Introduction:

In recent years, the paradigm of space exploration has shifted towards sustainability, catalyzing the development of eco-friendly alternatives to traditional rocket propellants. One area witnessing transformative innovation is the development of green propellants for next-generation launch vehicles and spacecraft. Small satellites, particularly CubeSats, have emerged as pivotal platforms for space-based research and technology demonstrations. Amidst this backdrop, the integration of green propulsion systems into these miniature spacecraft signifies a transformative leap towards environmentally responsible space exploration. Let’s delve into the significance of these advancements and their potential to revolutionize space travel.

The Evolution of Small Satellites:

Small satellites, epitomized by CubeSats, have democratized access to space, offering a standardized platform for a myriad of missions. With volumes less than a cubic meter and weights measured in tens of kilograms, these diminutive spacecraft continue to push the boundaries of space-based research and technology. Despite their compact size, advancements in miniaturized space systems have expanded their capabilities, making them indispensable tools for scientific inquiry and commercial applications.

The Role of In-Space Propulsion:

The inclusion of propulsion systems on small satellites represents a significant advancement, enhancing their maneuverability, momentum control, and orbital adjustment capabilities. However, the development of propulsion systems tailored to the unique constraints of small satellites necessitates meticulous design and innovation. Green propulsion technologies emerge as promising solutions, offering enhanced performance while mitigating environmental and health risks associated with traditional propellants.

The Need for Green Propellants:

Traditional rocket propellants, such as hydrazine and nitrogen tetroxide, have long been mainstays in space missions. However, their toxic nature poses significant environmental and health risks. The quest for greener alternatives stems from the imperative to mitigate these hazards while advancing sustainability in space exploration.

Hydrazine-based propulsion systems are state-of-the-art for various applications ranging from launchers to large and small satellites. They have a long and successful heritage and a great variety of space-qualified, off-the-shelf components. Hydrazine has dominated the space industry as the choice of propellant for over six decades, due to its high-performance characteristics, despite its environmental and health hazards and the challenges faced in its manufacturing, storage, ground handling, and transportation.

The surge in rocket launches for space tourism, lunar exploration, and interplanetary travel underscores the need for sustainable propulsion solutions. Concerns over the environmental impact of rocket emissions on Earth’s atmosphere have prompted a reevaluation of propulsion technologies. Studies highlighting the adverse effects of rocket exhaust on the ozone layer underscore the urgency of transitioning to eco-friendly alternatives.

Key Advantages of Green Propellants:

Green propellants are a new generation of fuels designed to be less toxic and more environmentally friendly. They offer several key advantages:

- Environmental Safety: Green propellants offer a safer alternative by minimizing toxic emissions and reducing the risk of environmental contamination during launch and in-space operations.

- Improved Safety: Their lower toxicity translates to safer storage, transportation, and launch operations.

- Health Benefits: By eliminating or reducing exposure to hazardous chemicals, green propellants prioritize the health and safety of personnel involved in spacecraft manufacturing, handling, and operation.

- Cost Efficiency: Many green propellants boast simpler manufacturing processes and reduced handling requirements, translating to potential cost savings over their traditional counterparts.

- Versatility: Green propellants exhibit versatility in application, catering to various mission requirements, including propulsion, attitude control, and maneuvering.

Applications in Next-Generation Spacecraft:

- Small Satellites: Green propellants facilitate the development of compact, agile propulsion systems for small satellites, enabling precise orbital maneuvers and extended mission lifetimes.

- Lunar and Planetary Exploration: Sustainable propulsion systems play a pivotal role in future lunar missions, supporting resource utilization, mobility, and habitat establishment.

- Crewed Spacecraft: Ensuring crew safety and environmental sustainability, green propellants are poised to feature prominently in crewed spacecraft propulsion systems, fostering a new era of human space exploration.

Green Propellants: Shaping the Future of Space Exploration:

Hydrazine, long considered the standard propellant for space missions, faces growing scrutiny due to its toxicity and environmental hazards. In response, space agencies and research institutions are actively exploring green propellants as viable alternatives. These propellants, such as hydroxylammonium nitrate (HAN) and hydrogen peroxide, offer reduced toxicity, improved performance, and enhanced safety during handling and storage.

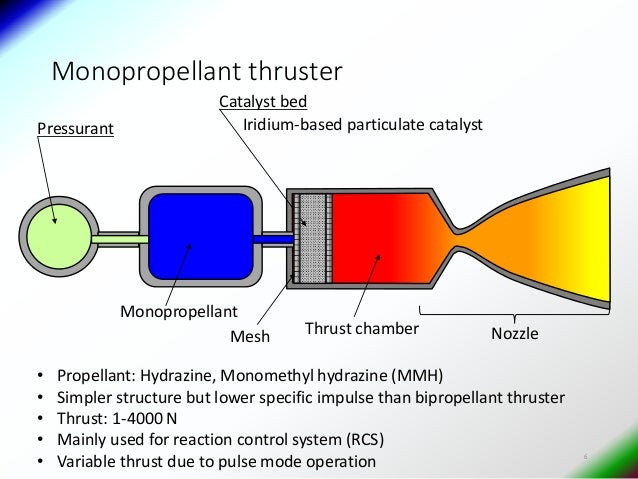

Monopropellant Propulsion:

Monopropellant propulsion relies on the controlled decomposition of a stored chemical propellant, typically heated and catalyzed to trigger the reaction. This decomposition produces a high-temperature gaseous medium that generates thrust when expelled through a nozzle.

Green Monopropellants:

Emerging formulations, such as ADN-based (Ammonium Dinitramide) monopropellants, offer promising alternatives to conventional hydrazine-based systems, exhibiting high energy density and reduced toxicity.

NASA and other space agencies are exploring alternatives to the hazardous chemical hydrazine, leading to the development of green monopropellants like LMP-103S and AF-M315E. These hydroxylammonium nitrate-based alternatives offer reduced toxicity, safer storage and handling, and simplified ground operations compared to hydrazine. Their enhanced performance capabilities and safety features make them promising candidates for future missions.

ADN Technology:

Ammonium dinitramide (ADN) technology involves a liquid monopropellant where solid oxidizer (ADN) is dissolved in water, with fuel and stabilizer added. Despite its solid form, ADN requires high temperatures for ignition, posing challenges compared to hydrazine thrusters. However, innovations like the ADN-based propellant LMP-103S, developed by companies like ECAPS, offer viable solutions for space propulsion.

AF-M315E:

AF-M315E, a hydroxyl ammonium nitrate fuel/oxidizer blend, represents a significant advancement in green propulsion technology. Developed by the U.S. Air Force Research Laboratory, AF-M315E offers reduced toxicity, higher density, improved specific impulse, and lower freezing point compared to hydrazine. Its adoption promises enhanced vehicle performance, simplified handling, and lowered costs for space missions.

Hydrogen Peroxide:

Hydrogen peroxide, utilized as a rocket propellant since 1934, presents another green alternative for space propulsion. Concentrated hydrogen peroxide, or ‘high-test peroxide’ (HTP), serves as a strong oxidizer, offering advantages in terms of specific impulse, storability, and low toxicity. Initiatives like the HYPROGEO project have qualified hydrogen peroxide blends for commercial use, contributing to the adoption of greener propulsion systems.

Water Propulsion:

Water propulsion systems utilize water as a stored propellant, which is decomposed into gaseous oxygen and hydrogen via electrolysis in orbit. These gases are then combusted to generate thrust, offering a semi-electric propulsion method with low-power propellant generation and short boost capability.

Liquid Oxygen (LOX):

As a readily available oxidizer, liquid oxygen complements a variety of green propellants, including liquid hydrogen and methane, enabling efficient combustion with minimal environmental impact.

Ionic Liquids:

These non-toxic, non-volatile fluids serve as propellants or propellant additives, enhancing performance and safety while minimizing environmental hazards.

Bioderived Propellants:

These fuels are derived from renewable sources like biomass, offering a sustainable alternative to traditional options.

Innovations and Collaborations:

Several startups and organizations are pioneering advancements in green propulsion technology. Israeli startup NewRocket is developing gel propulsion, using kerosene-based gel as a safer, more environmentally friendly alternative to traditional rocket fuels. Collaboration between companies like Astranis, Bradford ECAPS, and Spaceflight Inc. is driving the adoption of green propulsion systems in geostationary satellites, promising enhanced performance, safety, and cost-effectiveness.

Case Studies in Green Propulsion Innovation:

Efforts by organizations like the German Aerospace Centre (DLR) and the Indian Space Research Organisation (ISRO) underscore the global momentum towards green propulsion. Initiatives such as NASA’s Green Propellant Infusion Mission (GPIM) and partnerships between startups like NewRocket and Astranis showcase the transformative potential of green propulsion across diverse applications.

In February 2022, Phase Four clinched a contract from the Defense Advanced Research Projects Agency (DARPA) to showcase its innovative radio frequency (RF) thruster technology using a novel propellant.

Notably, Phase Four demonstrated the efficacy of its xenon-fueled Maxwell Block 1 engine in orbit last year, currently powering six small satellites with thrust. An additional four satellites are slated for launch by year-end.

Since its inception in 2015, Phase Four has been actively testing thrusters with various propellants, ranging from air and water to iodine and the Advanced Spacecraft Energetic Non-Toxic (ASCENT) propellant, developed by the U.S. Air Force Research Laboratory. For each propellant iteration, Phase Four meticulously assesses performance vis-a-vis RF thrusters employing xenon propellant, followed by custom modifications to both the thruster and the feed system to optimize performance. As Jason Wallace, Phase Four’s VP of Advanced Development, explained, each propellant introduces unique characteristics necessitating specific tweaks.

Each propellant variant offers distinct advantages for satellite operators. For instance, iodine, priced at roughly one-tenth that of xenon, provides comparable performance at a significantly reduced cost. Phase Four is also exploring propellants that could be harvested in space, on planetary surfaces, or salvaged from other rocket engines.

With ASCENT, Phase Four aims to showcase the versatility of space vehicles, envisaging multiple propulsion modes akin to gears in a car. Chemical propulsion would deliver high thrust for swift maneuvers such as orbit adjustments and collision avoidance, while electric propulsion would offer lower thrust but enhanced efficiency for prolonged orbit transfers and station-keeping tasks. This strategic approach promises to revolutionize propulsion systems, enhancing both versatility and efficiency in space exploration endeavors.

DRDO successfully launches Green Propulsion System in orbit

The Ministry of Defence announced that DRDO has successfully deployed a Green Propulsion System developed under the Technology Development Fund (TDF) scheme in orbit through a payload launched by PSLV C-58. This project, involving the development of a 1N Class Green Monopropellant thruster for microsatellite altitude control and orbit maintenance, was assigned to Bengaluru-based startup Bellatrix Aerospace Pvt Ltd. Telemetry data from the PSLV Orbital Experimental Module (POEM) at ISRO’s ISTRAC in Bengaluru has been verified against ground-level solutions, surpassing all performance parameters.

The system is optimized to provide attitude control and orbit maintenance for microsatellites, meeting propulsive requirements with high thrust in a green way.

This eco-friendly propulsion system, comprising indigenous components like propellant, valves, and electronics, is tailored for missions requiring high thrust. Critical functional components also rely on native manufacturing capabilities.

These include custom fill and drain valves for propellant tank integration, pyrotechnic valves for initial activation event sequencing (latch valve), electrically commanded valves for thrust modulation (solenoid valve), specialized catalyst hardware to decompose the propellant, and electronic controllers for precise ignition and shutdown.

Additional valve configurations within the system architecture allow for propellant scavenging once the propulsive mission is complete. This endpoint procedure passivates residual propellant by evacuating residual propellant from the feed system and neutralizing chemical potential energy, prior to prolonged storage in orbit.

The integrated complement of custom valves, catalysts, electronics, and indigenous green monopropellant makes the Green Propulsion System a self-contained propulsive package tailored for small satellite applications. The entire project was executed by the Development Agency under the supervision of DRDO’s Project Monitoring and Mentoring Group, showcasing capabilities such as pulsed mode and steady state firing in vacuum, passivation of residual propellant in space, and establishment of filling procedures.

Separate from this defense-led project, the Indian Space Research Organisation (ISRO) has active development programs pursuing various green propellant options for future launch vehicles and the Gaganyaan manned spacecraft mission. Technologies under evaluation include liquid oxygen/liquid hydrogen propellants, ISORENE rocket-grade kerosene, and other combinations balancing performance with reduced environmental impact. These efforts complement DRDO’s pursuit of specifically engineered green satellite propulsion systems.

Challenges and Future Directions:

While green propellants offer compelling advantages, their widespread adoption faces technical and logistical challenges, including propulsion system compatibility, materials compatibility, and scalability. Challenges remain in terms of technological maturity, regulatory compliance, and operational feasibility. Integration into existing spacecraft architectures, compatibility with propulsion systems, and cost considerations necessitate collaborative efforts and continued innovation.

- Performance: Matching the raw power of traditional fuels is a hurdle for some green alternatives.

- Scalability: Producing green propellants in large quantities for commercial spaceflight requires further infrastructure development.

Addressing these hurdles requires collaborative efforts among industry stakeholders, government agencies, and research institutions to drive innovation, standardization, and regulatory compliance. Nevertheless, the advent of green propulsion heralds a new era of sustainable space exploration, driving progress towards a greener, more inclusive cosmos.

Recent Breakthroughs

Traditionally, a major drawback of green propellants was their lower thrust compared to conventional fuels. However, recent advancements are narrowing this gap. Researchers at the Massachusetts Institute of Technology (MIT) have developed a novel lithium–ammonia co-combustion technique. This method demonstrates impressive performance rivalling hydrazine while boasting significantly lower toxicity.

Bioderived Options Take Flight: Bioderived propellants, derived from renewable sources like plant oils and algae, are gaining traction. The European Space Agency (ESA) successfully test-fired a biopropane engine in 2023. This paves the way for utilizing sustainable, commercially-available biofuels for satellite applications.

3D Printing Propellant Grains: 3D printing technology is revolutionizing propellant design. Researchers at the Fraunhofer Institute for Chemical Technology (ICT) in Germany have successfully 3D-printed customized propellant grains with optimized burning properties. This allows for tailored green propellants with specific thrust profiles for various space missions.

Electrocatalysis for Super-Green Options: Electrocatalysis, the use of catalysts in electrochemical reactions, is opening doors for even cleaner propellants. Scientists at the RMIT University in Australia are exploring electrocatalysis to produce electrofuels from water and carbon dioxide. These electrofuels hold immense potential for zero-emission space travel.

Collaboration is Key:

Breakthroughs are often fueled by collaboration. The aforementioned Airbus-BMW Group Quantum Mobility Quest is a prime example. By bringing together industry leaders, researchers, and service providers, such initiatives accelerate innovation in green propellants, not just for spaceflight but for the entire transportation sector.

Conclusion:

The development and adoption of green propellants represent a critical milestone in advancing sustainability across the space industry. By prioritizing environmental stewardship and technological innovation, next-generation launch vehicles and spacecraft are poised to usher in a new era of exploration that balances human ambition with planetary responsibility. As we chart a course towards the stars, let us endeavor to leave a legacy of sustainability for future generations to inherit and cherish.

References and Resources also include:

https://www.thehindu.com/sci-tech/science/isro-making-green-propellant/article23874464.ece

https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/20140008870.pdf

https://www.israel21c.org/novel-gel-propulsion-to-slash-cost-of-communication-satellites/

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis