Nanotechnology deals with the understanding, control, and manufacture of matter in the nanoscale regime, usually between 1 nm to 100 nm, and exploiting them for a useful application. At this length scale, unique properties and phenomena arise as a result of increased surface-to-volume ratio and dominance of quantum mechanical effects. The field has opened up opportunities to design, manipulate and control structures and devices at the nanometer scale down to the molecular and even atomic level, offering improved or new functionalities.

The domain of nanotechnology encompasses a very large area. The scientific research has focused on developing materials at the nanoscale level, understanding their unique properties and finding potential applications on the one hand; while on the other hand, exploiting possibilities of miniaturization using nanotechnology, development of nanoscale devices with the required functionalities are also being explored. Accordingly, nanotechnology has been divided into two broad categories – i ) nanomaterials and ii) nanoscale devices.

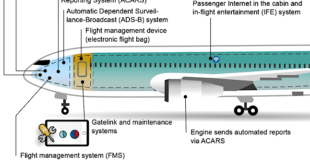

In the Defense and Aerospace nanotechnology can enhance the performance of devices such as sensors, memory storage, nanorobotics, transducers, nanoelectronics, propellants, explosives and weapon systems.

Due to the risks involved in flying, aircraft manufacturers are striving to make aerospace components stronger, tougher, and longer-lasting. The industry is also seeking to reduce weight in an ongoing bid to reduce fuel consumption and, by extension, operating costs. Further, pressure for air travel to be ‘greener’ has also come to bear.

Nanotechnology has the potential to significantly enhance Aerospace mission capability by enabling, among others, the development of materials that are significantly lighter and have mechanical properties and durability superior to those available today. The properties of these nanostructures are so unique and enhanced that it is finding applications in various spheres of life – right from bio-medical to optical and to space applications.

Nanomaterials are utilized in the aerospace industry for improved (or tailored) properties that improve their functional performance (e.g. mechanical or electrical properties) or that deliver multi-functional properties (e.g. lightweight conductive nanocomposites). The bulk of R&D into aerospace applications of nanomaterials at present focuses on structural reinforcement of composite materials. Nanomaterials will potentially allow for the development of lighter, high-performance, robust and cost-efficient, multi-functional aircraft.

Carbon nanotubes (CNTs)

Carbon nanotubes (CNTs) are hollow cylindrical tubes formed by rolling a sheet of carbon atoms arranged in a hexagonal ring, as in a sheet of graphite. They may be either in the form of a monolayer (single-walled nanotube, SWCNT) or multilayer (multi-walled nanotube, MWCNT) consisting of several concentrically interlinked nanotubes. Their diameter may range from 0.7 (SWCNT) to more than 100 naometers (MWCNT). Their length can reach several micrometers or even millimeters.

CNT being a hollow tube comprised entirely of carbon, they are extremely light weight. Current research showed that CNT was one of the strongest and hardest materials in the world, meanwhile it possessed low density, high length–diameter ratio of fiber structure, high conductivity, and conductivity characteristics of thermoelectric conductivity. They exhibit extraordinary strength and unique electrical properties, at the individual tube level: 200X the strength and 5X the elasticity of steel; 5X the electrical conductivity, 15X the thermal conductivity and 1,000X the current capacity of copper; at almost half the density of aluminum.

Based on the angle of the lattice that the nanotube’s carbon atoms form, the material can be highly conducting of electricity, semiconducting, or non-conducting. Carbon nanotubes are also about five times better at conducting heat than the industry workhorse, copper, and even exceed

diamonds.

Just like graphite, they are highly chemically stable and resist virtually any chemical impact unless they are simultaneously exposed to high temperatures and oxygen – a property that makes them extremely resistant to corrosion.

Their hollow interior can be filled with various nanomaterials, separating and shielding them from the surrounding environment – a property that is extremely useful for nanomedicine applications like drug delivery.

All these properties make carbon nanotubes ideal candidates for electronic devices, chemical/electrochemical and biosensors, transistors, electron field emitters, lithium-ion batteries, white light sources, hydrogen storage cells, cathode ray tubes (CRTs), electrostatic discharge (ESD) and electrical-shielding applications.

Aerospace Applications

CNT applications under development for aerospace applications include composites for lightweight structural components, aircraft braking systems (carbon/carbon composites), as well as electromagnetic interference (EMI), radio frequency interference (RFI), electrostatic discharge (ESD), de-icing, anti-fouling, lightning strike protection, anti-corrosion and fire-resistant coatings, thermal management systems, and energy storage-related applications.

The cost benefits of utilizing CNTs are are high in aerospace markets: For Satellites, the weight savings equates to launch cost savings; for UAVs, the weight savings equates to mission time and for Aircraft, lifetime cost savings for an aircraft is equated from fuel savings.

Nanotubes have outstanding mechanical and physical properties, making them ideal

building blocks for high-performance multi fibres and composites. CNT-based composite materials are increasingly being considered for mechanical, electrical and space applications due to their high specific stiffness, strength-to-weight ratio, low thermal expansion coefficient, and high thermal conductivity.

Carbon-based composite aircraft often get residual current from lightning strikes. They use metal to protect the aircraft, but the residual current is still present. CNT enables better shielding for basically the weight of a coat of paint and allows you to shield the internals of a carbon fiber-based airplane. Carbon nanotube sheets can act as “Faraday cage” effectively shielding sensitive electronic equipment such as radar and radios from electromagnetic interference (EMI) without adding a lot of weight to aircraft and satellites.

“Carbon nanotubes have at least the tensile strength of carbon fiber, but they are quite flexible. They don’t have the same brittleness, so the strain to failure is different. They’re able to be in a fabric like format where they can be put into the composite themselves, or be the composite themselves,” said Peter Antoinette,” CEO of Nanocomp Technologies

“One can imagine that the surface of a wing would be both structural, it would de-ice itself, it could be the antenna, it could report back to the aircraft and say ‘we are or are not integral or not’, you have enormous numbers of multifunctional applications that carbon nanotube technology can bring to aircraft and spacecraft,” said Per Antoinette.

Many groups, for instance, are researching nanotubes for enhanced batteries, which are of course integral for advancing the state of electric aircraft. Computer engineers are also devising processor architectures that would incorporate nanotubes instead of silicon, with implications in particular for UAS and spacecraft.

Carbon nanotube make stronger, lighter composites

The newest jets flying today are made of advanced composite materials such as carbon fiber reinforced plastic — extremely light, durable materials that reduce the overall weight of the plane by as much as 20 percent compared to aluminum-bodied planes. However, composite materials are also surprisingly vulnerable: While aluminum can withstand relatively large impacts before cracking, the many layers in composites can break apart due to relatively small impacts.

In the last decade, many research groups have explored the unique properties of the CNT-based nanocomposites and their application as flexible and lightweight radiation shielding materials and fabrics. Besides the ability to absorb and dissipate electromagnetic radiation, such nanocomposites exhibit outstanding mechanical properties and excellent processability.

IT aerospace engineers have found that by fastening the layers of composite materials together using carbon nanotubes, the resulting material is substantially stronger and more resistant to damage than other advanced composites. In experiments to test the material’s strength, the team found that, compared with existing composite materials, the stitched composites were 30 percent stronger, withstanding greater forces before breaking apart.

They embedded tiny “forests” of carbon nanotubes within a glue-like polymer matrix, then pressed the matrix between layers of carbon fiber composites. The nanotubes, resembling tiny, vertically-aligned stitches, worked themselves within the crevices of each composite layer, serving as a scaffold to hold the layers together.

More work needs to be done, but we are really positive that this will lead to stronger, lighter planes,” says Guzman, who is now a researcher at the IMDEA Materials Institute, in Spain. “That means a lot of fuel saved, which is great for the environment and for our pockets.”

CNTs in aerospace coatings

A number of aerospace companies and agencies are developing CNTS and graphene coatings to add special characteristics to aircraft frames and interior and engine parts and component surfaces, which can include properties such as: self-cleaning; de-icing; anti-fouling; improved hardness; wear and corrosion resistance; improvement in fuel efficiency; and improved thermal performance and flame retardancy.

Desirable functional properties for the aerospace and aviation industry afforded by nanomaterials in coatings include:

• Reduced weight and increased strength (carbon nanomaterials)

• High temperature control/resistance (SiC Nanoparticles in SiC-particle-reinforced alumina, Yittria stabilized nanozirconia)

• Electrostatic discharge, EMI shielding and low friction (CNT, graphene, nano aluminium, copper, iron, silver

nanoparticles)

• Corrosion/Wear Resistance (silica nanoparticles, aluminium, Nanocrystalline Carbide, Diamond-like Carbide and metal dichalcogenide, TiN nanocrystallites embedded in amorphous Si3N4, graphene)

• Easy reparability & reusability

• Less maintenance & increased durability.

CNTs and graphene are seen as an alternative to the more traditional carbon black/graphite or metal particle additives; their high conductivity and high aspect ratio result in the formation of percolated conductive networks within coatings at very low loadings.

Deicing

According to the Environmental Protection Agency, 25 million gallons of deicing agents are applied to aircraft at U.S. commercial airports each year. The aviation industry is also using energy-intensive pneumatic and electric anti-icing systems on aircraft to prevent ice formation on wings and other surfaces. GE are one of a number of companies developing anti-icing nanocoatings that reduce ice adhesion and have also been shown to delay the onset of ice formation. Battelle has also developing anti-icing coatings incorporating CNTs.

Metis Design Corp. and the Department of Aeronautics and Astronautics at the Massachusetts Institute of Technology have developed carbon nanotube (CNT) heater-based technology for aircraft electrothermal ice protection. Aircraft ice protection systems remove or prevent ice from accumulating on the leading edges of wings, stabilizers, and engine nacelles.

Products built with CNT enable the use of lightweight heaters, have lower thermal inertia and increased damage tolerance compared to traditional electrothermal systems. This technology supports the aerospace industry’s growing need for more durable, lightweight, damage-tolerant and low-power ice protection systems.

Another development is the deployment of CNTs as anti-icing coatings on unmanned aerial vehicles (UAV) in military applications. Current de-icing methods are not compatible with aircraft as small as UAV’s. They are generally more complex, heavier, and require more power. De-icing technology utilizing CNTs is significantly lighter than other de-icing systems. The application also utilizes simple painting methods-coating the surface of the aircraft with a fibrous, CNT-enhanced coating that prevents ice from building up on the area of application.

The EU-funded SANAD project is combining graphene with CNTs to make a coating for planes that can be connected to the electrical system and heated up to stop the build-up of ice. SAAB has also filed a patent for the development of de-icing coatings. The graphene additive could strengthen the acrylics and shield against EMI interference.

Sponsored by the U.S. Special Operations Command, or SOCOM, HeatCoat is an ultrathin, lightweight, nanotube-doped layer sprayed onto surfaces underneath a regular coat of paint. Electrical leads connected to a drone’s wiring system serve as a power source to disperse de-icing heat through the layer. Because HeatCoat is so close to the wing surface, it requires little energy to achieve de-icing, says Greg Kimmel, the national security business line manager for Battelle who is overseeing HeatCoat’s continued development. Furthermore, because it’s a spray-on layer, HeatCoat can be applied to components and areas with complex geometries, such as nosecones and engine intakes.

Carbon nanotubes for anti-icing

When a plane travels through clouds in cold weather, layers of ice can form on its wings, propellers, or jet intakes, increasing drag and reducing lift, which may lead to loss of control of the aircraft. Conventional passenger aircraft anti-icing systems divert a portion of hot air from the engines and pipe it to the wing’s inner surface. The heat transfers to the outer surface by thermal conduction, stopping ice build-up. In addition to adding weight and maintenance requirements, this system is not energy efficient, particularly on the new generation of composite aircraft.

A team of experts at Queen’s University Belfast have developed a more efficient alternative – an ultra-lightweight heater, based on webs made from carbon nanotubes (CNT) – which can also be used for de-icing. We started by creating a CNT web, where individual CNTs are aligned in the draw direction, and horizontally stacking 10-to-40 layers of the webs, at different orientations, to achieve the desired heating characteristics. “Each layer of CNT web can be as thin as 1/2,000th the thickness of a human hair, and the weight of a web large enough to cover a football field would be less than 30 sheets of letter-size photocopy paper.” The CNT webs were cured within a thin glass fiber laminate to provide structural support, and connected to a power supply. When researchers carried out testing, they discovered that the newly developed CNT heaters achieved rapid heating, showing that they could quickly de-ice aircraft and provide ice protection in flight.

Yao says: “Compared with state-of-the-art heating systems currently used on aircraft, the CNT heater that we have created at Queen’s is lighter, provides rapid and more uniform heating, and is more energy efficient. It is also more flexible in terms of fitting the shape and performance of any surface or power requirement to achieve rapid anti-icing and de-icing.”

Carbon nanotubes for shielding

Depending on the wavelength, electromagnetic radiation can be divided into gamma rays, X-rays, UV, visible light, infrared, microwave, and radio waves. High-energy electromagnetic radiation, such as gamma rays and X-rays, is also categorized as ionizing radiation, as it causes the formation of charged particles when absorbed in matter.

Exposure to natural or artificial electromagnetic radiation can harm living organisms as well as sophisticated electronic components. Sensors, communication units, remote sensing instruments, computers, transformers, medical devices, and many others, both onboard spacecraft and Earth, can be disturbed or damaged by undesirable EMI.

Effective EMI shielding materials combined with radiation-tolerant electronic components can eliminate the adverse effects of electromagnetic radiation. In the past, metallic materials, such as copper, aluminum, and steel, have been used as effective shielding materials because of their high electrical conductivity and good permeability. However, these materials are disadvantageous in terms of weight and flexibility as many modern applications, like space exploration, wearable electronics, and biomedical sensing, require smaller and lighter devices.

Carbon nanotubes (CNTs), owing to their unique electronic properties, have shown a great potential for use in EMI shielding nanocomposite materials and radiation-tolerant microelectronic components. Such molecular systems are highly tolerant to high-energy radiation since the absorbed energy can spread over the whole system and dissipate rapidly. Polymer nanocomposites that incorporate CNTs have emerged as an alternative to conventional EMI shielding materials due to their remarkable electrical properties, lightweight, and flexibility.

The Rice lab of Professor Matteo Pasquali has developed a coating that could replace the tin-coated copper braid that transmits the signal and shields the cable from electromagnetic interference. The metal braid is the heaviest component in modern coaxial data cables. Replacing the outer conductor with Rice’s flexible, high-performance coating would benefit airplanes and spacecraft, in which the weight and strength of data-carrying cables are significant factors in performance.

Rice research scientist Francesca Mirri, lead author of the paper, made three versions of the new cable by varying the carbon-nanotube thickness of the coating. She found that the thickest, about 90 microns – approximately the width of the average human hair – met military-grade standards for shielding and was also the most robust; it handled 10,000 bending cycles with no detrimental effect on the cable performance. Replacing the braided metal conductor with the nanotube coating eliminated 97 percent of the component’s mass, Mirri said.

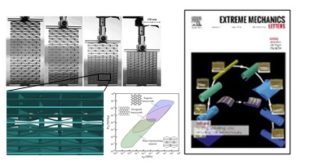

Carbon nanotube film produces aerospace-grade composites with no need for huge ovens or autoclave, reported in Jan 2020

A modern airplane’s fuselage is made from multiple sheets of different composite materials, like so many layers in a phyllo-dough pastry. Once these layers are stacked and molded into the shape of a fuselage, the structures are wheeled into warehouse-sized ovens and autoclaves, where the layers fuse together to form a resilient, aerodynamic shell.

Now MIT engineers have developed a method to produce aerospace-grade composites without the enormous ovens and pressure vessels. The technique may help to speed up the manufacturing of airplanes and other large, high-performance composite structures, such as blades for wind turbines. The researchers detail their new method in a paper published today in the journal Advanced Materials Interfaces.

“If you’re making a primary structure like a fuselage or wing, you need to build a pressure vessel, or autoclave, the size of a two- or three-story building, which itself requires time and money to pressurize,” says Brian Wardle, professor of aeronautics and astronautics at MIT. “These things are massive pieces of infrastructure. Now we can make primary structure materials without autoclave pressure, so we can get rid of all that infrastructure.” Wardle’s co-authors on the paper are lead author and MIT postdoc Jeonyoo Lee, and Seth Kessler of Metis Design Corporation, an aerospace structural health monitoring company based in Boston.

In 2015, Lee led the team, along with another member of Wardle’s lab, in creating a method to make aerospace-grade composites without requiring an oven to fuse the materials together. Instead of placing layers of material inside an oven to cure, the researchers essentially wrapped them in an ultrathin film of carbon nanotubes (CNTs). When they applied an electric current to the film, the CNTs, like a nanoscale electric blanket, quickly generated heat, causing the materials within to cure and fuse together. With this out-of-oven, or OoO, technique, the team was able to produce composites as strong as the materials made in conventional airplane manufacturing ovens, using only 1 percent of the energy.

The researchers next looked for ways to make high-performance composites without the use of large, high-pressure autoclaves—building-sized vessels that generate high enough pressures to press materials together, squeezing out any voids, or air pockets, at their interface. “There’s microscopic surface roughness on each ply of a material, and when you put two plys together, air gets trapped between the rough areas, which is the primary source of voids and weakness in a composite,” Wardle says. “An autoclave can push those voids to the edges and get rid of them.”

Researchers including Wardle’s group have explored “out-of-autoclave,” or OoA, techniques to manufacture composites without using the huge machines. But most of these techniques have produced composites where nearly 1 percent of the material contains voids, which can compromise a material’s strength and lifetime. In comparison, aerospace-grade composites made in autoclaves are of such high quality that any voids they contain are neglible and not easily measured. “The problem with these OoA approaches is also that the materials have been specially formulated, and none are qualified for primary structures such as wings and fuselages,” Wardle says. “They’re making some inroads in secondary structures, such as flaps and doors, but they still get voids.”

Carbon nanotubes for space

Current and future space missions will push the limits of human exploration, taking astronauts further than ever before. A key safety issue throughout space travel stems from the continuous stream of damaging cosmic radiation that spacecraft are subjected to throughout their journey.

This radiation can damage or even destroy onboard electronics, causing data glitches, prompting vital computer systems to break down, and ultimately putting the mission in jeopardy and the safety of the crew at risk.

NASA has reported that these effects have caused incidents of communications and guidance issues, increased error rates, memory errors, and even spontaneous processor resets reported during solar events. New research reported in Oct 2021 by the American Chemical Society (ACS) in the ACS Nano journal has showcased the potential of carbon nanotubes to help address this issue, discussing how these nanotubes can be developed and configured to maintain their electrical properties and memory, even after being bombarded by significant amounts of radiation.

The research focuses on the use of single-atom-thick carbon nanotubes’ potential to shield field-effect transistors from potentially damaging radiation, and the nanotubes’ capacity to improve the transistors’ energy efficiency versus standard silicon-based versions. Carbon nanotubes were deposited on a silicon wafer which functioned as the semiconducting layer in field-effect transistors. It was discovered that situating shields above and below the carbon nanotubes allowed the transistor’s electrical properties to be protected against incoming radiation up to 10 Mrad, much more than could be achieved via the use of most silicon-based radiation-tolerant electronics.

NASA worked with Nanocomp to produce carbon nanotube (CNT) fibers to fabricate a carbon nanotube Composite Overwrap Pressure Vessel. NASA’s Space Technology Mission Directorate (STMD) is interested in nanotechnology – an approach that can reduce the mass and improve the performance of aerospace systems. For example, NASA computer modeling analysis has shown that composites using carbon nanotube reinforcements could lead to a 30 percent reduction in the total mass of a launch vehicle.

The agency has targeted getting the nanomaterials to the point where they have approximately twice the tensile strength of the current material of choice, carbon fiber-reinforced composites. That, in turn, could enable a reduction in vehicle mass on the order of 50%. “It would be a game changer in terms of weight savings,” says NASA’s Meador.

“No single technology would have that much of an impact to reduce the mass of a launch vehicle by that much,” says Michael Meador, program element manager for lightweight materials and manufacturing at NASA’s Glenn Research Center in Cleveland, Ohio. “I’m not trying to be cliché, but that is a game changer.”

Researchers at Metis and MIT came up with this concept of how a carbon nanotube-outfitted sensor embedded within an aircraft wing, for example, could register changes in a baseline level of electrical resistance caused by structural fatigue or damage. Accordingly, these devices could work very well as crack gauges, monitoring wing structural integrity. The data would be diagnostically helpful for both maintenance and post-mission repair. “You can easily correlate the change in resistance to the length of the crack needed to cause that change in resistance,” says Kessler.

Challenges

Three main methods are currently available for the production of CNTs: arc discharge, laser ablation of graphite, and chemical vapor deposition (CVD). In the first two processes, graphite is combusted electrically or by means of a laser, and the CNTs developing in the gaseous phase are separated. All three methods require the use of metals (e.g. iron, cobalt, nickel) as catalysts.

High-end nanotubes — distinguished by their purity, uniformity and consistency within batches — remain relatively costly. “All carbon nanotubes are not created equal,” says Sprengard. Nanotubes also do not behave like metals that can be simply melted down and molded into desired shapes; instead, nanotubes must be bound together in a matrix, for instance with resin, in order to transfer loads for structural purposes and to deliver their conductive properties at scale. Irksomely, though, nanotubes tend to agglomerate instead of evenly dispersing when added to another material; for instance, when adding the manufactured nanotubes (which in bulk look like a powder) to composites, the formulations grow too viscous and unworkable, limiting the numbers of tubes that can be added and ultimately the material property gains being sought.

Researchers are still laboring to retain the attractive properties displayed by individual nanotubes at size scales relevant to human technologies. “The real challenge is how to take something at a molecular level and apply it and convert it into a macroscopic form that then delivers a system-level capability in a commercial environment,” says Joe Sprengard Jr., president, CEO and co-founder of Veelo Technologies, an Ohio-based startup developing new materials — some based on nanotubes — for boosting the performance of next-generation aircraft.

“We’ve finally learned how to work with these materials, getting them into the forms and scale that allow us to do meaningful things,” says Michael Meador, who retired last year after a 36-year career at NASA, where he worked on nanomaterials as a manager for the agency’s Game Changing Development Program at Glenn Research Center in Ohio.

Yet progress is being made on all these fronts, with ever-improving manufacturing techniques and the use of dispersants to more evenly distribute nanotubes in their binders.

“We’re getting beyond the hype of the ’90s,” Meador adds. “Carbon nanotubes are not a one-size wonder material that’s going to solve everyone’s problems, but there’s a lot of potential and they’re close to reality.”

References and Resources also include:

https://www.sciencedaily.com/releases/2018/07/180710153742.htm

https://www.nanotechmag.com/wp-content/uploads/2014/08/CNTs-aerospace-4-pages.pdf

https://www.aerospacemanufacturinganddesign.com/article/carbon-nanotubes-for-anti-icing/

https://www.azonano.com/article.aspx?ArticleID=5916

https://aerospaceamerica.aiaa.org/features/resetting-expectations-for-carbon-nanotubes/

https://www.azom.com/news.aspx?newsID=57107

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis