Next-Gen Propulsion Systems for Small and Micro UAVs: Powering the Future of Aerial Innovation

From hydrogen fuel cells to AI-driven tri-source hybrids, advanced propulsion technologies are redefining endurance, stealth, and mission flexibility for the next generation of UAVs.

The rapid evolution of small unmanned aerial vehicles (SUAVs) and micro air vehicles (MAVs) is revolutionizing military tactics, urban security, and commercial operations. At the heart of this transformation lies propulsion technology—a critical enabler of flight endurance, payload capacity, and mission adaptability. From hydrogen fuel cells to AI-driven energy management, cutting-edge innovations are redefining the capabilities of these compact aerial platforms. Here’s an in-depth exploration of the latest advancements and challenges in SUAV propulsion systems.

Why Propulsion Matters

Small and miniature unmanned aerial vehicles (UAVs) are transforming modern operations with their portability, versatility, and rapid deployment. Ranging from micro air vehicles (MAVs) small enough to fit in a soldier’s hand to larger small UAVs (SUAVs) under 25 kilograms, these platforms are designed for missions where traditional aircraft are impractical. Their lightweight design allows a single operator to launch and control them, making them valuable in both military and civilian settings.

Globally, regulatory definitions vary, but most agencies set weight thresholds between 2 and 25 kilograms, shaping standards for certification, airspace integration, and safe operation. Militaries employ micro and nano UAVs for reconnaissance, urban combat, and survival missions—such as tracking enemy movement or relaying signals for search and rescue. On the civilian side, applications are rapidly expanding into search and rescue, agriculture, fire protection, infrastructure inspection, and aerial photography, fueled by demand for longer flight endurance, sustainability, and cost efficiency.

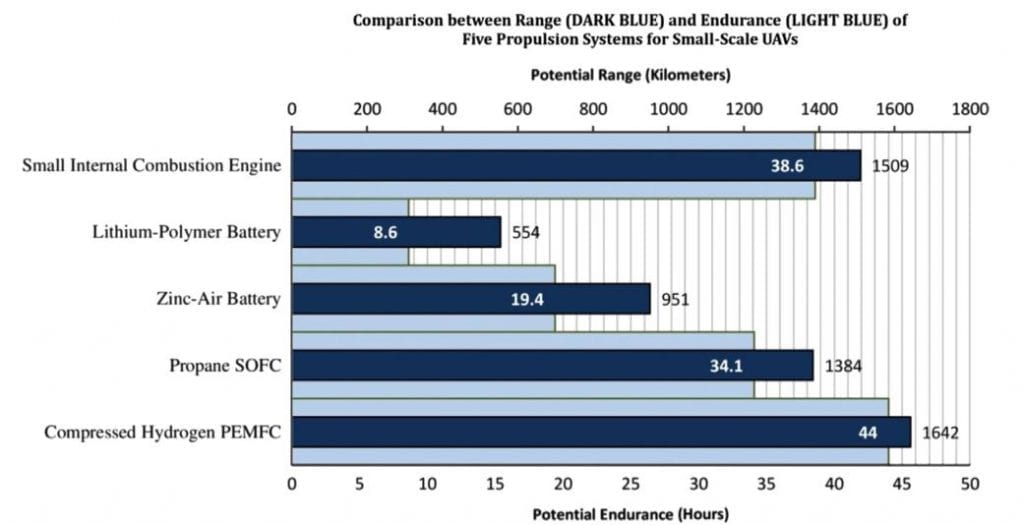

In UAVs, propulsion determines more than just flight—it defines endurance, payload capacity, stealth, noise signature, altitude range, and even cost. Ultimately, the choice of propulsion and endurance technology remains central to the effectiveness of small UAVs. Systems that maximize flight time, simplify refueling, and reduce environmental impact will dictate not only battlefield utility but also their integration into commercial industries striving toward sustainability and net-zero carbon goals. Traditional electric motors and internal combustion engines (ICEs) are now being reimagined or replaced entirely to meet the emerging needs of lightweight, intelligent aerial systems.

Propulsion Systems for Small UAVs

Designing an effective propulsion system for small UAVs requires careful consideration of the operating environment. Key parameters such as cruise speed, cruise altitude, aerodynamic drag and lift forces, and the maximum power output needed during critical phases of flight (such as takeoff and landing) must all be assessed. These factors determine the overall performance envelope and directly influence propulsion system requirements.

Small Unmanned Aerial Vehicles (sUAVs) and Micro Air Vehicles (MAVs) demand propulsion systems that combine lightweight design, high efficiency, and power sources with high energy density. Electric motors are generally suitable because of their efficiency and reliability, but energy storage remains a critical bottleneck. While lithium-based batteries dominate today’s UAV landscape, alternative power sources such as fuel cells, hydrocarbons, hydrogen, ultra-capacitors, and even solar cells are under active exploration. In parallel, hybrid systems and microturbine propulsion are emerging as next-generation solutions, while artificial intelligence is being integrated for intelligent power management and in-flight recharging strategies.

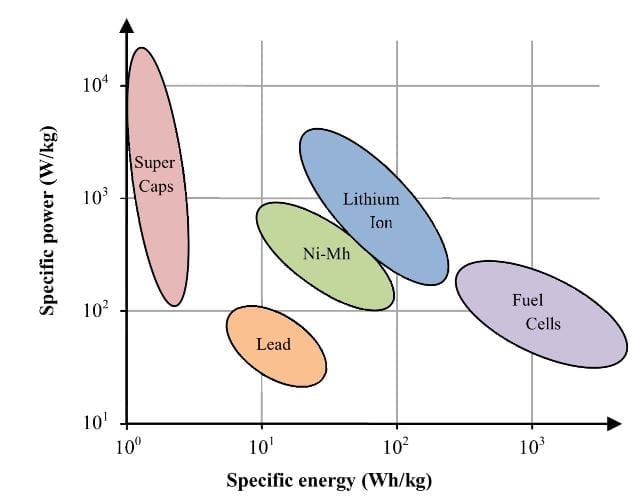

The efficiency of each module—from storage through conversion—affects overall system performance. Higher efficiency reduces losses, allowing more of the stored energy to be converted into thrust. The specific power, or power output per unit weight of the mechanical converter, is also vital, particularly during high-demand operations like rapid ascent. Ultimately, the goal is to combine high power with high energy density while minimizing weight, ensuring longer missions, quicker refueling, and greater operational flexibility.

However, scaling down propulsion systems introduces unique engineering challenges. As engines become smaller, tolerances such as clearances and flow leakages no longer scale proportionally, while turbomachinery must operate at higher rotational speeds. This makes it difficult to maintain efficiency and durability in miniature designs. Moreover, UAV engines are increasingly required not only to produce thrust but also to supply power for onboard electronics, sensors, and control systems. As UAV capabilities expand, the share of engine output allocated to these offtakes continues to grow, placing additional strain on compact designs. Thermal management becomes another critical concern in confined spaces, requiring innovative solutions to prevent overheating and extend system life.

Energy Sources for Small UAVs

A UAV propulsion system can be broken down into four essential components: the energy source, the energy storage medium, the mechanical energy converter, and the lift/thrust converter. Each stage introduces its own performance considerations, from fuel type and density to energy efficiency and weight. For example, specific energy (measured in joules per kilogram) indicates how much energy a fuel or battery provides relative to its weight, while fuel density (measured in kilograms per cubic meter) determines how much volume it occupies. In small UAVs, where space and payload capacity are severely constrained, achieving a balance between high specific energy and compact fuel storage is critical. Similarly, maximizing the percentage of fuel weight in the storage system reduces total system weight, extending flight endurance.

Battery Systems

Battery-powered UAVs remain the most common configuration. With efficiency levels above 70%, lithium-ion and lithium-polymer (LiPo) batteries offer high specific power (200 W/kg) but limited energy capacity. LiPo batteries, for instance, have specific energy values between 0.36–0.72 MJ/kg, insufficient for long endurance missions. The tradeoff is evident: batteries are excellent for short bursts of power but restrict flight endurance due to low energy density.

Fuel Cells

Fuel cells, particularly Proton Exchange Membrane (PEM) types, offer significantly higher energy densities than batteries and convert chemical energy directly into electricity with efficiencies of 40–60%. They provide high power density, fast startup, and low operating temperatures (50–100°C). However, their transient response is slower compared to batteries, making hybridization attractive.

Hydrocarbons

Hydrocarbon fuels like gasoline, biofuels, and jet fuel remain attractive because of their very high specific energy (~43 MJ/kg) and energy density (~35 MJ/L). These values enable long endurance and high payload capacity, though they require internal combustion engines (ICEs) or microturbines, which increase noise and maintenance requirements.

Hydrogen

Hydrogen is an energy-dense candidate with a specific energy of 120 MJ/kg, though its low volumetric density complicates storage. Compressed or liquid hydrogen can be paired with PEM fuel cells to provide long endurance. Composite tanks improve storage efficiency up to 15%, but challenges include evaporation losses for liquid hydrogen and the cost/environmental footprint of hydrogen production.

Ultra-Capacitors

Ultra-capacitors complement batteries by providing rapid bursts of power with very high specific power, rapid recharge rates, and long lifetimes. Their drawback is low specific energy, making them unsuitable as a standalone power source. Instead, they excel in hybrid propulsion where short, high-power demands (e.g., takeoff, maneuvering) are required.

Solar Cells

Solar energy offers theoretically unlimited endurance in daylight conditions, making it highly attractive for ISR missions. However, performance depends on weather and daylight availability, and design constraints arise from the need for large surface areas. UAV wings and fuselages must therefore be optimized to maximize photovoltaic efficiency, limiting widespread adoption.

Emerging Trends in UAV Propulsion

Researchers are therefore pursuing new propulsion technologies, advanced materials, and novel engine architectures tailored for small UAVs. Affordable, control-based solutions—such as active clearance management, improved cooling techniques, and optimized flow control—are being explored to enhance efficiency and longevity. In parallel, entirely new propulsion concepts, from hybrid-electric systems to alternative fuels and distributed propulsion, are being investigated to meet the dual demands of performance and sustainability. These breakthroughs will ultimately dictate how effectively small UAVs can operate across both military and civilian domains.

Electric Propulsion: Balancing Efficiency and Limitations

Electric motors remain the backbone of SUAVs due to their low noise, minimal maintenance, and rapid power response. Lithium-polymer (LiPo) and lithium-ion batteries dominate the market, offering specific power outputs of ~200 W/kg. However, their limited energy density (0.36–0.72 MJ/kg) restricts flight times to ~30 minutes for most micro-drones, pushing innovators toward hybrid solutions and alternative energy sources.

Recent breakthroughs in electric propulsion focus on overcoming energy limitations. Ultra-capacitors, for instance, have emerged as a game-changer for scenarios requiring short bursts of energy. With 10 times the specific power of LiPo batteries, they excel during rapid ascents or evasive maneuvers, making them ideal for tactical military operations. Their fast recharge rates further enhance their utility in high-stakes environments.

High-Efficiency Brushless Motors

Brushless DC motors (BLDC) are the current standard in small and micro UAVs due to their efficiency, lightweight construction, and minimal maintenance requirements. However, the latest generations of these motors are incorporating high-energy magnets, enhanced coil windings, and advanced electronic speed controllers. These improvements lead to better thrust-to-weight ratios and more efficient thermal management, which together extend flight times and reduce the risk of system failure during critical missions.

Another advancement comes from integrated motor-controllers, such as those developed by companies like ePropelled. By merging motors and controllers into single units, these systems reduce weight and complexity while boosting thrust efficiency. The Sparrow Series, for example, slashes system weight by 30%, enabling longer flight times for surveillance drones without compromising agility.

Hydrogen Fuel Cells: Extending Range and Stealth

Hydrogen fuel cells are emerging as a game-changing alternative to lithium-based batteries, offering extended endurance and zero-emission operation. Fuel cells provide energy densities much higher than traditional battery systems, enabling flight times up to eight times longer in some applications. Their low acoustic signature and environmentally friendly profile make them ideal for missions in sensitive areas, such as wildlife monitoring, scientific surveys, and humanitarian operations.

Hydrogen propulsion addresses the energy-density bottleneck, offering a specific energy of 120 MJ/kg—far surpassing traditional batteries. Recent partnerships, such as HevenDrones and Mach Industries, aim to produce 1,000 hydrogen-powered H2D250 drones monthly, capable of 10-hour flights and 100-mile ranges.

Key innovations in hydrogen systems include composite storage tanks, which achieve 15% gravimetric efficiency. These tanks reduce weight while maintaining safety, as seen in the Black Hornet 4 PRS nano-UAV. Weighing just 70 grams, this drone uses hydrogen for 30-minute reconnaissance missions, emitting minimal thermal signatures to avoid detection.

Proton Exchange Membrane (PEM) fuel cells are another critical development. Operating at 50–100°C, PEM systems like those from Protonex power drones such as the Ion Tiger, which achieved a groundbreaking 26-hour flight with a 5 lb payload. Despite their advantages, challenges persist, including reliance on Chinese-supplied rare-earth metals and carbon fiber, which risks geopolitical disruptions.

Hybrid Systems: Merging Strengths for Mission Flexibility

Hybrid propulsion is gaining ground in UAV technology by combining the long-range capability of internal combustion engines with the quiet, clean operation of electric motors. Such systems are especially valuable for applications like reconnaissance and delivery, where both range and stealth are important. Smart energy management systems intelligently switch between power sources to maximize efficiency, while some hybrid UAVs even use regenerative braking mechanisms to recharge onboard batteries during descent or gliding phases, further increasing operational time.

Hybrid propulsion systems combine the high specific energy of fuel cells with the power density of batteries or ultra-capacitors. The Wolverine micro-UAV exemplifies this approach, achieving 30-minute flight times while carrying 2 kg payloads. This capability is ideal for missions like explosive disposal or supply delivery in hostile zones.

Military applications of hybrid systems are expanding. The U.S. Army’s AI-driven recharge initiative enables drones to autonomously dock with unmanned ground vehicles (UGVs) for wireless charging. This innovation extends mission durations without requiring soldiers to carry thousands of batteries, addressing a critical logistical challenge in battlefield operations.

Solid-State and Micro-Turbine Engines: Reliability in Demanding Environments

Micro-turbine engines, which were originally popular in model aircraft, are making a comeback in high-performance micro UAVs. They offer a high power-to-weight ratio and can operate on common fuels such as jet-A or kerosene. These compact powerplants are suitable for UAVs requiring sustained high-speed performance.

Microturbine engines, such as UAV Turbines’ Monarch RP, are gaining traction for their reliability and fuel flexibility. Designed for Group 3–4 UAVs, these engines run on heavy fuels like jet fuel and offer over 2,000 hours between overhauls—a 200% improvement over conventional piston engines.

The Monarch RP’s variable-pitch propeller enables faster climbs and higher dash speeds, enhancing performance in both commercial and military contexts. Additionally, it generates 2–3 times more onboard electricity than traditional engines, supporting advanced sensors and communication systems. This flexibility makes microturbines a robust choice for forward operating bases where fuel logistics are complex.

Meanwhile, research is progressing in solid-state propulsion systems, including plasma-based and electromagnetic thrust technologies. These promise silent, high-altitude operation and are of particular interest for stealth and surveillance applications.

Solar and Energy Harvesting Technologies

Solar-powered UAVs are being developed for missions where ultra-long endurance is more critical than speed or agility. These UAVs incorporate lightweight, flexible solar panels directly into their airframes, enabling them to generate electricity during flight. When coupled with efficient energy storage systems and low-power avionics, these platforms can theoretically sustain flight indefinitely under the right conditions. Additionally, materials that harvest ambient energy—such as piezoelectric surfaces—are being integrated into UAV wings and structures to supplement onboard power, particularly for micro drones with limited battery capacity.

Ducted Fan and Coaxial Propulsion Configurations

Innovative propulsion configurations are also shaping the future of UAV design. Ducted fans offer increased thrust efficiency while improving safety by enclosing rotating blades, which is particularly useful for UAVs operating in cluttered or indoor environments. Coaxial rotor systems—featuring counter-rotating propellers on a single axis—enhance vertical lift capabilities and provide excellent stability during hovering. These configurations are becoming popular in tactical and inspection UAVs that require precise maneuverability in tight or urban spaces.

AI and Autonomy: Revolutionizing Energy Management

Artificial intelligence is transforming how SUAVs manage energy and navigate. The U.S. Army’s AI algorithms, for instance, optimize routes for drones to autonomously return to UGVs for recharging. These systems calculate energy-efficient paths, minimizing downtime even in contested areas.

The U.S. military is actively integrating artificial intelligence (AI) to extend UAV endurance. A four-year program with the University of Illinois Chicago is developing AI/ML algorithms for route optimization, autonomous battery monitoring, and recharging via Unmanned Ground Vehicles (UGVs). These drones use LED-based indicators to signal power levels and autonomously dock for wireless recharging.

AI also enables autonomous rerouting when UAVs face collisions or contested environments, ensuring mission continuity. By combining AI-driven power management with autonomous ground-based charging, the military aims to overcome the 26-minute endurance ceiling imposed by current battery technology.

Swarm coordination represents another frontier. Nano-UAVs like the Ninox 40 MT use mesh networking to share targeting data and operate in GPS-denied environments. Equipped with follow-the-leader kits, these drones execute coordinated missions with minimal human intervention, enhancing tactical resilience.

Challenges Ahead

Despite significant progress, several critical challenges continue to impede the widespread adoption of next-generation propulsion systems for small and micro UAVs.

Thermal management remains a persistent hurdle, particularly for miniaturized engines operating at high power densities. The compact form factors of small UAVs leave little room for effective cooling solutions, making heat buildup a key threat to performance and reliability. Advanced materials like silicon carbide (SiC) and high thermal conductivity composites are being explored to enhance heat dissipation and improve system longevity.

Regulatory constraints are another major barrier—especially those related to Beyond Visual Line of Sight (BVLOS) operations, which are essential for unlocking the full potential of long-endurance propulsion technologies like hydrogen fuel cells and hybrid-electric systems. Without consistent and streamlined regulatory frameworks, widespread deployment remains limited, especially in commercial and urban environments.

Cost-performance trade-offs also present a significant challenge. While high-efficiency propulsion solutions like microturbines and fuel cells offer impressive capabilities, their complexity and material costs can be prohibitive for many commercial applications. Achieving scalability without compromising performance is essential for making these technologies accessible to industries beyond defense and specialized sectors.

Miniaturization without compromise is another ongoing engineering struggle. As UAVs shrink in size, integrating powerful propulsion systems without sacrificing payload capacity, flight duration, or system stability requires breakthroughs in design and manufacturing precision. Likewise, battery technologies—while improving—still lag behind in terms of energy density, charge cycles, and weight efficiency, limiting mission durations for fully electric platforms.

Finally, scalable manufacturing of advanced propulsion components continues to challenge developers. Precision engineering, materials with exotic properties, and tight tolerances all contribute to high production costs and slow ramp-up times, impeding mass-market adoption.

Yet, the horizon is promising. Breakthroughs in AI-based power optimization, solid-state battery development, nanomaterials, and additive manufacturing are actively pushing the envelope. As these innovations mature, they will pave the way for more robust, efficient, and accessible UAV propulsion systems—bringing us closer to the vision of fully autonomous, long-endurance, and high-performance aerial platforms across both civilian and defense landscapes

Recent trends and Road Ahead

Some of the most exciting advancements in UAV propulsion are coming from hybrid systems that combine multiple energy sources. A new class of “tri-source” designs integrates solar panels, hydrogen fuel cells, and batteries into a single architecture. These drones can harvest sunlight during flight, cruise efficiently on hydrogen for long endurance, and tap into batteries for sudden bursts of power during takeoff, landing, or high-demand maneuvers. This dynamic switching between energy sources allows the system to optimize performance across different phases of a mission, bringing unprecedented flexibility and efficiency.

Hydrogen fuel cell UAVs are also moving from prototypes to field-proven platforms. In 2025, Ukraine’s Skyeton successfully demonstrated a hydrogen-powered version of its Raybird UAV, showing that these systems are not just laboratory concepts but are being tested in real-world environments. Such demonstrations highlight the growing viability of hydrogen as a clean, high-energy-density option for small and medium UAVs.

Beyond fuel cells, researchers are exploring other innovative approaches to extend endurance. One promising direction is thermoelectric energy harvesting, where butane-fueled thermoelectric generators could supplement existing power systems. While this technology is still in its early research phase and efficiency challenges remain, it represents a potentially valuable supplement for small UAVs that operate under tight weight and space constraints.

The broader market context underscores the importance of these innovations. The UAV propulsion market is already a multibillion-dollar industry, projected to reach around $7 billion by 2025 and to continue expanding through 2030. As new energy sources, hybrid architectures, and advanced management systems become commercially viable, propulsion will remain at the core of unlocking longer flight times, higher payloads, and more complex missions for UAVs.

The future of UAV propulsion is inherently interdisciplinary, blending aerospace engineering with advances in material science, power electronics, and intelligent software systems. Researchers are now exploring propulsion concepts inspired by nature, such as flapping-wing designs that mimic birds or insects. Experimental ion propulsion systems that enable nearly silent operation without moving parts are also under development. Furthermore, concepts like UAV swarms that can share or redistribute power in flight are beginning to emerge, heralding a new era of aerial collaboration and autonomy.

Governments, research institutes, and private tech companies are heavily investing in this area, recognizing that propulsion innovation is the key to unlocking the next frontier in aerial mobility, automation, and intelligence.

Conclusion: Toward Smarter, Longer-Lasting UAVs

The propulsion landscape for small and micro UAVs (SUAVs) is rapidly evolving into a high-stakes arena of innovation—where success is defined by breakthroughs in energy density, stealth, modularity, and adaptability. From hydrogen-powered platforms enabling extended covert operations to AI-optimized hybrid systems balancing range and efficiency in real time, these next-generation propulsion technologies are rewriting the playbook across military, commercial, and humanitarian domains.

Applications once constrained by short flight times and limited payloads are now being reimagined. In agriculture, SUAVs can monitor vast fields with fewer recharges. In disaster response, they can provide continuous situational awareness in areas inaccessible to humans. And in logistics, long-range drones are paving the way for point-to-point delivery in remote or congested regions.

Strategic partnerships, like the HevenDrones-Mach collaboration, are further accelerating development cycles and scaling production. Meanwhile, AI-powered autonomy is reducing the operational burden on human pilots, making smart, self-optimizing UAVs more viable than ever. The convergence of these advancements signals a future where SUAVs are not just longer-lasting—but significantly more intelligent, mission-adaptable, and environmentally sustainable.

Ultimately, next-generation propulsion systems are not merely enhancing flight—they are redefining what UAVs can do. As these systems grow more compact and capable, they will reshape how we deliver goods, conduct research, secure infrastructure, and interact with our environment. The propulsion innovations of today are setting the course for tomorrow’s aerial revolution—one that is smarter, cleaner, and fundamentally more connected.

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis