“Between 2011 and 2018, WHO tracked 1483 epidemic events in 172 countries. Epidemic-prone diseases such as influenza, severe acute respirator syndrome (SARS), Middle East respiratory syndrome (MERS), Ebola, Zika, plague, yellow fever and others are harbingers of a new era of high-impact, potentially fast-spreading outbreaks that are more frequently detected and increasingly difficult to manage.”

“Negative impacts are particularly profound in fragile and vulnerable settings where poverty, poor governance, weak health systems, lack of trust in health services, … and sometimes ongoing armed conflict greatly complicate outbreak preparedness and response.”

“The tools and systems needed to respond effectively to a fast-moving and lethal respiratory pathogen are in place: A universal influenza vaccine is effective and routinely used to protect the global population new therapeutics and broad-spectrum antivirals are widely available to treat and reduce mortality from a range of viruses; novel pathogens are routinely identified and sequenced, and the sequences are shared on a globally accessible website. Distributed manufacturing of vaccines (including nucleic acid types) begins within days of obtaining the new

sequencing and effective vaccines are pre-tested and approved for use within weeks.”

The U.S. military routinely deploys throughout the world where warfighters can potentially be exposed to regional endemic diseases as well as chemical, biological, radiological, or nuclear (CBRN) threats. Rapid access to medical countermeasures (MCMs) against these threats is critical to protect Defense Department (DoD) personnel and local populations; however, manufacturing, stockpiling, and distribution issues remain. The DoD relies on an outdated manufacturing paradigm that limits rapid access to medical countermeasures (MCMs) against CBRN threats in austere environments

DARPA launched Nucleic acids On-demand Worldwide (NOW) program aims to develop a mobile medical countermeasure (MCM) manufacturing platform for use in stabilization and humanitarian operations to rapidly produce, formulate, and package hundreds of doses of nucleic acid therapeutics (DNA and/or RNA).

“The speed and success of nucleic acid vaccines in combating COVID-19 have been truly amazing, and we have an exceptional opportunity and responsibility to make our medical countermeasures for pandemic response faster and more accessible,” said Michael J. Kamdar, President and CEO of Molecular Assemblies. “Our enzymatic DNA synthesis technology is an exceptional fit for on-demand manufacturing of DNA/RNA vaccines and therapeutics because it is designed to deliver higher purity, uses non-toxic reagents, and minimizes purification and processing.”

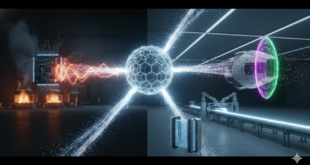

The Vision of Integrated MCM manufacturing platform that synthesizes any nucleic-acid based prophylactic in military stabilization operations. World-wide response capability for stabilization operations : Fast, Distributed, Adaptable/flexible, Deployable device

To address these challenges, DARPA has established the Nucleic acids On-demand Worldwide (NOW) program to develop a mobile MCM manufacturing platform to rapidly produce, formulate, and package hundreds of doses of nucleic acid therapeutics in days – rather than months or years. These on-demand pure, sequence accurate MCMs can also better prepare our deployed, field-forward forces against bio-threat attacks and emerging infectious disease. Further, the mobile nature of the NOW platform will provide immediate threat response anywhere the military operates, mitigate surprise from disease threats, and ensure a resilient, readily accessible nucleic acid MCM manufacturing pipeline.

The system promises to provide significant advancement over current cell-based methods, and the resulting product could allow for end-to-end synthesis of Good Manufacturing Practice (GMP) quality material, even in austere environments. The mobile nature of the NOW platform aims to provide immediate threat response anywhere the military operates, mitigate surprise from infectious disease threats, and ensure a resilient, readily accessible nucleic acid MCM manufacturing pipeline.

“This mobile manufacturing system is designed to fit into a CONEX box and taken ‘on the go’ for stabilization and humanitarian missions in addition to traditional military operations,” noted Dr. Amy Jenkins, NOW program manager. “The ability to manufacture therapeutics on-site is a huge advantage in time to produce a product and reduction in logistical burden.”

NOW Program

The NOW program will be organized into three phases. In the 36-month Phase 1, performers will investigate new bio/chemical methods to synthesize nucleic acids (Technical Area 1), and explore downstream purification, analysis, and formulation of newly synthesized material (Technical Area 2). A 12-month Phase 2 will focus on system integration to finalize a contained, end-to-end mobile manufacturing platform. In coordination with the U.S. FDA, the 12-month Phase 3 will focus on a human clinical study that directly compares a NOW-derived product with traditionally-manufactured material. This will demonstrate full platform functionality while producing an MCM targeting a DoD relevant disease indication.

Nucleic Acids Worldwide (NOW) Technical Approach

TA1: Upstream Process

New/improved methods for DNA and/or RNA synthesis. Performers can choose DNA or RNA synthesis; however both is preferred

Key Challenges: Polymer length, Error-free synthesis, and Ensuring simplified starting materials

TA2 : Downstream Process

End-to-end platform for continuous DNA and RNA manufacturing

Key Challenges: Automated production, Integrated quality control/product identity assessment, and Systems engineering

Awards

Contracts have been awarded to Moderna, Inc. and GE Research to advance the goals of the program.

“These teams are well positioned to combine the novel approaches to nucleic acid cell free synthesis and the required system engineering approaches for a distributed manufacturing system to ensure the NOW program requirements are met,” noted Jenkins. “Upon program completion, the NOW platform could have important commercial applications by providing increased MCM production and manufacturing during periods of high demand.”

Moderna, Inc

Moderna, Inc., (Nasdaq: MRNA) a biotechnology company pioneering messenger RNA (mRNA) therapeutics and vaccines to create a new generation of transformative medicines for patients, announced i Oct 2020 an agreement for a commitment of up to $56 million from the Defense Advanced Research Projects Agency (DARPA) to fund development of a mobile manufacturing protype leveraging Moderna’s existing manufacturing technology that is capable of rapidly producing vaccines and therapeutics. The agreement builds on a previous assistance grant with DARPA established in 2013.

The award is part of DARPA’s Nucleic Acids On Demand World-Wide (NOW) initiative to develop a mobile, end-to-end automated manufacturing platform to provide in-field, just-in-time manufacturing of Good Manufacturing Practice (GMP) quality nucleic acid (including mRNA) vaccines and therapeutics intended to deliver near-instantaneous protections and treatments to both military personnel and local populations. The design envisions a manufacturing unit capable of producing hundreds of doses of medicines in a matter of days in a 6 foot x 6 foot x 6 foot (1.8m x 1.8m x 1.8m) container in remote locations around the world.

“We are pleased to continue our collaboration with DARPA with a new award and we look forward to building on our experience rapidly designing and manufacturing vaccines as demonstrated with mRNA-1273, our COVID-19 vaccine currently in a Phase 3 study, and mRNA-4157, our personalized cancer vaccine currently in a Phase 2 study,” said Stéphane Bancel, Chief Executive Officer of Moderna. “This new award will allow us to explore the reach of our technology to potentially enable fast, in-field, automated manufacturing of vaccines and therapeutics for both military personnel and civilians around the world in a container that can be deployed rapidly to make customized vaccines or therapeutics. The ability to make medicines in a mobile unit could have an important impact on the ability to respond to future viral challenges. Moderna is committed to being part of the solution in preventing future pandemics.”

Molecular Assemblies, Inc.,

Molecular Assemblies, Inc., a pioneer in the field of enzymatic DNA synthesis, announced in march 2021 the company’s participation in a new project with a multidisciplinary team, led by GE Research, to enable the production of DNA- and/or RNA-based vaccines and therapeutics, anywhere in the world in just days. As part of the project, Molecular Assemblies will receive up to $6.5 million and contribute the company’s proprietary enzymatic DNA synthesis technology, which uses aqueous, non-toxic reagents and is designed to deliver on-demand highly-pure, sequence-specific DNA.

The four-decade-old method for chemically synthesizing DNA and RNA is inherently limited to short DNA sequences, requires extensive post-synthesis processing, and uses hazardous chemicals. Scientists at Molecular Assemblies have pioneered a novel, two-step enzymatic DNA synthesis method. This proprietary, template-free process can scale to longer DNA sequences, uses aqueous reagents, and requires minimal post-synthesis purification and processing. Molecular Assemblies’ enzymatic nucleic acid synthesis approach is designed to reliably, affordably, and sustainably produce long, high quality DNA, which could then be converted to RNA, optimized for biomedical applications.

GE team

The GE team, comprised of Dr. John Nelson and his colleagues, Wes Griffin, Ph.D., Erik Kvam, Ph.D., and Brian Davis, Ph.D., represents a highly multidisciplinary group with deep expertise in chemistry, molecular biology, cell biology, fluidic handling, engineering, automation, and quality control to simplify the production of DNA therapies. Dr. Nelson said, “Together with our project partners, we bring all of the elements required to design this mobile manufacturing platform.”

GE’s project, called RUN FAST (Rapid Universal Nucleic Acids using Fieldable Automated Synthesis Technology), will leverage the expertise of the GE Research team, led by Dr. Nelson, to build automated systems in the biological production of medicines and therapies with a novel synthetic method for making DNA and RNA to assemble a complete mobile medical manufacturing platform. For more on GE’s project, see their press release here.

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis