In mission-critical and safety-critical systems, preventing failures, errors, or defects is paramount. These systems, which often govern industries like aerospace, nuclear power, medical devices, and defense, require stringent safety measures to ensure reliability, performance, and the well-being of people and the environment. To address this, various tools and methodologies have been developed to ensure reliability, availability, and maintainability (RAM) of these systems. Among these tools, Failure Mode and Effect Analysis (FMEA) and Fault Tree Analysis (FTA) stand out as essential for preventing errors, failures, or defects in mission-critical and safety-critical systems. Both tools play a crucial role in analyzing potential risks and ensuring that systems function correctly under all conditions. This blog explores how FMEA and FTA help avoid potential errors or failures in mission-critical and safety-critical systems, providing insight into their application and benefits.

Relaibility and Risk Management

The design, acquisition, and operation of defense systems must meet exceptionally high reliability standards to avoid catastrophic consequences. Reliability is a key factor in product design and manufacturing, ensuring systems meet performance expectations, especially in mission-critical applications like space projects, where in-situ repairs are not possible. This makes reliability engineering crucial, employing tools such as Failure Modes and Effects Analysis (FMEA), which evaluates potential failure modes in components.

The Department of Defense’s (DoD) Reliability, Availability, and Maintainability (RAM) guidelines and the U.S. Military’s reliability prediction handbook (MIL-HDBK-217) provide critical frameworks for ensuring system dependability, especially as military equipment increasingly integrates advanced electronics and microelectronics.

Risk management is a systematic process aimed at identifying and mitigating potential issues that could jeopardize a program’s success. It encompasses both programmatic risks, such as high staff turnover and tight schedules, and technical risks, like equipment failures and system malfunctions. By understanding and analyzing these risks—focusing on their probability, impact, and severity—teams can prioritize their mitigation efforts effectively. This analysis is crucial in ensuring that resources are allocated to address the most significant risks, ultimately enhancing the reliability of the system and preventing potential failures that could affect mission goals.

A well-developed mitigation strategy is essential for reducing risks and ensuring project success. This strategy should include action plans outlining potential methods for risk reduction, decision points for evaluating effectiveness, and testing protocols to verify that risks have been adequately managed. Continuous monitoring of both identified and mitigated risks throughout the project lifecycle is critical for proactively addressing threats before they escalate.

Risk management and reliability are inherently connected. By systematically identifying, analyzing, and mitigating risks, organizations can enhance the reliability of their systems and increase the likelihood of mission success. Effective risk management not only addresses immediate technical challenges but also fosters long-term programmatic stability, ensuring that resources are utilized efficiently and effectively throughout the project lifecycle. By integrating risk management with reliability efforts, organizations can foster long-term stability and enhance the overall success of their programs.

Failure Mode and Effect Analysis (FMEA)

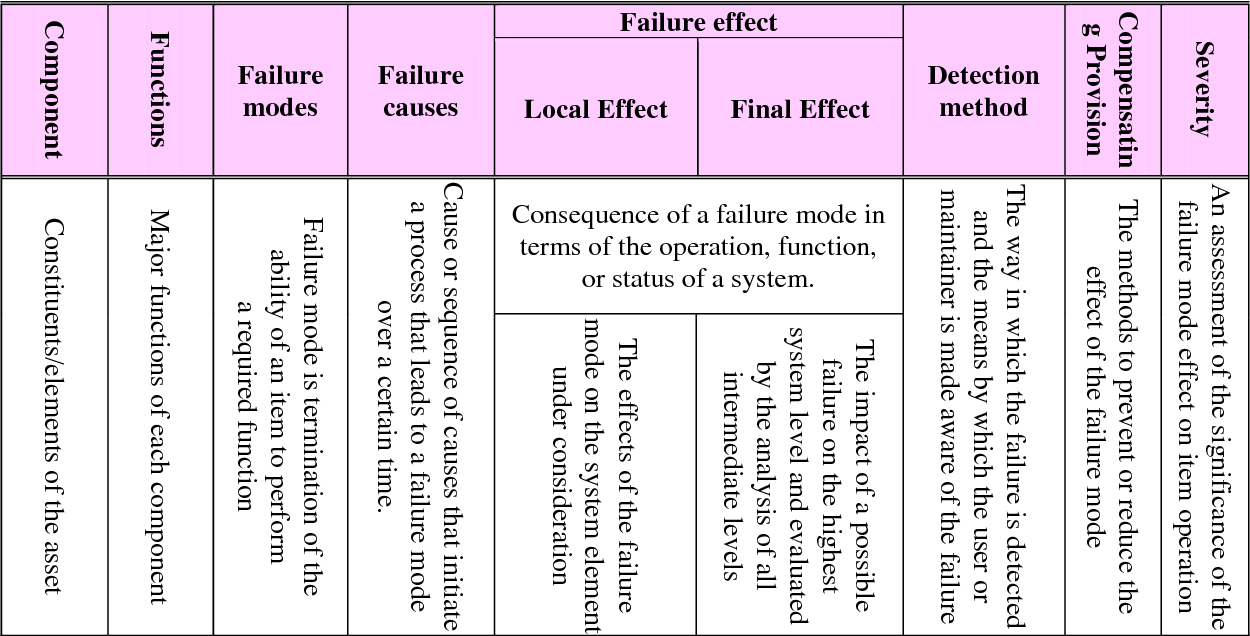

Failure Mode and Effect Analysis (FMEA) is a systematic, step-by-step approach for identifying and analyzing potential failure modes in a system, process, or product and evaluating their effects. The aim is to identify areas where failures are likely to occur, determine the severity of their consequences, and take corrective measures to eliminate or minimize risks.

Failure Mode and Effect Analysis (FMEA) is a bottom-up approach that identifies potential failure modes at the component or subsystem level and evaluates their effects on the overall system. Unlike FTA, which starts with a top event, FMEA begins at the ground level, analyzing each component for potential failure. The FMEA process is a bottom-up approach to system analysis, In other words, it analyses the system from the lowest level of the components and determines which components may fail, how and why they fail and what the effects of these failures on the system are.

FMEA is typically used in the design and development phases, but it can also be applied during the operational life cycle to continuously improve system safety and reliability.

Steps in FMEA:

- Describe the System/Subsystem/Component: Break down the system into components and identify the functions of each part.

- Identify Failure Modes: For each component, identify all possible failure modes. Failure modes might include issues like short circuits, material fatigue, or software bugs. Input from various teams (e.g., design, manufacturing, and quality control) is often necessary. The information of failure modes can be achieved from different units such as design, manufacture, assembly, quality control and installation along with using references of similar experiences.

- Assess the Effects: Determine the consequences of each failure mode. This assessment should include the impact on system performance, safety, mission success, and personnel/equipment safety.

- Determine Causes: Identify the root cause(s) of each failure mode. This step often involves cross-disciplinary collaboration, as different failure modes may have diverse causes.

- Evaluate Severity, Occurrence, and Detection: Each failure mode is evaluated in terms of severity (how critical the failure is), occurrence (how likely it is to happen), and detection (how easily it can be detected). These values are used to calculate a Risk Priority Number (RPN):RPN=Severity×Occurrence×Detection

- Mitigate Failures: Based on the RPN, failures are ranked in order of priority, and mitigation actions are developed to reduce the risk of high-priority failures. After mitigation, the RPN is recalculated to ensure that the risk is acceptable. Then the failures which are critical for the success of the mission are specified and ranked according to their severity.

Application in Mission-Critical Systems:

In mission-critical systems such as aerospace, medical devices, or automotive industries, FMEA ensures that every potential failure point is identified early, and its impact on safety and functionality is minimized. For instance, in aerospace, FMEA might be used to examine the potential failure modes in aircraft navigation systems or engine components to ensure that any faults are detected and resolved before they compromise the entire system’s operation.

FMEA is especially valuable because it allows engineers to prevent failures before they occur, making it an essential tool in the proactive maintenance of systems where even a small failure can have catastrophic results.

Some key applications of this technique include:

- Reducing product development time and costs by identifying potential issues early

- Aiding in the selection of optimal system designs

- Determining the necessary system redundancy for improved reliability

- Identifying effective diagnostic procedures for failure detection

- Prioritizing design improvements based on failure severity and likelihood

- Highlighting critical or significant system characteristics for focused improvement

- Listing potential failure modes and evaluating the magnitude of their effects

- Providing a foundation for developing test programs during both the development and validation phases

- Offering historical documentation to assist in analyzing field failures and guiding future design, process, or service modifications.

Failure Modes and Effects Analysis (FMEA) in Nuclear Security

Example 1: Reactor Cooling System Failure

- Failure Mode: A failure in the reactor’s cooling system could lead to overheating and potential core meltdown.

- Effect: If the cooling system fails, the reactor may reach unsafe temperatures, resulting in a critical incident.

- Mitigation Measures: Implement redundant cooling systems, regular maintenance schedules, and real-time monitoring systems to detect anomalies early.

Example 2: Control Room Staffing Failure

- Failure Mode: Insufficient staffing or inadequate training in the control room can lead to improper responses to emergencies.

- Effect: In a critical situation, the lack of trained personnel could result in delayed or incorrect actions, escalating the severity of an incident.

- Mitigation Measures: Establish comprehensive training programs and maintain minimum staffing levels to ensure proper response capability.

Satellite Communication Payload Failure Effects and Reliability Improvement

In a satellite communication payload, the key components include the RX block (with input waveguide filter, low noise amplifier (LNA), and coupler), Down Converter block (comprising oscillator, phase-locked loop, filters, isolators, mixers, and amplifiers), and IMUX block (with circulators, waveguide filters, and coaxial switches). Other critical blocks include the High Power Amplifier (HPA), made of channel amplifiers (CAMP) and traveling wave tube amplifiers (LTWTA), the OMUX block (waveguide filters and switches), and the harmonic filter block with low-pass filters. Failures in any of these components can disrupt the satellite’s communication capabilities.

To improve the system’s reliability, measures such as redundancy, rigorous pre-launch testing, and better parts selection are essential. Identifying potential failure modes and assessing their severity allows for the development of a critical items list, guiding preventive and compensatory strategies. The likelihood of failure can be reduced by refining the design and enhancing technical conditions. Regular detection and monitoring systems can also play a key role in identifying potential issues early, thus reducing the probability of failure and maintaining a desired reliability of over 95%.

Fault Tree Analysis (FTA)

What is FTA?

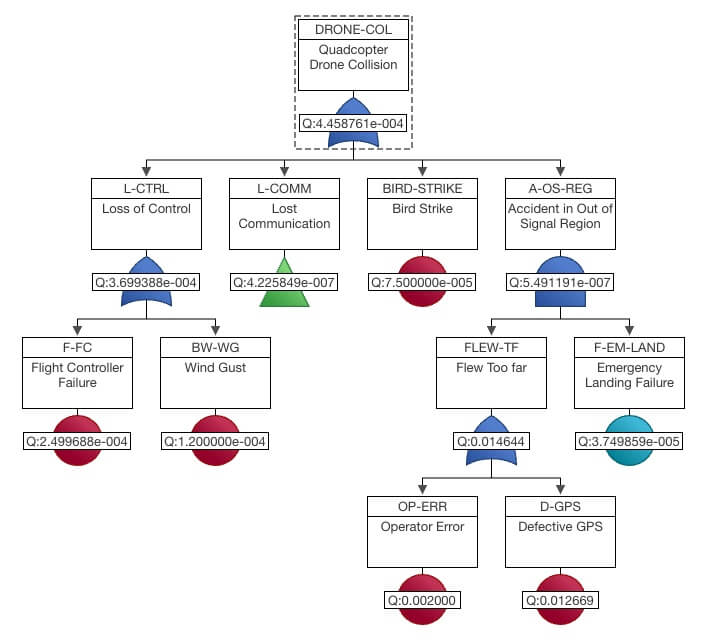

Fault Tree Analysis (FTA) is a top-down, deductive approach used to identify the root causes of system failures. It starts with a “top event” (typically a failure or fault) and works backward to identify all the potential causes. Fault tree analysis (FTA) is a graphical tool to explore the causes of system level failures.

Fault Tree Analysis (FTA) is a Risk Management tool that assesses the safety-critical functions within a system’s architecture and design. It analyzes high-level failures and identifies all lower-level (sub-system) failures that cause it. It is represented visually using a fault tree diagram, where the top event (usually a system failure or hazard) is linked to potential causes, branching downward. FTA aims to systematically break down the root causes of system failures and analyze how they interact.

FTA is often used in risk assessment, root cause analysis, and reliability engineering to provide a deeper understanding of how complex systems can fail and how these failures can be avoided. FTA is commonly applied in high-risk industries such as aerospace, nuclear, and defense, where understanding the root cause of failure is crucial for system safety

Fault Tree Analysis (FTA) can be applied both to existing systems and systems under development. In the design phase, where specific data may not yet exist, FTA uses generic data to estimate the probability of failures and identify key contributors to potential system malfunctions. This allows engineers to bracket design components and concepts, helping to shape a performance-based design that accounts for possible risks and failures early on.

During the product design phase, FTA serves as a valuable tool for evaluating a system’s reliability and fault probability. It helps define performance reliability requirements aimed at reducing the likelihood of undesired events. When applied to an existing system, FTA can identify vulnerabilities, evaluate potential system upgrades, and monitor ongoing system behavior. Additionally, FTA is useful in diagnosing the causes of observed failures and determining corrective actions, providing a comprehensive framework for both preventative and reactive reliability management.

Fault tree construction

Fault trees are built using gates and events (blocks). The two most commonly used gates in a fault tree are the AND and OR gates. As an example, consider two events (called input events) that can lead to another event (called the output event). If the occurrence of either input event causes the output event to occur, then these input events are connected using an OR gate. Alternatively, if both input events must occur in order for the output event to occur, then they are connected by an AND gate.

Steps in FTA:

Application in Safety-Critical Systems:

In safety-critical industries like nuclear energy, healthcare, or defense, FTA is essential for analyzing and mitigating hazards that could lead to accidents or malfunctions. For example, in nuclear power plants, FTA may be used to analyze the potential failure of safety systems, such as emergency cooling systems or reactor shutdown mechanisms, and determine the probability of these failures leading to an uncontrolled release of radiation.

FTA is particularly valuable in safety-critical systems because it visualizes how different failure points interact to cause a critical failure. By identifying these failure chains, engineers can develop robust safety protocols to prevent high-impact incidents.

One of the main benefits of FTA is that it shows how various combinations of events can lead to a major undesired state, and furthermore, a fault tree can reveal relationships between events across different subsystems. Because individual parts of the system are usually designed by separate teams and integrated only after each part is completed, it can be difficult to predict how the parts will interact with one another once they are incorporated into a single system. Thus, identifying how the interactions between subsystems can lead to undesired events is one of the most powerful applications of FTA

Fault Tree Analysis (FTA) in Nuclear Security

Example 1: Security Breach Leading to Unauthorized Access

- Top Event: Unauthorized access to the nuclear facility.

- Contributing Factors:

- Failure of Surveillance Systems: Malfunctioning cameras or alarm systems.

- Inadequate Physical Barriers: Weaknesses in fencing or entry points.

- Insider Threats: Employees or contractors with malicious intent.

- Mitigation Strategies: Enhance surveillance technology, strengthen physical barriers, and conduct regular background checks on personnel.

Example 2: Radiation Leak Due to Equipment Failure

- Top Event: Radiation leak from a nuclear reactor.

- Contributing Factors:

- Failure of Containment Structures: Cracks or weaknesses in containment vessels.

- Malfunction of Safety Valves: Inability to close properly during emergencies.

- Inadequate Maintenance Protocols: Failure to perform regular inspections and maintenance on critical components.

- Mitigation Strategies: Regular inspections of containment structures, investment in advanced monitoring systems, and strict adherence to maintenance schedules to prevent equipment failures.

FMEA vs. FTA: Complementary Tools for Risk Management

While FMEA and FTA have distinct approaches, they are often used together in comprehensive safety analyses to cover both bottom-up and top-down risk assessments.

- FMEA is ideal for identifying potential failures early in the design process, focusing on individual components and processes. It helps prevent failures by addressing issues before they manifest in the system.

- FTA provides a broader view of how system failures can occur by tracing the root causes of a critical event. It allows for a top-down analysis, providing insight into how different failure modes can combine to result in an undesirable outcome.

Advantages of Fault Tree Analysis (FTA):

Fault Tree Analysis provides a visual representation of system failures, enabling teams to logically analyze the causes of an event leading to failure. It highlights critical components linked to system breakdowns, making it an efficient method for system analysis. FTA is unique in its ability to include human errors in the analysis, unlike some other methods. Additionally, it helps prioritize action items to address the root causes of issues, offering both qualitative and quantitative analysis for decision-making.

Disadvantages of Fault Tree Analysis (FTA):

A key drawback of FTA is that it focuses on only one “top event,” limiting its scope. For complex systems, FTA can become cumbersome with too many gates and events to consider. Furthermore, it struggles to capture common cause failures and time-related or delay factors, which can affect the accuracy of the analysis in dynamic systems.

Comparison with FMECA:

Fault Tree Analysis (FTA) and Failure Mode, Effects, and Criticality Analysis (FMECA) are complementary risk analysis methods, with the choice depending on the type of risk being assessed. FTA is simpler as it focuses on potential system failures leading to a top undesired event, while FMECA evaluates all possible failure modes without regard to their severity. FTA, being a top-down approach, is prone to misinterpretation at lower levels, whereas FMECA, starting from the lowest level, provides a more detailed risk assessment. However, FMECA only considers single failures, while FTA takes multiple failures into account, which impacts the accuracy and scope of both methods.

Using both tools in tandem offers a more complete view of system reliability and safety, especially in complex mission-critical and safety-critical systems. FMEA prevents failures from occurring at the component level, while FTA ensures that complex interactions leading to catastrophic failures are addressed.

Conclusion: Strengthening Mission-Critical and Safety-Critical Systems

In industries where the cost of failure is immense—whether it’s a satellite system in aerospace, a nuclear reactor, or a life-support machine in healthcare—comprehensive safety analysis is essential. FMEA and FTA provide a powerful combination of tools to help engineers and program managers avoid potential errors, failures, or defects. While FTA offers a top-down view of system failures, FMEA provides a bottom-up approach, ensuring that all potential failure modes are accounted for. Together, these tools play a vital role in maintaining the reliability and safety of complex defense systems, ensuring that mission success is achieved even in the most challenging environments. By systematically identifying and addressing risks, these methodologies ensure that mission-critical and safety-critical systems remain reliable and resilient in the face of operational challenges. Embracing these safety analysis tools not only reduces risks but also builds trust and confidence in industries where the stakes are high, ensuring the safety of people and the environment while maintaining optimal system performance.

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis