From Plastic Waste to Building Power: The New Materials Reinventing Construction

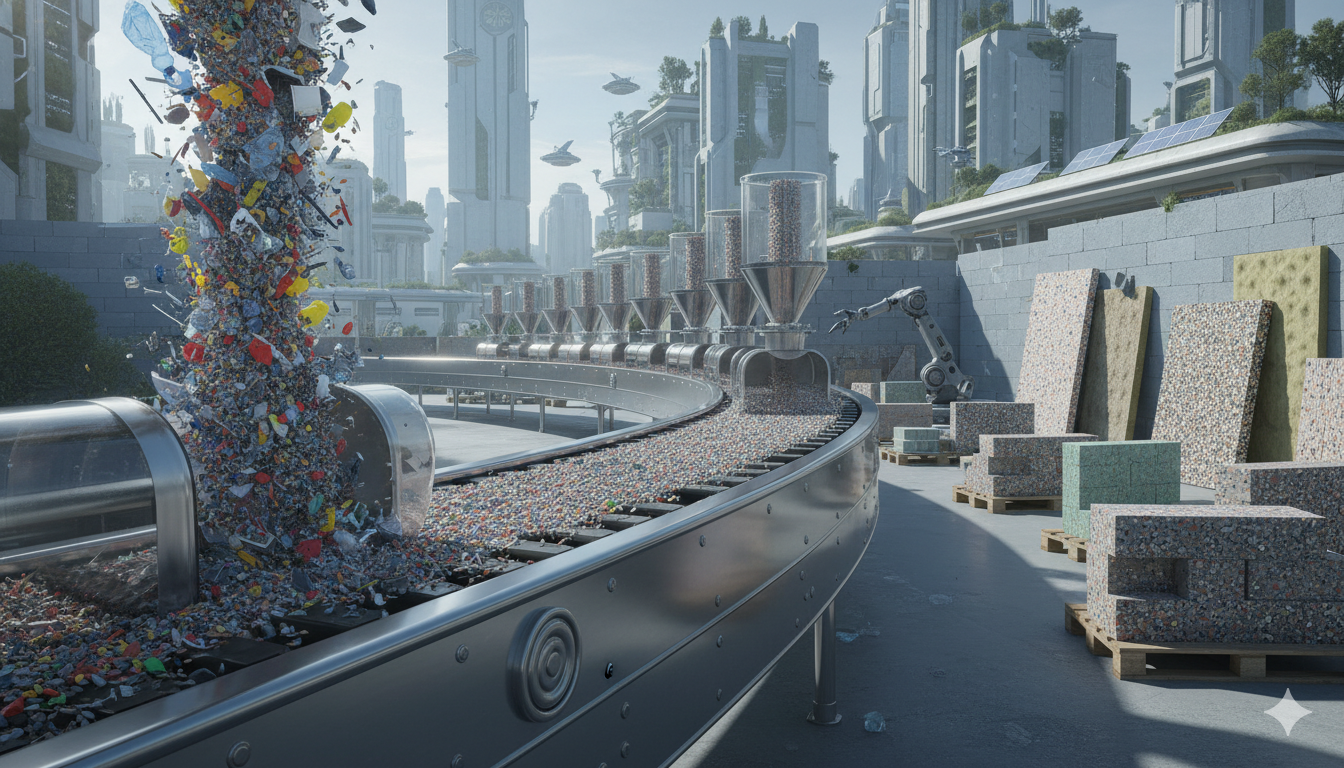

How breakthrough eco-aggregates and plastic-based composites are transforming global waste into the foundation of tomorrow’s sustainable cities.

Plastic waste has long been the stark emblem of our disposable economy. Yet, a profound shift is underway, transforming this environmental liability into a valuable resource. While innovators are already upcycling discarded bottles into sneakers and furniture, the most impactful evolution is happening in the construction industry. The sector, one of the world’s largest consumers of raw materials and a significant carbon emitter, is now witnessing a revolution powered by plastic waste, led by advanced materials like RESIN8 that are redefining the very foundations of sustainable building.

The Converging Crises: A Singular Opportunity

The scale of the plastic problem is staggering, with annual production exceeding 400 million tons and a dismal recycling rate of just 9%. This tidal wave of waste chokes our oceans and landfills. Simultaneously, the construction industry’s insatiable appetite for sand and gravel—consuming 50 billion tons annually—drives ecosystem degradation and accounts for a substantial portion of global CO₂ emissions. These two crises are converging into a single opportunity, where the waste of one industry becomes the lifeblood of another, creating a powerful circular economy model.

The Evolution of Upcycling: Beyond Traditional Recycling

Moving beyond traditional recycling, which often downcycles plastic into lower-value products, true upcycling creates materials with enhanced performance and longevity. In infrastructure, countries like India have paved thousands of kilometers of roads using plastic-modified asphalt, improving durability and reducing maintenance costs. The frontier of this movement now lies in advanced composites and aggregates that integrate plastic waste directly into structural building components, offering scalable, long-lasting solutions.

RESIN8: A Technological Leap in Eco-Aggregate

At the forefront of this movement is RESIN8, a proprietary material developed by CRDC Global. Unlike conventional recycling, RESIN8 transforms 100% mixed plastic waste—including non-recyclable types—into engineered, mineral-polymer aggregates suitable for concrete. Its thermal-mechanical process produces a lightweight, inert material that integrates seamlessly into standard concrete mixes. The benefits are substantial: up to 15% lighter concrete, lower transportation emissions, and less energy consumption than traditional recycling. Real-world applications—from earthquake-resilient housing in Costa Rica to community-led building projects in South Africa—are validating its performance.

Global Momentum and Emerging Innovations

The movement is accelerating worldwide. ByFusion produces construction-grade blocks from unsorted plastics, while Trex has popularized composite lumber for decking. Nonprofits like New Story are pioneering 3D-printed homes using plastic-based polymers, cutting build times and waste. In Europe and the Netherlands, researchers are experimenting with biohybrid concrete combining plastic aggregates with self-healing biocements, while at the University of Manchester, stabilized graphene oxide membranes enable ultra-low-energy composite production. These innovations demonstrate a clear trend toward more durable, sustainable, and carbon-efficient construction materials.

Overcoming Barriers and Scaling Solutions

Challenges remain: processing toxic plastics, sourcing renewable energy for thermal conversion, and navigating slow-moving building codes. Yet, international standards are evolving, AI-powered sorting improves feedstock quality, and corporate partnerships—like CRDC Global’s collaboration with Holcim—signal mainstream adoption. Collectively, these solutions are making plastic upcycling economically viable, scalable, and socially impactful, particularly in regions where plastic pollution and housing shortages intersect.

The Future Built on Plastic

Looking ahead, plastic-based construction materials have the potential to divert over 150 million tons of waste annually, reduce global construction emissions by an estimated 5%, and empower communities to turn waste into essential infrastructure. Blockchain and traceability systems are enabling transparent supply chains, incentivizing recycling, and ensuring accountability from collection to finished building component. This integrated approach combines environmental sustainability, social impact, and circular economy principles, pointing toward a future where plastic is a cornerstone of resilient cities.

Conclusion: Redefining Waste, Rebuilding Our World

Plastic is not the enemy; it is a resource catastrophically mismanaged. The breakthroughs in plastic-based construction materials show that waste is a design flaw, not an inevitability. By re-engineering materials and integrating them into mainstream infrastructure, we can transform a global environmental challenge into the foundation for sustainable development. Individuals, businesses, and policymakers each have a role to play—supporting local upcycling programs, integrating recycled materials into supply chains, and updating building codes to encourage innovation. The blueprint for a sustainable, circular future exists; it is time to start building it.