In the realm of naval warfare, the effectiveness of a vessel often hinges on its propulsion system. From massive aircraft carriers to nimble autonomous underwater vehicles (AUVs), advancements in marine propulsion technology are reshaping the landscape of underwater warfare. In this article, we delve into the evolution of marine propulsion systems across various naval platforms and their profound implications for the future of naval operations.

Marine transport

Marine transport stands as the cornerstone of global trade, facilitating approximately 90% of merchandise trade via sea routes due to its unparalleled cost-effectiveness. At the heart of marine transport lies marine propulsion systems, which propel ships through water, ensuring safety standards for marine ecosystems while remaining economically viable. According to data from the International Chamber of Shipping, a staggering 90% of global merchandise trade occurs via sea routes, owing to the cost-effectiveness compared to other modes of transportation like rail and road.

Diesel propulsion has traditionally dominated the marine propulsion landscape, boasting benefits such as reliability and economical operation. However, the environmental toll of heavy fuel oil combustion, responsible for 2-3% of global carbon emissions, calls for urgent action towards greener alternatives.

Today, 80 percent of the world’s shipping fleet runs on heavy fuel oil, or bunker fuel. However, the combustion of this fuel to provide propulsion and auxiliary power to ships causes between 2% and 3% of global carbon emissions. The World Bank estimates that a single large shipping vessel, produces as much sulphur as 50 million cars. At around 800 million tonnes per year, the industry as a whole is responsible for approximately 2.2 per cent of all global emissions. Combustion of bunker fuel also emits sulfur and particulate matter that causes respiratory illness. A 2018 study found that health impacts due to pollution from shipping include 14 million cases of childhood asthma annually and 400,000 premature deaths a year from lung cancer and cardiovascular disease.

In response, the maritime industry is exploring innovative propulsion methods such as electric, fuel cell, and nuclear propulsion to curb emissions and reduce environmental impact. The International Maritime Organization (IMO) has set ambitious emission reduction targets to combat climate change, spurring the adoption of sustainable propulsion technologies.

Propelling Progress: Understanding Marine Propulsion Systems

At the heart of maritime transportation lies marine propulsion systems, which not only drive ships forward but also uphold safety standards for the marine ecosystem while remaining cost-efficient. These systems, whether powered by diesel engines or advanced fuel cell technology, play a pivotal role in shaping the future of maritime trade.

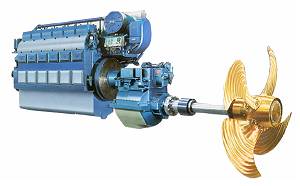

Diesel propulsion stands as the most prevalent marine propulsion system across vessel types, offering reliability, economic viability, and global availability. Despite its dominance, diesel engines come with drawbacks such as noise generation and emissions, prompting the industry to explore alternative propulsion methods.

Exciting advancements include battery-powered ferries, biofuel trials, and wind-assisted propulsion, showcasing the industry’s commitment to sustainability. Navies worldwide are embracing electric hybrid gas turbine propulsion, enhancing operational efficiency and performance while reducing reliance on fossil fuels.

Innovations like the German Navy’s GE LM2500 gas turbine-based propulsion system and India’s consideration of hybrid electric propulsion for future aircraft carriers underscore a shift towards greener naval propulsion technologies.

Furthermore, the integration of nuclear power in submarines and aircraft carriers extends mission endurance, enhances stealth, and reduces reliance on vulnerable fuel supply tankers. While nuclear propulsion remains limited to military applications, ongoing investments in propulsion technologies aim to improve affordability, efficiency, and environmental sustainability across naval ship designs.

Propulsion Requirements: Designing for Efficiency and Reliability

Developing ship power and propulsion requirements demands a comprehensive understanding of the power and energy needs dictated by each vessel’s mission and capabilities. The choice of a suitable powerplant hinges on various factors, including the vessel’s size, speed requirements dictated by cargo type, voyage duration, operational costs, and fuel availability. Ships are equipped with one or more propulsion engines, tailored to their size and gross tonnage.

Similar to determining engine ratings for automobiles, ship design power requirements are intricately linked to mission demands. Each ship concept undergoes rigorous analysis to ascertain maximum power requirements, ensuring seamless support for propulsion and onboard electrical loads throughout its service life.

Moreover, addressing the energy needs of a vessel is akin to sizing a “gas tank.” Mission requirements, encompassing propulsion speed, range, and electrical energy usage over sustained periods, dictate the energy demands for fossil fuel variants. In the case of nuclear propulsion options, mission needs are meticulously evaluated to determine the energy rating of the nuclear reactor, ensuring optimal performance throughout the ship’s service life.

Steam Turbine: Harnessing Power with Elegance

The marine steam turbine, pioneered by Sir Charles Algernon Parsons, stands as a testament to engineering elegance and efficiency. Renowned for its low noise, lightweight design, and minimal maintenance requirements, the steam turbine offers a remarkable power-to-weight ratio, maximizing available space onboard. However, it’s essential to note that this technological marvel comes with a trade-off: higher fuel consumption. Consequently, steam turbines find their niche primarily in specialist vessels like nuclear-powered ships and certain merchant vessels such as LNG and coal carriers, where cargo can serve as bunker fuel.

Gas Turbine: Powering Naval Dominance

In the realm of naval propulsion, gas turbines have emerged as the epitome of power and versatility. Functioning through a process where a compressor draws in atmospheric air, mixes it with fuel in a combustion system, and ignites it to generate power for the turbine shaft, gas turbines offer unparalleled advantages. Navies worldwide favor gas turbines for their rapid acceleration and deceleration capabilities, crucial for evasive maneuvers during combat scenarios. Moreover, they boast low noise levels, exceptional reliability, and impressive power density. Notably, the design of gas turbines facilitates the creation of unmanned engine rooms, leading to significant crew savings.

Gas turbines often complement other engine types, as seen in recent installations aboard vessels like the RMS Queen Mary 2, which integrates gas turbines alongside diesel engines. However, due to their lower thermal efficiency at low power outputs during cruising, ships typically utilize diesel engines for sustained low-speed operations, reserving gas turbines for high-speed requirements.

Diesel Propulsion: A Pillar of Naval Power

Despite the ascendancy of gas turbines, diesel engines remain the cornerstone of naval propulsion systems. Their enduring popularity stems from several factors, including durability, space efficiency, and economic operation. Diesel engines require less bunker space and offer cost-effective performance, provided they are not continuously throttled up and down. Additionally, they leverage existing civilian infrastructure for support personnel and logistics provisions, further cementing their status as the primary power source for the majority of the world’s warships.

Navigating Towards Sustainability: Embracing Green Propulsion

The environmental impact of traditional marine propulsion systems cannot be overlooked, with heavy fuel oil combustion contributing to significant carbon emissions and air pollution. As concerns over climate change mount, the maritime industry is actively seeking greener propulsion alternatives to reduce its carbon footprint.

The colossal engines of large ships are not just behemoths of power; they also churn out significant pollution. Each year, ships contribute over 2 percent of global CO2 emissions, a figure projected to surge to 17 percent by 2050, given the enduring dominance of sea travel in global commerce. Marine diesel engines alone burn through approximately 60 million barrels of crude oil annually, spewing out nearly one billion tonnes of CO2 equivalents, along with substantial amounts of NOx, SOx, and particulates.

The looming specter of air pollution and its ramifications for climate change necessitates urgent action. Shipbuilding’s future trajectory must prioritize the mitigation of emissions to align with existing and forthcoming regulations set by the International Maritime Organization (IMO) on greenhouse gas and pollutant emissions.

The 2020 imposition of a cap on sulfur content underscores the urgency for maritime stakeholders. Compliance now hinges on decisive choices: adopting exhaust gas scrubbing alongside high-sulfur fuel oil (HFO) or transitioning to lower-sulfur alternatives like marine gas oil (MGO), liquefied natural gas (LNG), methanol, or other sustainable options.

However, IMO’s ambitious target to halve shipping’s CO2 emissions by 2050 presents a formidable challenge. Even the most energy-efficient combustion engines, with or without carbon capture mechanisms, may fall short. Meeting this ambitious goal demands a paradigm shift towards supplementary or alternative propulsion technologies.

The maritime industry has embraced a plethora of environmentally conscious strategies to navigate towards sustainability. These include the development of alternative fuels, hybrid propulsion systems, energy auditing, engine waste heat recovery mechanisms, speed and voyage optimization practices, and the adoption of slow steaming and wind-powered propulsion solutions. Collectively, these initiatives chart a course towards greener seas, where ships can navigate with reduced environmental impact and greater sustainability.

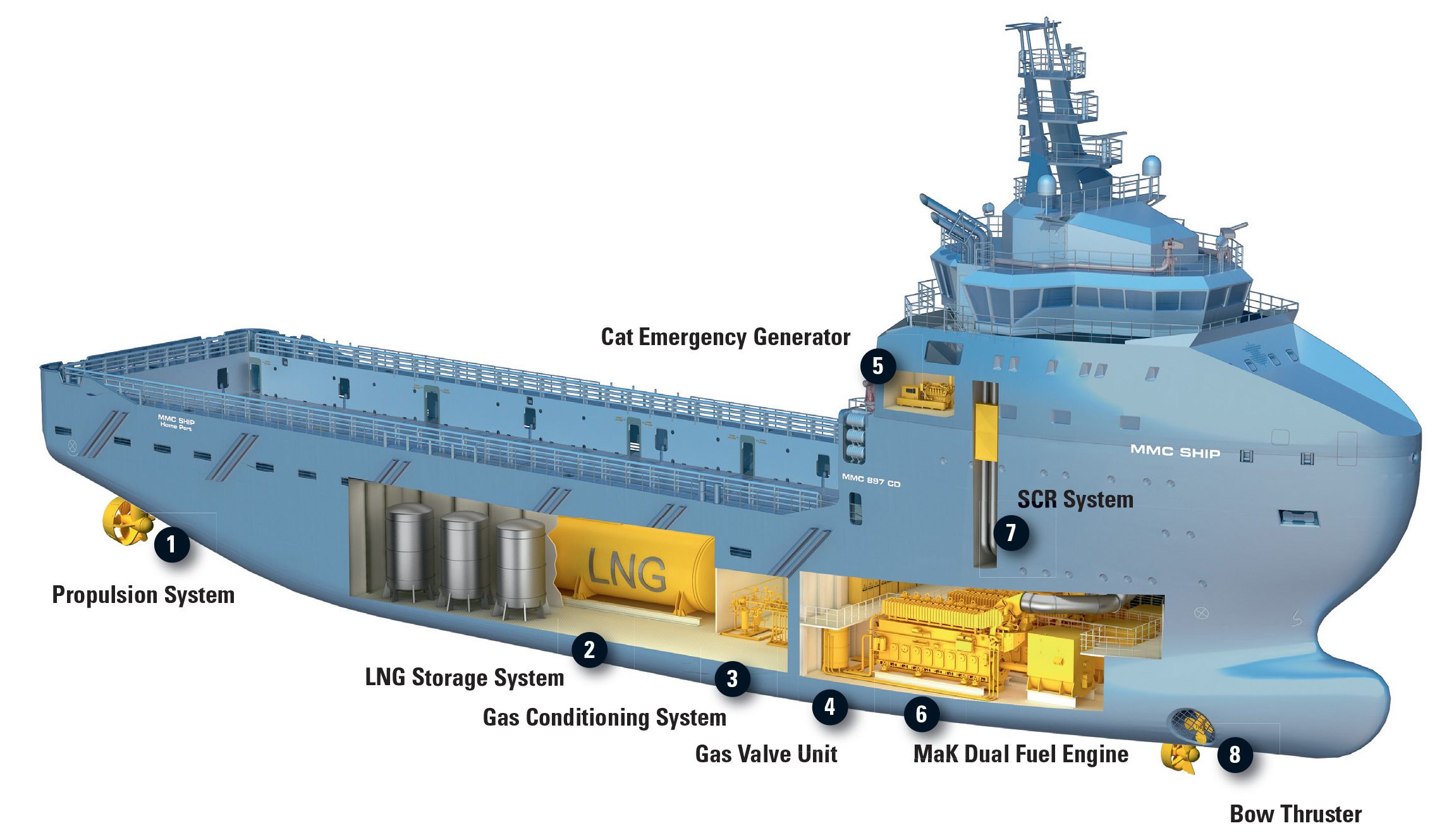

One promising avenue is liquefied natural gas (LNG) fuel-based propulsion, which offers reduced emissions and improved engine efficiency compared to traditional fuels. Collaborations between industry leaders like Bloom Energy and Samsung Heavy Industries are driving innovations in solid oxide fuel cell technology, paving the way for emissions-free ship propulsion.

Hydrogen propulsion emerges as another frontier in sustainable shipping, with companies exploring its potential as a clean energy source for maritime vessels. While challenges remain in terms of onboard fuel storage and cost, ongoing research and development efforts aim to overcome these barriers and unlock hydrogen’s full potential as a marine fuel.

As the maritime industry navigates towards a sustainable future, the quest for innovative propulsion solutions remains pivotal in mitigating environmental impact, ensuring the vitality of global trade, and preserving marine ecosystems for generations to come.

LNG Fuel-Based Propulsion: Charting a Sustainable Course

LNG fuel emerges as a beacon illuminating the path to a greener future for the shipping industry. By leveraging LNG, ships can significantly curb air pollution, with a blend of LNG and diesel oil enhancing engine efficiency and driving fuel savings. The widespread availability of LNG and the maturation of supporting infrastructure render its adoption as bunker oil both practical and promising. The ongoing advancements in liquefied natural gas (LNG) fueled engines garner acclaim for their remarkable reductions in emissions and cost-effectiveness, marking a pivotal shift towards cleaner propulsion technologies.

Despite its prowess in curbing SOx and NOx emissions, LNG’s impact on CO2 reduction remains modest, slashing emissions by approximately 20 percent compared to conventional bunker fuel. While Stirling engines, renowned for their superior efficiency, quiet operation, and reduced harmful emissions, power several small submarines, scaling up this technology for larger surface vessels poses a challenge. Industry analysts foresee a burgeoning fleet of LNG-fueled ships surpassing 200 vessels by 2020, underscoring the industry’s growing embrace of sustainable propulsion solutions.

In a landmark collaboration, Bloom Energy and Samsung Heavy Industries (SHI), a prominent member of the Samsung Group, joined forces in September 2019 to pioneer ships propelled by Bloom Energy’s solid oxide fuel cell technology. This groundbreaking endeavor aims to propel SHI to the forefront of sustainable shipbuilding, with a vision to deploy large cargo vessels powered by fuel cells running on natural gas. Such innovation promises to propel SHI towards surpassing the International Maritime Organization’s (IMO) mandated 50 percent emissions reduction target by 2050, firmly establishing the company as a leader in environmental stewardship within the maritime sector. As the global standard-setting agency for international shipping’s safety, security, and environmental performance, the IMO’s endorsement underscores the transformative potential of LNG-based propulsion in shaping a sustainable maritime landscape.

Pioneering Hydrogen Propulsion: Charting a Course to Sustainability

In the quest to realize the ambitious targets set by the United Nations for the shipping industry, industry leaders advocate for the integration of the first net-zero ships into the global fleet by 2030. Propelled by green hydrogen, these vessels stand as promising contenders to achieve this milestone. Produced through electrolysis—a process of splitting water into hydrogen and oxygen using renewable energy—green hydrogen boasts emissions-free credentials, offering a compelling solution to mitigate maritime carbon footprints.

Despite its environmental allure, hydrogen faces a formidable obstacle: its low density relative to other fuels necessitates larger onboard storage capacities, posing a significant challenge for deep-sea shipping. Kasper Søgaard, Head of Research at GMF, underscores this challenge, noting that the substantial cargo volume sacrificed for hydrogen storage on long voyages could render its adoption economically unviable. Consequently, hydrogen propulsion finds more immediate viability in vessels operating on shorter routes, where its storage demands are more manageable.

In a testament to the growing momentum behind hydrogen propulsion, Japanese firms Kawasaki Heavy Industries, Yanmar Power Technology, and Japan Engine Corporation have forged a consortium to collaboratively develop hydrogen-fueled marine engines tailored for oceanic and coastal vessels. This partnership encompasses a spectrum of endeavors, ranging from foundational experiments and material analyses to the development of hydrogen combustion techniques and storage systems, all aligned with the stringent standards of classification societies. Similarly, Korea Shipbuilding & Offshore Engineering (KSOE), in conjunction with the Korean Register (KR), embarked on a groundbreaking initiative to formulate the world’s inaugural hydrogen vessel standard, focusing on ensuring the safe handling of hydrogen across maritime operations. As hydrogen’s price trajectory gradually aligns with the decline in renewable energy and electrolyzer costs, green hydrogen emerges as a compelling contender poised to redefine the maritime industry’s sustainability landscape.

Pioneering Partnership: Revolutionizing Marine Propulsion with Solid Oxide Fuel Cells

In a landmark collaboration, Bloom Energy and Samsung Heavy Industries (SHI), a subsidiary of Samsung Group, have unveiled plans to pioneer ships powered by Bloom Energy’s cutting-edge solid oxide fuel cell technology. This partnership pairs Bloom Energy’s expertise as a global leader in stationary fuel cells with SHI’s renowned stature as one of the world’s foremost shipbuilding entities.

SHI has set its sights on an ambitious goal: to become the inaugural shipbuilder to deliver a sizable cargo vessel for oceanic operations propelled by fuel cells fueled by natural gas. This groundbreaking initiative is poised to propel SHI towards surpassing the International Maritime Organization’s (IMO) mandate of achieving a 50 percent reduction in emissions by 2050, compared to 2008 levels. As the preeminent global authority on maritime standards, the IMO’s endorsement underscores the significance of this eco-conscious endeavor.

Diverging from conventional bunker fuel combustion methods, Bloom Energy’s solid oxide fuel cells operate via an electrochemical reaction, circumventing combustion and drastically mitigating particulate emissions, NOx, and SOx pollutants—a pivotal advancement for the maritime sector’s environmental sustainability. Utilizing natural gas, biogas, or hydrogen as fuel sources, Bloom Energy Servers offer versatile solutions tailored to the dynamic needs of marine transportation. With a modular design conducive to space-constrained ship environments, these servers can be flexibly deployed in increments as small as 200 kilowatts, optimizing space utilization and potentially displacing existing power generation sets without imposing additional spatial burdens. Through this innovative collaboration, Bloom Energy and SHI are poised to revolutionize marine propulsion, heralding a new era of cleaner, more efficient maritime operations.

Fuel Cell Revolution: Navigating Towards Green Propulsion

Fuel cell propulsion systems, relying on hydrogen as their primary fuel component, herald a paradigm shift in marine propulsion. Distinct from conventional combustion methods, fuel cells generate electricity through clean, combustion-free processes, positioning them as pivotal alternatives for sustainable marine transportation. Diverse propulsion variants, such as PEM (Proton Exchange Membrane) and molten-carbonate systems, underscore the versatility and promise of fuel cell propulsion in mitigating greenhouse gas emissions. Harnessing power from an amalgamation of fuel cells, solar cells, and battery systems, this innovative approach significantly curtails GHG emissions, paving the way for greener maritime practices.

In the realm of propulsion innovation, electric motors coupled with battery storage have emerged as viable solutions, finding application in submarines and electric boats. Envisioning the future of surface combatant power, the Advanced Electric Power Systems (AEPS) initiative embraces an all-electric ship propulsion paradigm, epitomizing the maritime sector’s transition towards sustainability. Pioneering research collaborations between industry leaders like ABB and SINTEF Ocean underscore the concerted efforts to validate fuel cells as primary energy sources for main ship propulsion. With a focus extending beyond technical scalability to optimized fuel cell-battery synergies, these endeavors represent critical strides towards enhancing integration, control, and safety of fuel cell technologies in marine applications. As researchers delve deeper into fuel flow dynamics, energy storage optimization, and infrastructure feasibility, the quest for decisive solutions to propel fuel cell technology into the maritime mainstream gains momentum, promising a greener, more sustainable future for marine transportation.

Electric Propulsion: A Silent Revolution in Naval Power

In recent years, electric propulsion has emerged as a frontrunner in naval powertrain technology, offering quieter operation and reduced emissions compared to conventional systems. Adopted initially by the British Royal Navy for their Type 23 frigates, electric propulsion systems have become increasingly prevalent across various naval platforms.

By employing electric motors driven by generators powered by diesel engines or gas turbines, electric propulsion systems eliminate the need for direct mechanical coupling between engines and propellers, resulting in quieter and more efficient propulsion. This approach not only enhances stealth capabilities but also reduces environmental impact by minimizing underwater noise pollution.

In the past half-decade, a remarkable series of technological breakthroughs has propelled electric propulsion from obscurity to the forefront of maritime powertrain innovation, poised to dominate naval vessels for the foreseeable future. Spearheading this modern resurgence is the British adoption of a combined diesel-electric/gas turbine (CODLAG) propulsion system for their Type 23 frigates, marking a watershed moment in naval engineering.

The electric propulsion paradigm comprises a prime mover, typically either diesel or turbine-driven, both generating mechanical energy to power generators. These generators, in turn, supply power to propulsion motors, which propel the ship’s propeller shaft. Whether driven by DC or AC power, these motors drive the vessel forward with remarkable efficiency and reduced environmental impact compared to traditional marine propulsion systems reliant on heavy oil combustion.

In this revolutionary setup, diesel engines no longer directly drive the ship’s propellers. Instead, they function as electric generators, feeding power to electric motors responsible for propelling the vessel. This innovative configuration allows for the placement of diesel engines in sound-insulated compartments away from the propellers, minimizing vibration transmission to the water. Notably, this design obviates the need for gears between engines and shafts, streamlining production processes and resulting in an exceptionally silent propulsion system—an invaluable asset in both military operations and environmental conservation efforts.

Hybrid diesel-electric propulsion

One of the significant challenges with diesel engines is their narrow efficient operating speed range, leading to poor fuel economy and increased exhaust emissions, especially during slow vessel movement in harbors and ports. Diesel-electric propulsion addresses this issue by utilizing diesel engines to power generators, producing electricity to drive electric motors that propel the ship. An essential component in this system is the AC drive, enabling precise control of the propulsion motors’ speed without affecting the diesel engines’ running speed. Consequently, the diesel engines can maintain efficient operation, minimizing emissions regardless of the propulsion motors’ speed requirements.

Enhancing the diesel-electric system with energy storage through batteries further amplifies its advantages. By integrating batteries into the DC link of the AC drive, the system gains additional energy storage capacity, allowing the ship’s generators to charge the batteries while in operation. During low-speed maneuvers or harbor stays, the ship can solely rely on battery power for propulsion, saving fuel, reducing emissions, and minimizing noise levels, particularly crucial for vessels near shorelines. Additionally, the ability to charge batteries from shore power when in port, especially from renewable sources like wind energy, enhances the system’s environmental sustainability while optimizing costs, especially during off-peak tariff periods. However, effective battery management and precautions for managing high short-circuit currents are essential, alongside the inclusion of a grid converter for maintaining a constant frequency in the ship’s grid, ensuring seamless power supply compatibility regardless of the port’s electrical specifications.

Magneto Hydrodynamic Propulsion for Ocean Vehicles:

The principle behind Magneto-Hydrodynamic (MHD) propulsion involves leveraging electric and magnetic fields without any moving parts to propel vehicles, utilizing magnetohydrodynamics to accelerate an electrically conductive propellant, whether liquid or gas. By directing the fluid rearward, the vehicle gains forward acceleration as a reaction. This propulsion method relies on the Lorentz force, where an electrically conductive fluid, such as a plasma or ionized gas, is accelerated through the cross product of an electric current and a perpendicular magnetic field. Despite its promise, marine MHD propulsion faces challenges due to seawater’s low electrical conductivity, limiting current density by factors such as Joule heating and water electrolysis. Moreover, constraints in increasing magnetic field strength, driven by electromagnet size, cost, and power requirements, hinder its practical application, particularly for larger-scale vessels.

Solar Propulsion:

Solar propulsion, introduced in 2008, offers substantial benefits including a significant reduction in carbon dioxide emissions. These systems can generate capacities up to 40 kilowatts, leveraging solar energy for ship propulsion. While offering environmental advantages, solar propulsion systems are currently limited in widespread adoption due to the requirement for consistent sunlight. Nevertheless, ongoing advancements in solar technology and integration methods may pave the way for broader utilization in the future, especially in regions with ample sunlight availability.

Water-Jet Propulsion:

Water-jet propulsion, dating back to 1954, presents advantages such as noise reduction and high vessel speed. However, its maintenance costs pose challenges, potentially impacting users. Despite its drawbacks, water-jet propulsion remains a favored option for vessels prioritizing noise reduction and maneuverability.

Wind Propulsion:

Emerging as an eco-friendly alternative, wind propulsion systems like kite propulsion and sail propulsion offer promising solutions to reduce CO2 emissions in marine environments. However, their adoption faces challenges related to the need for consistent wind conditions, limiting their applicability in large commercial vessels.

Biodiesel Fuel Propulsion:

Considered a potential marine propulsion system for the future, biodiesel offers environmentally friendly alternatives to conventional fuels. Although research is ongoing to assess its viability, challenges such as feedstock costs, compatibility issues, and storage considerations hinder widespread adoption in shipping and fishing applications. Efforts to explore alternative oils, such as recycled waste oils, show promise in addressing some of these challenges, presenting a sustainable solution for marine diesel engines.

Nuclear Propulsion:

Utilized primarily in naval vessels, nuclear propulsion systems harness nuclear fission processes to fuel ships, providing virtually unlimited range and mission time. While historically employed in submarines using steam-driven turbines, newer electric propulsion systems demonstrate quieter operation and enhanced efficiency, particularly in Chinese naval vessels. The adoption of advanced technologies like Integrated Electrical Propulsion Systems (IEPS) and rim-driven pumpjets signifies significant advancements in nuclear submarine capabilities, potentially altering the landscape of underwater warfare.

China’s advancements in submarine technology, particularly the development of an Integrated Electrical Propulsion System (IEPS) and a “shaftless” rim-driven pumpjet, mark a significant leap forward in underwater warfare capabilities. Rear Admiral Ma Weiming’s unveiling of the IEPS, which converts all engine output into electricity, alongside the rim-driven pumpjet, showcases China’s commitment to innovation in naval engineering. Unlike traditional propulsion systems, the IEPS offers enhanced efficiency and reduced noise levels due to its minimal moving parts, making it ideal for stealth operations, particularly in submarines.

The integration of the rim-driven pumpjet, characterized by its ring-shaped electrical motor and submerged operation, further underscores China’s quest for quieter and more efficient propulsion methods. By eliminating the propeller shaft and minimizing moving components, the rim-driven pumpjet reduces noise emissions and cavitation, enhancing stealth capabilities. This technological advancement not only benefits China’s attack submarines, such as the Type 095 SSN, but also holds potential for application in nuclear ballistic missile submarines (SSBNs), bolstering China’s second strike nuclear capability and overall naval prowess. As China aims to enhance the stealthiness of its submarine fleet to rival Western and Russian counterparts, the adoption of innovative propulsion systems signifies a strategic shift towards bolstering its maritime capabilities and reshaping the balance of power in naval warfare.

From Warships to AUVs: Adapting Propulsion for Diverse Missions

Naval vessels come in all shapes and sizes, each designed to fulfill specific mission objectives. Warships, including destroyers, cruisers, and frigates, require robust propulsion systems capable of providing both speed and agility in combat situations. Traditionally, these vessels relied on conventional diesel engines or gas turbines for propulsion. However, with the emergence of advanced electric propulsion systems, warships now have access to quieter, more efficient propulsion options.

Electric propulsion offers numerous advantages, including reduced acoustic signatures, improved maneuverability, and enhanced stealth capabilities. By integrating electric propulsion systems with advanced power management technologies, modern warships can operate more quietly underwater, making them less susceptible to detection by enemy forces.

In addition to traditional warships, the rise of unmanned naval platforms, such as AUVs and unmanned surface vessels (USVs), has spurred innovation in marine propulsion technology. These autonomous platforms play a critical role in reconnaissance, surveillance, and mine countermeasure operations. Compact electric propulsion systems, coupled with advanced autonomy algorithms, enable AUVs and USVs to navigate complex underwater environments with precision and efficiency, expanding the capabilities of naval fleets in diverse mission scenarios.

Submarines: Silent and Lethal

Submarines have long been the silent sentinels of the sea, capable of covertly gathering intelligence, conducting reconnaissance, and projecting power in enemy territory. The propulsion systems of submarines are paramount to their effectiveness, as they determine the vessel’s stealth and endurance underwater.

Traditional diesel-electric submarines rely on a combination of diesel engines for surface operations and electric motors powered by batteries for submerged propulsion. While this setup provides stealth during submerged operations, it limits the endurance of the submarine due to the finite capacity of onboard batteries.

To address this limitation, nuclear-powered submarines offer virtually unlimited endurance, allowing them to remain submerged for extended periods without the need to surface for refueling. Nuclear propulsion systems utilize nuclear reactors to generate steam, which in turn powers turbines to drive the submarine’s propellers. This enables nuclear submarines to operate at high speeds for prolonged durations, making them formidable assets in naval warfare.

Aircraft Carriers: The Backbone of Naval Power

At the pinnacle of naval power projection, aircraft carriers serve as mobile airbases capable of launching and recovering a variety of aircraft, including fighter jets, reconnaissance planes, and helicopters. The propulsion systems of aircraft carriers are designed for both speed and endurance, allowing them to traverse vast distances while supporting sustained aerial operations.

Modern aircraft carriers typically employ nuclear propulsion systems, similar to those found in nuclear-powered submarines. These advanced propulsion systems provide the carrier with unparalleled speed, range, and endurance, enabling it to maintain a constant presence in strategic regions around the world.

Sustainable Shipping

As the maritime industry navigates towards a more sustainable future, the adoption of advanced propulsion technologies will be instrumental in achieving emission reduction targets and mitigating environmental impact. From LNG-fueled engines to hydrogen fuel cells and electric propulsion systems, the quest for greener marine propulsion solutions continues to drive innovation and collaboration across the industry.

With concerted efforts towards sustainability and technological advancement, the maritime sector can chart a course towards a cleaner, more efficient future, ensuring the continued vitality of global trade while preserving the health of our oceans for generations to come.

Conclusion: Charting the Course for Future Naval Operations

As naval technology continues to advance, marine propulsion systems will play an increasingly critical role in shaping the future of underwater warfare. From the silent prowlers beneath the waves to the mighty behemoths that rule the seas, each naval platform relies on its propulsion system to achieve its mission objectives effectively.

With ongoing research and development efforts focused on improving efficiency, reliability, and sustainability, the next generation of marine propulsion systems promises to revolutionize underwater warfare. Whether it’s enhancing the stealth capabilities of submarines, extending the endurance of autonomous underwater vehicles, or powering the mightiest aircraft carriers, these advancements will undoubtedly redefine the capabilities of naval forces in the 21st century and beyond.

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis