3D printing or additive manufacturing is ongoing revolution in manufacturing with its potential to fabricate any complex object and is being utilized from aerospace components to human organs, textiles, metals, buildings and even food. 3D printing is also revolutionizing defence by printing small components to full drones on naval vessels, replacement parts for fighter aircrafts to printing ammunition.

“From an engineering-design perspective, a significant benefit to advanced manufacturing is the potential to decrease design limitations imposed by traditional manufacturing methods such as design-for-performance – not just manufacturability,” said Maj. Gen. Darren Werner, Commanding General, U.S. Army Tank-automotive and Armaments Command (TACOM). “In the Army, we are working to manufacture parts and components with lighter, stronger materials and produce complex components as one piece, thereby reducing failures while increasing reliability. All of those benefits increase readiness, which gets to the core of our mission.”

Leaders from across the Army gathered at Auburn University in June 2021 to hear from industry members, academia, and standards-developers on best practices for certifying and qualifying parts produced through additive manufacturing. The process to certify a part for use is important; Warfighters’ safety and the reliability of military equipment depends upon components that will hold up to the heavy demands that combat operations put them through. When these components are manufactured in a new way, like through additive manufacturing, they are heavily studied and scrutinized against established standards.

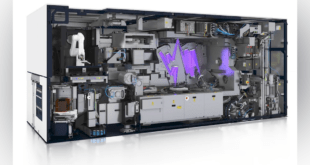

The summit placed a special emphasis on metal additive manufacturing, sometimes called “3D printing” and the special considerations using metal for this process requires. Michael Cadieux is the Director of the U.S. Army Combat Capabilities Development Command (DEVCOM) Ground Vehicle Systems Center. Along with TACOM and its Rock Island Arsenal-Joint Manufacturing and Technology Center, GVSC recently entered an agreement with ASTRO America to build one of the world’s largest 3D printers; a printer large enough to manufacture a ground vehicle’s hull in one piece.

“GVSC remains at the forefront of support to Army’s readiness through our aggressive pursuit of Advanced Manufacturing capability,” said Cadieux. “Advanced Manufacturing’s sustainment efforts, working with our TACOM partners, determine what current parts can be made more efficiently with advanced manufacturing while retaining the quality standards of the original part. Ground-floor prototype design of parts, coding advanced manufacturing equipment, and the process of iterative adjustments to these designs can provide replacement parts more quickly and smoothly through the logistics chain.”

Also presenting at the summit were representatives from General Electric. Representing an industry member who has successfully navigated the certifying and qualifying process for additively manufactured fuel nozzles, GE was able to share their experiences in ensuring their part met the necessary quality standards.

Beyond U.S. Army participants, representatives and subject matter experts attended from NASA’s Marshall Space Flight Center (NASA has also successfully certified and qualified additively manufactured parts), the Federal Aviation Administration, Auburn University, and Wichita State University.

Requirements

Qualification and certification of AM processes and components have been and continue to be a challenging but high-level priority for DoD. Before the potential of AM can be realized within DoD, qualification and certification procedures for targeted components must be developed and demonstrated.

Specifically, there is a need to investigate the testing and evaluation techniques appropriate for 3D printed parts. For example, the traditional shipboard parts are required to have certain military specifications (MILSPEC) in order to be utilized and are then tested to ensure that they meet those parameters. Typical MILSPEC inspection involves destructive tests that ensure that the manner in which the part is built and constructed satisfies the potential austere environments it could face onboard a ship. This process is the foundation of both safe and reliable parts that are purchased and used in the Navy.

The reason that 3D printed parts are currently not able to be used on naval ships to their full capacity is because of the way they are created; it skirts around the entire process that is currently in place. There is no mechanism to assess whether or not these AM parts are more or less compliant with established MILSPECs than traditional subtractively manufactured parts. Qualifying and certifying AM parts for use in flight safety critical applications is a challenge given the strict manufacturing quality requirements for aerospace.

The need to qualify and certify additively manufactured parts is a fundamental barrier to more extensive use of AM across platforms. With AM, the resultant properties of the part are determined by the material, the processing and the component geometry simultaneously, making

qualification and certification very complex.

The complexity of AM processes, coupled with the sheer variety of materials and applications being explored within DoD, make advancing the qualification and certification of AM difficult. One of the major challenges facing the Navy as they work towards implementing 3D printing into the maintenance realm is the vast number of both materials and machines that are available. Not just any machine can be utilized to create a part based on what materials it can print and the resolution and accuracy of the printer. The part must be made out of materials that are safe for shipboard use in regards to toxic gas production, smoke production as well as melting and burn characteristics.

In addition to there being an overwhelming combination of 3D printing machines, printing styles and materials, an aspect that plays a large part in a printed item’s strength are the print settings and orientation. Some of the most important printer settings include the extruder temperature, printer bed temperature, extruder volume per second, extruder diameter, distance from the extruder to the bed, print speed, slice height, percent infill, position on printer bed, layer height, base layer type and support configuration.

Overarching trends in AM at DoD include considerable work on the following topics as related to AM:

• Materials: Qualification, standards, and availability

• Processes: Validation, qualification, standards, configuration control, and repeatability

• Components: Validation, qualification, and integration into supply chains

Qualification and standards

Office of Naval Research effort analyzes both integrated computational materials engineering (ICME) approaches to predict and evaluate AM resultant material properties and evaluate closed loop feedback strategies to make processes more repeatable and reliable.

The right material choice for the application and post heat treatment (based upon part geometry and function) are critical to ensure desired mechanical properties can be achieved. The USAF approach for developing AM material standards that produce optimum material properties is based upon a realization that successful AM is a marriage between the material, the type of AM machine, machine settings, post processing steps, and sometimes redesigning parts for AM. To that end, USAF is currently developing an enterprise material properties database based on the AM machine, optimized process parameters and the powder characteristics (i.e., Particle size distribution, powder shape, and flow characteristics). All critical factors are being identified, captured and incorporated into an AM design rule guidebook to reduce duplication and ensure the engineering/design community leverages best practices and lessons learned.

ASTM standards

American Society for Testing and Materials, the “international standards organization that develops and publishes voluntary consensus technical standards for a wide range of materials, products, systems, and services. ASTM maintains the standards to which the additively manufactured components and the processes that built them must meet or exceed.

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis