Digital transformation has become the hottest buzzword of this decade. New technologies and tools are supporting the transformation journey of companies big and small as they compete to get a bigger slice of business in a fast-paced competitive environment. Although digital transformation fast-tracks a company’s growth, it has to be equally supported by management methods of quality control and business transformation.

Crosby described quality as, “the conformance to requirements realized through prevention and reduction of defects and nonconformances. There are many paths to sound and robust quality. Two of the most comprehensive and prevalent in the industry are Lean and Six Sigma.

Six Sigma is both a quality management philosophy and a methodology that focuses on reducing variation, measuring defects, and improving the quality of products, processes and services.

The purpose of Lean is, to maximize customer value while minimizing waste. Now, Lean and Six Sigma are emerging to get the most of both improvement philosophies. Using Lean and Six Sigma tools, empowers us to eliminate waste and excess cost, reduce variation and defects and improve our processes and the customer experience in our business.

Six Sigma

Six sigma has three different meanings. At its core it is a statistical tool, a process and finally as a buisness philosophy. Six Sigma is a defined and disciplined business methodology to increase customer satisfaction and profitability by streamlining operations, improving quality and eliminating defects in every organization-wide process.

Six Sigma has evolved into a more general business-management philosophy, focusing on meeting customer requirements, improving customer retention, and improving and sustaining business products and services.

It calls to transform the corporate culture to embrace a process improvement/measurement focus, teamwork and empowerment. It is an integrated buisness strategy. Company leaders need to understand and committed to the six sigma trategy before deploying techniques to the workforce. The whole company and employees need to be informed and motivated.

Six Sigma is a data-driven process improvement methodology that seeks to improve the quality of any process from product to manufacturing to service by identifying and removing the causes of defects (errors) and minimizing variability in manufacturing and business processes. Using Six Sigma Methodology, a business can strategize its plan of action and drive revenue increase, cost reduction and process improvements in all parts of the organization.

A Goal: Using Six Sigma methodology, organizations can keep a stringent goal for themselves and work towards achieving them during the course of the year. Right use of the methodology often leads these organizations to achieve these goals. The Six Sigma methodology is grounded in a process known as DMAIC. DMAIC stands for Define, Measure, Analyze, Improve and Control.

There are four main sources of process variation:

- Poor design: resulting from bad design practices, unrealistic or unclear requirements, and requirement shift and creep

- Variation in a manufacturing process: due to varying manpower levels, work methods and ethics, environmental factors, training, and machine wear

- Variation in measurement: systems due to improper calibration and implementation

- Variation in parts and supplies: from vendors and subcontractor

It uses a statistical methodology for eliminating defects. “Six Sigma” comes from the bell curve used in statistics, where one Sigma symbolizes a single standard deviation from the mean. The goal of six sigma is to produce a process where 99.99966% of the products manufactured are statistically expected to be free of defects (3.4 defects per million). This means that an error generally occurs with a six-standard deviation event from the mean because only 3.4 out of a million events along a bell curve would fall outside of six standard deviations.

Six Sigma’s goal of 99.99966 Percent defect-free or 3.4 defects for every one million opportunities means we can realize 68 wrong drug prescriptions each year. One short or long landing at a major airport every five years, 1.7 incorrect surgical procedures every week, seven lost articles of mail per hour, and one unsafe minute of drinking water every seven months. And, no electricity for almost seven hours every five years.

The Six Sigma Methodology

The fundamental objective of the Six Sigma methodology is the implementation of a measurement-based strategy that focuses on process improvement and variation reduction through the application of Six Sigma improvement projects. This is accomplished through the use of two Six Sigma sub-methodologies: DMAIC and DMADV.

DMAIC is a data-driven method used to improve existing products or services for better customer satisfaction. It is the acronym for the five phases: D – Define, M – Measure, A – Analyse, I – Improve, C – Control. DMAIC is applied in the manufacturing of a product or delivery of a service.

- Define: In this phase, the boundaries for the process being analyzed are set and the expectations or desired performance for that process are defined from a customer perspective. A team of people, led by a Six Sigma champion, defines a faulty process on which to focus, decided through an analysis of company goals and requirements. This definition outlines the problem, goals, and deliverables for the project.

- Measure: In this phase the current performance of the process, product or service is measured to determine what is actually occurring, especially from a customer perspective. These statistical measures make up a list of potential inputs, which may cause the problem and help the team understand the process’s benchmark performance.

- Analyze: In this phase the process, product or service is analyzed using the measured data to determine the source or sources of the variation that are causing the problem. This is to ensure the true root cause(s) is identified and not just a symptom. The team analyzes the process by isolating each input, or potential reason for the failure, and testing it as the root of the problem. The team uses analytics to identify the reason for process errors.

- Improve: In this phase the possible changes to the process, product or service are assessed and a solution set of changes is designed and tested. This is to ensure the solution creates the desired effect and that the variation is reduced or eliminated.

- Control: In this phase, the changes are implemented, the supporting systems are also updated and the process, product, or service is put under control – normally statistical process control – to ensure the solution is fully implemented in a sustainable manner and to identify if performance starts to degrade. The group adds controls to the process to ensure it does not regress and become ineffective once again

When seeking to improve an EXISTING process, we apply the DMAIC methodology. Design for Six Sigma (DFSS) helps organizations create NEW products, services and processes in a way that ensures customer satisfaction by using a structured framework (DMADV, IDDOV, or DMADOV)

DMADV is a part of the Design for Six Sigma (DFSS) process used to design or re-design different processes of product manufacturing or service delivery. The five phases of DMADV are: D – Define, M – Measure, A – Analyse, D – Design, V – Validate. DMADV is employed when existing processes do not meet customer conditions, even after optimization, or when it is required to develop new methods.

Lean Manufacturing?

Lean manufacturing is a production process based on an ideology of maximising productivity while simultaneously minimising waste within a manufacturing operation. The lean principle sees waste is anything that doesn’t add value that the customers are willing to pay for. The benefits of lean manufacturing include reduced lead times and operating costs and improved product quality.

The Toyota Production System originally detailed seven wastes that don’t provide value to the customer. These wastes were:

- Unnecessary transportation

- Excess inventory

- Unnecessary movement of people, equipment or machinery

- Waiting – either people or idle equipment

- Over-production of a product

- Over-processing or adding unnecessary features to a product

- Defects that require costly correction

An eighth waste has since been highlighted by many lean practitioners is Unused talent and ingenuity.

Cost-saving is the most obvious advantage of lean manufacture. More efficient workflows, resource allocation, production and storage can benefit businesses regardless of size or output. Time saving allows for reduced lead times and better service in providing products quickly to customers, but can also help save money through allowing for a more streamlined workforce.

Lean Six Sigma

Lean and Six Sigma are widely used in industry as continuous improvement best practices. They can also be very complementary in nature and, if performed properly, can produce unprecedented results

• Lean focuses on eliminating non-value added activities in a process and promotes work standardization and flow While Six Sigma focuses on reducing process variation and enhancing process control, from the remaining value-added steps.

• Lean provides speed ensuring products and services flow without interruption while Six Sigma ensures that critical product / service characteristics are completed correctly the very first time we do them

The distinction between Six Sigma and lean has blurred, with the term “lean Six Sigma” being used more and more often because process improvement requires aspects of both approaches to attain positive results.

Lean Six Sigma is a fact-based, data-driven philosophy of improvement that values defect prevention over defect detection. It combines Six Sigma methods and tools and the lean manufacturing-lean enterprise philosophy, striving to reduce waste of physical resources, time, effort, and talent while assuring quality in production and organizational processes. Any use of resources that do not create value for the end customer is considered a waste and should be eliminated.

Lean Six Sigma is a team-focused managerial approach that seeks to improve performance by eliminating waste and defects while boosting the standardization of work. It drives customer satisfaction and bottom-line results by reducing variation, waste, and cycle time, while promoting the use of work standardization and flow, thereby creating a competitive advantage. It applies anywhere variation and waste exist, and every employee should be involved.

Lean Six Sigma foundations and key principles

There are three key elements to Lean Six Sigma

Tools and techniques: A comprehensive set of tools and analytical techniques that are used to identify and solve problems.

Process and methodology: A series of phases that organize the use of the problem-solving tools to ensure that the true root causes are found and that a solution is fully implemented.

Mindset and culture: A way of thinking that relies on data and processes to achieve operational performance goals and continuously improve.

Each project team should use the guiding principles

Focus on the Customer

The primary goal is to bring maximum benefit to the customer. Customer satisfaction is the top priority. For this, a business needs to understand its customers, their culture and needs, and what drives sales or loyalty. This requires establishing the standard of quality as defined by what the customer or market demands. Focus on activities that add value to their products and eliminate those which do not. Build lasting relationships and anticipate customer needs to achieve a competitive edge. Be the supplier of choice.

Measure the Value Stream and Find Your Problem

Map the steps in a given process to determine areas of waste. Gather data to discover the specific problem area that is to be addressed or transformed. Have clearly defined goals for data collection, including defining the data to be collected, the reason for the data gathering, insights expected, ensuring the accuracy of measurements, and establishing a standardized data collection system. Ascertain if the data is helping to achieve the goals, whether or not the data needs to be refined, or additional information collected. Identify the problem. Ask questions and find the root cause.

Eliminate Waste / Variation

Once the problem is identified, make changes to the process to eliminate variation, thus removing defects. Create solutions that are within the boundaries established by leadership. Remove the activities in the process that do not add to the customer value.

If the value stream doesn’t reveal where the problem lies, tools are used to help discover the outliers and problem areas. Streamline functions to achieve quality control and efficiency. In the end, by taking out the above-mentioned junk, bottlenecks in the process are removed.

Involve, Align and empower employees

Involve all stakeholders. Adopt a structured process where your team contributes and collaborates their varied expertise for problem-solving. Six Sigma processes can have a great impact on an organization, so the team has to be proficient in the principles and methodologies used. Hence, specialized training and knowledge are required to reduce the risk of project or re-design failures and ensure that the process performs optimally.

Ensure a Flexible and Responsive Ecosystem

The essence of Six Sigma is business transformation and change. When a faulty or inefficient process is removed, it calls for a change in the work practice and employee approach. A robust culture of flexibility and responsiveness to changes in procedures can ensure streamlined project implementation. The people and departments involved should be able to adapt to change with ease, so to facilitate this, processes should be designed for a quick and seamless adoption.

Continuously Improve Knowledge in the Pursuit of Perfection

(Ensure teams are continuously striving to take the next step and never stop striving for perfection.) Ultimately, the company that has an eye fixed on the data examines the bottom line periodically and adjusts its processes where necessary, can gain a competitive edge.

Six Sigma Techniques

The Six Sigma methodology also uses a mix of statistical and data analysis tools such as process mapping and design and proven qualitative and quantitative techniques, to achieve the desired outcome. Key Six Sigma Techniques in use

Brainstorming

Brainstorming is the key process of any problem-solving method and is often utilized in the “improve” phase of the DMAIC methodology. It is a necessary process before anyone starts using any tools. Brainstorming involves bouncing ideas and generating creative ways to approach a problem through intensive freewheeling group discussions. A facilitator, who is typically the lead Black Belt or Green Belt, moderates the open session among a group of participants.

Root Cause Analysis/The 5 Whys

This technique helps to get to the root cause of the problems under consideration and is used in the “analyze” phase of the DMAIC cycle. In the 5 Whys technique, the question “why” is asked, again and again, finally leading up to the core issue. Although “five” is a rule of thumb, the actual number of questions can be greater or fewer, whatever it takes to gain clarity.

Voice of the Customer

This is the process used to capture the “voice of the customer” or customer feedback by either internal or external means. The technique is aimed at giving the customer the best products and services. It captures the changing needs of the customer through direct and indirect methods. The voice of the customer technique is used in the “define’ phase of the DMAIC method, usually to further define the problem to be addressed.

The 5S System

This technique has its roots in the Japanese principle of workplace energies. The 5S System is aimed at removing waste and eliminating bottlenecks from inefficient tools, equipment, or resources in the workplace. The five steps used are Seiri (Sort), Seiton (Set In Order), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain).

Kaizen (Continuous Improvement)

The Kaizen technique is a powerful strategy that powers a continuous engine for business improvement. It is the practice continuously monitoring, identifying, and executing improvements. This is a particularly useful practice for the manufacturing sector. Collective and ongoing improvements ensure a reduction in waste, as well as immediate change whenever the smallest inefficiency is observed.

Benchmarking

Benchmarking is the technique that employs a set standard of measurement. It involves making comparisons with other businesses to gain an independent appraisal of the given situation. Benchmarking may involve comparing important processes or departments within a business (internal benchmarking), comparing similar work areas or functions with industry leaders (functional benchmarking), or comparing similar products and services with that of competitors (competitive benchmarking).

Poka-yoke (Mistake Proofing)

This technique’s name comes from the Japanese phrase meaning “to avoid errors,” and entails preventing the chance of mistakes from occurring. In the poka-yoke technique, employees spot and remove inefficiencies and human errors during the manufacturing process.

Value Stream Mapping

The value stream mapping technique charts the current flow of materials and information to design a future project. The objective is to remove waste and inefficiencies in the value stream and create leaner operations. It identifies seven different types of waste and three types of waste removal operations.

The Six Sigma Tools

Identify the constraints and high leverage opportunities through the Business Diagnostic process. Combine the statistical process analysis techniques of traditional Six Sigma with the Lean manufacturing approach to eliminate waste and nonvalue added activity. Provide the right analytical tools for each situation. Cause and Effect Analysis, Flow Chart, Pareto Chart, Histogram, Check Sheet, Scatter Plot and Control Chart.

Radar charts are assessment tools used to evaluate and prioritize using multiple criteria and are useful to show the gaps between current organization performance and the vision. This example may be useful to assess project priorities in a program office. Get multiple perspectives on each project measured using each axis on the radar chart. Connect the ratings and evaluate priorities. Results from this example could be used to best allocate scarce acquisition management resources across multiple programs.

Design of Experiments

Optimal performance of your process is locked inside current performance, just waiting to be discovered. The optimal process can emerge once all the variables are adjusted appropriately. The Design of Experiments (DOE) tool helps align process variables and arrange them to ensure optimal performance.

Design of Experiments (DOE) is a Six Sigma tool that helps project teams determine the effects that the inputs of a process have on the final product. DOE helps uncover the critical relationships between variables in a process that are often hidden under all of the data and identifies the most critical inputs that must be modified to ensure optimal process performance. Once Design of Experiments identifies the critical inputs of the process, it helps project teams understand the impact that modifying the variables will have on process performance.

Six Sigma Design of Experiments is a systematic process that breaks down the variables of production and analyzes each one. This process has its own set of terms that we must understand to become conversant with how the technique works.

- Factor – This is an independent variable, or a variable you have control over. In DOE, factors are deliberately modified to determine the point of optimal performance.

- Level – This is a measurement of how much a factor has been modified. Levels can be discrete or numeric.

- Run – An experiment typically done at two or three levels for every factor; each separate level constitutes an experimental run.

- Response – The outcome of the run.

- Replication – Refers to multiple sets of experimental runs. Replication provides even more data and greater confidence in evaluating the results.

Kano Model

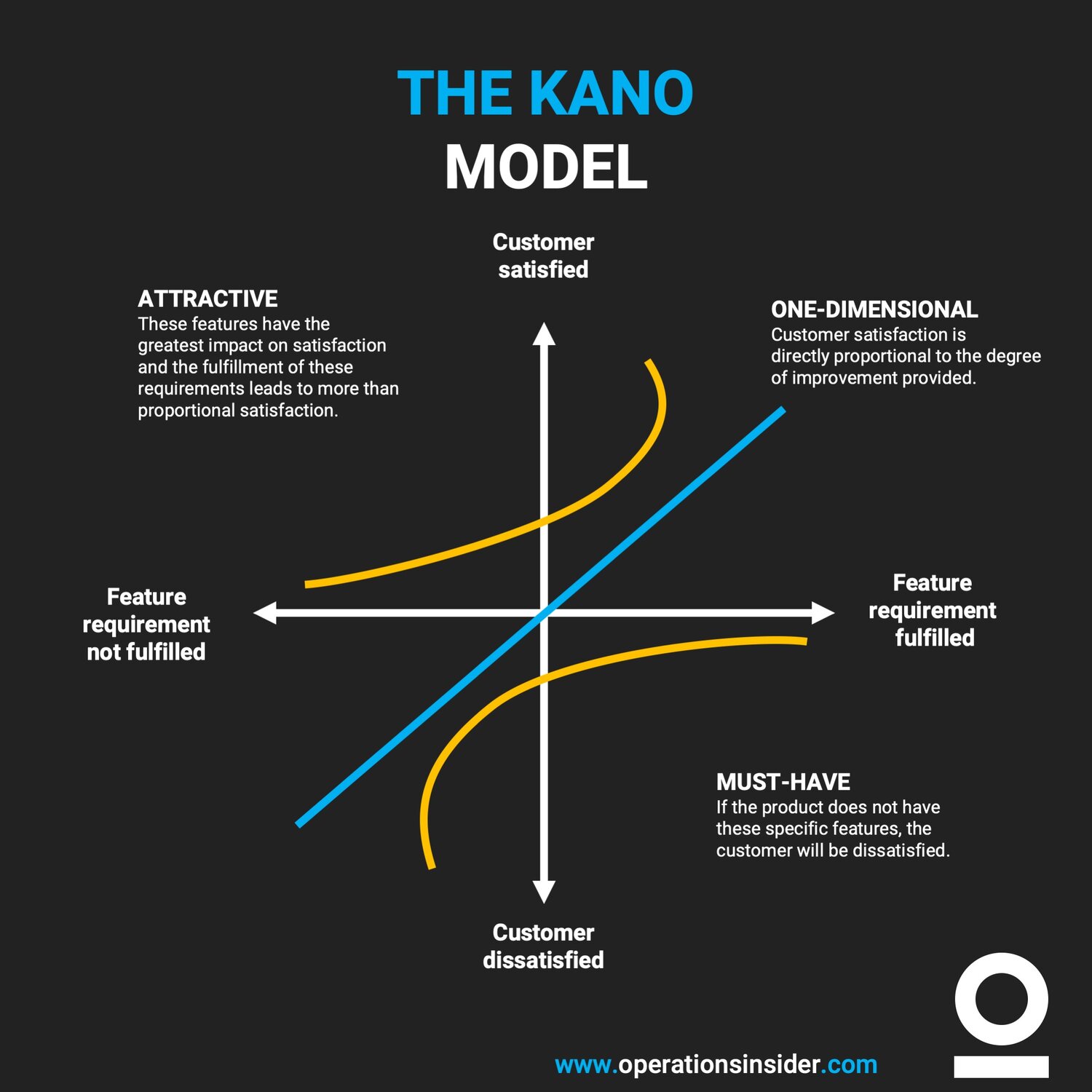

The Kano model is a framework designed to prioritize features based on the degree to which they will satisfy or delighted the users. In other words, a model that helps to prioritize the features based on how much that feature will delight the users. Kano Model is used after receiving the customer feedback (VOC). Often implemented along with QFD during Define phase of DMAIC of six sigma project.

Visual factory

The term “visual factory” refers to an approach to lean manufacturing processes based on visual information throughout the workplace. A visual factory uses a system of communication tools to share information at the time and place it is needed.

As part of the lean manufacturing process, a visual factory uses signs, labels, charts, infographics, and other communication tools to provide data in an efficient manner. Conveying this information visually reduces the time invested in reading, processing, and interpreting text-based instructions.

Visual controls improve working areas by answering questions; identifying equipment, materials, and locations; describing actions and procedures; and providing safety warnings and precautionary information. Visual tools also boost productivity by giving employees the information they need, where and when they need it.

Those may include:

- Electrical display boards, which provide real-time information about the status of production (or a process) within a facility and alerts workers whenever assistance is needed

- Floor marking aids and wayfinding signs, which can help employees find walkways, entrances, exits, navigational aids, and other instructions.

- Signs and labels that designate inventory, storage, tools, and other vital resources

Implementation

General Electric, one of the most successful companies implementing Six Sigma, has estimated benefits on the order of $10 billion during the first five years of implementation. Not surprisingly, the Aerospace & Defense Sector companies of the Fortune 500 are all using Six Sigma. Six Sigma has even found its way into the US Military – Army, Navy, Air Force and Marines.Other government organizations using Six Sigma include the Florida Department of Corrections, NASA and the Pentagon.

The U.S. Department of Defense has dictated the implementation of Lean Six Sigma to achieve the highest level of cost-wise readiness. Indeed, the life cycle costs of operating and maintaining today’s advanced weapons systems are more expensive than their acquisition. Hence, there is pressure to reduce the costs of operating aging equipment and maintain ever-higher levels of readiness.

BAE Systems is a multinational defense, security and aerospace business. With a workforce of 84,600 people it works hard to promote and maintain is culture of innovation and standards of excellence across the globe. On the company’s website it states, “Our culture focuses not on what we do, but on how we do it. If we focus on the how, the future that we wish to attain will follow. We have a culture of total performance; a commitment to the highest standards in every aspect of the way we do business.” One arm of its total performance strategy centres on lean six-sigma – a principle the business has adopted and endorsed for some time.

Raytheon SIX SIGMA™ (R6σ™) Six step Process

The knowledge-based process refers to Raytheon’s unique six-step process—visualize, commit, prioritize, characterize, improve, and achieve—to identify and accomplish productivity improvements to make customer satisfaction and business growth a reality. This process starts with the creation of a clear vision of the future with a clear and pressing need for change. The vision focuses the project team on the goal and business need.

Next, the Commit Step is required. The Commit Step ensures the project has the necessary support from business leaders. This step is a go/no-go point in the process, and project teams do not progress to prioritize until they have a committed sponsor and team aligned with the vision. The process is iterative and some teams will be asked to return to previous steps.

After Commit, the next step in the process is Prioritize. Using facts and data, project teams will discover improvement opportunities and understand organizational readiness for change. At this time, resources needed to work the project are identified and initial return on investment (ROI) estimates are completed. Teams will use this analysis to prioritize the highest leverage projects necessary to achieve goals. Those projects offering the highest returns will be scoped and resources are assigned to work project(s) that will make the most difference to the customer and business. Teams will typically revisit Commit with the project sponsor to ensure they remain aligned with the business needs and goals.

Next, the process teams characterize and define their understanding of the current state performance: identify opportunities, develop potential solutions, conduct tradeoffs, and create a plan for improvement. The results are reviewed prior to the implementation of the improvements. The Improve Step in the process completes the detailed design and implementation of improvements and control systems necessary to sustain the change. For example, this step delivers new operating instructions, training, capital equipment and facility changes, process changes, and most importantly, value for the customer.

The Achieve Step in the process delivers sustainable, measurable results to build momentum for continuous improvement. The project team leader(s) ensures all team members are recognized and celebrates success. Project results are publicized to share lessons learned and to motivate others to join the R6σ™ Journey.

Space Industry

Over the past several decades of years the small satellite mission market has been experiencing an advanced rate of growth in capabilities, number of missions and user investments due to the

increasing demand of small satellite applications among end users within academia, commercial,

defense, and government.

This higher scale of growth on an international basis in both interest level and actual participation

within the space communities is subsequently influencing the development of small satellite

spacecraft technologies, payload instruments, approaches to mission development and launch vehicle systems.

Small satellites are used to conduct missions both in earth orbit, cis-lunar and planetary. Small satellites are categorized into mini-satellites (mass of 100‐500 kg), microsatellites (10‐100 kg), and nanosatellites (1‐10 kg). The fastest growth in the number of small satellites recently is in the size category of less than 50-kilogram in mass.

“Lean” Small Satellite Missions Concept

In recent years, the term ‘lean satellite’ has been developed to describe missions that take unconventional risks during their development to achieve a low-cost and fast delivery. The approach focuses on the use of non-qualified COTS components to achieve a lower cost and shorter schedule, which typically leads to a smaller size.

The inherited risks associated with this concept are accepted, and the reliability of the mission is superseded by the project cost and schedule. Many satellites fall within the scale from a traditional satellite (those that follow strict standards and requirements) to a lean satellite, depending on the level of risk a mission will accept and the budget that a project can meet.

The concept of “lean satellite missions” was born from the creation and evolution of the practices of lean manufacturing, lean engineering, lean satellites , lean launch and lean operations. “Lean” is a both technical and management approaches to the “risk and reward” considerations, it is not a standard by itself.

References and Resources also include:

https://ntrs.nasa.gov/api/citations/20190026547/downloads/20190026547.pdf

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis