The increasing deployment of airplanes for passenger and cargo transport has intensified the need for high-performance, efficient materials in aircraft manufacturing. Modern aerospace materials have evolved from wooden frames to advanced solutions such as carbon-fiber composites, self-healing materials, and fiber-reinforced polymers. Weight reduction remains a key focus, as it directly impacts lift, drag, fuel efficiency, and operational costs.

Challenges in the Development of Advanced Materials for Aerospace and Military Applications

Military aerospace applications face some of the most rigorous material requirements in engineering. Components must endure extreme conditions, such as high velocities, intense pressure differentials, wide temperature variations, and harsh atmospheric and space environments. These materials must be both lightweight and strong, offering a delicate balance between performance and durability. For example, materials used in airframes and propulsion systems must withstand the stresses of high-speed flight while being light enough to ensure fuel efficiency and optimal performance.

Fretting Wear

Fretting wear occurs at the contact surface of materials due to small amplitude (less than 100 µm) oscillatory relative movement between surfaces. This leads to crack initiation, which can slowly develop into larger fractures and eventually cause material rupture. No material is immune to fretting wear, making its prevention a significant challenge. While surface hardness and adhesion have been shown to influence fretting behavior, a comprehensive understanding of how to mitigate fretting wear remains an area of ongoing research. Experimentation continues to focus on surface treatment techniques to enhance material resistance to this form of wear.

Corrosion Resistance

Corrosion, the degradation of materials due to chemical reactions with the surrounding environment, remains one of the most significant challenges in materials science. In aerospace and military applications, corrosion can lead to structural failure, which poses a significant risk to the safety and longevity of aircraft and military vehicles. Types of corrosion include uniform corrosion, pitting corrosion, crevice corrosion, and galvanic corrosion. In the U.S. alone, corrosion-related costs total over $276 billion annually, a figure that exceeds the costs of natural disasters. Despite advancements, only about 30% of corrosion-related losses are preventable using current techniques.

In aerospace, the challenge lies in using corrosion-resistant materials without compromising other material properties like weight, strength, and cost. New alloys and surface treatments are being explored to enhance corrosion resistance, but achieving long-term durability in aerospace environments continues to be a complex issue.

Materials for Aircraft Structural Applications

Aircraft structural materials must provide rigidity, strength, and support to withstand both static and dynamic loads while remaining lightweight. Additionally, these materials must endure extreme environmental conditions, including temperature variations and high-pressure differentials. For example, aircraft wings are subjected to bending during flight, with the upper surface experiencing compression due to lift and the lower surface undergoing tension from the aircraft’s weight. Similarly, the fuselage, subjected to high cabin pressurization and shear forces, requires materials that exhibit high tensile and shear strength. The careful selection of materials for these structural components is critical for the optimal performance of the aircraft.

The materials used for aircraft wings, fuselage, and other components must exhibit both high tensile and compressive strength, along with resilience to cyclic loading. Currently, the primary materials used for aircraft structures are aluminum alloys, polymer matrix composites (PMCs), and titanium alloys. Advances in these materials are pushing the boundaries of aircraft design, with an emphasis on improving strength, corrosion resistance, and overall performance.

While aluminum traditionally dominated the aerospace industry, composing up to 70% of aircraft in earlier generations, advanced materials like carbon-fiber composites and superalloys are now increasingly used to improve durability, damage tolerance, and corrosion resistance.

Titanium, aluminum alloys, and composites are some of the most commonly used materials in military aerospace due to their strength-to-weight ratio and resistance to corrosion. Currently, airframes are primarily constructed using aluminum alloys, polymer matrix composites (PMCs), and, to a lesser extent, titanium alloys. Titanium, in particular, is favored for its ability to withstand high temperatures and its excellent resistance to corrosion, making it ideal for critical components in both aircraft and missile systems.

Research and development efforts over the coming decades are likely to focus on advancing these materials. For instance, adding small amounts of scandium to aluminum alloys has significantly improved their strength, corrosion resistance, and weldability, though high scandium costs remain a limiting factor. Additionally, Al-Li alloys are re-emerging with improved fracture toughness and fatigue resistance, though achieving higher strength levels remains a challenge. High-strength aluminum alloys featuring non-equilibrium phases, such as amorphous and quasi-crystalline phases, are under investigation for enhanced thermal stability and ambient temperature properties. Furthermore, aluminum alloys developed through powder metallurgy (P/M) are being evaluated for use in high-speed vehicles, capable of withstanding temperatures up to 450°C. However, ensuring consistent reliability, reproducibility, and property retention at elevated temperatures is an ongoing challenge in advancing P/M technology for aerospace applications.

Meanwhile, advanced composites like carbon fiber-reinforced polymers (CFRPs) are increasingly used in military aircraft and space vehicles. These materials offer exceptional strength while significantly reducing weight, helping to improve fuel efficiency and maneuverability.

Aluminum Alloys

Aluminum alloys have been the primary material for airframes due to their favorable strength-to-weight ratio and ease of processing. Recent innovations include the addition of scandium to aluminum alloys, which enhances strength, corrosion resistance, and weldability. However, the high cost of scandium remains a limitation. To address this, the use of Al-Li (aluminum-lithium) alloys is gaining traction, offering improved fracture toughness and fatigue crack growth resistance.

Titanium Alloys

Titanium alloys are critical for modern fighter aircraft due to their exceptional strength-to-weight ratio, superior stiffness, and ability to withstand high temperatures. These alloys are particularly valuable in airframes of supersonic aircraft exceeding Mach 2.5, where temperatures often surpass the 150°C limit of most aluminum alloys. Titanium’s compatibility with composite materials also makes it ideal for hybrid airframe substructures. Widely used alloys like Ti-6Al-4V offer proven reliability, while newer variants like Ti-6-22 provide enhanced strength for advanced applications. Additionally, alternatives such as Alloy 54M are being explored for cost-effective and machinable solutions. Emerging technologies, like “meltless titanium,” enable the production of unique alloy compositions unattainable via traditional melting processes, opening doors to novel aerospace applications.

Titanium alloys are categorized into alpha, beta, and alpha-beta types, each tailored for specific roles. Alpha alloys, with their hexagonal close-packed (HCP) structure, offer excellent corrosion resistance, low density, and high creep resistance, making them ideal for compressor blades in engines despite limited high-temperature functionality. Beta alloys, characterized by a body-centered cubic (BCC) structure, excel in tensile and fatigue strength and ease of fabrication, with applications in high-stress components like landing gears. Beta stabilizers such as vanadium and molybdenum enhance their strength and durability. Alpha-beta alloys, the most versatile and widely used, combine the best properties of both categories. Alloys like Ti-6Al-4V dominate the aerospace market, finding applications in fuselage structures, landing gear, nacelles, and compressor discs due to their excellent strength, fracture toughness, ductility, and corrosion resistance. Together, these alloys play a pivotal role in advancing aerospace technology, meeting the demands of modern and future aircraft. Additionally, ‘meltless titanium’ processing methods are emerging to create alloys with compositions previously unattainable through traditional melting methods.

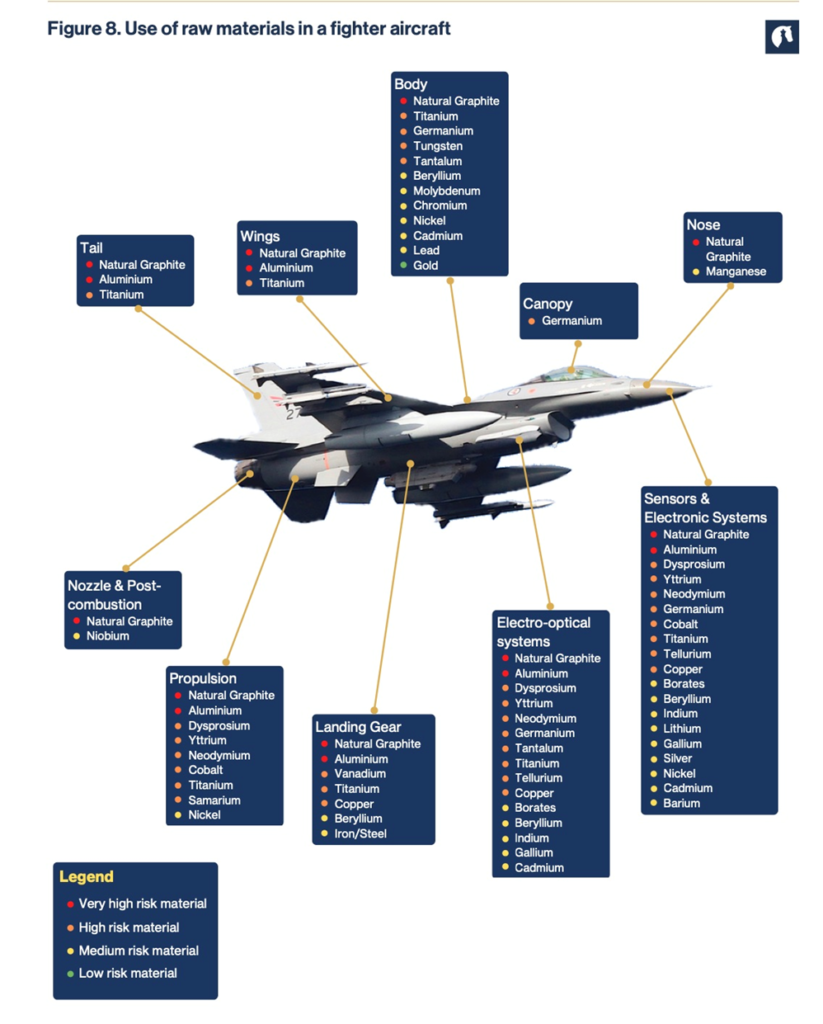

Graphite

Graphite plays a critical role in defense, aerospace, and energy sectors due to its unique properties, including high-temperature resistance, lightweight nature, machinability, and corrosion resistance. In aerospace, graphite improves fuel efficiency, extends aircraft service life, and enables the operation of hotter engines by reducing weight. The material is integral to the defense industry, used in fighter jets, tanks, missiles, and submarines, with significant concerns about supply chain security, as it is 100% import-dependent in the U.S. Graphite is also vital for electric vehicles, as it forms a key component of lithium-ion batteries, and its demand is expected to rise dramatically due to the electrification of transportation.

Composite Materials: Revolutionizing Aerospace Engineering

Composite materials, created by combining two or more distinct materials, deliver properties superior to their individual constituents. Their use is rapidly expanding in the aerospace industry, with composites accounting for over 25% of the Airbus A380 and nearly 50% of the Boeing 787. These materials are prized for their low density, exceptional specific strength, and enhanced corrosion and fatigue resistance compared to most metals, making them integral to modern aircraft design.

Ceramic Matrix Composites (CMCs)

CMCs, consisting of ceramic fibers embedded in a ceramic matrix, offer outstanding high-temperature stability (up to 1400°C), high hardness, and excellent corrosion resistance. Common examples include silicon carbide (SiC), alumina (Al₂O₃), and silicon nitride (Si₃N₄). These properties make CMCs ideal for high-temperature applications like exhaust nozzles. However, their poor fracture toughness has historically limited their usage. Recent advancements, such as incorporating carbon nanotubes (CNTs) and graphene nanoplatelets (GNPs), have significantly improved their fracture toughness. Studies reveal that adding just 1.5 vol% of graphene can enhance the fracture toughness of Si₃N₄ by 235%, paving the way for more durable and efficient CMCs in aerospace applications.

Metal Matrix Composites (MMCs)

MMCs combine reinforcing materials like carbon or glass fibers with metal matrices such as aluminum (Al), magnesium (Mg), titanium (Ti), copper (Cu), and nickel (Ni). These composites exhibit superior yield strength, fracture toughness, wear resistance, and low thermal expansion. However, the performance of conventional reinforcements is nearing its peak. The incorporation of advanced reinforcements like CNTs and graphene nanosheets is under active investigation to enhance the mechanical properties of MMCs. Controlled additions of these materials have shown remarkable improvements in tensile strength, yield strength, and hardness, particularly in lightweight metals like magnesium and aluminum. With their excellent vibration-damping, recyclability, and potential for electromagnetic shielding, magnesium-based MMCs are emerging as strong contenders for future structural applications.

Polymer Matrix Composites (PMCs)

PMCs are lightweight, versatile composites made from polymer matrices reinforced with fibers like fiberglass, carbon, and aramid. They are widely classified into thermosets (e.g., epoxy and polyurethanes) and thermoplastics, depending on their heat remolding characteristics. Carbon fiber-reinforced epoxy PMCs offer exceptional strength-to-weight ratios, with densities nearly half that of aluminum alloys while delivering tensile strengths three times higher. These composites form 30–40% of the weight of modern fighter aircraft, including their ailerons, flaps, and landing gear doors.

The focus in PMC development is now shifting to enhancing matrix toughness, ease of fabrication, moisture resistance, and temperature capabilities. Advanced polymers like bismaleimides, cyanate esters, and benzoxazines are increasingly used, offering higher temperature endurance (~350°C). For fifth-generation fighter aircraft, bismaleimide matrices already constitute over 50% of composite components due to their ability to withstand temperatures up to 220°C for extended periods.

Efforts to develop carbon fibers with both high tensile strength (~7 GPa) and stiffness are ongoing, alongside the exploration of CNT fibers for their superior mechanical properties. PMCs also hold potential for embedding functional materials like sensors and actuators, enabling future applications in adaptive and smart aerospace structures.

Technological Advancements Driving Material Innovation

The constant drive for technological advancement in aerospace materials is fueled by the need for greater performance and reliability. As military forces push for more advanced systems, including stealth aircraft, unmanned aerial vehicles (UAVs), and space systems, the demand for new materials and manufacturing technologies continues to rise. One of the major trends in the industry is the development of advanced composite materials that combine the benefits of metals and polymers. These composites are being used extensively in the construction of modern fighter jets, bombers, and drones, as they offer the durability needed for military operations while keeping weight to a minimum.

Another significant technological breakthrough is the use of additive manufacturing (3D printing) in military aerospace. This technology enables the creation of complex, lightweight structures that were previously difficult or impossible to manufacture. By using 3D printing, military aerospace manufacturers can produce highly customized parts that are lighter and stronger than traditional components. Furthermore, additive manufacturing allows for on-demand production of spare parts, reducing the need for large inventories and cutting down maintenance costs.

Military Aircraft Materials

In the context of military aircraft, advanced materials are essential for improving performance, survivability, and mission effectiveness. The Advanced materials play a transformative role in enhancing the operational effectiveness of military aircraft, enabling them to meet the rigorous demands of modern warfare. Military aircraft must be strong yet lightweight, capable of flying faster, resistant to heat, and designed for increased agility and heavier payloads. use of advanced composites, stealth materials, and high-performance alloys is key to meeting these demands.

Aluminum alloys, once dominant, are being increasingly replaced by advanced composites due to their superior fatigue resistance, weight reduction, and capability to optimize aircraft performance. However, aluminum alloys still hold their ground in specific applications due to their cost-effectiveness and high strength-to-weight ratio. Titanium alloys and superalloys are particularly favored for their high strength and ability to withstand the extreme temperatures encountered in high-speed, high-performance aircraft. Composites, particularly carbon fiber-reinforced polymers, are used extensively for their strength-to-weight ratio and versatility. Emerging materials like metamaterials, which manipulate electromagnetic waves to enhance stealth, further underscore the drive toward innovation.

Survivability remains a core design parameter, particularly for fighter jets, which often rely on stealth and low observability to reach their targets. The rise of fifth-generation aircraft technology, incorporating advanced composites and stealth materials, marks a significant trend, driving innovation and demand in the defense aerospace sector.

Source: Hague Centre for Strategic Studies

The use of advanced composites in fifth-generation fighter aircraft is helping to reduce weight, improve structural integrity, and enhance stealth capabilities. However, the cost of maintaining these materials, along with their complexity, remains a challenge. As aircraft materials become more sophisticated, the focus is shifting to materials capable of withstanding extreme temperatures, including ultrahigh temperature materials (UHTM) for hypersonic vehicles, missile systems, and re-entry vehicles.

Materials for Stealth and Survivability

As defense technologies advance, stealth capabilities have become a priority in military aerospace design. The materials used in stealth aircraft, for instance, need to absorb or deflect radar waves to reduce visibility and enhance the aircraft’s survivability in hostile environments. Radar-absorbent materials (RAM) are commonly used in the construction of stealth aircraft and other military platforms. These materials are designed to minimize the radar cross-section (RCS) of the vehicle, making it harder for adversaries to detect the craft using radar systems.

These materials often incorporate dielectric materials loaded with conductive, reflective, and magnetic elements to soak up radar waves. Modern RAMs, like low-weight honeycomb structures, are categorized as Radar Absorbing Structures (RAS), which are designed to be both lightweight and effective.

Frequency Selective Fabric Composites (FSFCs), made by weaving carbon and glass fibers in specific patterns, are another promising development. These composites not only absorb radio frequency (RF) energy but can also function as load-bearing structures, making them multifunctional.

Adaptive Radar Absorbers and Plasma-Based Solutions

Active radar absorbers, which adjust their electromagnetic properties in response to an external signal, represent the next step in stealth technology. This includes smart and adaptive RAMs, such as conductive polymers whose resonant frequency can be tuned by altering their resistive and capacitive elements. These materials could allow the radar cross section of an aircraft to be adjusted in real-time, depending on the operational needs—ranging from a high RCS during non-combat periods to a very low RCS in combat.

Plasma-based stealth technology is also under consideration, where free electrons in a plasma cloak absorb radar waves and convert them into heat, significantly reducing an aircraft’s radar cross section. Research into maintaining this cold plasma cloak in flight remains a critical area for future development.

Visual and Acoustic Signature Reduction

Reducing visual and acoustic signatures will be crucial, especially for unmanned aerial vehicles (UAVs) that fly at low altitudes. Active visual camouflage using electrochromic polymers that change color and brightness in response to applied voltage is a developing technology. These materials could allow the vehicle’s exterior to mimic its environment—whether matching the sky above or the terrain below—by utilizing photosensitive receptors. This would create a highly adaptive, nearly invisible surface for stealth operations.

In addition to stealth materials, military aerospace systems also require materials that can enhance the overall survivability of the platform. For example, aircraft and missile systems often incorporate advanced armor materials, including reactive and composite armor, to provide protection from ballistic threats. The use of ceramic composites and layered armor is becoming more common as it allows for enhanced protection against high-velocity projectiles while keeping the overall weight of the platform low.

Challenges in Manufacturing and Performance Testing

The complexity of military aerospace material requirements means that not only must materials meet stringent performance standards, but they also have to be produced in ways that ensure they are reliable and reproducible. The aerospace manufacturing process is often complex, requiring high-precision techniques to ensure that each component meets exact specifications. The challenge is even greater when the materials need to be fabricated in large quantities while maintaining their integrity and performance standards.

In addition to manufacturing challenges, military aerospace materials undergo rigorous testing to ensure their reliability under a wide range of conditions. These tests include extreme temperature simulations, pressure tests, and high-speed impact tests. Components are also subject to vibration and stress testing to simulate the effects of high-speed flight, combat, or space exploration. The goal of these tests is to ensure that materials can withstand the harsh conditions encountered during military operations and that they maintain performance over the lifespan of the aircraft or system.

The Future of Military Aerospace Materials

The future of military aerospace materials lies in the continued development of advanced, multifunctional materials that can adapt to the changing demands of the industry. Nanomaterials, self-healing materials, and materials that can change shape or properties under different conditions are all being explored for their potential in military aerospace. These next-generation materials promise to enhance the performance, survivability, and longevity of military platforms while addressing the growing need for sustainability and reduced operational costs.

As military aircraft and air systems evolve, the materials used must adapt to increasingly demanding operational requirements. The future of military aviation is likely to see further advances in composite materials, ultrahigh temperature materials (UHTMs), and multifunctional materials that can reduce weight while providing improved strength, stealth, and resistance to environmental stressors. UAVs and hypersonic vehicles will require materials that can perform at extreme temperatures and resist erosion, while innovations in stealth technology and survivability will continue to drive the need for specialized materials.

Smart Materials and Structures in Future Air Vehicles

In addition to stealth technologies, future air vehicles will integrate advanced smart materials and structures, revolutionizing performance, durability, and maintenance practices. These innovations will enable adaptive, resilient, and efficient aircraft systems that can meet the demands of next-generation aviation.

With advancing technology, smart materials like self-cleaning polymers and self-healing composites are poised to revolutionize aerospace design. These materials not only promise improved performance but also reduced maintenance needs, enhancing operational efficiency and safety in future airframes and aircraft components.

Self-cleaning materials, inspired by natural phenomena like the hydrophobicity of lotus leaves, are a prime example of biomimicry. The self-cleaning effect can be achieved via two mechanisms: surface wettability (as seen in lotus leaves) and photocatalytic properties, where photoactive surfaces generate oxidative radicals upon exposure to light, breaking down organic contaminants. Future developments could see these materials applied to aircraft seat fabrics, carpets, and even exterior surfaces, offering longer-lasting cleanliness and reduced upkeep for airlines. These innovations, coupled with their environmental benefits, make self-cleaning materials a crucial area of exploration.

Health & Usage Monitoring (HUM)

Smart materials embedded in airframe structures will enable real-time monitoring of structural integrity. These materials, combined with advanced sensors, actuators, and predictive modeling, facilitate Structural Health Monitoring (SHM) and usage tracking. By diagnosing damage and estimating residual life, HUM systems support predictive maintenance, preventing critical failures and reducing downtime. Current research focuses on:

- Developing highly sensitive sensors.

- Miniaturizing components for seamless integration.

- Advancing machine learning algorithms for damage prognosis and lifecycle prediction.

Active and Adaptive Structures for Shape Control

Shape-memory polymers, piezoelectric, and magnetostrictive materials enable morphing structures that adapt to changing flight conditions. These materials allow wings and control surfaces to adjust their shape in real-time, improving aerodynamics, fuel efficiency, and maneuverability. Such active and adaptive structures are key to next-generation aircraft designs.

Smart Skins

Smart skins are multifunctional materials that combine structural integrity with embedded electronics, such as antennas and sensors. These intelligent skins can actively respond to environmental stimuli, optimize performance, and enhance stealth. They represent a new frontier in integrating avionics and structural components seamlessly.

Self-Healing Materials

Self-healing materials are essential for enhancing aircraft longevity and safety. These materials can autonomously repair damage, such as cracks or corrosion, and are classified as:

Self-healing materials are another groundbreaking innovation that could transform aerospace structures. These materials can restore their structural integrity after damage, minimizing downtime and reducing repair costs.

- Intrinsic self-healing materials repair themselves through polymer chain mobility, as seen in innovative designs like “Wolverine fabric.”

- Extrinsic self-healing materials rely on embedded healing agents released when triggered by cracks or damage. For instance, boron-containing self-healing materials in aircraft engines can form boron oxide (B2O3) seals to repair high-temperature matrix cracks. Additionally, self-healing epoxy composites can protect airframes from corrosion, providing durable coatings that extend their lifespan.

Advanced research is exploring bio-inspired solutions, such as microvascular material systems capable of multiple healing cycles and boron-based materials that seal high-temperature cracks in engines. Additionally, self-healing epoxy composites protect aircraft from corrosion and enhance structural resilience, ensuring reliability in extreme conditions.

Incorporating smart materials and structures into aerospace design not only aligns with sustainability goals but also sets the stage for more reliable and efficient air travel. These innovations hold the promise of transforming aircraft into smarter, safer, and more adaptive systems, shaping the future of the industry.

New advancements in materials science are essential to ensuring the continued performance and safety of military and aerospace systems. Whether through the development of next-generation composites, alloys, or hybrid materials, the goal remains to create materials that not only meet but exceed the operational demands of modern military and aerospace applications.

Moreover, with the increasing integration of artificial intelligence and machine learning in military systems, future aerospace materials may be designed to self-monitor their condition, report maintenance needs, and even make decisions about their own performance in real time. This could lead to a significant leap in operational efficiency and safety, allowing military forces to maintain their edge in both conventional and asymmetric warfare scenarios.

Conclusion

The materials used in military aerospace are critical to the success of modern defense systems. From lightweight, high-strength alloys and composites to stealth-enhancing materials and advanced manufacturing techniques, the requirements for these materials are becoming more complex as technology progresses. The challenges of performance, durability, and adaptability are driving innovation in the field, ensuring that military aerospace systems can meet the ever-changing demands of modern warfare. With new advancements on the horizon, the future of military aerospace materials promises even greater capabilities, providing the defense sector with the tools needed to maintain superiority in the skies and beyond.

References and Resources also include:

https://cherrubics.com/recent-advances-in-the-development-of-aerospace-materials/

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis