Logistics is often referred to as the “sinews of war”, linking forward-deployed units with support elements to ensure they are supplied, maintained and ready for the next operation. There is a saying in military circles – made famous by US Marine General Robert H Barrow – that amateurs study tactics, but professionals study logistics.

Military Logistics—the transfer of personnel and materiel from one location to another, as well as the maintenance of that materiel—is essential for a military to be able to support an ongoing deployment or respond effectively to emergent threats. More generally, protecting one’s own supply lines and attacking those of an enemy is a fundamental military strategy.

One of the critical elements of logistics is sustainment, which refers to the resiliency of a logistics system. A high capacity for sustainment allows military forces to continue operations and to maintain required levels of manning and effectiveness. Sustainment ensures that the logistics pipeline continues to flow. Sustainment coalesces around several pivotal functions.

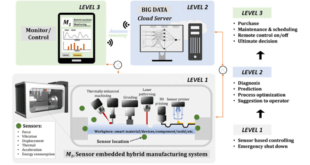

Maintenance – through a program of maintenance and repair, the operational life of existing assets can be extended, thereby enhancing the level of logistics support. By applying batch and real-time data analytics to “traditional” maintenance methods, the result is higher mission availability and mission effectiveness — at a reduced cost.

Preventive maintenance

Military systems are often operated in extreme and highly variable conditions. The resulting large variations in required maintenance are however hardly recognized, since traditionally these systems are subject to a static maintenance concept with fixed intervals. Moreover, these intervals are often very conservative due to the critical nature of the systems, which yields a quite inefficient maintenance process. Also, the traditional approach in determining maintenance intervals is experience-based and relies on a statistical or stochastic analysis of failures.

Data analytics research and development is focused on the forecasting of failure modes to enable predictive maintenance. Taking advantage of the internet-of-things era, there is greater use of instrumentation sensors for condition-based maintenance (CBM). With CBM, rather than changing engine oil on a set schedule, the maintenance interval is based on driving style, the oil’s viscosity and particulate level.

The UK Royal Navy is using drones to scan Navy vessels for damage. Due to the size and area of naval ships, inspections now take hours rather than days, with fewer people involved and can even be done while at sea. In the future, we may even see automated maintenance drones than can pick up on faults or damage and do the repairs themselves without the control of an engineer.

The operational efficiency of the assets can be improved significantly when the maintenance is performed in a more dynamic manner, i.e. by taking the variations in usage and operating environment into account. This predictive maintenance approach is only possible when firstly the relation between the degradation rate and the operational conditions can be quantified, and secondly the variations in these conditions are monitored.

The first requirement can be met by adopting physical failure models that quantitatively describe the damage rates as a function of the system usage. For most common failure mechanisms, like e.g. fatigue, wear and corrosion, failure models are available now. The key to applying these models in a predictive maintenance concept is the monitoring of the suitable usage parameter and its translation into the appropriate internal load.

The second requirement for a predictive maintenance approach is the monitoring of usage or loads. The challenge, in that case, is to find the parameter that is most relevant for the failure mechanism considered. For example, if a fatigue failure is considered, not the number of operating hours, but the number of start-stops of a (rotating) system (which determines the number of load cycles) governs the service life consumption. Again, only knowledge on the physical mechanisms enables to select the appropriate parameter to monitor

In case of combat vehicle, the failure of the track pads appears to be one of the critical failure modes and excessive wear was identified to be the failure mechanism causing this failure. The governing loads for a wear mechanism are the normal load, specific wear rate and travelled distance . This means for the track pads, that the terrain type is an important factor for the service life.

Armies Investing in Predictive Maintenance Technology

The U.S. Army has started implementing artificial intelligence programs to anticipate vehicle breakdowns and improve combat readiness. The software, facilitated by the Defense Innovation Unit, seeks to anticipate component failures and reduce the amount of unplanned maintenance. The result is increasing the readiness for all combat vehicles such as the fleet of Bradley tanks, which must be ready at a moment’s notice.

Data for the software is gathered via sensors and telematics that are already installed on critical machine components. It is collected and processed by artificial intelligence software to give insight into when a part may need maintenance. The military wants to increase readiness for commanders and have an empirical sense of the health of any given Bradley vehicle, as this will help increase equipment availability.

In June 2021, it was reported that Gastops has been selected by Canada’s Department of National Defence to contribute to the “All Systems Go!” Challenge, an initiative of the Government of Canada’s Innovation for Defence Excellence and Security (IDEaS) program. The objective of the challenge is to drive innovation in predicting and optimizing maintenance for military platforms through Health and Usage Monitoring Systems (HUMS) that will support the transition from schedule-based maintenance to Condition-Based Maintenance (CBM), and ultimately, to a truly predictive maintenance regime that will optimize the use of limited maintenance resources while increasing the operational platform availability.

Gastops will use the challenge funding to accelerate the development of the company’s multi-sensor, multi-platform HUMS solution for rotating and reciprocating equipment. The solution will address the gap between current oil condition and contamination sensor technologies and integrate machine learning to enable the detection and tracking of early-stage fault conditions. The company will also develop a model to identify diesel engine maintenance and cost drivers.

Gastops plans to produce a prototype HUMS solution including hardware and software that will drive the transition of oil changes from a scheduled activity – irrespective of equipment and oil condition – to an on-condition activity triggered by actual health and usage data. That transition will provide significant cost savings and environmental benefits in the form of reduced oil consumption, and increased platform availability thanks to the elimination of unnecessary maintenance downtime. Gastops will also deliver a comprehensive set of solution requirements (including fault data models, sensor technologies required, and packaging requirements) to ensure that platform operators realize high value-for-money.

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis