high-power, high-efficiency solutions, Rohm is contributing to the electrification of transportation and the advancement of more sustainable energy systems.

The motor driver landscape is evolving rapidly, driven by advancements in semiconductor materials, smart control technologies, and the global push for electrification. Companies like Microchip Technology, Texas Instruments, Infineon Technologies, NXP Semiconductors, STMicroelectronics, and Rohm Semiconductor are at the forefront of this transformation, developing innovative solutions that power everything from electric vehicles and industrial automation to next-generation aircraft.

These advancements are not just about improving motor efficiency—they’re enabling the future of electric mobility, sustainable aviation, and smart automation. As motor driver technology continues to evolve, it will play a pivotal role in shaping the future of clean energy, connected systems, and advanced transportation.

The Future of Motor Driver Technology in Electric Aviation

Motor driver technology is no longer just about controlling motors—it’s about enabling the next generation of electric-powered systems. In aviation, motor drivers are at the forefront of the electrification revolution, supporting all-electric aircraft with zero-emission capabilities and enhancing the efficiency of more electric aircraft (MEA) by replacing traditional mechanical systems with lightweight, energy-efficient electric alternatives.

The development of eVTOL aircraft for urban air mobility is heavily reliant on advanced motor driver technology. These aircraft require high-power, compact, and reliable motor drives to achieve vertical take-off and landing capabilities in densely populated areas. The future of electric aviation will be shaped by continuous improvements in motor driver efficiency, thermal management, and smart control systems.

With companies like Microchip Technology leading the charge, motor drivers are set to become even more powerful, compact, and intelligent. These advancements will not only support the growth of electric aviation but also contribute to broader sustainability goals, reducing the environmental impact of transportation and enabling new possibilities for electrified mobility.

Final Thoughts

As industries continue to embrace electrification, motor driver technology will play a critical role in powering the systems of tomorrow. Whether it’s improving energy efficiency in industrial robots, enabling zero-emission electric vehicles, or supporting the next generation of aircraft, the advancements in motor driver technology are paving the way for a cleaner, smarter, and more connected world. The journey toward sustainable electrification has just begun, and motor drivers will be at the heart of this transformative evolution.

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis