Acoustic Metamaterials: Shaping the Future of Sound and Silence

From stealth submarines to silent cities, acoustic metamaterials are transforming how we hear—and don’t hear—the world around us.

Introduction

Acoustic metamaterials have emerged as a groundbreaking technology capable of manipulating sound waves in ways that traditional materials cannot. Initially developed for military and defense applications, they are now finding use in noise control, medical imaging, telecommunications, and advanced acoustics.

What sets acoustic metamaterials apart is their ability to bend, absorb, and redirect sound waves through engineered structures rather than relying on mass or density. This article explores not only the applications but also the latest technological advancements, materials, and fabrication techniques that are driving the evolution of acoustic metamaterials.

The Science Behind Acoustic Metamaterials

Metamaterials are engineered materials designed to control and manipulate physical phenomena such as electromagnetic waves, sound waves, and even seismic waves in ways that traditional materials cannot achieve. These materials exhibit exotic properties not found in nature, enabling groundbreaking applications in wave manipulation. One of the most intriguing possibilities of metamaterials is their potential to protect buildings from earthquakes by bending seismic waves around them, redirect tsunami waves away from coastal areas, and control sound waves to create completely soundproof environments. These capabilities stem from the ability of metamaterials to shape the propagation of waves by tailoring their structure at the micro and nanoscale.

Acoustic metamaterials are engineered to manipulate sound waves at scales smaller than their wavelengths, enabling unprecedented control over wave propagation. Unlike conventional materials that rely on absorption or reflection, these metamaterials leverage their precisely designed geometric structures—rather than their chemical composition—to achieve unique acoustic properties. By carefully arranging unit cells within a structured lattice, researchers can tailor how sound waves interact with the material, leading to effects such as sound bending, cloaking, and selective filtering.

One of the most significant breakthroughs in acoustic metamaterials is their ability to exhibit negative bulk modulus and negative density, which are impossible in naturally occurring substances. Negative bulk modulus allows the material to control sound wave compression, effectively dampening pressure variations. Negative density enables wave redirection, creating acoustic cloaking effects that can render objects undetectable to sound waves. Additionally, these materials can form bandgaps, preventing specific frequencies from propagating, making them highly effective for noise shielding in industrial and urban environments. Compared to traditional soundproofing materials, which rely on mass and thickness for absorption, acoustic metamaterials achieve superior noise control with lightweight, compact designs, revolutionizing applications in architecture, aerospace, and medical acoustics.

Applications of Acoustic Metamaterials

In recent years, the metamaterial concept has been extended to acoustic waves, leading to revolutionary applications in acoustic cloaking, super-lensing, and precise sound confinement. Acoustic metamaterials are artificially structured materials designed to manipulate and control sound waves in ways that conventional materials cannot. Their unique properties arise from their engineered internal structures, which allow them to interact with sound waves differently than natural materials. Unlike traditional soundproofing methods that rely on bulk materials, acoustic metamaterials achieve superior noise reduction while remaining lightweight and compact. Their potential applications include noise cancellation in urban environments, sound cloaking for submarines, and precise acoustic focusing for medical imaging and therapeutic applications.

A significant breakthrough in sound attenuation has been achieved through acoustic metamaterials composed of thin elastic membranes embedded with patterned rigid platelets. These materials have demonstrated exceptional sound absorption capabilities and can be engineered to create acoustically “dark” materials, which effectively block sound waves. Additionally, they are being developed for vibration-dampening applications, offering new possibilities in industrial and automotive noise reduction. Military applications of acoustic metamaterials are also expanding, with potential uses in acoustic isolators (acoustic diodes), circulators, switches, and sensors, as well as in thermal management systems to control heat dissipation through phononic wave manipulation.

Noise Control in Urban and Industrial Settings

Acoustic metamaterials are revolutionizing noise control, sound manipulation, and structural engineering by offering lightweight yet highly effective soundproofing solutions. Traditional materials require significant mass to block low-frequency sound, but recent advances have overcome this limitation.

Urban noise pollution has become a significant challenge in modern cities, affecting quality of life, health, and productivity. Traditional noise barriers rely on thick and heavy materials, making them impractical for many environments where space, weight, and aesthetics are constraints. Acoustic metamaterials offer a groundbreaking alternative by providing lightweight, ultra-thin soundproofing solutions that effectively eliminate unwanted noise without the bulk.

One of the most promising applications of acoustic metamaterials in noise control is their ability to target specific frequency ranges, allowing for the selective elimination of disruptive sounds from highways, airports, and railways. Unlike conventional materials, which block all sound indiscriminately, these metamaterials can be tuned to cancel out only the most problematic noise frequencies while allowing other sounds, such as emergency signals, to pass through. This capability is particularly beneficial for urban environments where complete sound isolation is neither practical nor desirable.

In addition to public infrastructure, acoustic metamaterials are revolutionizing indoor noise management by enabling the development of soundproof offices, hospitals, and residential buildings. These materials can be integrated into walls, ceilings, and partitions, creating ultra-thin noise barriers that enhance privacy and comfort without sacrificing space. Furthermore, advancements in metamaterial-based soundproofing have led to the creation of silent HVAC and ventilation systems, which are essential for hospitals, recording studios, and other noise-sensitive environments.

Chinese researchers, including N. Sui and Y. Jing, have developed a honeycomb acoustic metamaterial that provides exceptional sound insulation with minimal weight penalty. This innovation utilizes no-mass-attached membrane-type metamaterials, making it ideal for aerospace, automotive, and transportation industries, where weight reduction is crucial. These materials can be integrated into sandwich structures that offer enhanced noise reduction, making them particularly useful for aircraft fuselages, high-speed trains, and urban noise barriers.

Active Metamaterials: Real-Time Tunability and Applications

Traditional acoustic metamaterials are typically designed with fixed properties, limiting their adaptability across different applications. To address this, researchers from Duke University’s Department of Electrical and Computer Engineering have developed active metamaterials that allow real-time reconfiguration of their acoustic properties without altering their physical structure. By integrating digital electronics, these metamaterials can dynamically adjust their response, enabling unprecedented control over sound waves. This breakthrough paves the way for highly versatile acoustic systems, as a single metamaterial can function as both a lens and a beam-steering device, depending on real-time requirements.

The team demonstrated this by designing a metamaterial slab that acted as a thin, tunable acoustic lens, manipulating consecutive sound pulses in different ways. This ability to dynamically reshape acoustic waves has profound implications, particularly for acoustic imaging technologies, such as second harmonic imaging systems that surpass the diffraction limit of conventional lenses. Beyond imaging, active metamaterials could revolutionize sonar, medical ultrasound, and noise control systems. Additionally, French researchers are exploring similar concepts for seismic wave redirection, using metamaterials to create earthquake shields that could protect buildings by deflecting destructive acoustic waves away from structures. These advancements highlight the immense potential of active metamaterials in enhancing imaging, communications, and structural safety in real-world applications.

A major breakthrough in this field comes from researchers at the University of Hong Kong, who have developed tunable acoustic panels capable of selectively blocking traffic and construction noise without obstructing airflow. This innovation marks a game-changing development in urban planning, offering a solution that reduces noise pollution while maintaining natural ventilation in densely populated areas.

Military Applications

Acoustic metamaterials have significant military applications, particularly in sonar evasion, stealth technology, and noise suppression. These materials can be used to create acoustic cloaks for submarines and naval vessels, bending sonar waves around the object to make it effectively invisible to detection. Additionally, they can enhance stealth aircraft and vehicles by minimizing acoustic signatures, reducing the risk of detection by enemy forces. Acoustic metamaterials also play a role in battlefield communication systems, where they can be engineered to block or channel specific sound frequencies, improving security and clarity in hostile environments. Furthermore, these materials can be integrated into protective structures to absorb shockwaves from explosions, enhancing the survivability of military personnel and equipment. As research advances, acoustic metamaterials may redefine covert operations, surveillance, and defensive countermeasures, offering a new layer of strategic advantage in modern warfare.

Beyond military applications, researchers are also exploring metamaterials for structural protection and vibration control. Prof. Martin Wegener has developed a honeycomb-like metamaterial that deflects physical forces, effectively making objects beneath it “unfeelable.” French physicists expanded on this concept, showing that a carefully drilled pattern of holes could redirect seismic waves, potentially mitigating earthquake damage. These findings indicate that acoustic and mechanical cloaking technologies could have significant applications in civil engineering, disaster resilience, and infrastructure protection.

Additionally, metamaterials have the potential to enhance optical and acoustic technologies. By absorbing and redirecting light with high efficiency, these materials could improve fiber optic communication, microchip data transmission, and high-resolution ultrasound imaging. As Anthony Vicari of Lux Research suggests, such innovations could lead to faster computing and advanced optical networks. While acoustic cloaking has traditionally been associated with military stealth, its expanding applications in communications, medicine, and structural engineering highlight its transformative potential across multiple industries.

Noise-canceling

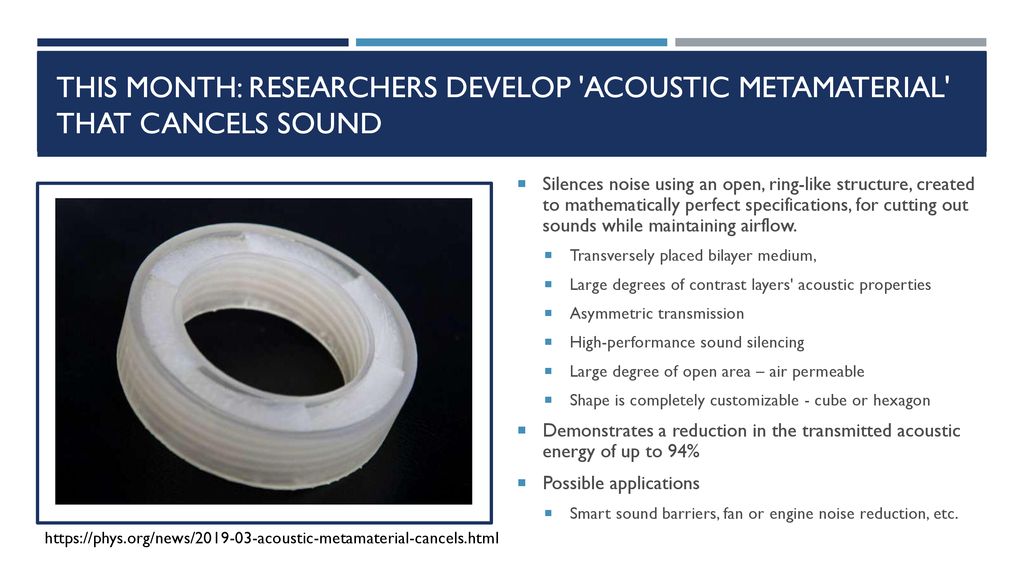

Researchers at Boston University, led by Xin Zhang and Reza Ghaffarivardavagh, have developed an acoustic metamaterial that cancels 94% of sound while allowing airflow to pass through. Their study, published in Physical Review B, demonstrates that a precisely designed, ring-like structure can effectively reflect sound waves back to their source, neutralizing noise without blocking ventilation. Using 3D printing, they fabricated an open-air, noise-canceling structure and tested it against loudspeaker-generated sounds. Their experiments confirmed that the metamaterial makes loud noises imperceptible to the human ear, opening new possibilities for noise control in real-world applications.

This innovation has broad practical applications, particularly in drone noise reduction. Companies like Amazon, exploring drone-based deliveries, face public concerns over noise pollution caused by rotor blades. The research team envisions integrating lightweight, sound-canceling metamaterial structures beneath drone fans to mitigate this issue. Additionally, these metamaterials could replace bulky highway noise barriers with aesthetic, permeable, and modular walls, improving urban landscapes. The technology also holds promise for medical applications, such as integrating metamaterial linings into MRI machines to shield patients from their loud vibrations. With customizable geometries, including hexagonal honeycomb structures, this breakthrough paves the way for next-generation architectural acoustics, transportation noise mitigation, and medical soundproofing.

Signal Amplification and Wave Manipulation

Beyond noise reduction, acoustic metamaterials are enhancing signal amplification and wave manipulation. Researchers from the University of Maryland’s A. James Clark School of Engineering, led by Miao Yu, have developed a metamaterial with a graded refractive index (GRIN) that amplifies acoustic signals over 10 times beyond conventional sensors. This compact and broadband metamaterial could significantly improve sonar technology, medical imaging (such as early cancer detection), and advanced acoustic sensing systems. Similarly, Harvard University’s Prof. Katia Bertoldi has engineered negative Poisson ratio materials, which contract in all directions when compressed and expand uniformly when stretched. These materials exhibit adaptive sound absorption properties, useful for applications such as tunable acoustic filters and fatigue-resistant engine components. Rolls-Royce, for instance, is exploring these materials to design engine parts with enhanced durability and resistance to stress cycles. With ongoing research, acoustic metamaterials continue to unlock new possibilities in transportation, defense, medical diagnostics, and industrial noise control.

Medical Imaging and Non-Invasive Therapeutics

The impact of acoustic metamaterials extends beyond noise control, significantly advancing medical imaging and non-invasive therapies. Traditional ultrasound imaging and focused ultrasound treatments face challenges related to sound wave distortion and limited penetration depth. By precisely controlling how sound waves propagate through biological tissues, acoustic metamaterials are improving ultrasound imaging resolution, leading to better diagnostics and earlier disease detection.

One of the most exciting applications is focused ultrasound therapy, which uses high-intensity sound waves to treat conditions such as kidney stones and tumors without the need for invasive surgery. By utilizing acoustic metamaterials, clinicians can enhance the precision and effectiveness of these treatments, reducing side effects and improving patient outcomes. Additionally, these materials enable wireless medical monitoring through acoustic wave-based biosensors, which have the potential to revolutionize wearable health technology by providing real-time, non-invasive tracking of vital signs.

A groundbreaking innovation in this domain comes from Stanford University, where researchers have developed an acoustic hyperlens that significantly improves ultrasound imaging. This technology enhances the ability of sound waves to penetrate deeper into tissue while maintaining high resolution, enabling earlier and more accurate detection of conditions such as cancer. The potential applications of this advancement extend to prenatal imaging, cardiovascular diagnostics, and even neuromodulation therapies.

Telecommunications and Directional Sound Control

The rise of 5G networks, smart devices, and AI-driven voice assistants has increased the demand for better sound transmission and noise management. Acoustic metamaterials are playing a crucial role in enhancing telecommunications by enabling highly directional sound transmission and improving signal clarity in noisy environments.

One of the most exciting developments in this field is the creation of personalized audio bubbles, a technology that allows sound to be directed to a specific individual without others hearing it. This innovation is being integrated into headphones, public announcement systems, and even automotive sound systems, allowing users to experience private, immersive audio without disturbing those nearby.

Acoustic metamaterials are also revolutionizing open-office environments, where excessive background noise reduces productivity and focus. By incorporating metamaterials into noise-canceling walls and partitions, companies can create zones of silence within shared workspaces, improving concentration and communication. These advancements are particularly beneficial in call centers, coworking spaces, and corporate offices where background chatter can be a major distraction.

Furthermore, smart acoustic coatings are being developed to enhance speaker and microphone performance, filtering out background noise for voice-controlled AI assistants and mobile devices. This technology is especially valuable for improving smartphone microphones, enabling clearer voice recognition in noisy environments.

A notable breakthrough in this field comes from researchers at ETH Zurich, who have developed metamaterial-based smartphone microphones that selectively filter out background noise while preserving speech clarity. This innovation has the potential to greatly enhance voice quality in digital communication, making voice calls, virtual meetings, and AI-assisted interactions more seamless and effective.

As acoustic metamaterials continue to evolve, their applications will expand across industries, shaping the future of urban development, healthcare, and telecommunications. These groundbreaking materials are not only redefining how we control sound but also opening new possibilities for innovation in areas ranging from stealth technology to immersive virtual experiences.

Technological, Engineering, and Manufacturing Challenges

Despite the remarkable advancements in acoustic metamaterials, several significant challenges remain in their development, large-scale engineering, and commercial manufacturing. These obstacles stem from the complexity of designing materials that precisely manipulate sound waves, the difficulty in achieving scalability, and the limitations of current fabrication techniques.

One of the primary technological challenges lies in the precise control of acoustic wave interactions. Acoustic metamaterials rely on intricate structures at the microscale to achieve negative refraction, sound redirection, or frequency filtering. However, designing these structures requires highly complex mathematical models and computational simulations, which can be computationally expensive and time-consuming. Additionally, real-world conditions, such as temperature variations, humidity, and mechanical stress, can alter the performance of metamaterials, making it difficult to achieve consistent results across different environments.

Duke University, in collaboration with MIT, UC Berkeley, Rutgers University, and the University of Texas at Austin, is part of a five-year research initiative sponsored by the US Office of Naval Research to develop real-world acoustic metamaterials. Led by Steve Cummer, a professor of electrical and computer engineering at Duke, the project leverages mathematical models and numerical simulations to optimize metamaterial designs before fabricating and testing them. A key focus of the research is creating acoustic metamaterial structures that can effectively control and transform sound waves in water-based environments, including underwater applications and medical technologies. The ability to manipulate sound arbitrarily, as demonstrated by acoustic cloaking structures, represents a natural evolution from earlier research in electromagnetic cloaking and transformation optics, which later extended into acoustic cloaking in air before transitioning to more complex 3D aqueous environments.

Designing for water presents unique challenges, as its mechanical properties differ significantly from air. Unlike air, where solid materials like plastic can act as rigid structures to guide sound waves, water’s mass density and compressional stiffness are much closer to that of solids, making the interaction between sound waves and materials more complex. This necessitates advanced multiphysics modeling to simulate how solid structures interact with water-based acoustic fields, ensuring fluid-structure interactions are accurately accounted for. Cummer emphasizes the need for new design techniques to control sound wave energy in water without losing desired metamaterial properties. Unlike airborne acoustics, where solid structures can be treated as infinitely rigid, underwater applications require a seamless integration of acoustics and structural mechanics to achieve the same level of precision and control. These advancements could lead to breakthroughs in sonar technology, stealth applications, and medical imaging by enabling highly efficient, tunable acoustic materials for complex aqueous environments.

From an engineering perspective, integrating acoustic metamaterials into existing industrial applications presents hurdles. For example, applying these materials in aircraft, automobiles, or urban noise barriers requires them to be lightweight, highly durable, and resistant to wear and tear. Many metamaterials are still fragile, especially those based on graphene, aerogels, or soft polymeric structures, which can degrade over time. Ensuring mechanical robustness while preserving acoustic properties remains a critical challenge in making these materials viable for long-term use.

Manufacturing these materials at commercial scale is another significant barrier. While 3D printing has enabled the production of intricate designs, current additive manufacturing techniques struggle to produce acoustic metamaterials with nanoscale precision at an industrial level. Mass production of these materials remains expensive, limiting their widespread adoption. Additionally, fabricating multi-functional metamaterials that combine acoustic, thermal, and electrical properties requires hybrid manufacturing techniques, which are still under development.

To overcome these challenges, researchers are exploring new material compositions, scalable manufacturing methods, and AI-driven design optimizations. Advancements in nanoengineering, microfabrication, and self-assembly techniques could pave the way for cost-effective, high-performance acoustic metamaterials in the near future. However, significant investments in research, infrastructure, and interdisciplinary collaboration will be required to transition these materials from laboratory innovations to mainstream commercial products.

Recent Technological Advancements in Acoustic Metamaterials

3D-Printed Acoustic Metamaterials

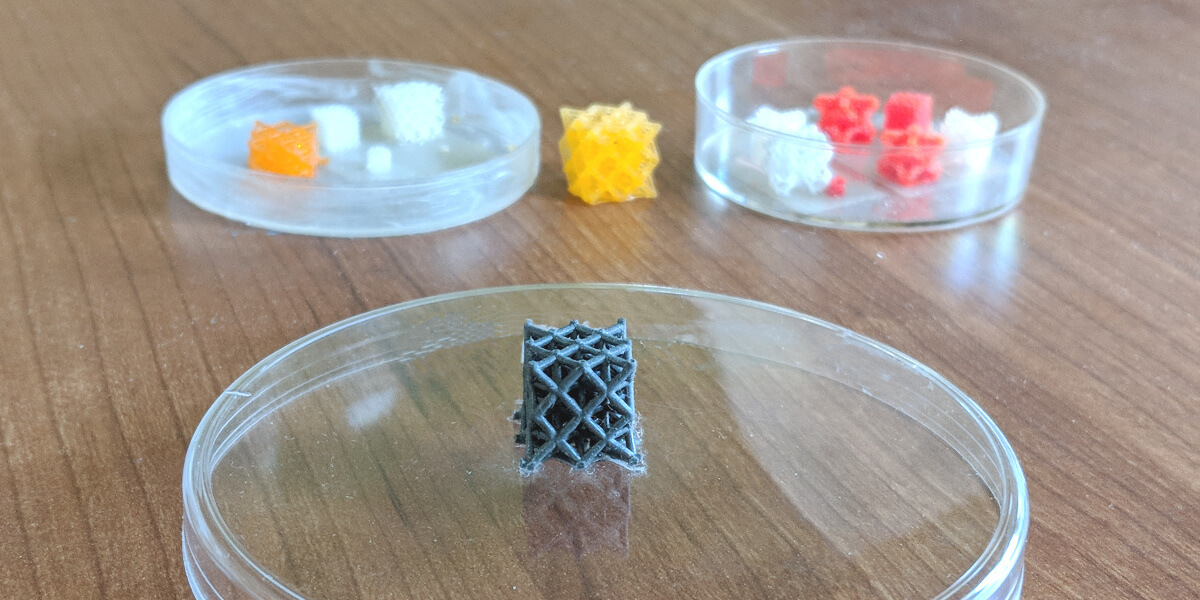

The adoption of 3D printing has significantly transformed the development of acoustic metamaterials by enabling the creation of intricate geometries at the microscale. This capability allows researchers to design and fabricate structures that effectively control sound waves while maintaining a lightweight and compact form. Traditional soundproofing materials often require substantial mass to block or absorb noise, but 3D-printed acoustic metamaterials achieve similar or superior performance with significantly less bulk. By leveraging computational design and additive manufacturing techniques, engineers have developed labyrinthine, honeycomb, and helical structures that manipulate sound waves with remarkable precision.

A research team at USC Viterbi, led by Assistant Professor Qiming Wang, has developed 3D-printed acoustic metamaterials that can be dynamically tuned to different frequencies. Unlike conventional metamaterials with fixed geometries and static frequency responses, these innovative structures can be remotely switched between active control and passive states using a magnetic field. This breakthrough enables real-time adaptability, allowing the materials to block or transmit sound waves and mechanical vibrations on demand. Wang highlights that most existing acoustic metamaterials are limited to specific frequency ranges, whereas the newly developed structures deform under magnetic fields, altering their geometries and function frequencies in a reversible and rapid manner.

The ability to tune acoustic properties dynamically is made possible through 3D-printed lattice structures infused with iron particles, which allow the metamaterials to compress under magnetic influence. The team employed two fabrication methods: direct printing of magnetic-particle-filled photoelastomers using a micro-projection stereolithography system and inverse printing, where a water-dissolvable scaffold is used to shape and cure the magnetic elastomer. Both techniques provide a high degree of design flexibility, enabling the creation of complex 3D architectures with precise acoustic control. Potential applications include switchable acoustic modules and filters for noise cancellation and sound optimization. For example, the technology could block unwanted noise while allowing desired sounds to pass through, making it valuable for personalized audio environments, architectural acoustics, and even advanced stealth technologies. By simply adjusting the magnetic field, users could selectively filter out background noise while preserving speech or music, offering a new level of acoustic control for consumer and industrial applications alike.

One of the most promising innovations in this field is the emergence of programmable acoustic metamaterials, which allow users to fine-tune their acoustic properties for specific noise frequencies. These materials can be dynamically adjusted to optimize sound absorption or reflection, making them suitable for various applications, including adaptive noise control in buildings and precision sound engineering in concert halls. Another breakthrough involves bio-inspired metamaterials, which mimic naturally occurring structures, such as butterfly wings and bird feathers, to enhance sound absorption. These biologically inspired designs not only improve efficiency but also contribute to the development of lightweight, environmentally friendly acoustic solutions.

Graphene-Based Acoustic Metamaterials

Graphene, a material celebrated for its exceptional strength, flexibility, and lightweight properties, is now at the forefront of acoustic metamaterial research. Due to its atomic-scale thickness and high mechanical resilience, graphene-based acoustic metamaterials offer unprecedented levels of sound attenuation while maintaining an ultra-lightweight form. Unlike conventional materials that rely on mass and density to block sound, graphene’s ability to manipulate sound waves arises from its unique atomic structure, which enables precise control over wave propagation.

One of the key advantages of graphene-based metamaterials is their ability to provide extreme sound attenuation with minimal weight, making them ideal for aerospace, automotive, and portable electronic applications where reducing weight is critical. Additionally, graphene’s enhanced thermal and electrical conductivity allows it to be integrated into smart noise-canceling systems, where soundproofing materials can dynamically adjust their properties in response to environmental conditions.

A significant breakthrough in this area was achieved by researchers at MIT, who developed graphene aerogels capable of blocking specific sound frequencies while remaining air-permeable. This innovation paves the way for advanced noise-canceling electronics and lightweight soundproofing solutions for the aerospace industry. By incorporating these aerogels into aircraft interiors or mobile devices, engineers can create quieter environments without adding unnecessary bulk.

Smart Acoustic Metamaterials with Active Control

Traditional acoustic metamaterials operate passively, meaning their acoustic behavior is predetermined by their structural design. However, recent advancements in smart acoustic metamaterials have introduced active control mechanisms that allow for real-time adjustments to sound wave interactions. These materials integrate electronic and mechanical tuning capabilities, enabling them to dynamically alter their sound-absorbing, reflecting, or redirecting properties.

One major development in this field is the integration of piezoelectric acoustic metamaterials, which incorporate piezoelectric transducers to actively cancel or redirect sound waves based on external control signals. This capability allows for adaptive noise control in environments where sound conditions change frequently, such as aircraft cabins, office spaces, and smart homes.

Another cutting-edge innovation involves MEMS (Micro-Electromechanical Systems) integration, where tiny actuators embedded within the metamaterial structure enable real-time adjustments to sound reflection and absorption properties. This technology is particularly valuable for adaptive noise-canceling walls and headsets, which can modify their acoustic properties in response to user preferences or external noise conditions.

Additionally, the emergence of acoustic metasurfaces has introduced thin, flexible layers capable of programming how sound waves scatter or reflect. These metasurfaces can be engineered to create “tunable silence,” where specific sounds are selectively blocked while others are allowed to pass through. This technology has exciting potential applications in stealth technology, precision acoustics, and urban noise control, offering unparalleled flexibility in managing sound environments.

As these smart acoustic metamaterials continue to evolve, they will unlock new possibilities in noise reduction, stealth applications, and advanced telecommunications. The ability to dynamically control sound waves in real time represents a major leap forward in acoustic engineering, paving the way for next-generation applications that were once considered science fiction.

Future Prospects of Acoustic Metamaterials

The future of acoustic metamaterials is filled with exciting possibilities, as researchers continue to explore new applications and refine existing technologies. These advanced materials have the potential to revolutionize fields ranging from aerospace and medicine to wearable technology and entertainment, making them a critical component of next-generation sound control systems.

One of the most promising applications is in spacecraft and aircraft soundproofing, particularly for deep-space missions where astronauts must endure prolonged exposure to mechanical vibrations and ambient noise from onboard systems. Traditional soundproofing materials add weight and bulk, a significant drawback for space exploration. Acoustic metamaterials offer a lightweight and ultra-thin alternative, capable of minimizing vibrations and unwanted noise while maintaining structural integrity. Future spacecraft could integrate these materials into their design, ensuring a quieter and more comfortable environment for astronauts.

Another key area of development is in advanced hearing aids. Current hearing aids struggle to isolate specific sounds in noisy environments, making conversations difficult for users in crowded spaces. With acoustic metamaterials, precise noise filtering can be achieved, allowing hearing aids to dynamically adjust to ambient sound conditions and enhance speech clarity while reducing background noise. This technology could drastically improve the quality of life for individuals with hearing impairments.

Wearable acoustic sensors are also emerging as a revolutionary innovation in biometric monitoring. By integrating metamaterials into ultra-thin, flexible devices, researchers are developing non-invasive sound-based sensors capable of tracking heartbeats, breathing patterns, and even vocal cord vibrations. These sensors could be embedded in smart clothing or earpieces, enabling real-time health monitoring and early detection of medical conditions such as arrhythmias and respiratory disorders.

Acoustic metamaterials are also set to transform the entertainment industry by enabling tunable concert halls and theaters. Traditional concert venues rely on fixed acoustics, which may not be ideal for different types of performances. With metamaterial-based panels, theaters and music halls could dynamically adjust their acoustic properties in real time, optimizing soundscapes for different performances, from classical symphonies to live rock concerts. This could lead to a more immersive and customizable listening experience for audiences.

Next-Gen Research Directions

As the field of acoustic metamaterials continues to evolve, several cutting-edge research directions are emerging that could define the future of this technology.

One exciting development is the creation of self-healing acoustic metamaterials. These materials are designed to repair themselves when damaged, ensuring longevity and reliability in extreme environments. Inspired by biological systems, researchers are working on embedding microcapsules of repair agents within metamaterials, allowing them to automatically heal cracks or wear over time. This innovation could be particularly useful in aerospace, military, and industrial applications, where durability and long-term performance are crucial.

Another promising avenue is the use of AI-optimized acoustic structures. Machine learning and artificial intelligence are being applied to design the most efficient acoustic patterns by analyzing vast amounts of data and identifying optimal material configurations. By leveraging computational algorithms, researchers can develop highly precise acoustic metamaterials that outperform manually designed counterparts. This AI-driven approach could lead to breakthroughs in noise cancellation, speaker technology, and stealth applications.

A particularly innovative concept is metamaterial-based energy harvesting, where sound waves and vibrations are captured and converted into usable energy for powering wireless devices and IoT sensors. This approach could lead to the development of self-sustaining acoustic sensors that operate indefinitely without the need for batteries, making them ideal for smart cities, environmental monitoring, and industrial applications. By harnessing ambient noise and mechanical vibrations, metamaterials could serve as a new frontier in sustainable energy solutions.

With rapid advancements in material science, AI-driven optimization, and nanotechnology, acoustic metamaterials are set to redefine how we interact with sound. Whether in space exploration, medical innovation, or immersive entertainment, these materials are paving the way for a smarter, quieter, and more efficient future.

Conclusion

Acoustic metamaterials are rapidly evolving from a theoretical concept into a disruptive technology that is revolutionizing noise control, medical imaging, telecommunications, and industrial applications. With breakthroughs in smart materials, 3D printing, and AI-driven design, these engineered materials will soon be ubiquitous in our daily lives.

As research continues, we are moving towards a world where sound can be precisely controlled, manipulated, and optimized—paving the way for quieter cities, clearer medical scans, and smarter acoustic technologies.

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis