In the UK, there are some 7,000 people on the list who are in dire need of organ transplants and In the US, the number awaiting transplant is around 120,000, with 20 dying each day for want of an organ. There is a large and growing need for an alternative to …

Read More »3D Printing revolutionising aerospace propulsion by production of motors & Rockets

3D printing or additive manufacturing is ongoing revolution in manufacturing with its potential to fabricate any complex object and is being utilized from aerospace components to human organs, textiles, metals, buildings and even food. Additive manufacturing is defined by ASTM International as the process of joining materials together, layer by …

Read More »Vehicle Manufacturing trends

Vehicle manufacturing has come a long way since 1908 when Henry Ford began production of the Model T automobile using a mass production assembly line.

Read More »Thermoplastic Welding for commercial and military aircrafts

The composites industry is constantly being shaped and reshaped by myriad forces – people, markets, technologies – all stimulating innovative new ways to apply fiber-reinforced materials in everything from boats and wind blades to airplanes and automobiles Thermoplastics are synthetic plastics that can be melted, shaped, and cooled to …

Read More »MEMS Manufacturing

Mechanical-Systems (MEMS) is the integration of mechanical elements (levers, springs, deformable membranes, vibrating structures, etc.), sensors, actuators, and electronics (resistors, capacitors, inductors, etc.) on a common silicon substrate through microfabrication technology. MEMS devices are today considered as one among the most promising technologies of this century, capable to revolutionize the …

Read More »Protein A Resins Market

Most antibody drugs treat cancer and autoimmune diseases, and many of the rest are used to treat orphan and infectious diseases. Unfortunately, antibodies are complex proteins in many ways, which complicates their purification and characterization, making it difficult for their developers to meet the rigid requirements for therapeutics. Process …

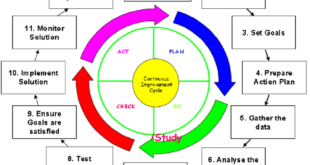

Read More »ISO 9001:2015 Quality management systems

Within a global economy with enormous and fierce competition, the survival and development of a company depend on its ability to attract customers, make them loyal, and above all, constantly, exceed their expectationss and desires, in order to retain them. Quality standards provide requirements, specifications, or guidelines that can …

Read More »ARPA-H will Accelerate biomedical breakthroughs on lines of DARPA

The biomedical research system has historically been supported by two main pillars: fundamental research on the mechanisms of disease, largely funded by the National Institutes of Health (NIH), and the pharmaceutical industry, which creates products to treat these conditions. Recent advances in biomedical research and health sciences present an opportunity …

Read More »Biomimicry or Biomimetics to solve humanity’s Biggest Challenges through nature’s Proven Solutions

The field of biomimicry, also known as biomimetics, seeks to emulate nature with technology. Biomimicry or biomimetics examines nature, its models, systems, processes, and elements to emulate or take inspiration from to solve human problems. Humans have always looked to nature for inspiration to solve problems. From a drone …

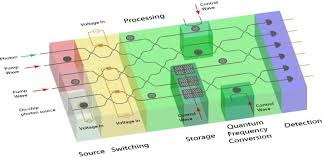

Read More »Photonic Integrated Circuits technologies promise Quantum computers and sensors, as system-on-chip solutions integrated into laptops and cell phones.

Photonics is a breakthrough technology as it uses photons (smallest unit of light) as the data carrier instead of electrons (smallest unit of electricity) used in electronic ICs. As light travels very high speeds, photonics is widely used to transfer huge amounts of data at a very high speed. Thus …

Read More » International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis