From Soviet Ekranoplans to Strategic Game-Changer

For decades, militaries have chased the elusive dream of runway-independent heavy airlift—an aircraft that can launch from water and carry substantial payloads without needing traditional infrastructure. The Soviet Union’s Lun-class ekranoplans offered a glimpse of what was possible, using ground-effect aerodynamics to skim over the Caspian Sea. However, these vehicles were plagued by limitations in maneuverability and poor performance in rough weather. Today, DARPA is resurrecting and revolutionizing that vision with the Liberty Lifter program, a seaplane built not only to lift heavy cargo from the ocean’s surface but to thrive in turbulent maritime conditions. With the AG600 Kunlong—China’s own large amphibious aircraft—advancing in parallel, Liberty Lifter’s anticipated first flight in 2028 may be crucial for sustaining U.S. military logistics across the vast, infrastructure-poor Indo-Pacific theater.

Amphibous Aircrafts

Phase 2: Aurora’s Single-Hull Vision Takes Flight

Following a competitive first phase in 2023 that saw General Atomics and Aurora Flight Sciences present divergent designs, DARPA made a strategic pivot in 2024 by selecting Aurora to lead the program into Phase 2. Backed by an $8.3 million contract, Aurora’s refined concept embraces a single-hull, flying-boat design equipped with eight turboprop engines to deliver both redundancy and power. Its 216-foot wingspan incorporates wingtip floats for maritime stability, and a pi-shaped tail enhances aerodynamic control.

The aircraft will feature a rear cargo ramp for rapid, beach-side deployment of ground vehicles directly onto littoral terrain. The initial 80% scale demonstrator is designed to match the C-130’s payload capacity of 25 tons, setting the stage for a future production model that could lift up to 82 tons—equivalent to the much larger C-17 Globemaster III. This makes Liberty Lifter uniquely suited to forward operations in contested environments.

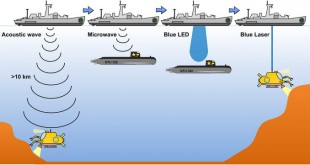

A comparison with similar platforms reveals its strengths. While China’s AG600 offers a 53-ton payload and can operate in sea states up to 3 (4-ft waves), Liberty Lifter is planned for operations in sea state 5 (13-ft waves). It also has the unique ability to fly both in ground-effect mode and at altitudes up to 10,000 feet—surpassing the capabilities of both China’s seaplane and the Soviet-era ekranoplans.

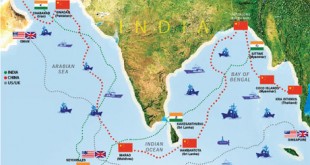

Indo-Pacific Imperative: Why Liberty Lifter Matters

The Liberty Lifter isn’t just an experimental marvel—it directly addresses a pressing strategic need. DARPA’s Christopher Kent underscored its importance, noting that many Western Pacific islands lack runways or deep ports, making traditional logistics methods impractical. In such an environment, a sea-based, runway-independent aircraft could be a game changer.

Compared to conventional sealift, Liberty Lifter travels an order of magnitude faster—over 300 mph versus the 20 mph speed of most cargo ships. It can carry two Marine Amphibious Combat Vehicles (67 tons total), tripling the C-130’s payload capability. Moreover, its low-altitude sea-skimming profile minimizes radar visibility, a decisive advantage for stealthy resupply missions in contested environments like the South China Sea.

By operating from water and avoiding dependence on existing port or airfield infrastructure, Liberty Lifter supports distributed operations and agile force projection—two pillars of modern Indo-Pacific military doctrine.

2025–2030 Roadmap: From Simulations to Flight

DARPA’s development schedule for Liberty Lifter is ambitious but tightly structured. The 2024–2025 phase focuses on component validation, including propeller testing, wind tunnel trials, and cockpit simulator development to refine pilot interfaces and mission control systems. By 2026, the program is slated to complete its Critical Design Review and initiate shipyard construction of the full-scale demonstrator.

Flight testing is targeted for 2028–2029, with a unique twist: the demonstrator will be entirely waterborne, foregoing landing gear and focusing on true sea-based operations. If successful, the early 2030s could see the platform entering operational service with the U.S. Navy and Marine Corps, offering new strategic flexibility for theater commanders.

The Strategic Horizon: Beyond Cargo

While designed with heavy airlift in mind, the Liberty Lifter’s utility could extend far beyond traditional logistics roles. Its massive interior volume and access to waterborne sites make it ideal for search-and-rescue operations, with the potential to evacuate over 500 people in emergency scenarios.

In disaster response missions, the aircraft could deliver mobile hospitals, generators, and relief supplies directly to flood-affected or storm-isolated coastal regions. Additionally, it opens new possibilities for Marine Expeditionary Operations, resupplying units such as the 31st Marine Expeditionary Unit from mobile sea bases or unprepared beaches—without ever needing a port or runway.

As Aurora Flight Sciences executive Richard Koucheravy put it, “We’re merging shipbuilding with aerospace—this isn’t just an aircraft; it’s a new category of vehicle.”

Conclusion: The Amphibious Airlift Revolution

The Liberty Lifter represents more than technological innovation—it offers a new paradigm for force mobility and resilience in the age of peer competition. While China’s AG600 is optimized for calm-weather resupply and disaster response, the Liberty Lifter is being engineered for all-weather, heavy-payload, forward-area operations. Its ability to fly above or skim the sea, land in rough surf, and deploy combat equipment directly onto austere shores could render conventional airlift and sealift obsolete in key military scenarios.

If DARPA and Aurora succeed, the Liberty Lifter will prove that the future of logistics might not be built on airstrips or ports—but on the open sea itself.

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis